High-precision micro hole machining method and device

A processing method and processing device technology, applied in the field of high-precision micro-hole processing, can solve problems such as defects, polycrystalline recrystallization of single crystal blades, hidden dangers buried in raw material performance guarantee, etc., to achieve no orifice, internal concentration balance, The effect of maintaining the stability of the droplet size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

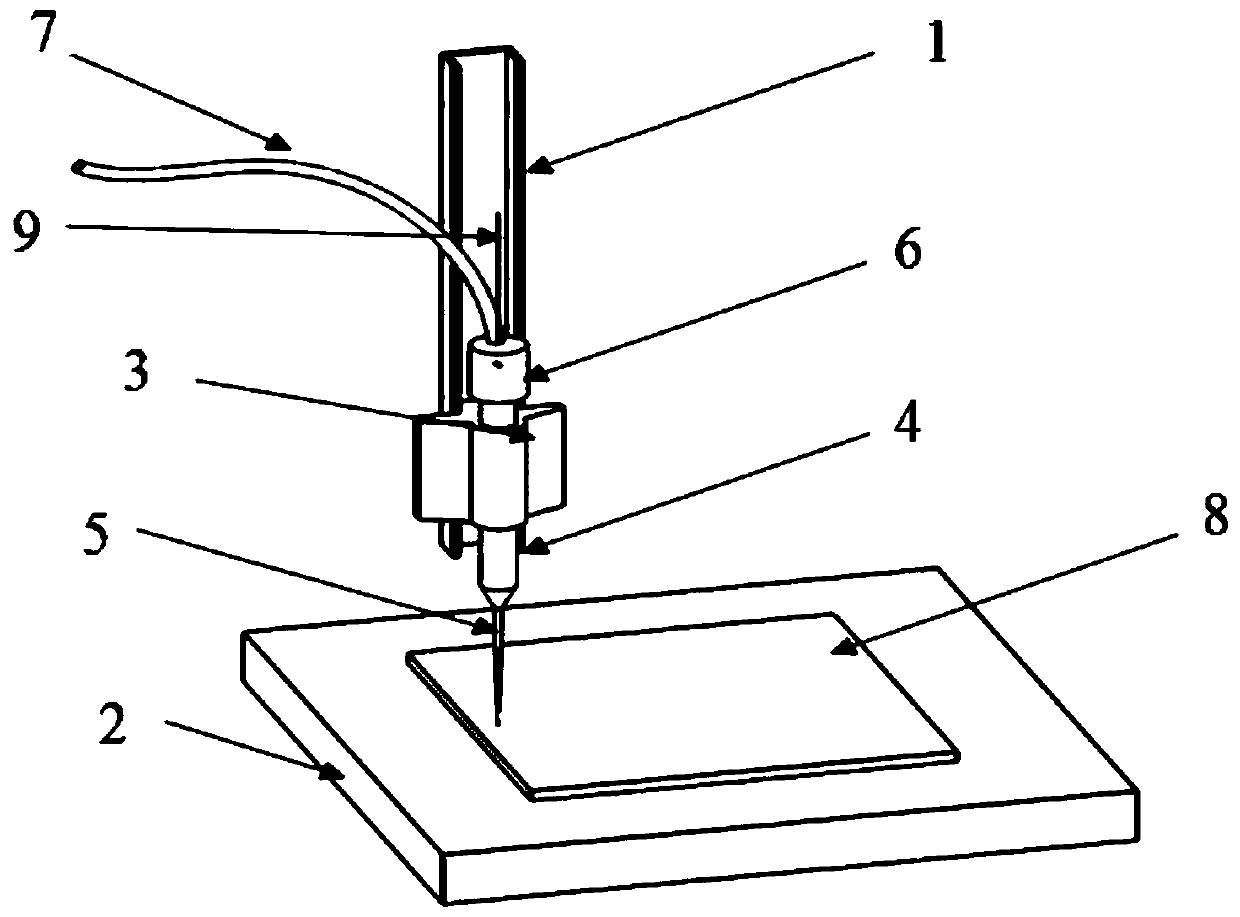

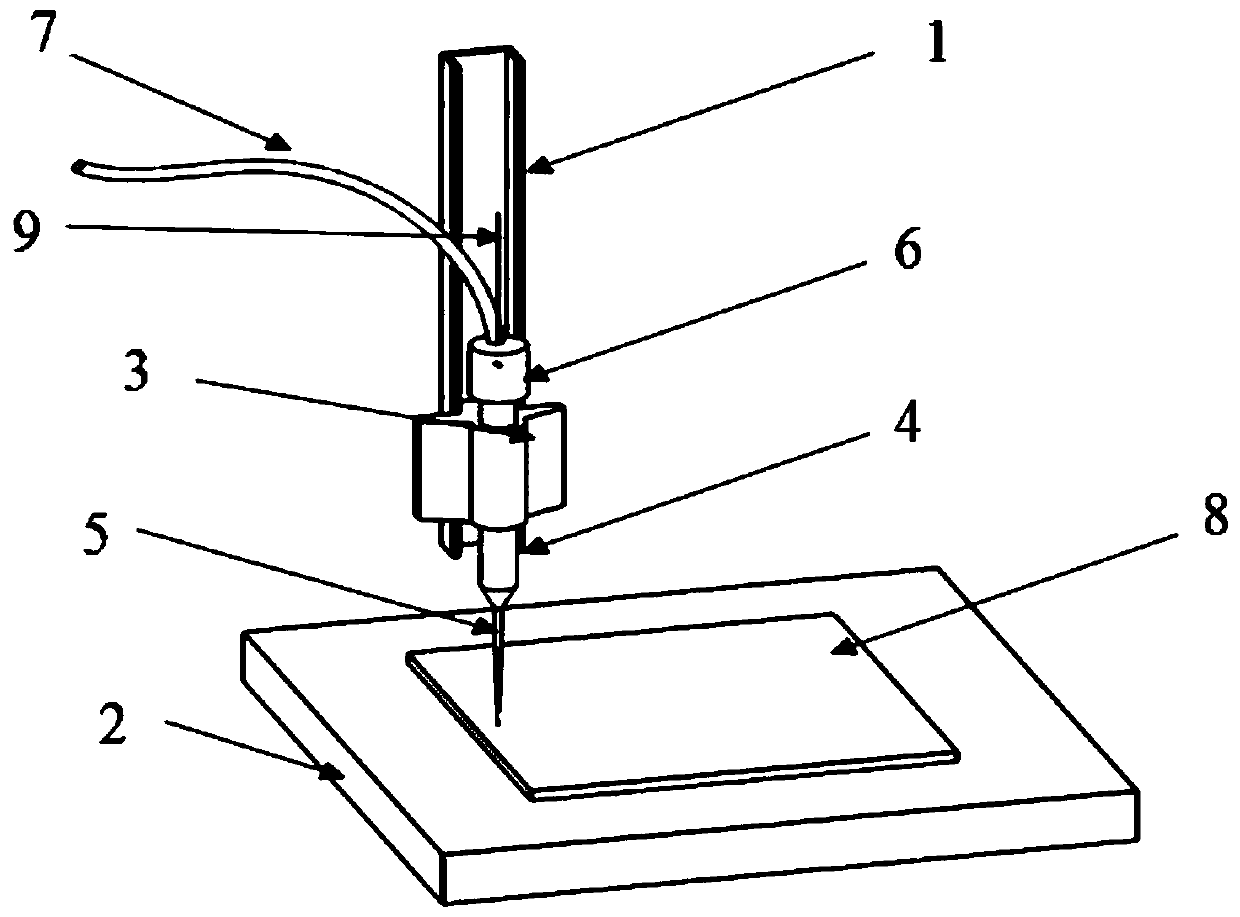

[0037] The high-precision microhole processing device in this embodiment includes a lifting platform 1, a push pump, and an X-Y moving platform 2, and the lifting platform 1 is arranged above the X-Y moving platform 2;

[0038] The lifting platform 1 is equipped with a fixed card 3, a tube body 4, a glass needle 5 and a cover 6, the tube body 4 is fixed in the fixed card 3, the glass needle 5 is set at the lower end of the tube body 4, and the upper end of the tube body 4 is connected with a cover 6;

[0039] The push pump communicates with the tube body 4 through the conduit 7, and the conduit 7 passes through the cover 6 for passing the electrolyte into the inside of the glass needle 5;

[0040] The X-Y mobile platform 2 is used to place the processing material 8. The processing material has conductivity and is connected to the positive pole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com