Skid-mounted device for ultrasonically dehydrating, removing liquid, purifying and separating for natural gas

A purification separation, supersonic technology, applied in gas fuel, petroleum industry, fuel, etc., can solve the problems of environmental pollution, high price, high cost, etc., and achieve the effect of protecting the environment, processing a large amount, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

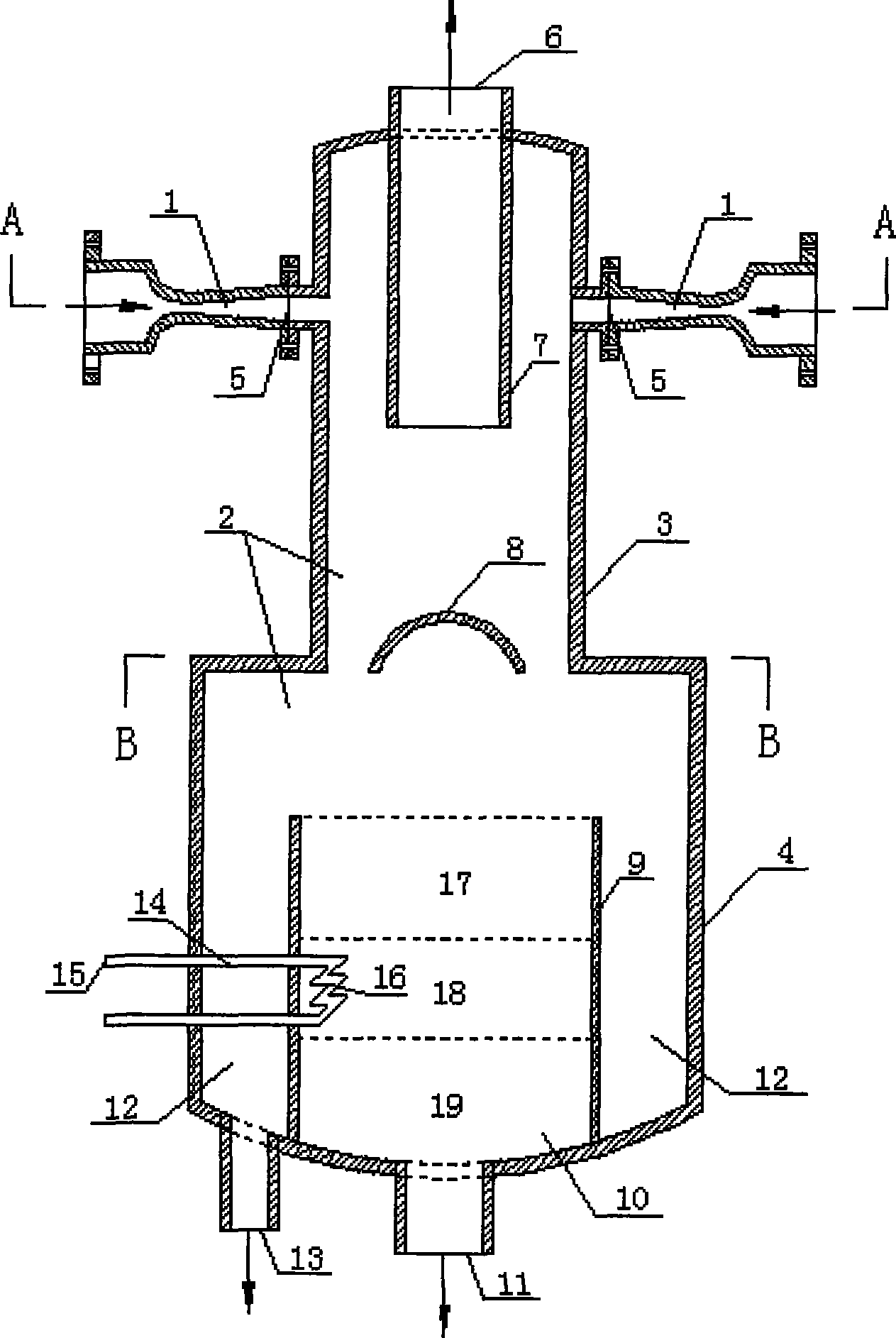

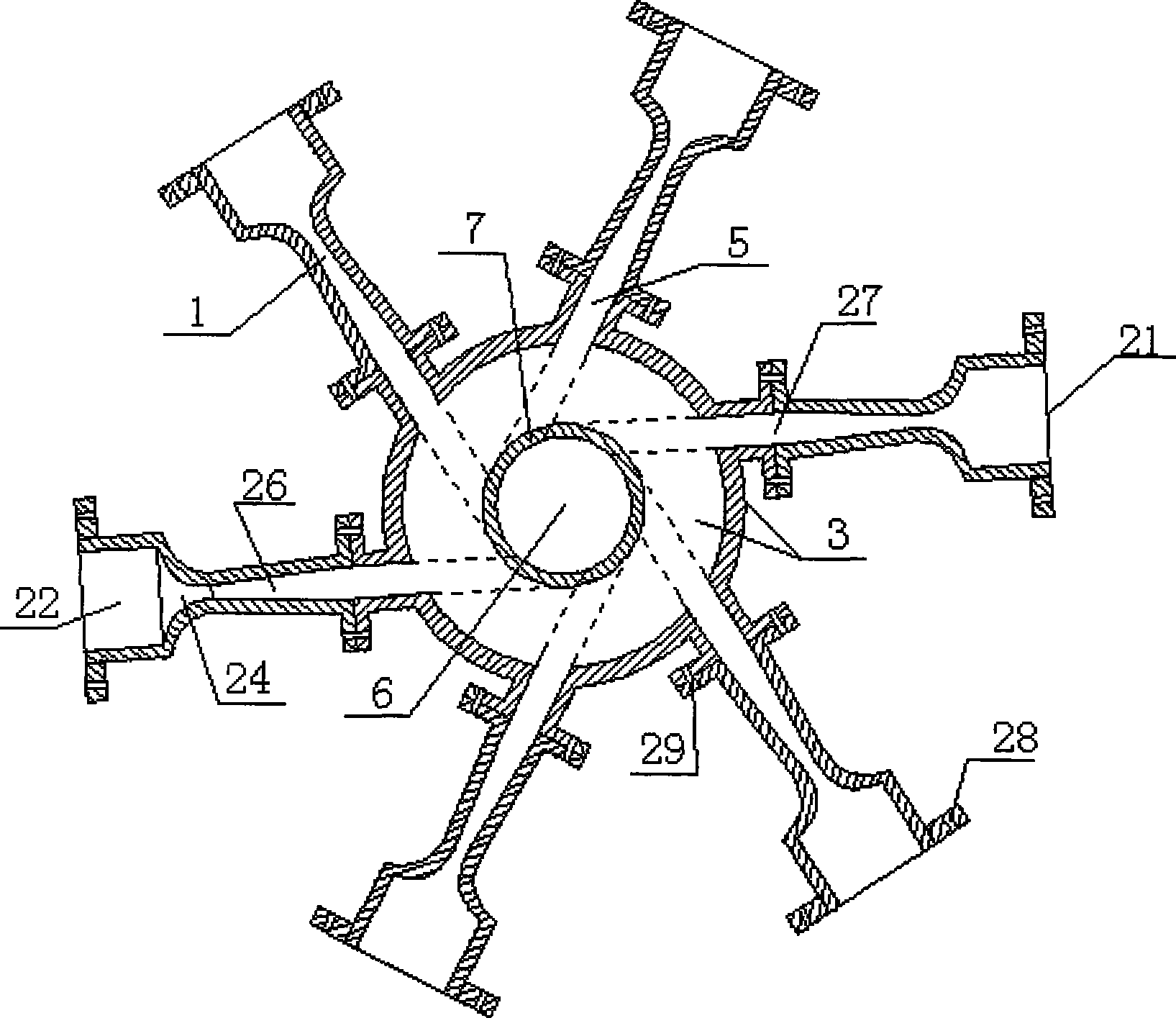

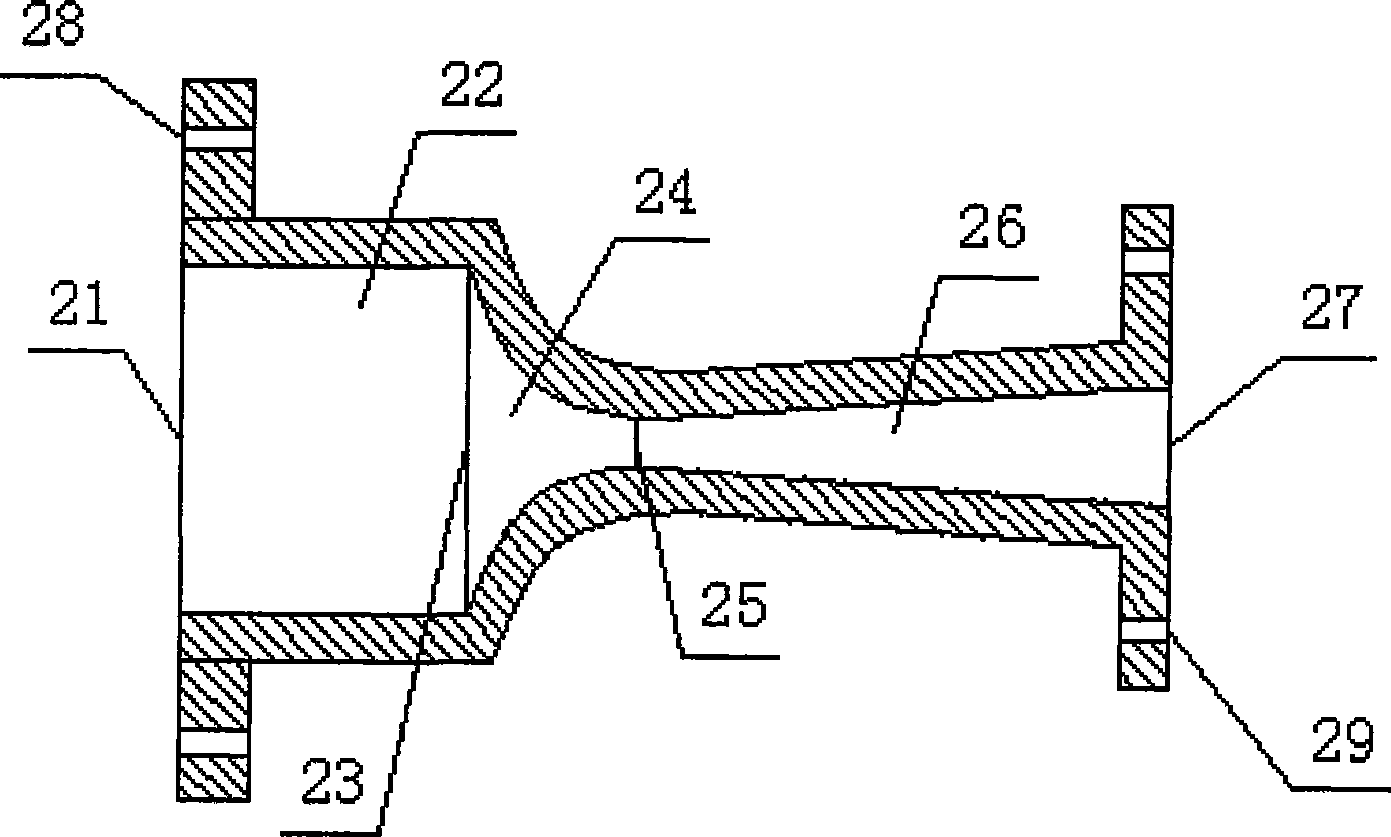

[0033] see Figure 1-6 The technical scheme of the present invention is implemented by conventional processing technology.

[0034] Such as figure 1 As shown, the device is composed of a gas purification device (supersonic separation tube 1) and a gas separation device (hydrate separator 2). The gas supply pipe is connected to the inlet of the supersonic separation pipe through a flange, and the outlet 27 of the supersonic separation pipe is connected to the inlet 5 of the hydrate separator through a flange. The number of supersonic separation tubes 1 is determined according to the flow rate, generally no more than six, and the number of supersonic separation tubes 1 is the same as the number of hydrate separation 2 inlets. In this embodiment, six supersonic separation tubes are set. Separation tube 1.

[0035] The six offshore gas supply pipes are respectively connected to the inlets 21 of the six supersonic separation pipes, and the outlets 27 of the six supersonic separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com