High-precision and low-resistance alloy chip resistor efficiently resistance-regulating technique

A chip resistor and low-resistance technology, applied in non-adjustable metal resistors, resistors, resistor manufacturing, etc., can solve the physical and mental safety hazards of workers, low yield rate of alloy chip resistors, low yield rate of resistor products, etc. problems, to achieve the effects of no chemical pollution, high production efficiency, and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

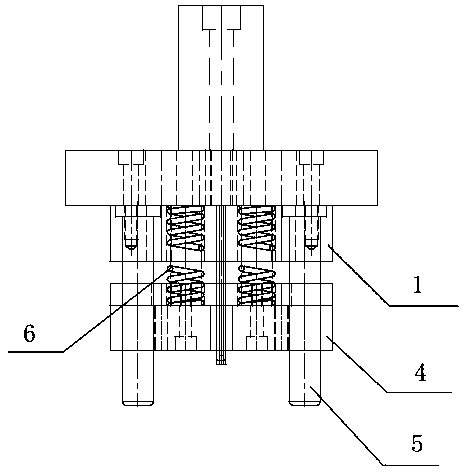

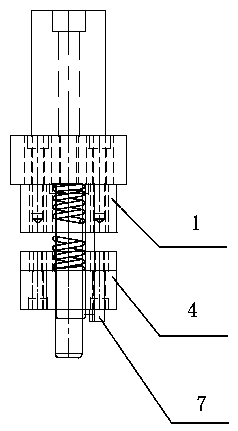

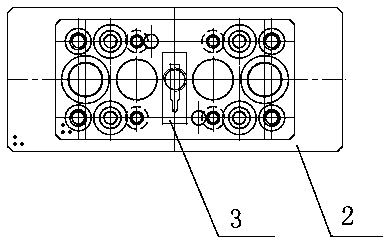

[0021] Example 1: Reference figure 1 :

[0022] A high-precision and low-resistance alloy chip resistor high-efficiency resistance adjustment process, including: 1) The raw material strip is stamped into a fixed-size alloy chip resistor through a punching machine and a mold; 2) All alloy chip resistors are tested for each resistance value , and then sorted into several gears, the specific gearing is: a certain target resistance value of the alloy chip resistor with a target accuracy of 1% can be sorted into: the target resistance value is less than 5% and the target resistance value is less than 4% -5%, the target resistance value is too small by 3%-4%, the target resistance value is too small by 2%-3%, the target resistance value is too small by 1%-2%, the target resistance value is within 1%, the target resistance value is too large by 1 % or more; resistors within 1% of the target resistance value are taken out as good products, alloy chip resistors with a target resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com