Patents

Literature

371results about How to "No chemical pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-pressure gas blasting-based coal seam roof advance presplitting method

ActiveCN103334790ASmall power disturbanceGood pre-cracking effectMining devicesChemical explosiveExplosive Agents

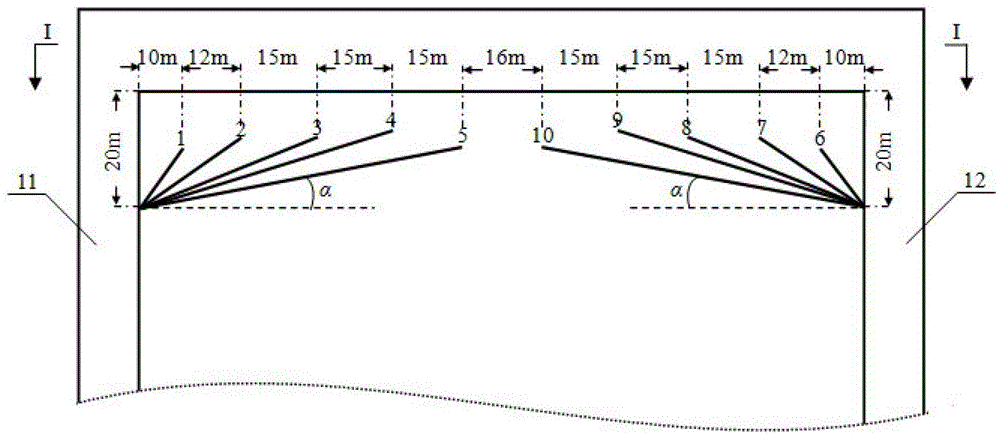

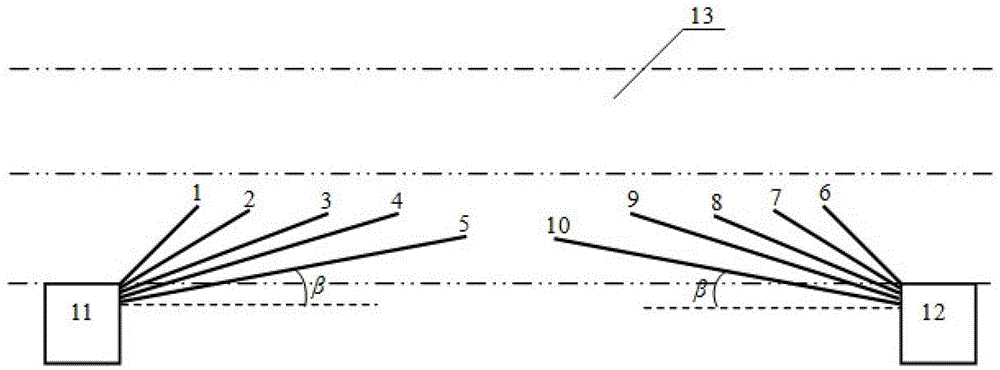

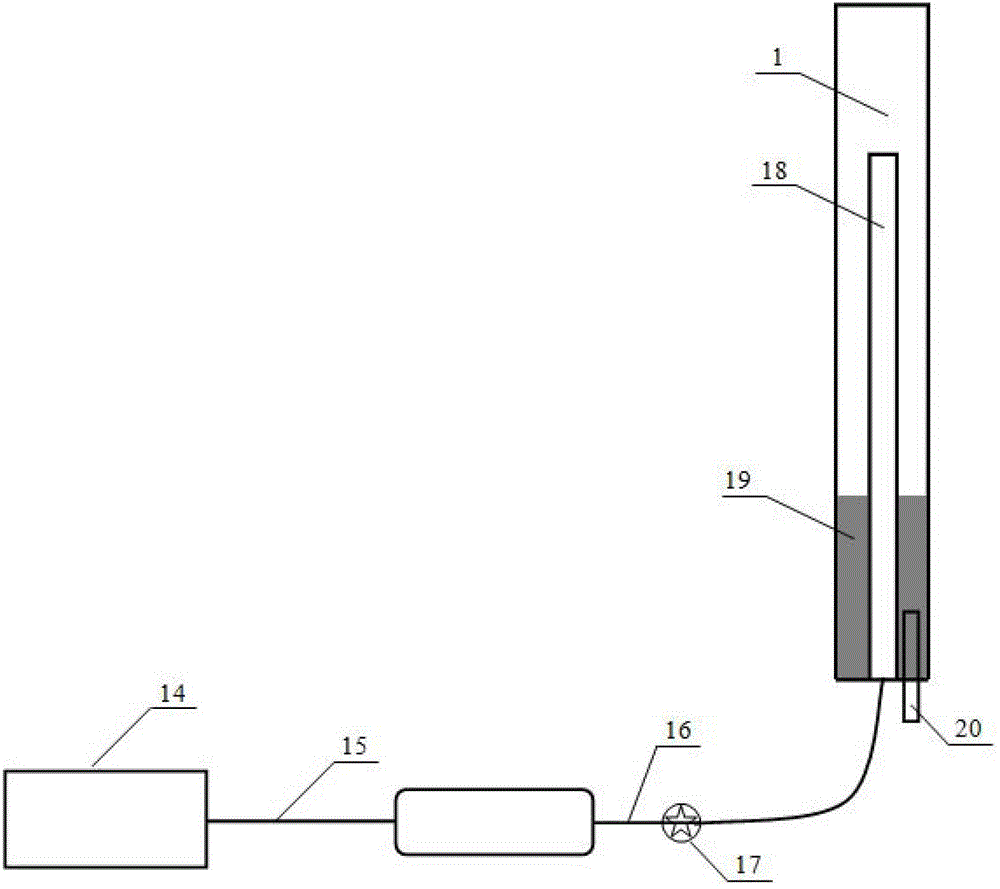

The invention discloses a high-pressure gas blasting-based coal seam roof advance presplitting method, which belongs to the technical field of mine safety. The method is performed according to the following steps: (1) forming a group of drilled holes in a coal seam roof every a certain distance on a conveying roadway and a track roadway of a working face, wherein each group of drilled holes is arranged in a fan shape and faces towards a goaf; (2) placing a gas detonation gun which is connected with a high-pressure gas compression system in the drilled hole and sealing the hole by using high-strength fast setting concrete or resin; (3) starting the high-pressure gas compression system and instantaneously releasing high-pressure gas in a high-pressure gas storage tank in the drilled hole through the gas detonation gun to blast so as to communicate the crack around the drilled holes with adjacent drilled holes; and (4) repeating the steps (2) and (3) on each group of drilled holes in sequence to finish advance presplitting of the coal seam roof. According to the method, the potential spark hazard of chemical explosive blasting is eliminated; and since the pressure of the high-pressure gas is controllable and impact blasting can be repeatedly performed on the rock body, the dynamic disturbance of a coal seam is small, the roof presplitting effect is good, and the method is environment-friendly, safe and reliable.

Owner:LIAONING TECHNICAL UNIVERSITY

Biophysical method for removing endopleura of walnut

InactiveCN102972850AEasy to operateMild treatment conditionsFood preservationHuskingPectinaseWalnut Nut

The invention provides a biophysical method for removing the endopleura of a walnut. The walnut with the shell is soaked by tap water for 12 to 24 hours, the shell is removed, the kernel is taken out, pectinase with the activity being 30000 IU is dissolved into disodium hydrogen phosphate-citric acid buffer liquid with the pH being 3.2 to 3.8, and 3 percent to 5 percent of pectic enzyme liquid is prepared and is heated to 50 DEG C. The soaked walnut kernel is soaked in the pectic enzyme liquid and is placed into an ultrasonic generator with the power being 250W and the work frequency being 40KHZ, the enzymolysis and the ultrasonic treatment are carried out for 2.5 to 5 hours at the constant temperature being 50 DEG C, the walnut kernel is fished out and is sprayed and flushed by flowing water with the pressure being 7 to 10 MPa until the endopleura is completely removed, the walnut kernel with the advantages that the color and the luster are opacified, the kernel fruit is complete, the texture is flexible, the mouth feeling and the flavor are pure and sweet as those of the fresh walnut kernel can be obtained, and when the walnut kernel is in vacuum package and freezing storage, a fresh walnut kernel storage method is obtained. The biophysical method adopts the advanced biological enzyme technology to be combined with the ultrasonic physical technology and has the obvious characteristics that the operation is simple, the processing condition is mild, no chemical pollution exists, the kernel and the nutrition are kept complete, and the sensory quality is good.

Owner:BEIJING UNION UNIVERSITY

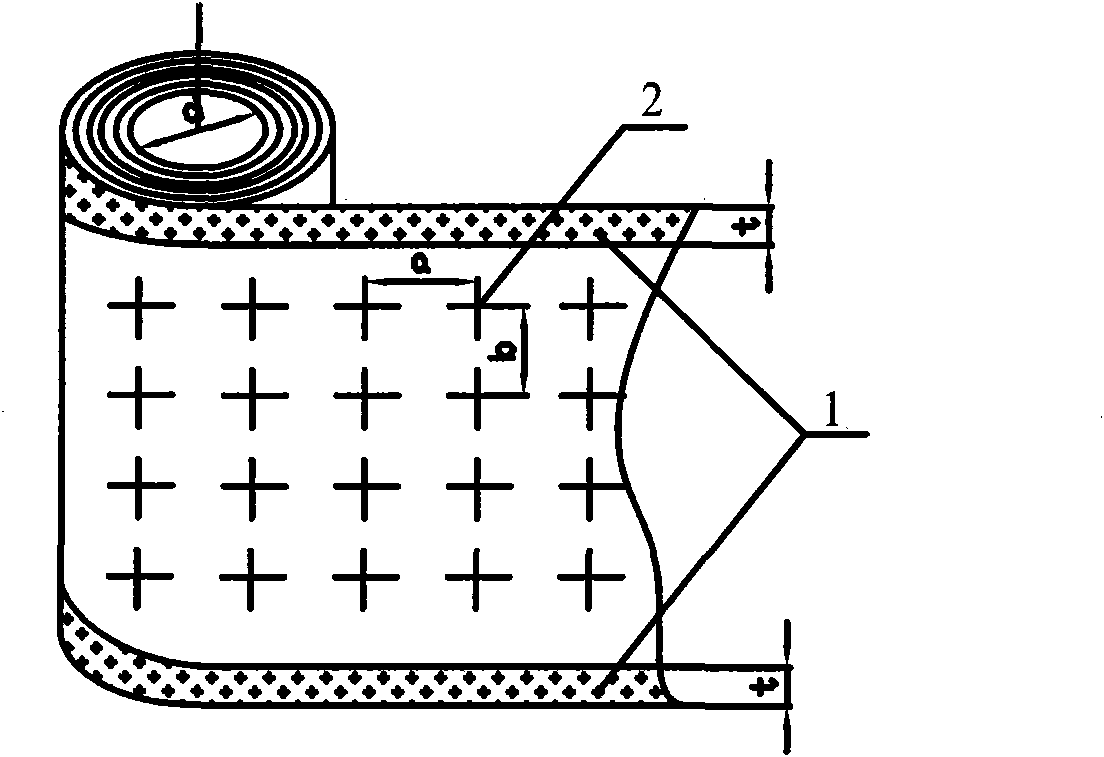

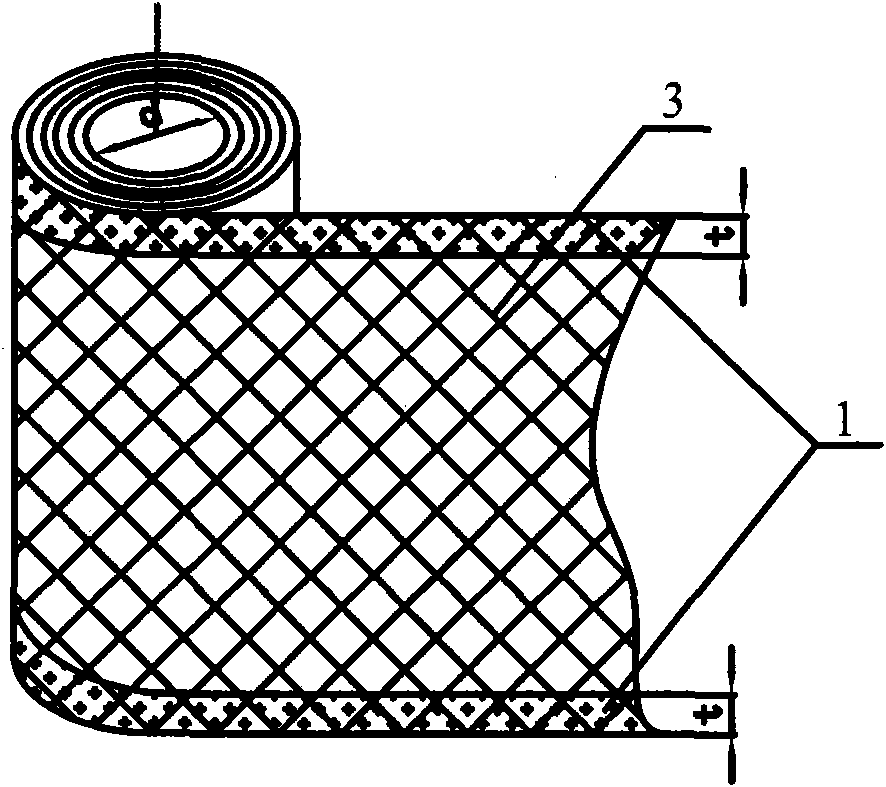

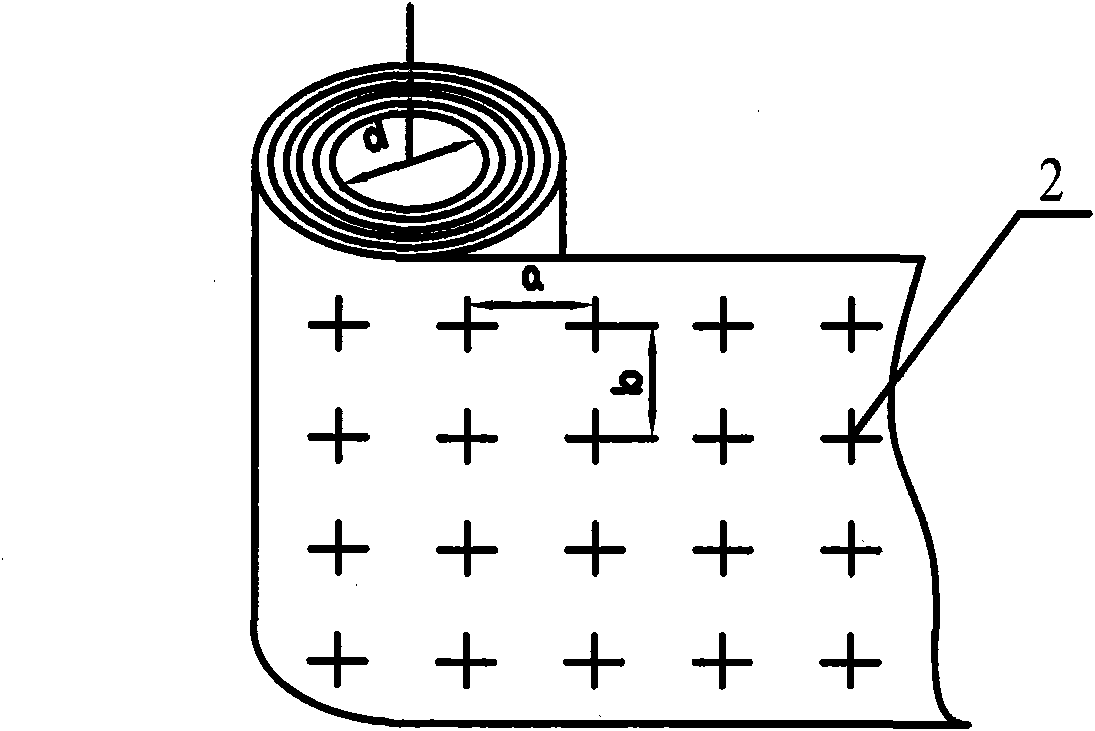

Biogas residue fiber mulch film and manufacturing method thereof

ActiveCN101659760ANo pollutionNo chemical pollutionNatural cellulose pulp/paperReinforcing agents additionGround temperatureManufacturing technology

The invention relates to a biogas residue fiber mulch film and a manufacturing method thereof, which belong to the technologies of protective cultivation biomass materials of paddy and upland crops. The fiber mulch film consists of biogas residue fibers, plant fibers and an environment-friendly functional auxiliary agent, wherein the biogas residue fibers account for 50-90%, the plant fibers account for 10-50%, and the sum of the two types of the fibers is 100% by weight of dry matters; and the environment-friendly functional auxiliary agent mainly comprises rosin, bauxite and a wet strengthening agent and accounts for 6%-7.4% of 100% of the total weight of the two types of the fiber dry matters. The manufacturing technology adopts the biological and mechanical way for preparing the fibersand pulp and adds the environment-friendly functional auxiliary agent for manufacturing paper and forming the film. The biogas residue fiber mulch film has excellent performance for inhibiting the breeding of weeds and can simultaneously adjust the ground temperature, preserve the soil moisture, increase the humidity, improve the ecological environment of the crops, can be completely biodegradedduring the growth period of the crops, improve the content of organic matters in the soil, have no residue or pollution and realize good economy.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

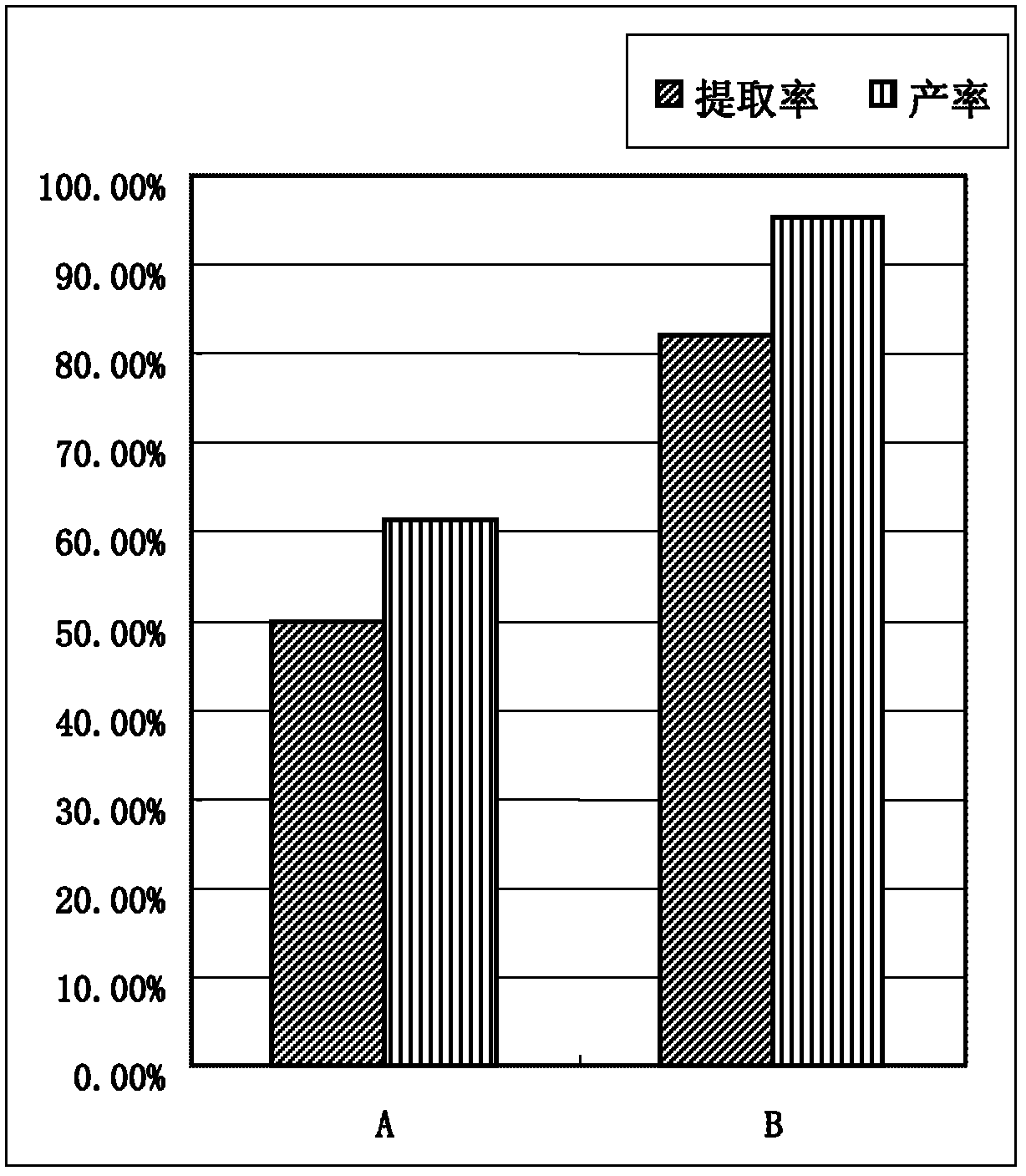

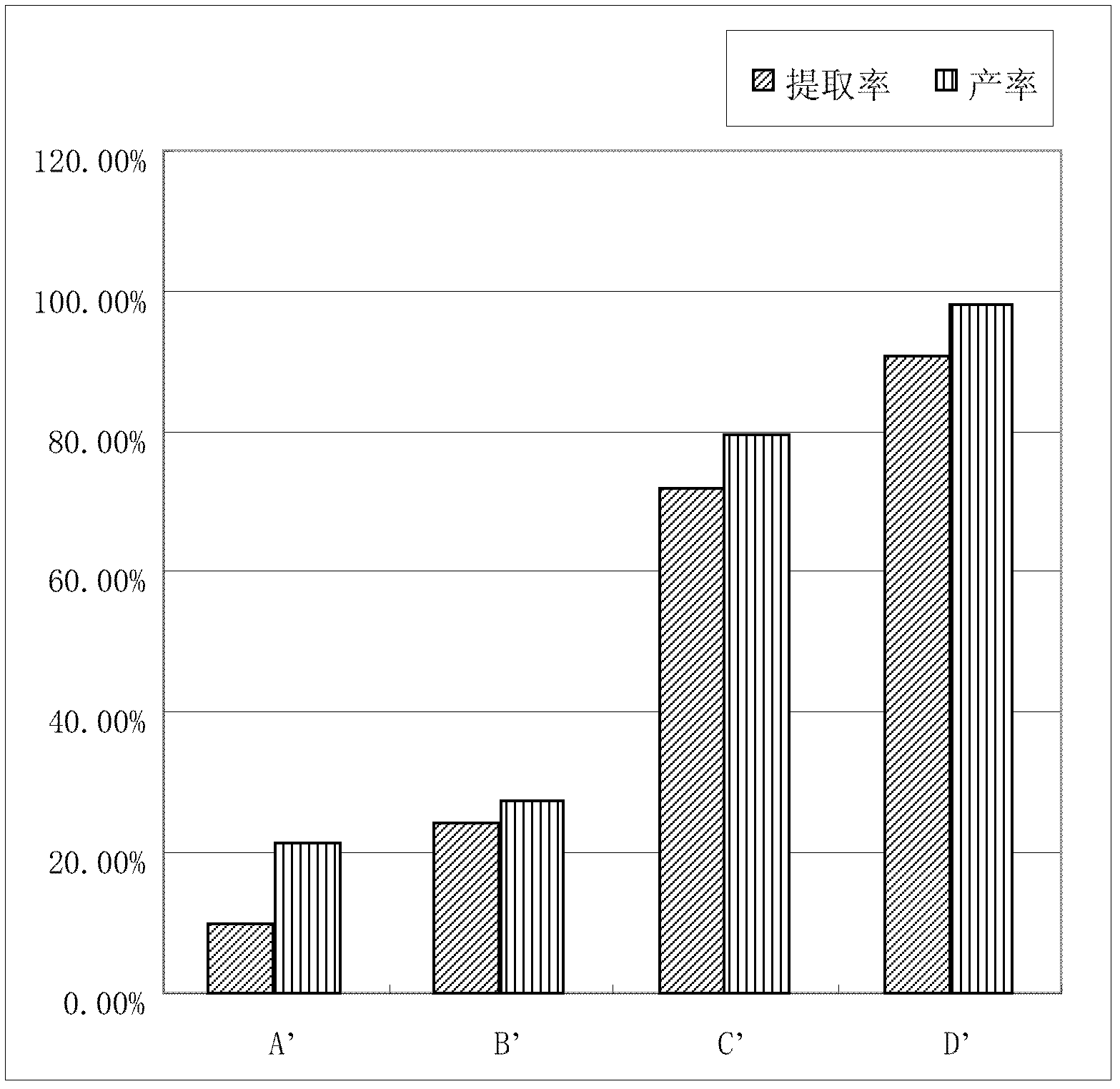

Microalgae grease extraction method

The invention provides a microalgae grease extraction method which comprises the following steps: regulating the pH value of a microalgae solution, heating, pressurizing, and then returning to the normal pressure state; and adding biological enzymes, and mixing, wherein the biological enzymes are added in two steps, non-proteinase is firstly added, and proteinase is secondly added. According to the method provided by the invention, when the biological enzymes are used for treating wet algae, the proteinase is added after the non-proteinase acts for some time, so that the non-proteinase can not be decomposed or destroyed by the proteinase, thereby greatly increasing the wall-breaking efficiency. Compared with the method of simultaneously adding the proteinase and the non-proteinase, the wall-breaking efficiency is obviously increased, thereby obviously increasing the grease extraction rate and yield.

Owner:ENN SCI & TECH DEV

Process for producing high-purity kanjak mannan-oligosaccharides

The invention provides a method for preparing high- purity konjak mannan with production purity over 95%. It comprises following steps: taking konjaku flour as raw material, producing mannan through enzymolysis, centrifuging and filtering and microfiltering and purifying, desalting with ion-exchange technology, decoloring, odour- removing, cutting off macromolecule with ultrafiltering membrane technology from sugar liquid, spray drying and getting high purity konjak mannan with purity over 95%. The invention is characterize by employment of enzyme technology, ion- exchange technology, membrane technology system, simple operation, good separation effect, low cost, no chemical pollution, realization of industrial production. The product can not only be used as functional health care product, but aslo as high- grade food ingredient, medical intermediate, and high- grade feed addictive.

Owner:WUHAN TAIYUAN INVESTMENT GUARANTEE

Preparation method of long-acting anti-microbial textile

InactiveCN106978721AImprove antibacterial propertiesReduce chemical pollutionRadio/micro wave fibre treatmentUltrasonic/sonic fibre treatmentMicrowaveRoom temperature

The invention discloses a preparation method of a long-acting anti-microbial textile. The preparation method concretely comprises the following processes: firstly a desizing or refining process is carried out for the textile, and pretreatment is carried out for the textile by using low temperature plasma; textile which is pretreated is dipped at a room temperature for 10-30 minutes in a mixed finishing solution which comprises a chitosan solution and a silver nitrate solution, the textile is taken out and superfluous finishing solution is rolled out, liquor retention is 100-150%, the textile which is dipped in the finishing solution is transferred into a piece of microwave equipment for carrying out treatment for a certain period of time, after the reaction ends, the textile is taken out and washed with water, and after drying, the anti-microbial textile is obtained. The anti-microbial textile has the advantages of excellent anti-microbial properties, washing resistance, lasting anti-microbial effects, simple preparation technology, and low chemical pollution; the method overcomes the problems of complex processes, bad stability of nanometer silver, bad anti-microbial durability and the like existed in the prior art.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Organic leaf surface fertilizer rich in organic selenium and vitamins and preparation method for organic leaf surface fertilizer

InactiveCN103664286AFull of nutritionReduce the chance of diseaseOrganic fertilisersFertilizer mixturesRaw materialChemistry

The invention discloses an organic leaf surface fertilizer rich in organic selenium and vitamins and a preparation method for the organic leaf surface fertilizer. The organic leaf surface fertilizer rich in the organic selenium and the vitamins comprises the raw materials in parts by weight: 40-60 parts of selenium-enriched bombyx mori, 40-60 parts of selenium-enriched plant waste, 40-60 parts of selenium-enriched edible mushroom waste, 40-60 parts of sodium selenite, 20-30 parts of vitamins and 1-10 parts of a composite fungicide. The selenium-enriched bombyx mori, the selenium-enriched plant waste and the selenium-enriched edible mushroom waste of the fertilizer can supply selenium elements and also supply animal proteins, plant proteins and microorganism proteins and are fermented by composite bacteria to polypeptide combined with the selenium elements. Therefore, the fertilizer can be used for supplying enough organic selenium and beneficial substances such as microorganisms and probiotics to the growth of crops; a large amount of waste is turned into treasures, so that social and natural resources are saved, the environment is protected, and cyclic economy is realized.

Owner:汤俊杰

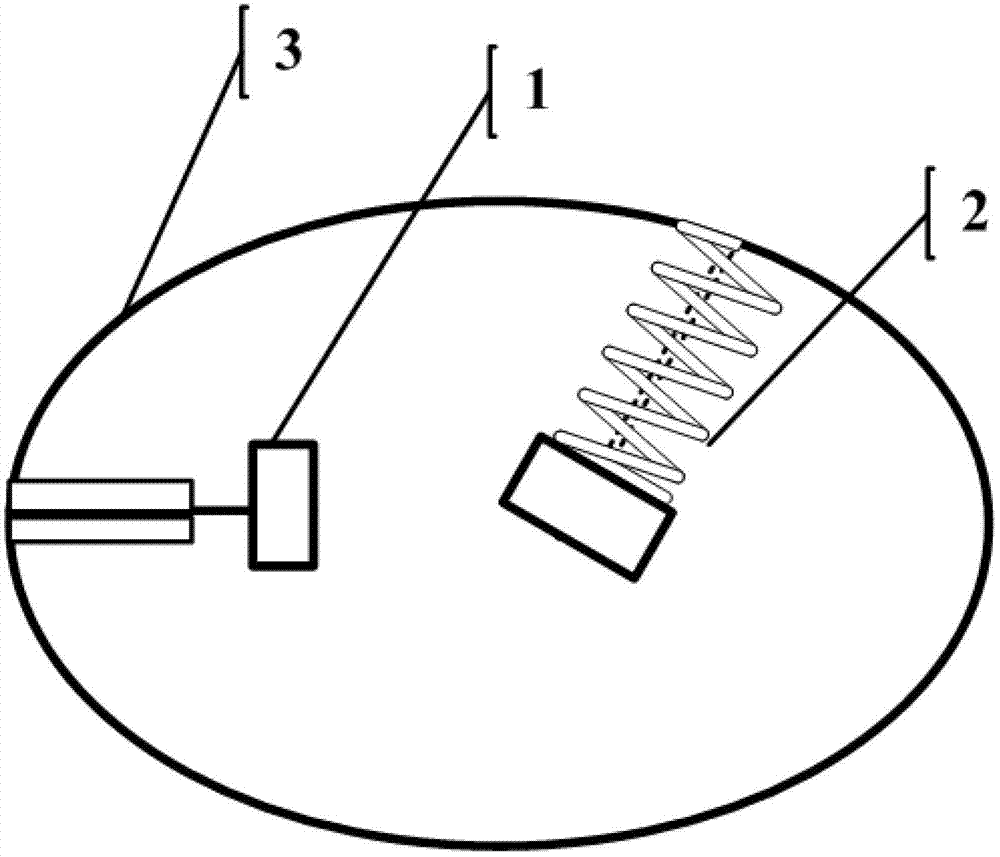

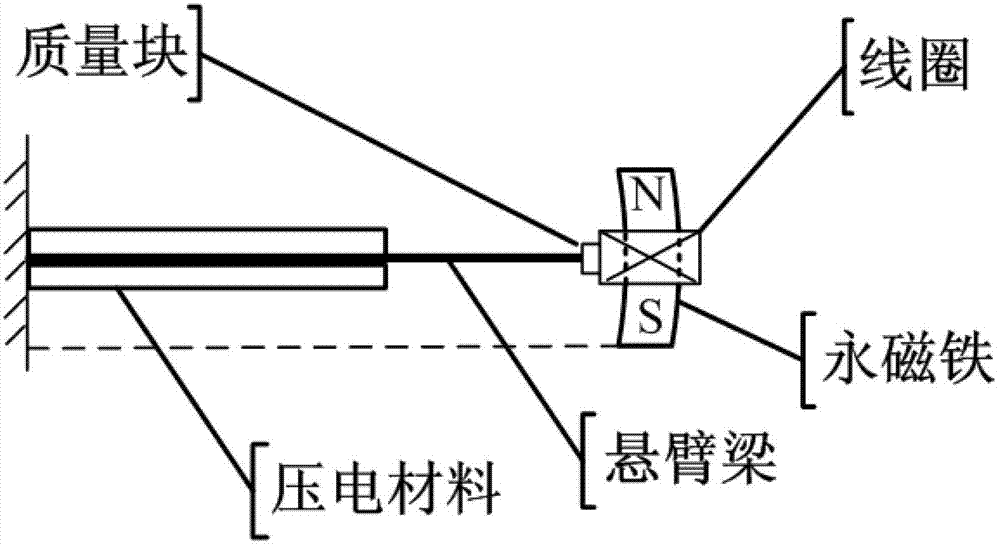

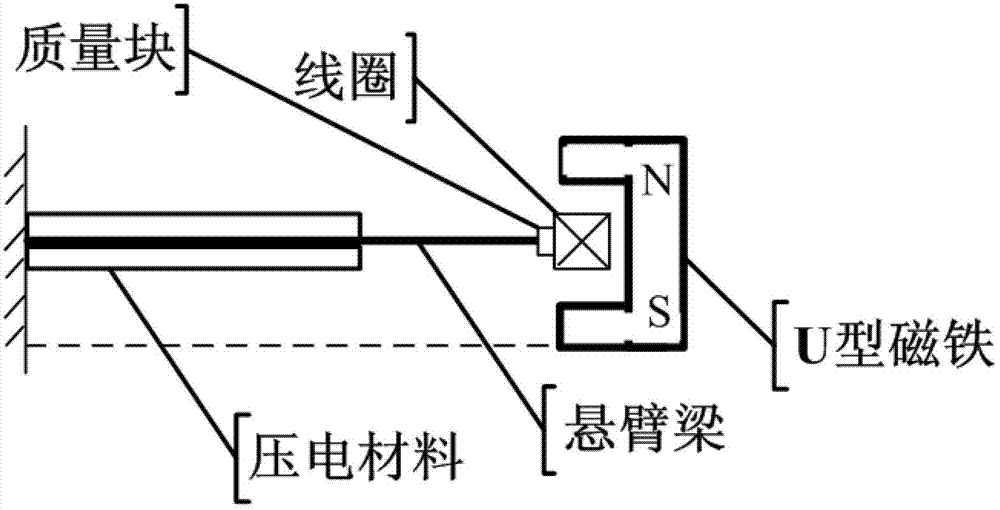

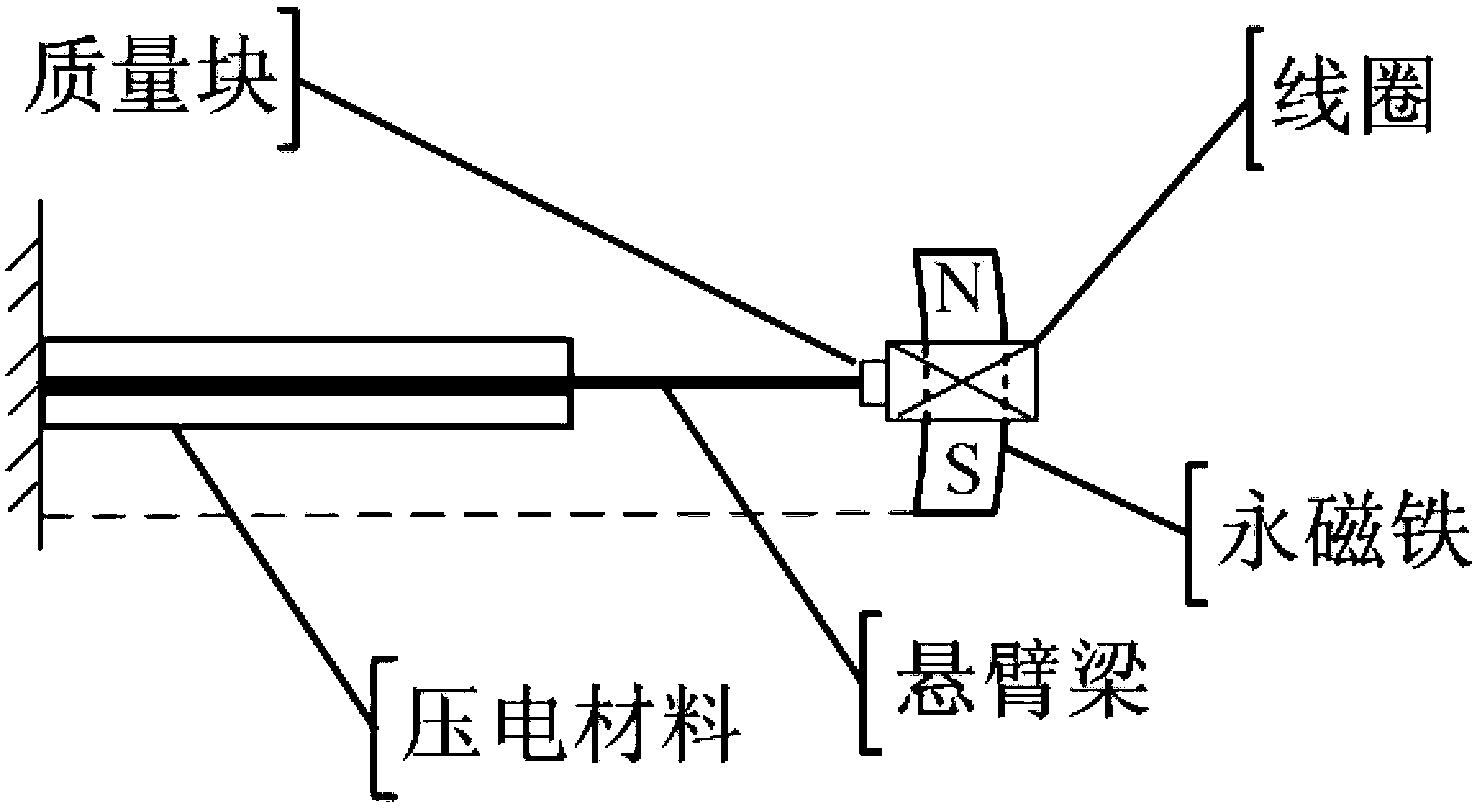

Sea wave and wind power generation device

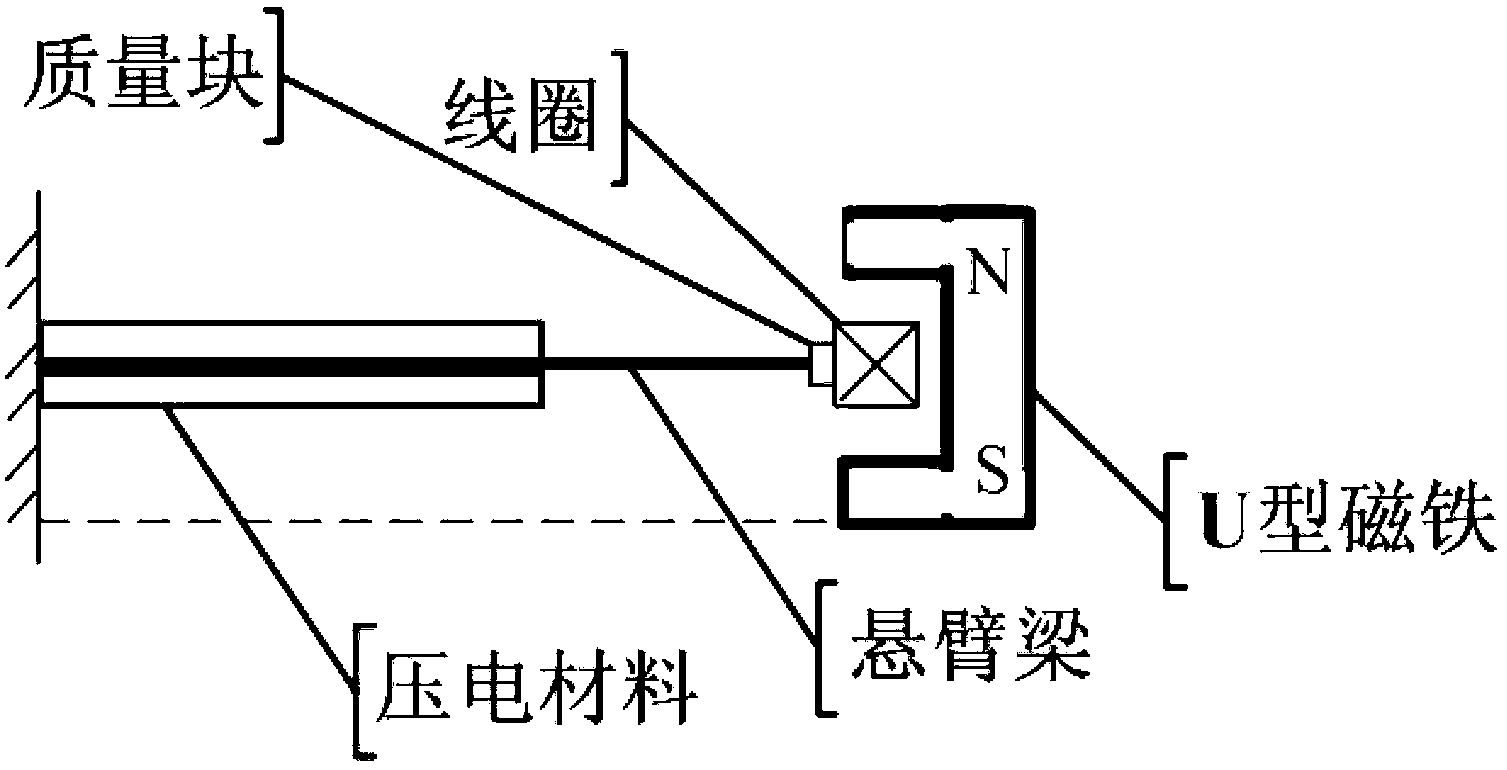

InactiveCN103199739ANo chemical pollutionAvoid damagePiezoelectric/electrostriction/magnetostriction machinesDynamo-electric machinesElectricityElastic component

The invention discloses a sea wave and wind power generation device which is characterized by comprising a closed cavity and at least three micro power generation structure bodies. Each micro power generation structure body is composed of an elastic component, piezoelectric material, a permanent magnet and a coil, the micro power generation structure bodies are fixed on the inner wall of the cavity, the axial lines where the three micro power generation structures are positioned are in a three-dimensional orthogonality state, the inner space of the cavity is of a certain size, therefore the device can be supported to float on the water, the piezoelectric material is fixed on the outer surface of the elastic component, each elastic component drives two power generation units simultaneously to output electric energy outward, one power generation unit outputs electric energy by adoption of the direct piezoelectric effect of the piezoelectric material, and the other power generation unit outputs the electric energy by adoption of the electromagnetic induction principle.

Owner:张平

Method for using natural grape seed dyeing extract in textile dyeing

InactiveCN101476248AImprove pollutionMeet environmental protection requirementsBleaching apparatusDyeing processGrape seedExtracted grape seeds

The invention discloses a method for dyeing fabric by natural grape seed extract. The dyeing method comprises: pre-treating fabric blank by scouring enzyme; bleaching by hydrogen peroxide solution with concentration of 27%; preparing dyeing composition; heating the prepared dyeing composition; putting the fabric into the dyeing composition and dyeing; soaping the dyed fabric circularly by soda water; and dewatering and drying the soaped fabric. The method has good environment compatibility, biodegradability and medicament health caring property; can obtain the product with high chroma brilliant color or soft color, meanwhile avoids the serious pollution caused by chemical dye, and meet the requirement of environment protection; can obtain various brilliant high chroma colors and a large number of demitints by multiple dyeing of different times and different colors; and is nontoxic, harmless, has no anaphylaxis or carcinogenicity to skin. The invention can be widely used for producing high-grade real silk product, health caring underwear, hometextile product, and ornaments.

Owner:XIAN JIHUA 3511 HOMETEXTILE

Calcium alginate fiber with pH (Potential of Hydrogen) value indicating function and preparation method thereof

InactiveCN105803578AWith continuous color changing effectRaw materials are easy to getNatural dyesAlginate artificial filamentsAlkalinityFiber

The invention discloses calcium alginate fiber with a pH (Potential of Hydrogen) value indicating function and a preparation method of the calcium alginate fiber. The preparation method comprises the following steps: (1) preparation of natural dye; (2) preparation of a spinning solution; (3) wet spinning. The prepared and obtained calcium alginate fiber is red and has a pH value indicating function, and the color of the calcium alginate fiber can be subjected to red-purple-blue-green continuous change when the pH value of an external environment is changed from acidity to alkalinity. Raw materials adopted by the calcium alginate fiber have good biocompatibility, the obtained fiber has good color fastness and an obvious pH value discoloring function and can be used for medicinal textiles with the pH value indicating function, such as band-aids and dressing, and real-time monitoring on a wound infection situation is realized.

Owner:WUHAN TEXTILE UNIV

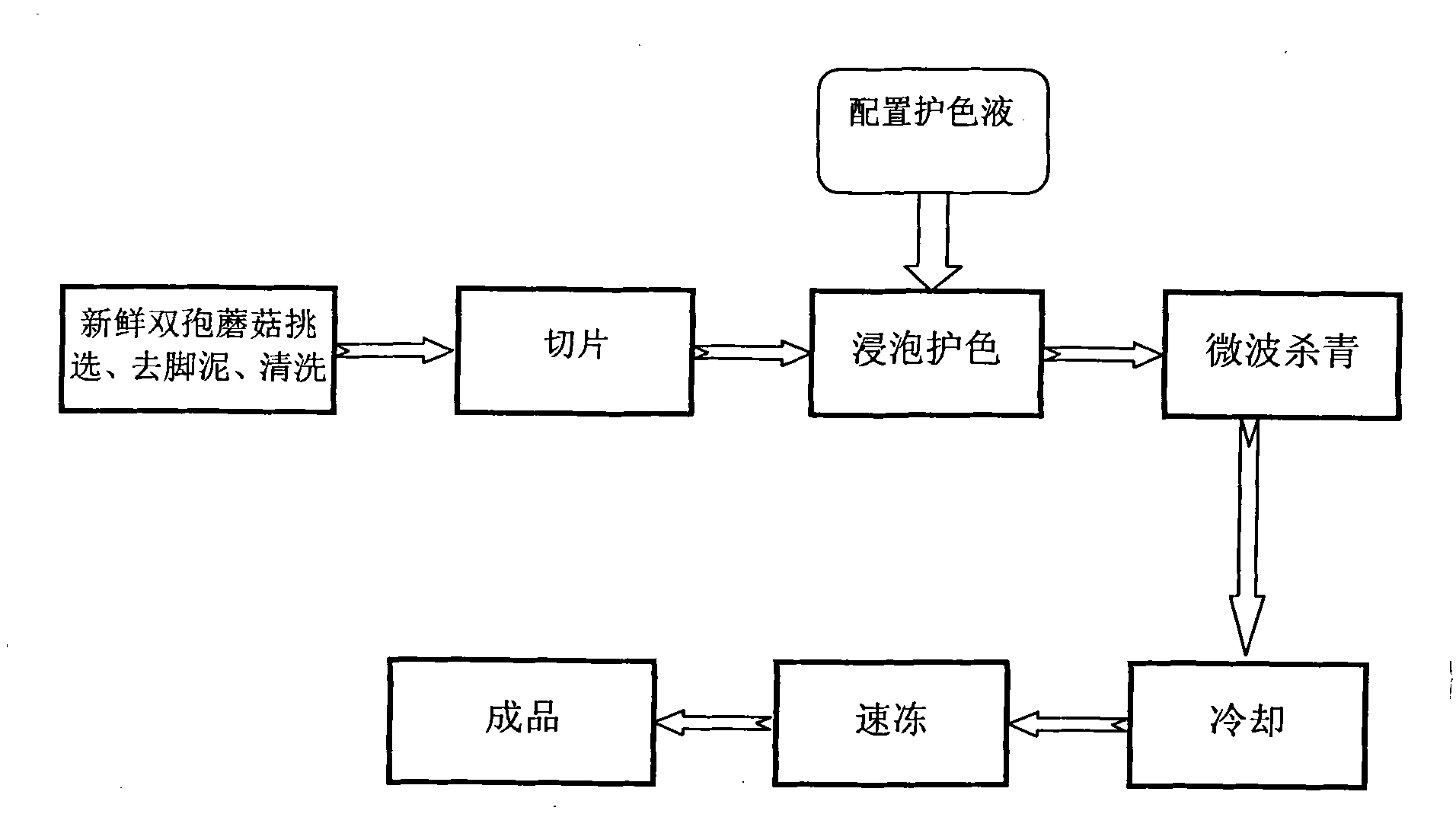

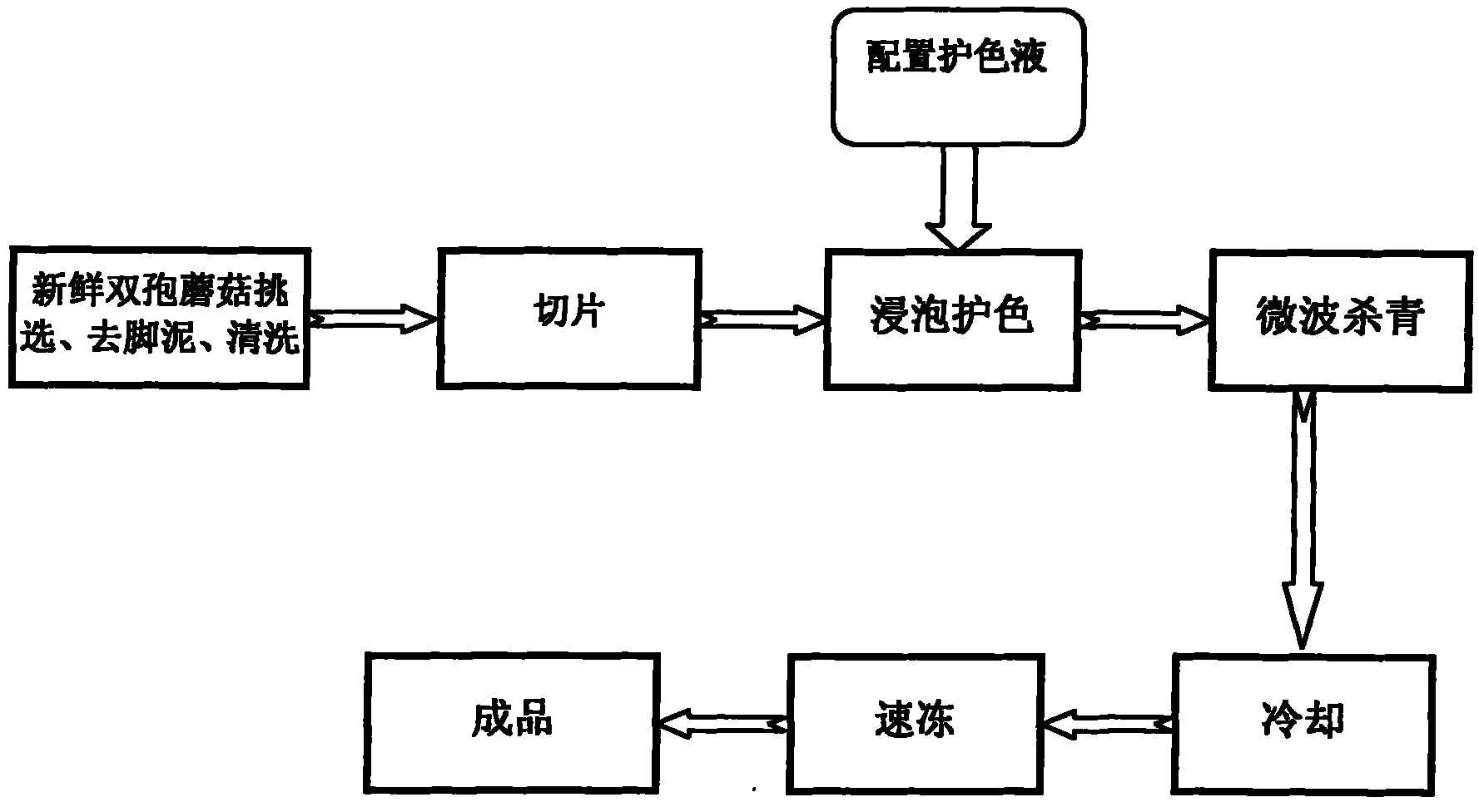

Method for preparing white mushroom slices

InactiveCN101961045AReduce churnLess nutrient lossFruits/vegetable preservation by heatingMicrowaveMoisture

The invention belongs to the technical field of edible fungus processing and relates to a preparation method of white mushroom slices. In the method, fresh white mushroom is used as a raw material; and the white mushroom slices are prepared by pretreatment, slicing, soaking, preserving color, killing green in microwaves, cooling, quickly freezing and refrigerating. The white mushroom slice products prepared by the method have natural color, full structure, less moisture loss, less nutrient loss, cooking effect similar to that of fresh white mushroom.

Owner:NANJING WILD PANT COMPREHENSIVE UTILIZATION INST THE ALL CHINA SUPPLY & MARKETING COOPERATIV +1

Organic-selenium-enriched microorganism organic composite fertilizer and preparation method thereof

The invention discloses an organic-selenium-enriched microorganism organic composite fertilizer and a preparation method thereof. The organic-selenium-enriched microorganism organic composite fertilizer comprises the raw materials in parts by weight: 40-60 parts of selenium-enriched bombyx mori, 40-60 parts of selenium-enriched plant waste, 40-60 parts of selenium-enriched edible mushroom waste, 40-60 parts of minerals, 20-30 parts of vitamins and 1-10 parts of a composite fungicide. The organic-selenium-enriched microorganism organic composite fertilizer can supply enough minerals such as organic selenium and beneficial substances such as microorganisms and probiotics to the growth of crops; meanwhile, the fertilizer can improve the soil, prevent diseases, and realize sterilization; a large amount of waste is turned into treasures, so that social and natural resources are saved, the environment is protected, and cyclic economy is realized. The organic-selenium-enriched microorganism organic composite fertilizer is one of the best fertilizers for producing pollution-free food, green food and organic food.

Owner:汤俊杰

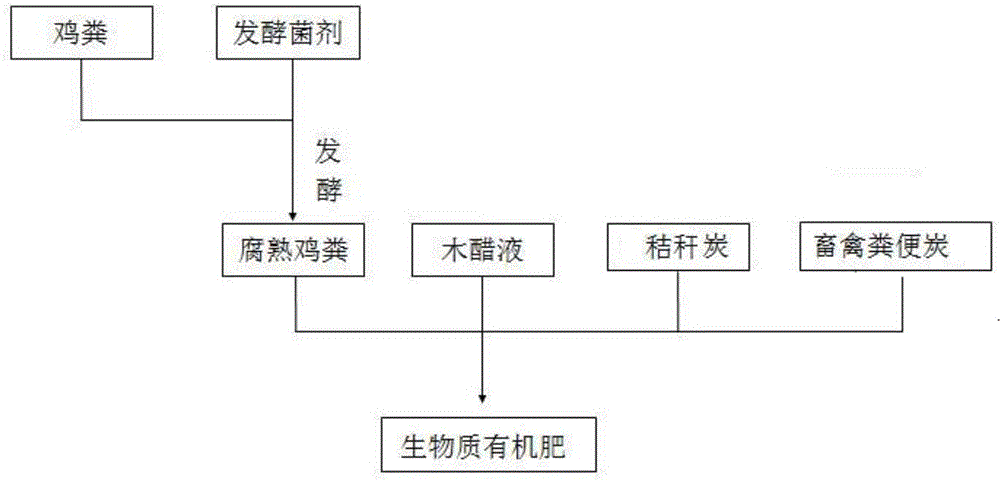

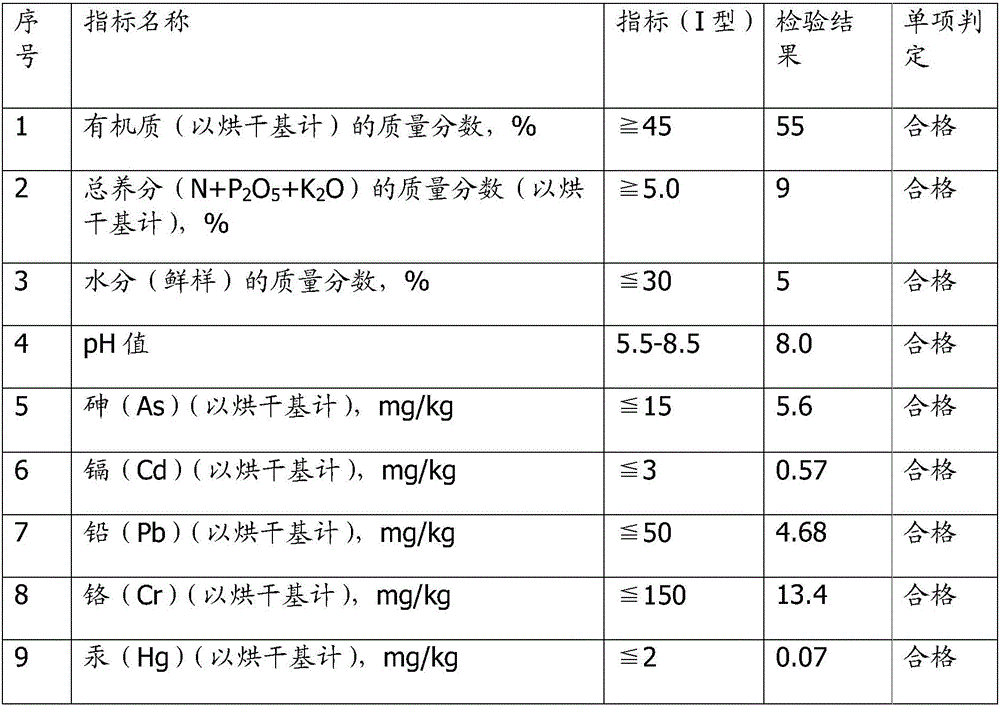

Biomass organic fertilizer and preparation method thereof

InactiveCN106083453AHigh carbon contentHigh nutrient contentBio-organic fraction processingAlkali orthophosphate fertiliserBacillus licheniformisBiotechnology

The invention provides a biomass organic fertilizer and a preparation method thereof, which belong to the field of biomass fertilizer production. The biomass organic fertilizer comprises the following raw material in parts by weight: 20-30 parts of stalk carbon, 30-40 parts of livestock and poultry night soil charcoal, 21-44 parts of decomposed chicken manure, and 5-10 parts of pyroligneous liquor. The decomposed chicken manure is composed of chicken manure and a fermentation inocula and a stabilizing agent through fermentation, the fermentation inocula comprises Bacillus licheniformis, bacillus subtilis and aspergillus oryzae. The biomass organic fertilizer has the advantages of good fertilizer efficiency and no chemical pollution.

Owner:HEBEI TIANSHAN BIOTECH CO LTD

Rhizosphere growth-promoting water-soluble microbial bacterium manure

ActiveCN104844284AImprove physical and chemical propertiesPromote decompositionFungiBacteriaBacillus cereusGrowth promoting

The invention discloses rhizosphere growth-promoting water-soluble microbial bacterium manure. The rhizosphere growth-promoting water-soluble microbial bacterium manure is prepared from culture obtained by carrying out aerobic mixed fermentation on bacillus cereus GF-1, streptococcus thermophilus BLST, bacillus mucilaginosus G3, bacillus subtilis B7348, bacillus subtilis N9-1-35, lactobacillus plantarum LP and candida utilis CUM on a universal culture medium, wherein the total number of biological living bacteria in the microbial bacterium manure is greater than or equal to 2*10<10> CFU / g. The invention also discloses a preparation method of the rhizosphere growth-promoting water-soluble microbial bacterium manure. The microbial bacterium manure disclosed by the invention utilizes exogenous plant growth-promoting bacteria and associated bacteria to improve the micro-environment of root soil, and the prepared microbial bacterium manure is applied into the soil, the soil environment can be effectively improved, the growth of plants is promoted, and the resistances of the plants are improved.

Owner:山东宝来利来生物工程股份有限公司 +1

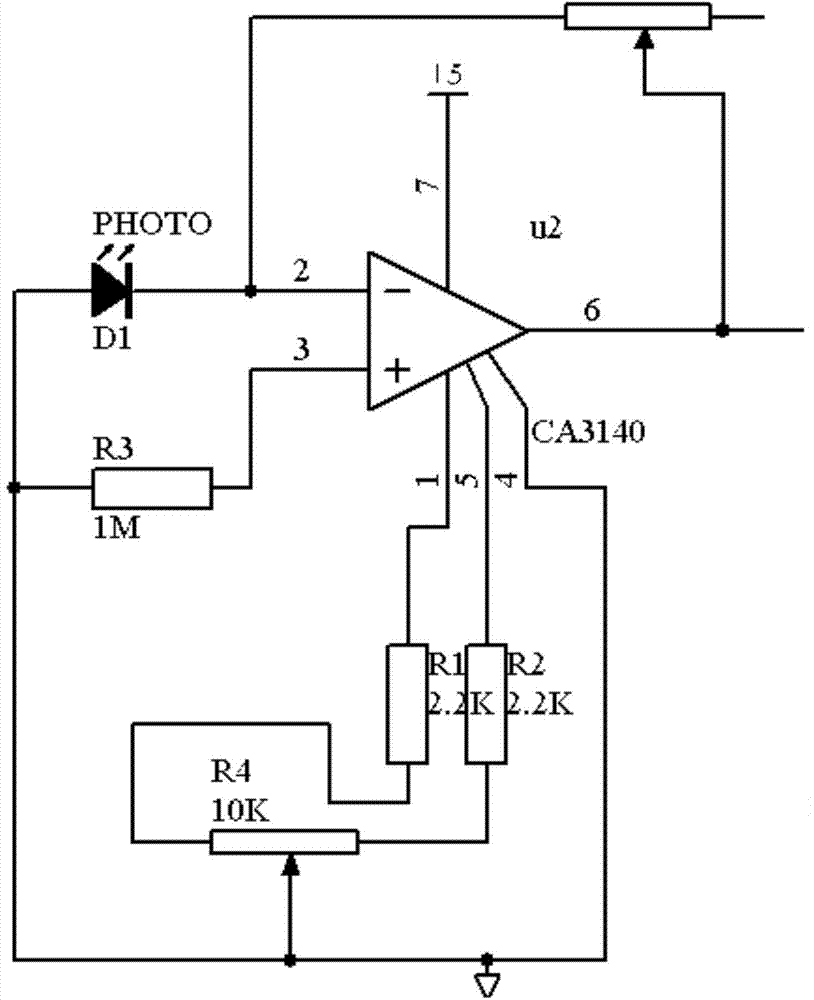

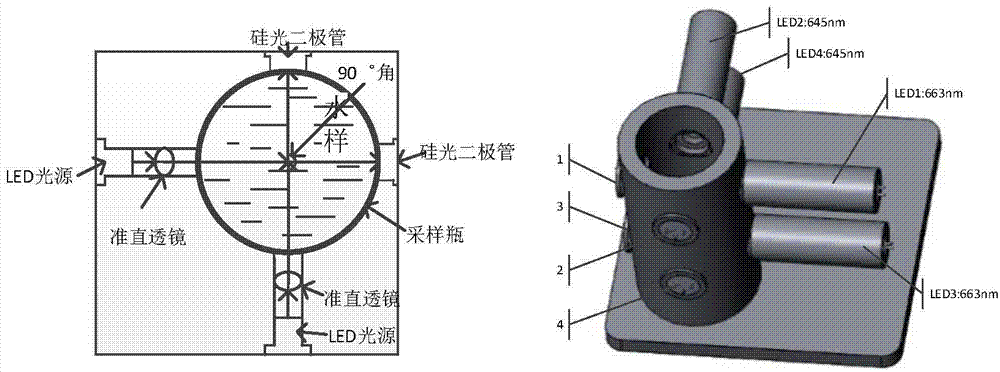

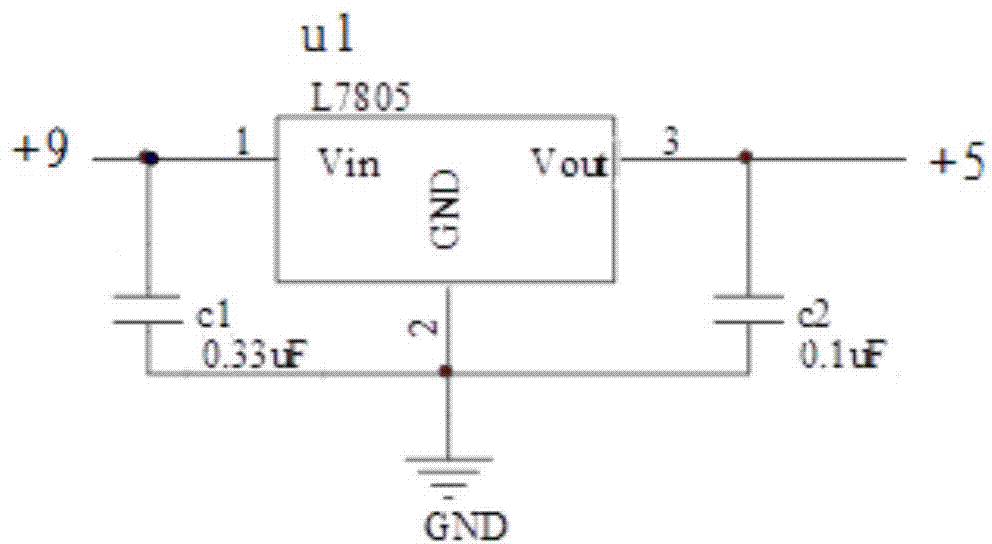

Detection apparatus and method for content of chlorophyll

ActiveCN104777108AEasy to prepareFast analysisColor/spectral properties measurementsLength waveAbsorbance

The invention discloses a detection apparatus and method for the content of chlorophyll. The method comprises the following steps: establishing a chlorophyll detection model by using chlorophyll solutions with different concentrations; detecting a to-be-detected sample by using incident light of two wavelengths so as to acquire the absorbance of chlorophyll in the to-be-detected sample; and substituting the absorbance of chlorophyll in the to-be-detected sample into the chlorophyll detection model so as to obtain the concentration of chlorophyll in the to-be-detected sample. According to the invention, light with wavelengths of 645 nm and 663 nm is used to irradiate the sample, the value of absorbance at corresponding wavelength can be obtained by measuring the intensity of transmitted light via a photoelectric sensor, so the relative concentration value of chlorophyll can be calculated. The detection apparatus and method have the main advantages of a fast analysis speed, a wide measurement range, simple preparation of the sample, no consumption of the sample, no chemical pollution, etc.

Owner:CHINA AGRI UNIV

Mulberry leaf tea for spot removing and face nourishing, and its preparation method

InactiveCN102845571AGreat tasteLight tasteTea substituesGranular deliverySalvia miltiorrhizaNon toxicity

The invention provides a mulberry leaf tea for spot removing and face nourishing, and its preparation method. The mulberry leaf tea comprises mulberry leaf, peach blossom, Rubus idaeus, Poria cocos, Millettia dielsiana, Radix Codonopsis, Fortune Eupatorium Herb, Gynostemma pentaphylla, Chinese angelica, Rhizoma Polygonati Odorati, Peach Seed, Radix Curcumae Aromaticae, Rhizoma Cyperi, dahurian angelica root, Ligusticum wallichii, Salvia miltiorrhiza, coix seed, Rhizoma Atractylodis Macrocephalae, Urena lobata L., Bletilla striata, Ligustri Lucidi Fructus, Flos Campsis and white peony root. Disadvantages of easy heaping yellowing, frangibility and tea soup redness of the mulberry leaf are solved, and polyphenol substances in the mulberry leaf are converted into amino acids as possible, so it is in favor of the removal of the bitter taste of the tea and the realization of a delicious taste; and mulberroside F contained in the mulberry leaf can inhibit the biological synthesis of melanin. Researches prove that a mulberry leaf juice has the advantages of anti-oxidation, non-toxicity, and no chemical pollution, and can be used for the treatment of face acne removal, color spot removal, phlegm elimination, sore throat relief, hair generation, hair caring, liver clearing and eyesight improving, and traditional Chinese medicinal materials for the blood circulation promoting and blood stasis removal are added to well reach the efficacies comprising skin beautifying, face nourishing, and color spot removing, wherein the traditional Chinese medicinal materials have a light mouthfeel, do not affect the taste of the mulberry leaf tea, and can be easily accepted by people.

Owner:WUPING HONGXIN IND TECH DEV

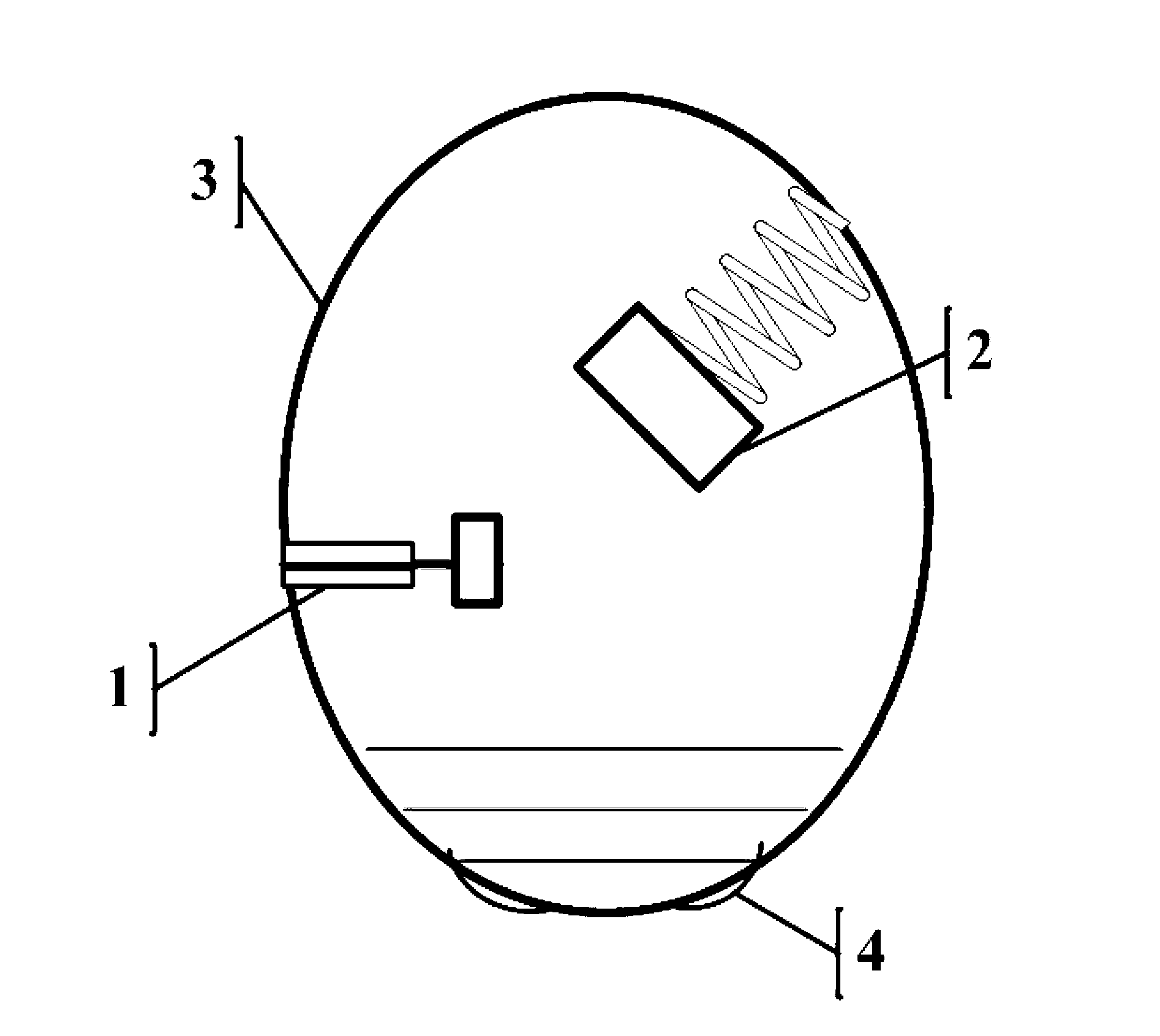

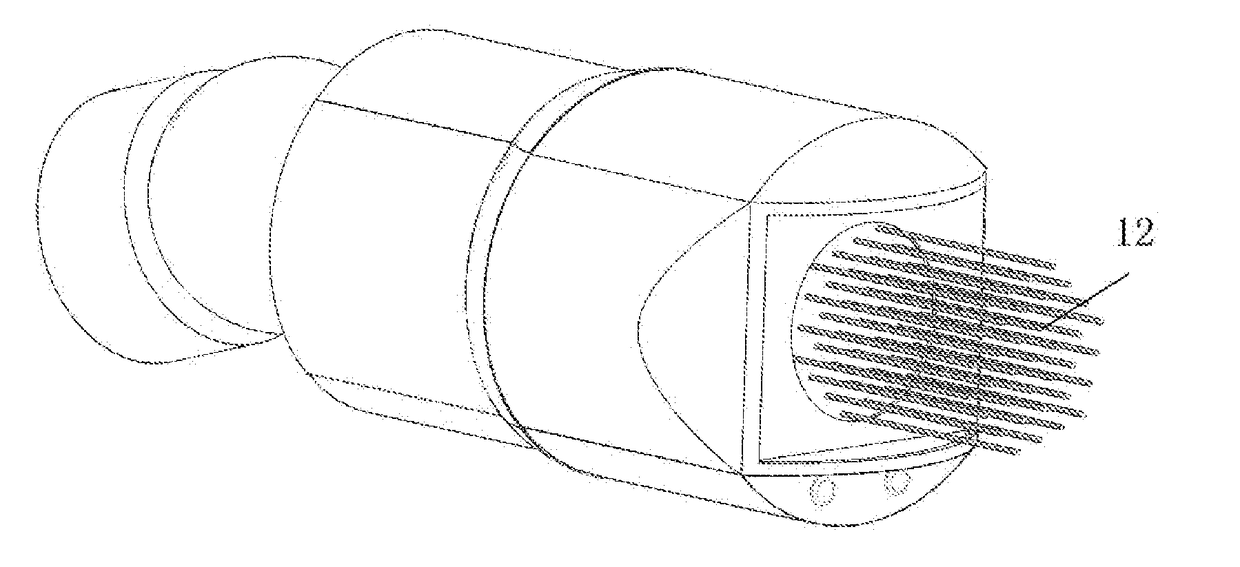

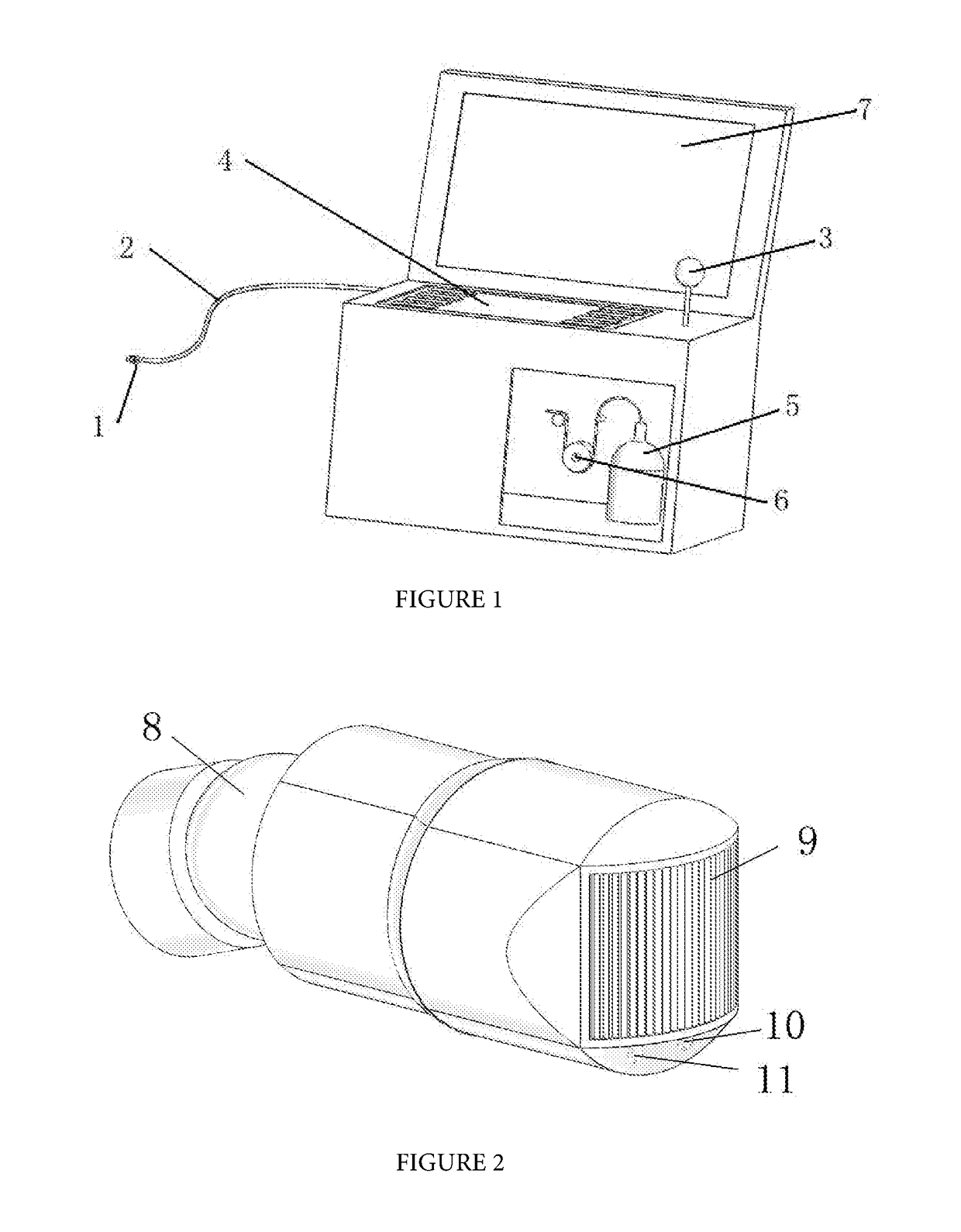

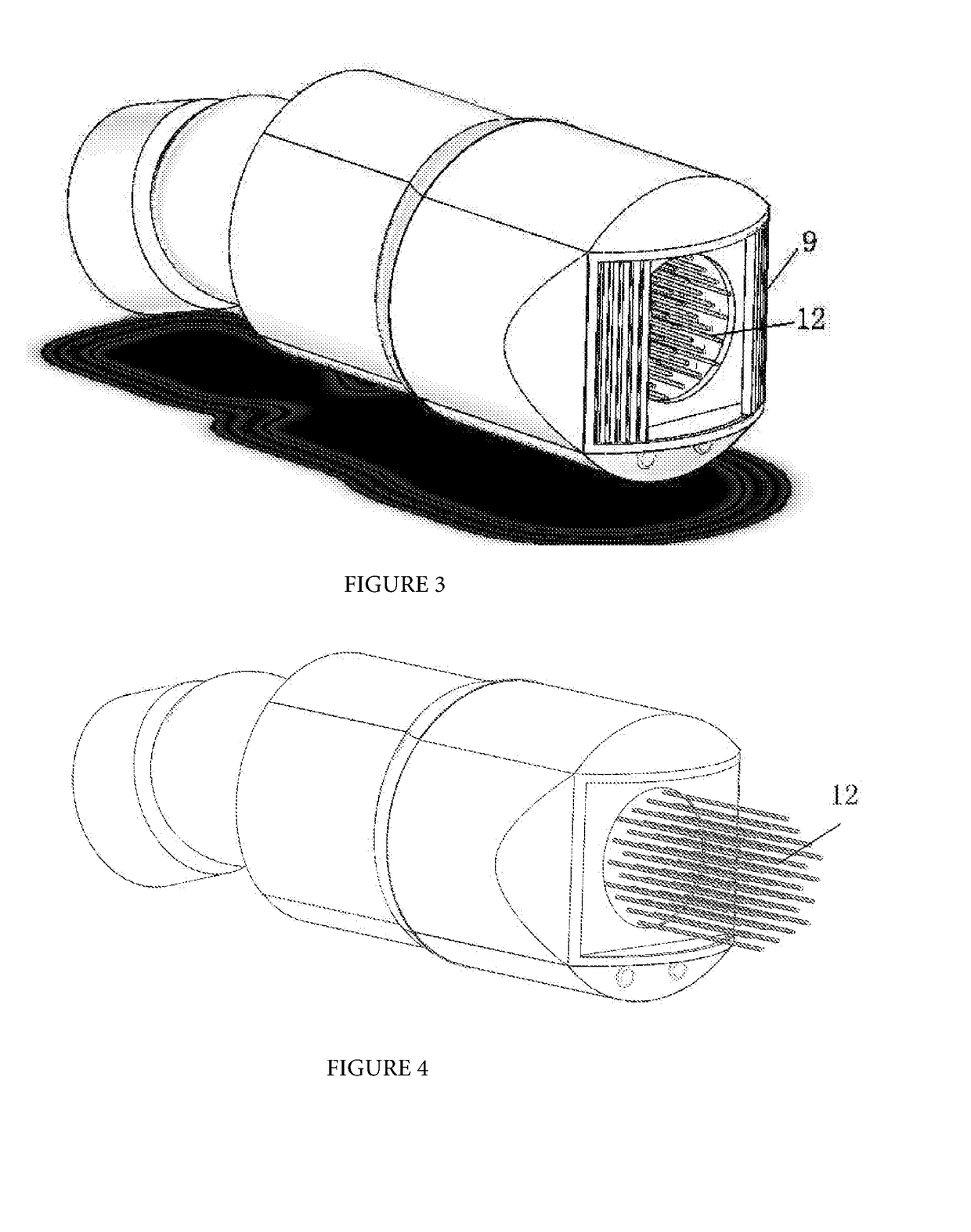

Tumbler type multimode power generating device

InactiveCN103174616AIncrease wind areaImprove stabilityWind motor combinationsMachines/enginesElectricitySea waves

The invention discloses a tumbler type multimode power generating device which comprises a tumbler structural body, a micro power generating structural body and a piezoelectric material, wherein the micro power generating structural body is fixed on the inner wall of a cavity body, axial lines where three micro power generating structures of the micro power generating structural body are located are in a three-dimensional orthogonal state, the micro power generating structural body drives two power generating units to output power at the same time, one power generating unit outputs power by utilizing the direct piezoelectric effect of the piezoelectric material, the other power generating unit outputs power by utilizing the electromagnetic induction principle, and the piezoelectric material is fixed near the position where the outer side of the bottom of the tumbler structural body is combined with the ground. The tumbler type multimode power generating device can be used for power generation by wind power, water power, sea wave and vibrational energy, and is simple in arrangement, low in cost, and wide in application range.

Owner:张平

Preparation method of reishi shell-broken spore powder at temperature difference ultrahigh pressure by wet process

ActiveCN104223038AImprove athletic performanceEffective absorptionFood preparationPlant ingredientsSporelingUltra Low Temperature Freezer

The invention discloses a preparation method of reishi shell-broken spore powder at temperature difference ultrahigh pressure by a wet process. The preparation method comprises the following steps: soaking fresh reishi spore powder so as to absorb water, putting into a centrifugal machine, centrifuging, airing, then putting into an ultralow-temperature refrigerator and liquid nitrogen sequentially, refrigerating so as to obtain the ultralow-temperature wet spore powder with cracked pore shells, then carrying out microwave unfreezing treatment so as to obtain dried shell-broken spore powder, and finally acquiring sterile spore powder with high shell breaking rate under ultrahigh pressure. The method provided by the invention can be used for solving the technical difficulties of low shell breaking rate, food pollution and difficulty in releasing polysaccharide in the processing course; the reishi shell-broken spore powder prepared by the invention has the characteristics of high spore powder shell breaking rate, no pollution source and easiness in absorption of functional inclusions.

Owner:SHANGHAI JIAO TONG UNIV

Device and method of electroporating drug-delivering by using hollow needle electrode

ActiveUS20170080221A1Precise positioningGood electroporating effectMedical devicesPressure infusionDisplay deviceControl line

An electroporating drug delivering device using hollow needle electrode includes a drug delivering head, a control console as well as a control line and a tube for connecting the drug delivering head and the control console. The drug delivering head includes a universal joint, a camera, an illuminating lamp, a molecular drug delivery structure, an electric connector, a grille, a hollow needle electrode array, and a stretchable structure. The control console includes a display for observing images, a rocker for controlling the universal joint, and a remote starting unit for controlling the generation of electric pulses. The control console is connected with the electric connector inside of the drug delivering head by the line arranged inside of the tube. The electroporating drug-administration device enhances the drug utilization efficiency and reduces the treatment time, and can accurately adjust the intensity and region of the electric field.

Owner:ETTA BIOTECH

Method for preparing polyethylene glycol composite nanofiltration membrane and its products

InactiveCN101053791ANo emissionsNo chemical pollutionSemi-permeable membranesCoated membraneRoom temperature

The invention relates to a method for preparing polyethylene glycol composite nanofiltration membrane and the product thereof. The preparation method comprises: the preparation of polyethylene glycol coating liquor with a concentration of 1*10-4g / L-3g / L: the prepared polyethylene glycol coating liquor is uniformly coated on the surface of basement membrane to obtain the polyethylene glycol coating membrane after dry in room temperature; the said polyethylene glycol coated membrane is irradiated in the electron accelerator field, and the irradiation dose is 5Gry-1*104Gry; the irradiation time is 1min-10min; the coated membrane irradiated is laid for 12-24h in room temperature to obtain the said polyethylene glycol composite nanofiltration membrane. The polyethylene glycol composite nanofiltration membrane of the invention is prepared by the method mentioned in the invention. The preparation method does not bring in chemical crosslinking agent, and has no remain and pollution of organic liquor, which is beneficial to environmental protection. The component of the method is easy to buy, the cost is low and it is convenient for practical application. The nanofiltration membrane has a good hydrophilicity, separation selectivity and water penetration, and is also organic fouling resistant.

Owner:TIANJIN MOTIAN MEMBRANE ENG & TECH

Natural petals face-mask and preparation method thereof

InactiveCN101336869AGood effectInstant hydrationCosmetic preparationsToilet preparationsCelluloseSide effect

The invention provides a natural petals face-mask and preparation method thereof, comprising by weight percent: 1-5% of humectant, 5% of glycerol, 0.3% of cellulose, 0.1-0.5% of thickener, 0.01-1.25% of antiseptic, 0.01-0.05% of buffer, 1% of jojoba oil, 0.1% of hyaluronic acid, 25-50% of spermaphyta mixed extracting solution, 0.1%-1% of plant essential oil, 2% of camomile extracting solution, 2% of alga extracting solution, 2% of green cucumber extracting solution, 2% of calendula extracting solution, 2% of aloe extracting solution, 0.1-1% of natural plants petals, 0.1-2% of spermaphyta mixed petals and balancing amount of water. The natural petals face-mask is only applied on the clear face for about 15-25 minutes and then is rinsed up. Due to rich natural ingredient and no side-effect, the natural petals face-mask has remarkable cosmetic effect and quite environment protection.

Owner:吴志刚

Preparation method for mother strain of wild dictyophora rubrovolvatain of Mount Fanjing

ActiveCN104920065AMother species is fastNo chemical pollutionCultivating equipmentsOrganic fertilisersCulture mediumsRaw material

The invention discloses a preparation method for a mother strain of wild dictyophora rubrovolvatain of Mount Fanjing. The preparation method includes taking talinum paniculatum, rice, glucose and agar as raw materials, and preparing a talinum paniculatum test tube bevel culture medium serving as a mother strain culture medium for standby application; collecting strain eggs of the wild dictyophora rubrovolvatain of the Mount Fanjing, wrapping and sealing each strain egg with a preservative film immediately, and taking the strain eggs to a laboratory; disinfecting the strain eggs with tap water, alcohol, sodium hypochlorite, sterile water and the like, cutting the strain eggs open, taking out strain stems, cutting the strain stems into a plurality of blocks with the side length of 0.5-1cm, and inoculating each mother strain culture medium test tube with one block, wherein each strain egg can be used for inoculation of 8-12 test tubes; culturing the inoculated test tubes at the temperature of 20 DEG C in a dark place for 45 days to obtain the mother strain of the wild dictyophora rubrovolvatain of the Mount Fanjing. The preparation method has the advantages that the talinum paniculatum substitutes for chemical reagents added into ordinary culture media, simplicity and convenience in operation, low cost and short cycle are achieved, chemical pollution is avoided, and mother strains of similar edible mushrooms such as dictyophora indusiata can be prepared.

Owner:TONGREN UNIV

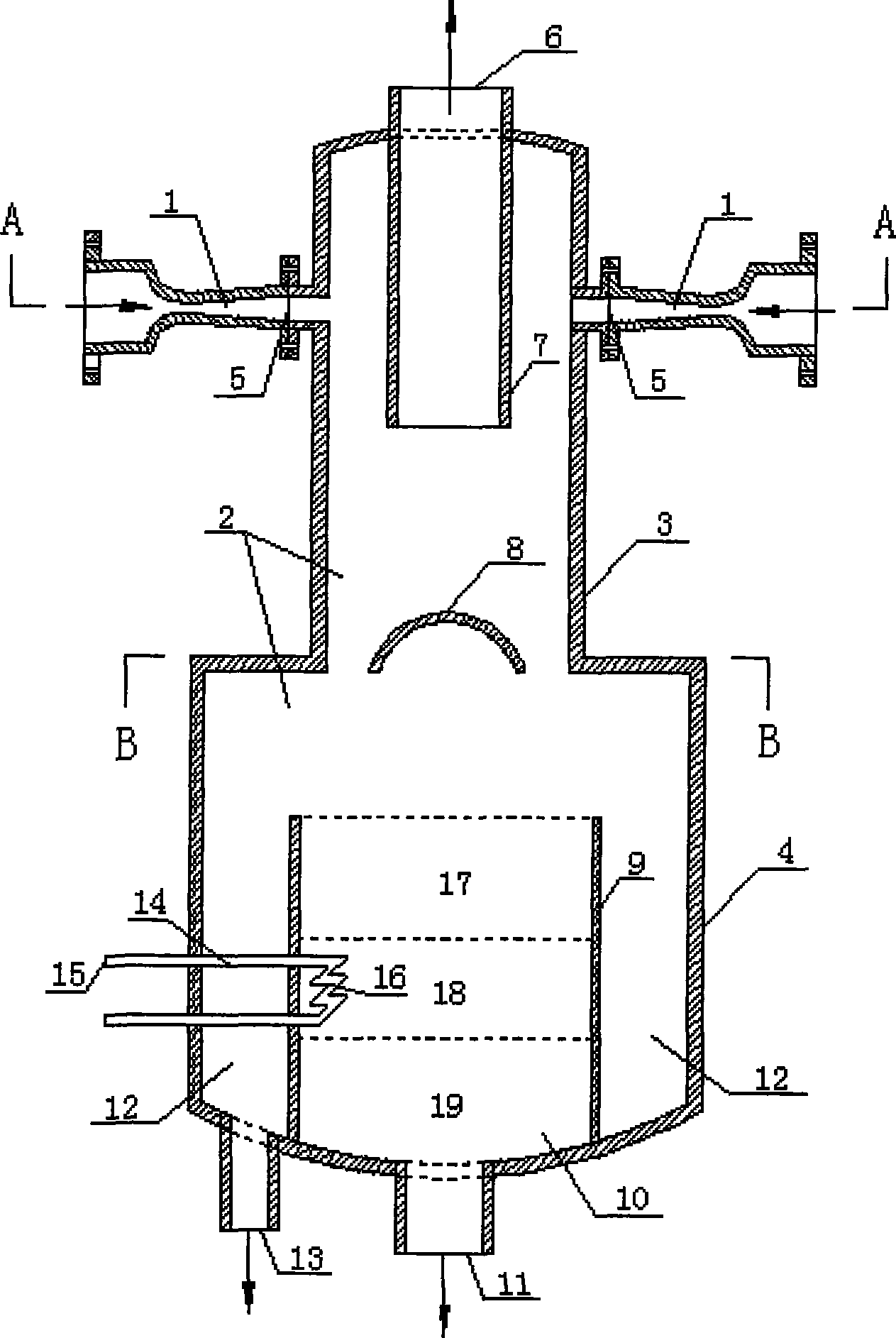

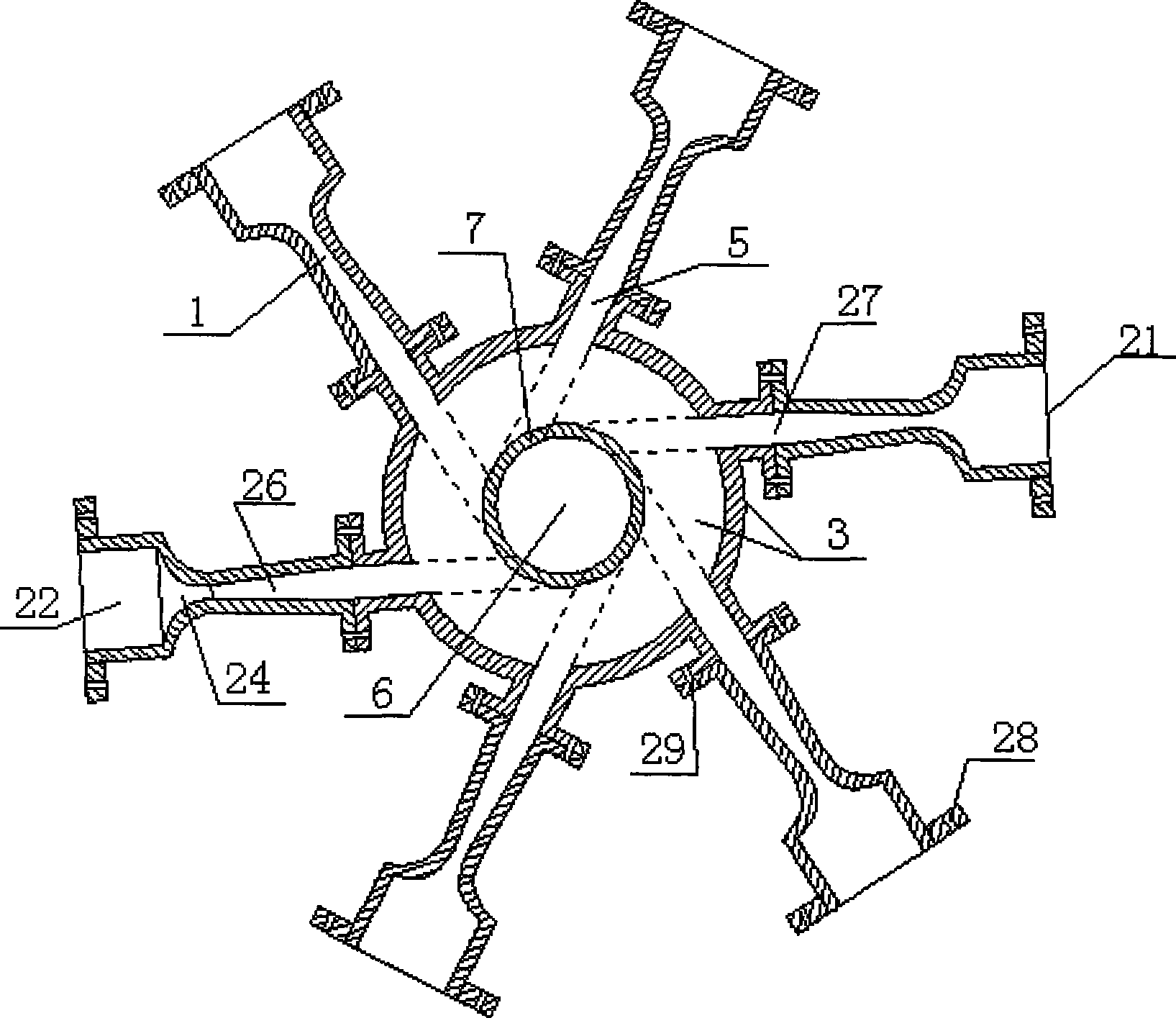

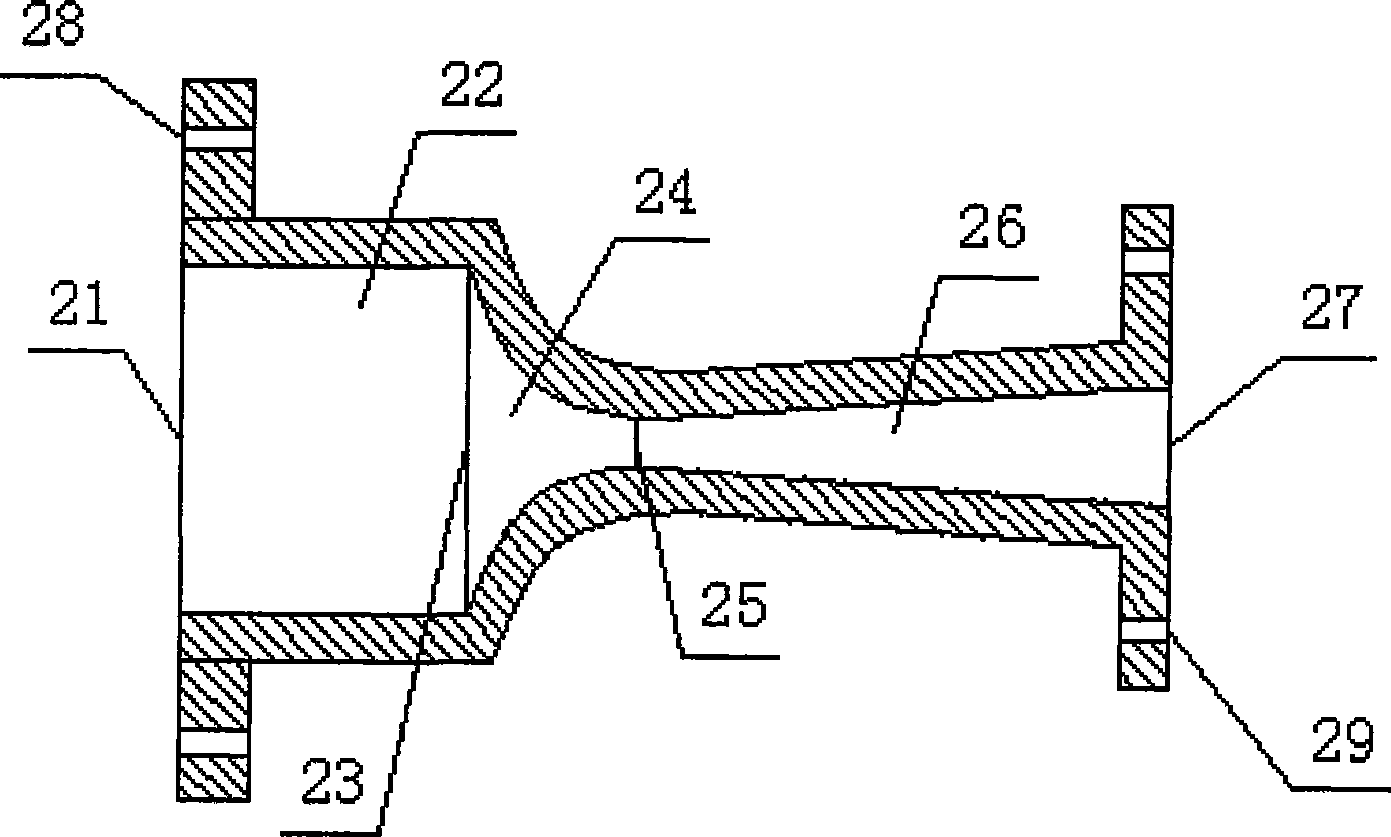

Skid-mounted device for ultrasonically dehydrating, removing liquid, purifying and separating for natural gas

InactiveCN101544921AEfficient separationAvoid it happening againGaseous fuelsNatural gas dehydrationThree-phase

The invention relates to a skid-mounted device for ultrasonically dehydrating, removing liquid, purifying and separating for natural gas, belongs to an energy-saving purification device of heat engineering, and is mainly applied in the field of dehydrating, removing liquid, purifying and separating for natural gas. The device consists of a gas purification device and a gas separation device. Wet natural gas enters an ultrasonic separation spray pipe respectively; because the temperature is reduced, water and heavy paraffin hydrocarbon components in the natural gas become liquid and then are condensed to form high-speed rotational flow to tangentially flow into a hydrate separator cylinder; and then three-phase separation of the natural gas, condensate and water is carried out, and simultaneously the hydrate is prevented from being generated. The device efficiently separates out the water and the heavy hydrocarbon liquid from the natural gas without adding any chemical drugs, has the advantages of energy conservation, environmental protection, compact structure, and little occupied area, reduces the running cost, can achieve unmanned operation and free maintenance, and can be applied to remote or severe environmental land and offshore platforms.

Owner:SICHUAN ZHONGKEDA OIL&GAS NEW TECH

Coating method for preventing bird from building nest

InactiveCN101651305ABright colorHigh light perceptionOverhead installationCoatingsEngineeringSpontaneous reaction

The invention relates to a coating method for preventing birds from building nests, in particular to a method which is capable of effectively preventing birds from building nests on power transmissionand transformation circuits and equipment. The coating method for preventing birds from building nests adopts coating of any two or three of a red colour system, a yellow colour system and a blue colour system to carry out interval coating. The invention applies the characteristics of biological spontaneous reaction and utilizes the sensitivity of the birds to colors to prevent the birds from building the nests and prevent bird damage. Meanwhile, the coating method has no environmental pollution or chemical pollution, and simple and convenient construction.

Owner:HENAN SUNSHINE ANTICORROSIVE PAINTING CO LTD

Plant fiber foam material production method

The invention relates the preparing method of plant fiber expanded material, comprising the following steps: cutting and disintegrating plant fiber, putting it into microwave oven for 1-3min, cooling, and getting the product. The product can be used in many foaming products, such as mess-tin, heated board, acoustic Celotex board, basin, cup, packaging material, and so on. The invention has the advantages of uniformity, quick-speed, good effect and non-pollution.

Owner:ZHEJIANG FORESTRY UNIVERSITY

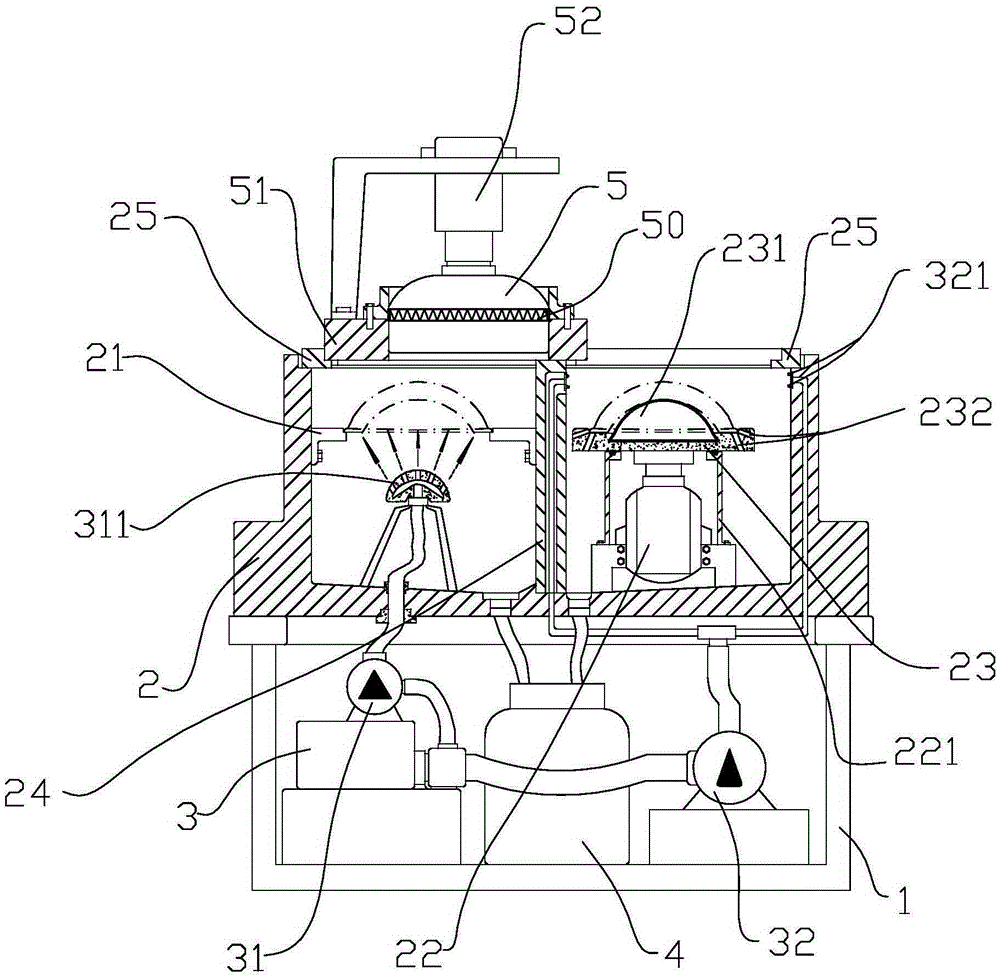

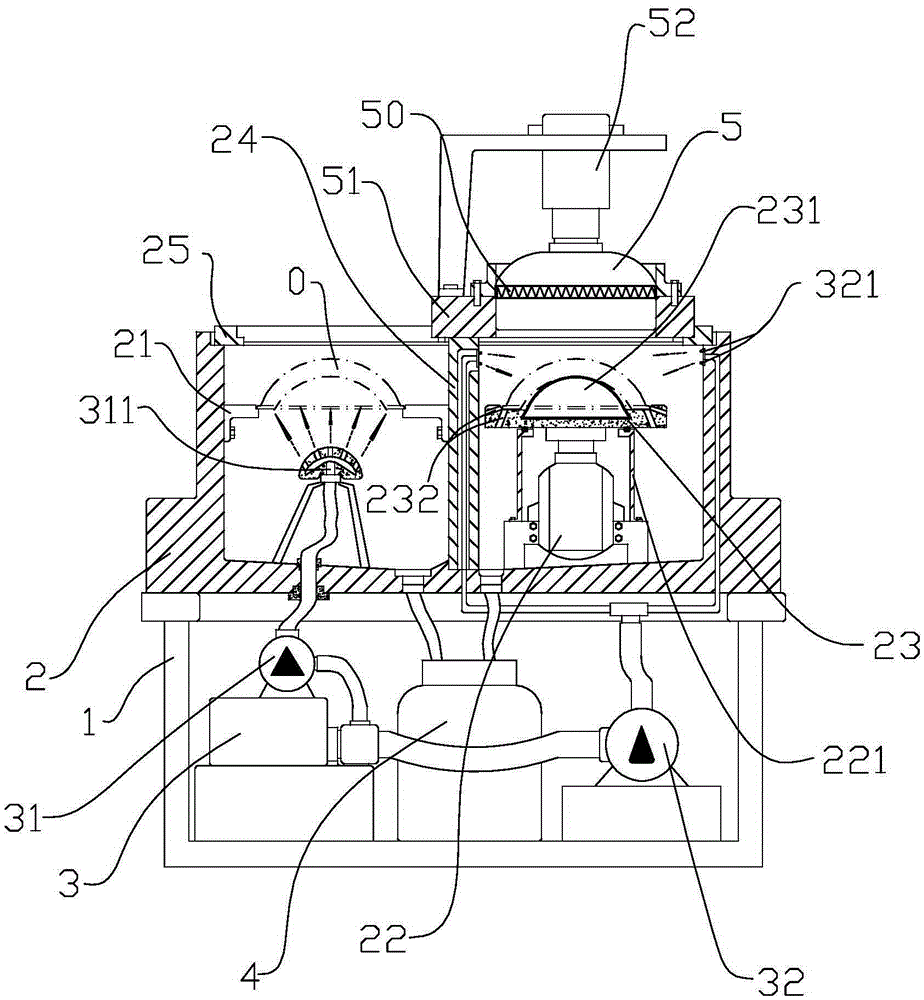

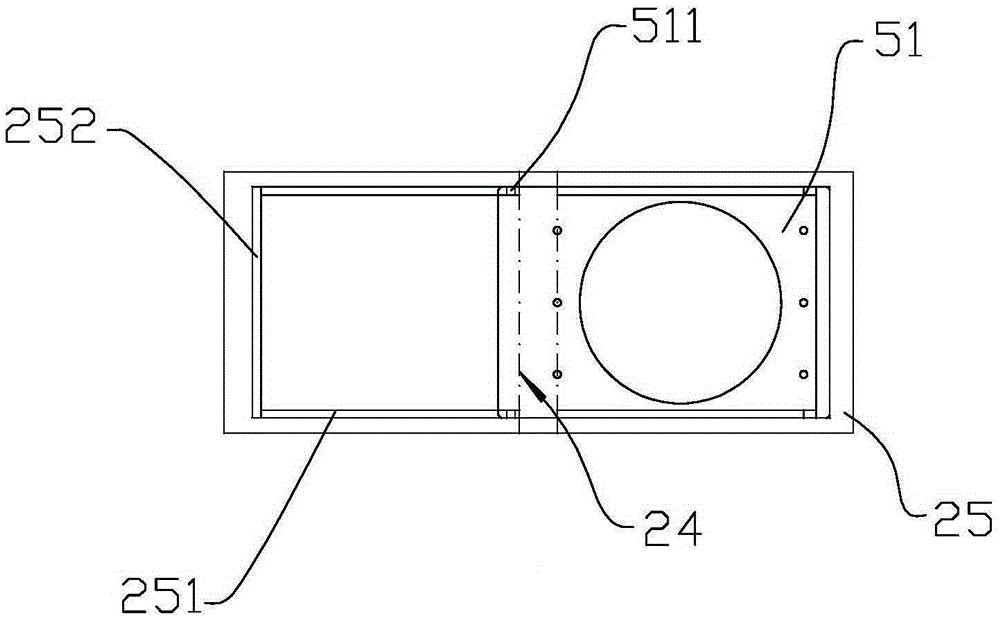

Helmet cleaning machine

ActiveCN105327871ASimple structureEasy to useCleaning using toolsCleaning using liquidsHydraulic cylinderSpray nozzle

The invention discloses a helmet cleaning machine and belongs to the field of cleaning equipment. The helmet cleaning machine comprises a frame body, a cleaning chamber, a heater, a high pressure steam pump and a spraying water pump, wherein the cleaning chamber is formed in the upper end surface of the frame body; and the heater, the high pressure steam pump and the spraying water pump are arranged in the frame body. The cavity of the cleaning chamber is divided into a left cavity and a right cavity; a semi-spherical spraying head and a supporting base arranged on the upper side of the semi-spherical spraying head are arranged in the left cavity; a rotating motor, a supporting plate mounted at the output shaft end of the rotating motor and spraying nozzles at the upper end are arranged in the right cavity. A cover plate is arranged at the upper end of the cleaning chamber. A slide base is arranged on the cover plate and is provided with a vertical through hole and a hydraulic cylinder. A cleaning bowl is arranged at the end of a hydraulic cylinder rod. The heater is connected to the high pressure steam pump and the spraying water pump through a T-joint. The high pressure steam pump is communicated with the semi-spherical spraying head, and the spraying water pump is communicated with the spraying nozzles. The helmet cleaning machine is simple in structure and convenient to use and can clean external shells and interior linings of helmets efficiently and rapidly; cleaning is thorough by adopting high pressure steam; chemical pollution is avoided, dirty water generated in the cleaning process can be recycled, and therefore the environment is protected and the resources are saved.

Owner:STATE GRID SHANDONG SHANGHE POWER SUPPLY +1

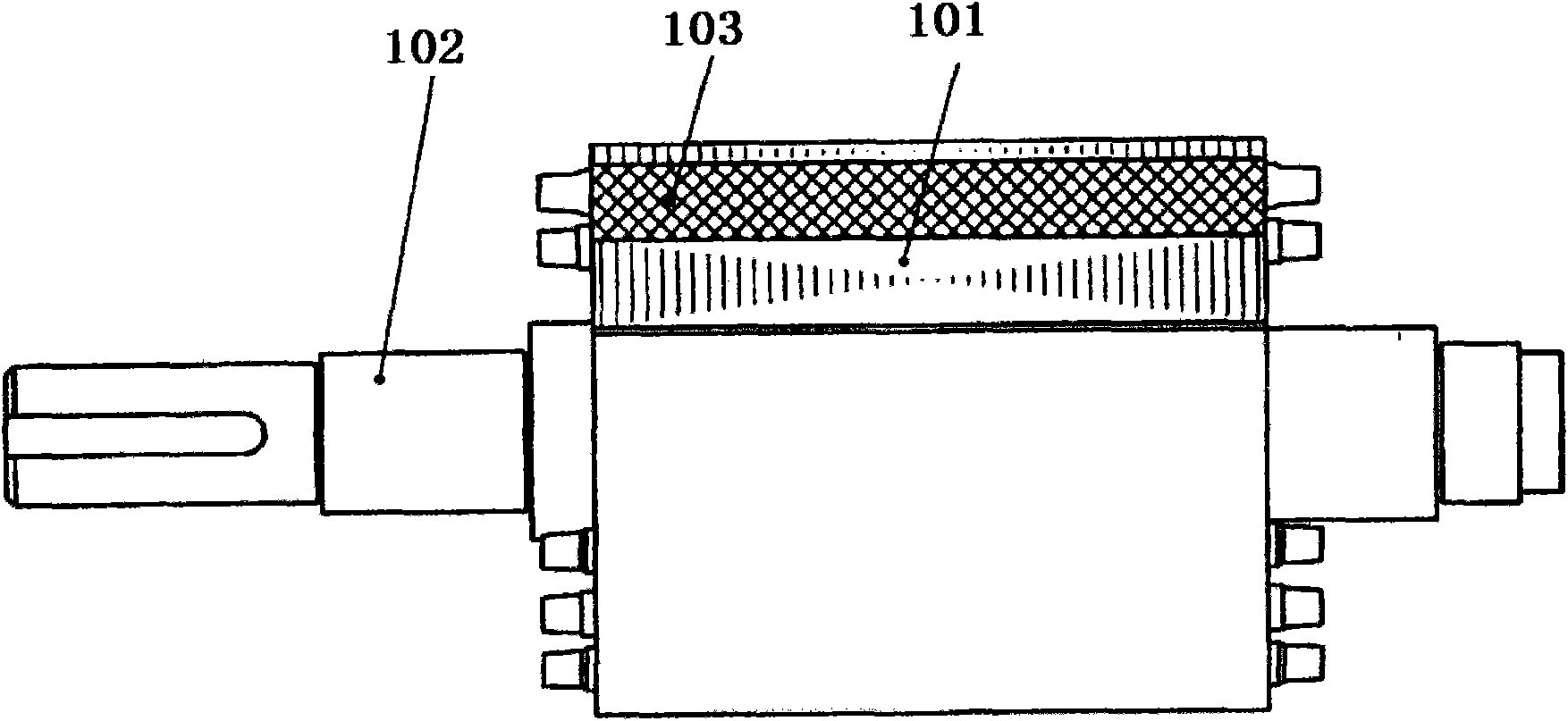

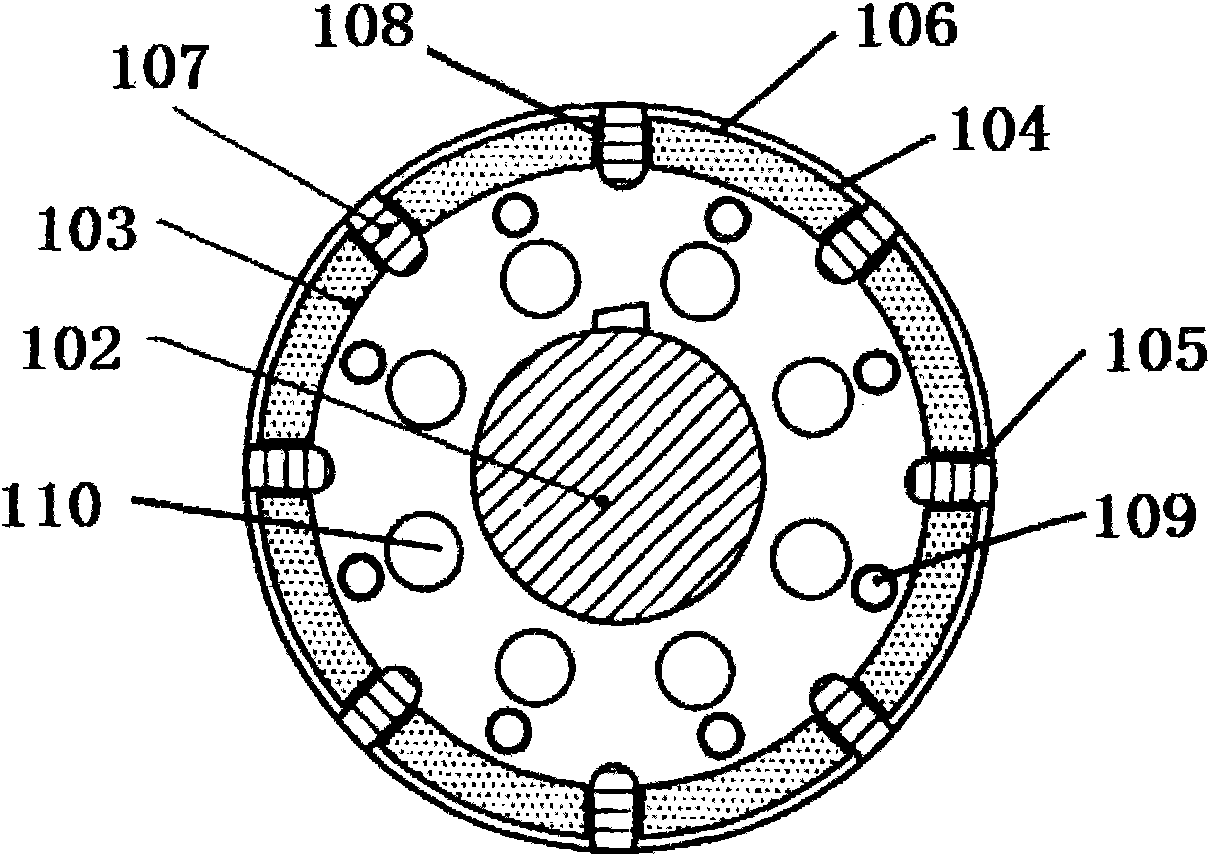

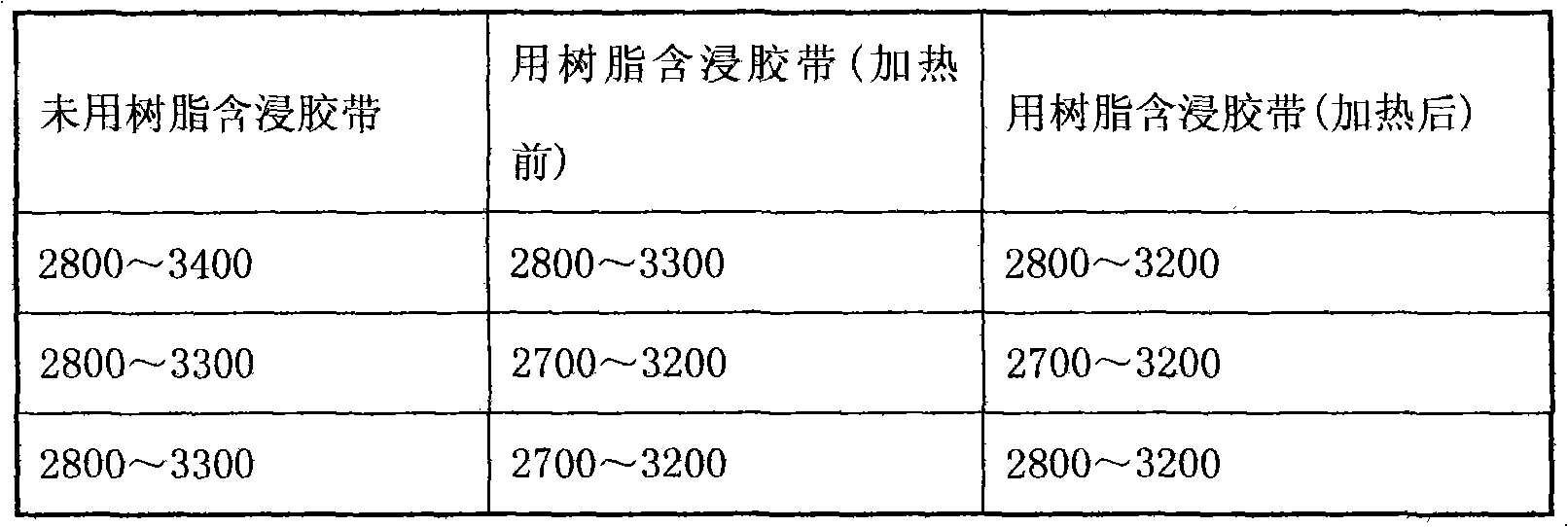

Process for fixing resin impregnated adhesive tapes for rotor

ActiveCN102468718AFacilitate conductionGood magnetic performanceManufacturing stator/rotor bodiesMagnetic circuit characterised by insulating materialsNon magneticElectrical tape

The invention discloses a process for fixing resin impregnated adhesive tapes for a rotor. In the process, a rotor iron core, a rotary shaft and magnets are adopted, wherein the rotor iron core is formed by laminating a plurality of rotor blades; and a plurality of magnet grooves and non-magnetic grooves are formed on the circumferential surface of the rotor iron core. The process comprises the following steps of: firstly, putting the rotor iron core into a baking oven, and pre-heating the rotor iron core; secondly, uniformly coating glue on the surface of the rotor iron core, and inlaying the magnets into the magnet grooves; thirdly, winding the resin impregnated adhesive tape on the surface of each magnet, and winding an insulating adhesive tape outside the resin impregnated adhesive tape; and finally, putting the rotor iron core into the baking box again, baking the rotor iron core to make the resin impregnated adhesive tape tightly wrap on the surface of the magnet, and thus obtaining a finished product for fixing the resin impregnated adhesive tapes for the rotor. The process for fixing the resin impregnated adhesive tapes for the rotor has the advantages that: the thickness of each resin impregnated adhesive tape can be a fraction of that of metal; an interval between the adhesive tape and the magnet can be quite smaller than the interval between a metal annular ring and the magnet; the friction between the rotor and a stator is greatly reduced; the conduction conversion rate of a magnetic field of a motor is higher; and the rotor can be polished and shaped.

Owner:腾禾精密电机(苏州)有限公司

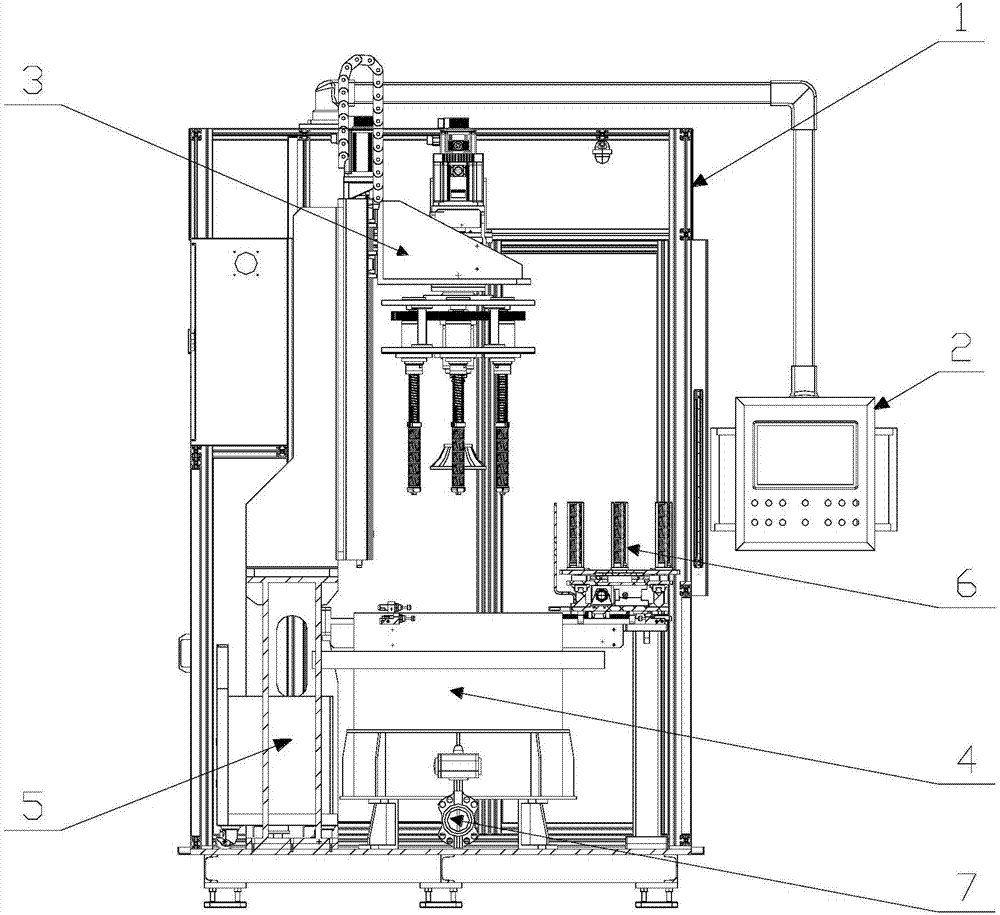

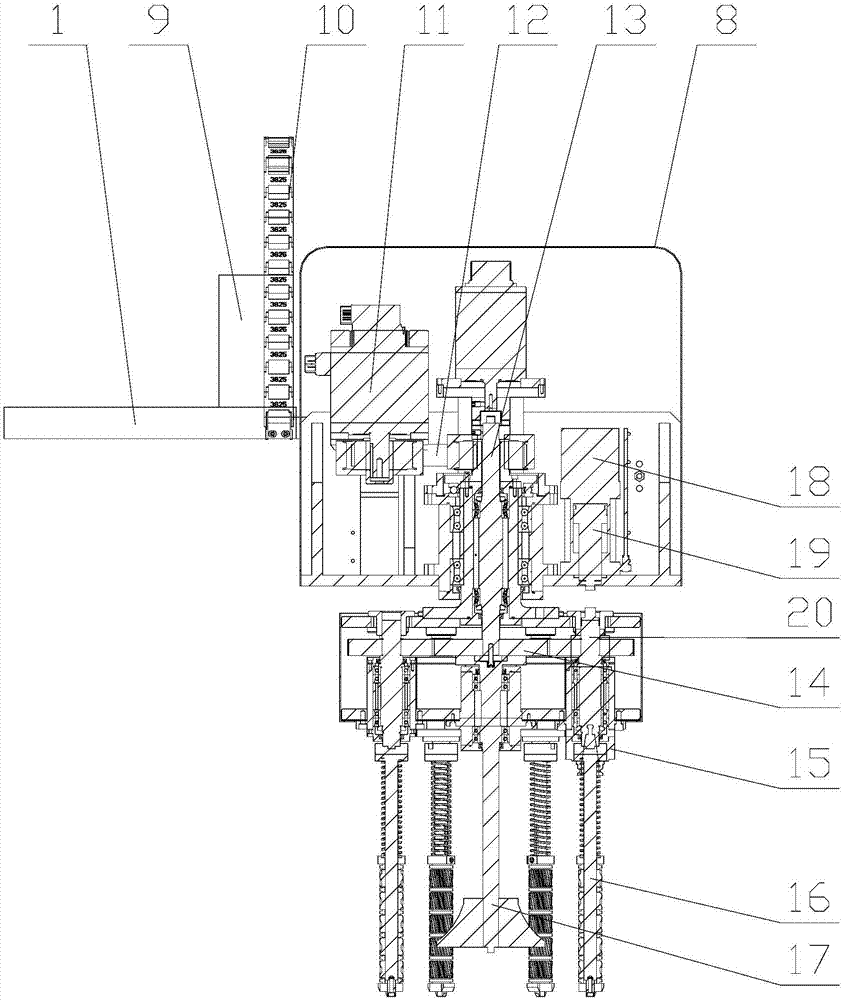

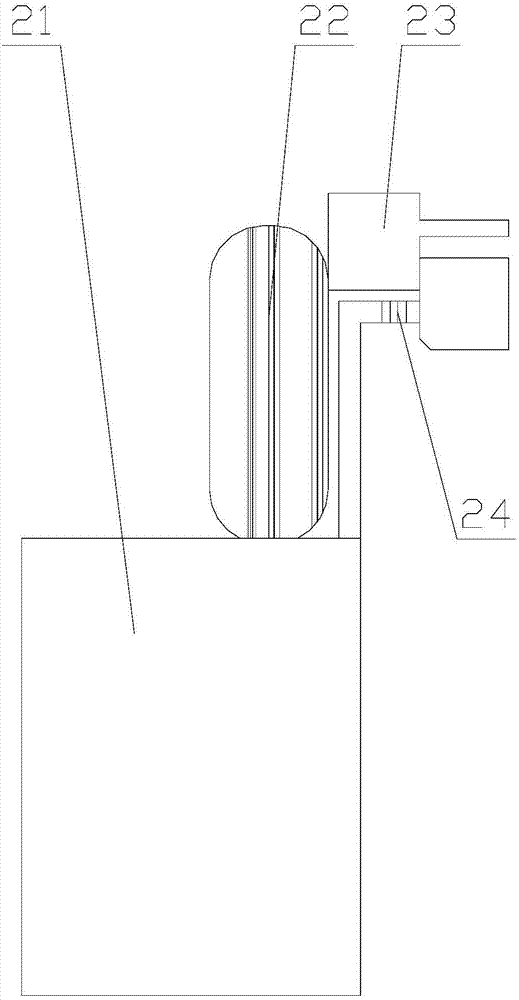

Deburring, grinding and polishing integrated ultra-fine processing machine

PendingCN107511737ADoes not affect dimensional accuracyExtended service lifeEdge grinding machinesGrinding drivesMachineFiltration mechanism

The invention relates to a deburring, grinding and polishing integrated ultra-fine processing machine. The machine comprising a frame, wherein a control box is arranged on the frame; a planetary mechanism is arranged inside the frame; a storage tank is arranged below the planetary mechanism; a grinding fluid filling and circulating filtration mechanism is arranged at one side of the storage tank; and a work fixture is arranged at the other side of the storage tank. The deburring, grinding and polishing integrated ultra-fine processing machine has the advantages that no chemical pollution, dust pollution or noise pollution is generated by adopting physical methods; precise positioning can be carried out through a positioning rod and impact damage is avoided during a cleaning process; meanwhile, all-directional three-dimensional deburring and cleaning can be realized through the planetary mechanism, the surface finish of a part can be increased through the grinding fluid filling and circulating filtration mechanism and the surface of the part is cooled and hardened to improve the service life of the part; and the machine adopts intelligent control to realize high efficiency and low cost and can be connected to a track type production line and a robot to realize the automatic production and reduce the labor cost.

Owner:李涛

Regenerative foam material taking granite powder as raw material and preparation method of regenerative foam material

The invention discloses a regenerative foam material taking granite powder as a raw material and a preparation method of the regenerative foam material. A formula of the regenerative foam material comprises the following components in parts by weight: 40-69 parts of granite powder, 2-8 parts of fly ash, 6-25 parts of fluxing filler, 1-5 parts of pore forming material, and 1-5 parts of polymeric material. The preparation method of the regenerative foam material sequentially comprises the following steps that grain fineness of the powder is controlled above 100 meshes; the powder is stirred and mixed uniformly; a mixture is pressed to a required granular material; the granular material is sent to a high-temperature furnace for warming, cooled and taken out; and a finished product is obtained. The regenerative foam material and the preparation method have the advantages that granite powder waste can be digested sufficiently; a long-term severe environmental pollution problem of a granite processing base can be solved; and environmental requirements can be met. The regenerative foam material is stable in physical property, light in weight, heat-insulated, compression-resistant and fracture-resistant, and can be used for building wall or external wall decoration; objectives of building weight reduction and energy saving can be achieved; in addition, the regenerative foam material has fireproof, waterproof and soundproof properties, and can be used for fireproof materials and wall partitioning materials.

Owner:宁波振强科技有限公司

Green peeling method for kiwi fruit

ActiveCN109673926AShorten soaking timeImprove the degradation effectFood ultrasonic treatmentFood ingredient for microbe protectionKiwi fruitKiwi

Owner:HUNAN AGRI PRODS PROCESSING INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com