Biogas residue fiber mulch film and manufacturing method thereof

A fiber and biogas residue technology, which is applied in the fields of cellulose raw material pulping, non-fibrous pulp addition, and fiber raw material treatment, can solve the problems of serious environmental pollution, decline in the quality of agricultural products, deterioration of soil structure, etc., and achieve no environmental pollution and manufacturing. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

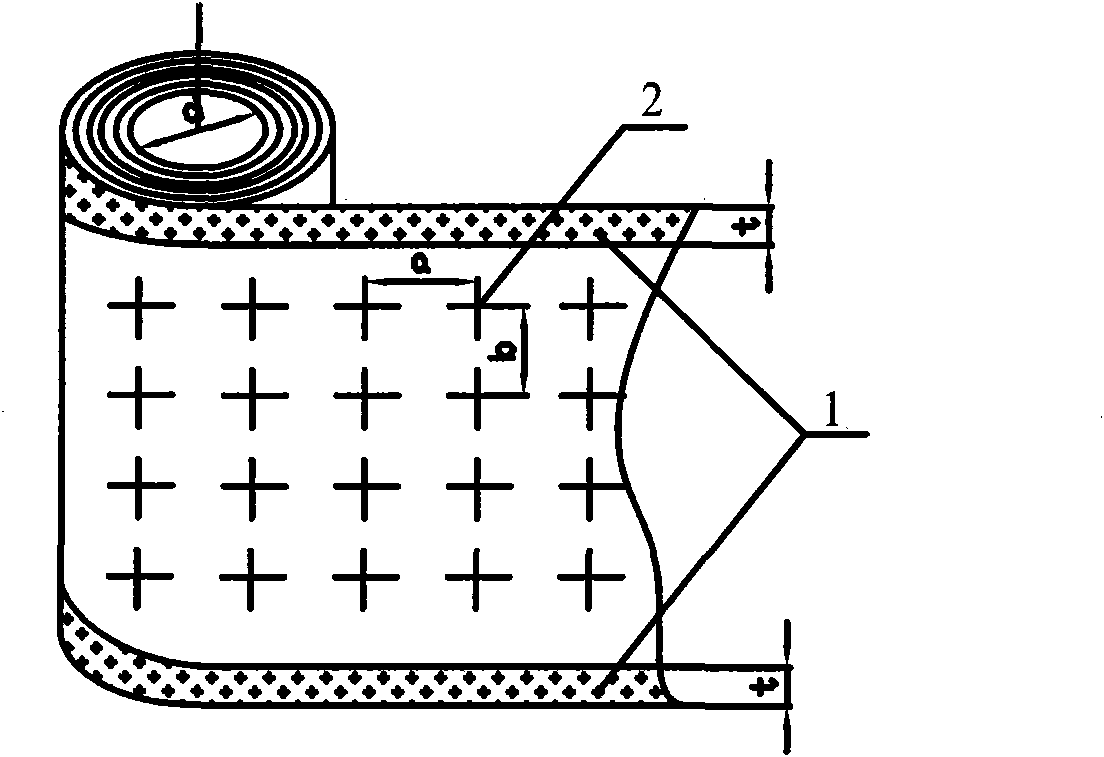

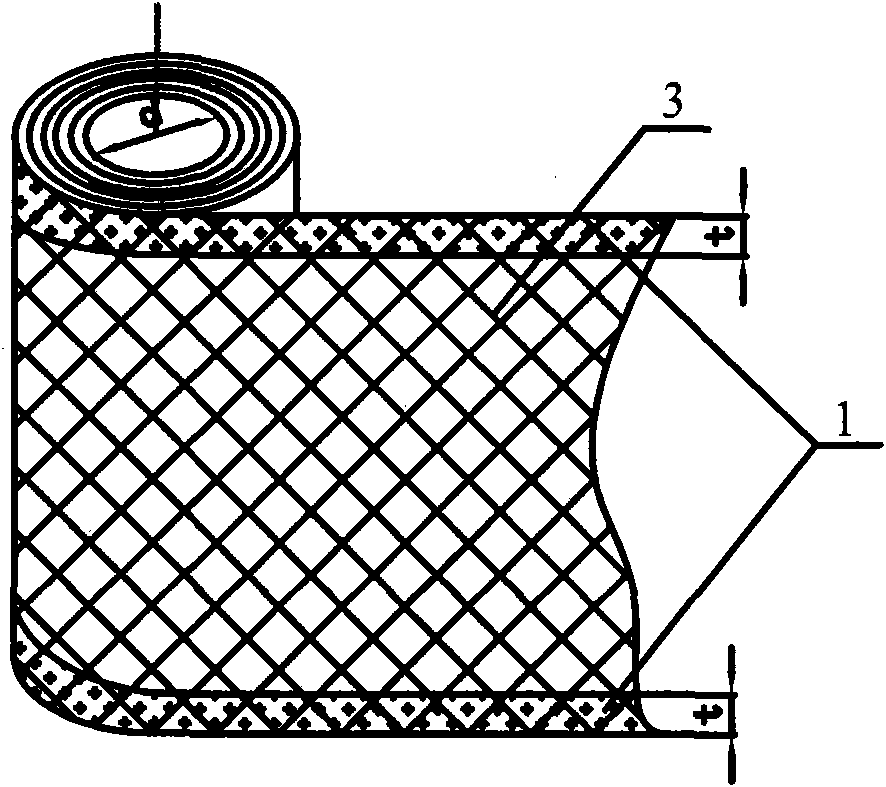

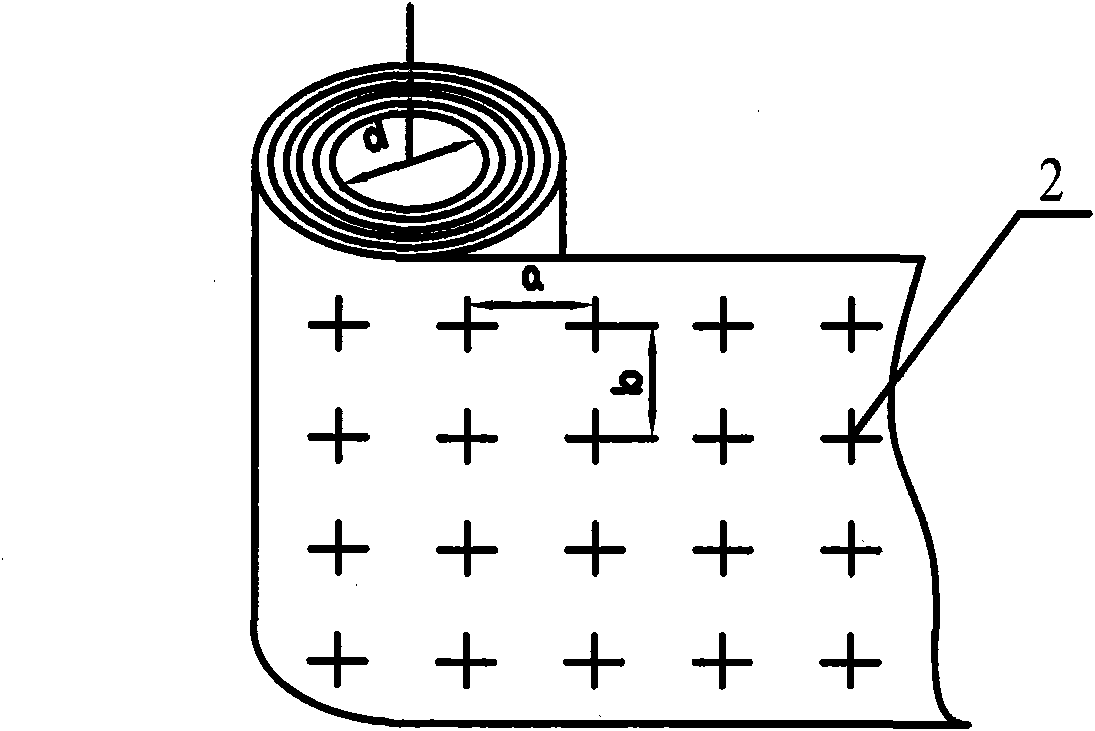

[0018] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] A biogas residue fiber mulch film is composed of biogas residue fiber, plant fiber and environment-friendly functional additives, in which the biogas residue fiber is 50-90% and the plant fiber is 10-50% by weight of dry matter , the total of the two fibers is 100%; the environmentally friendly functional additive mainly composed of rosin, alumina and wet strength agent accounts for 6% to 7.4% of the total weight of the dry matter of the two fibers 100%.

[0020] Manufacturing method of biogas residue fiber mulch film:

[0021] (1) The fiber residue after fermenting ruminant manure and crop straw to produce biogas, after solid-liquid separation, is screened and sand-removed by a sieving machine with an aperture of 1-2 mm, and the obtained fiber is used for beating, when the beating degree is At 35°SR, release the pulp for standby use, the beati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com