Sea wave and wind power generation device

A wind power generation device and sea wave technology, applied in the direction of electromechanical devices, generators/motors, electrical components, etc., can solve the problems of slow wave movement, regular maintenance, and failure to work normally, achieving small environmental damage, low construction cost, The effect of high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

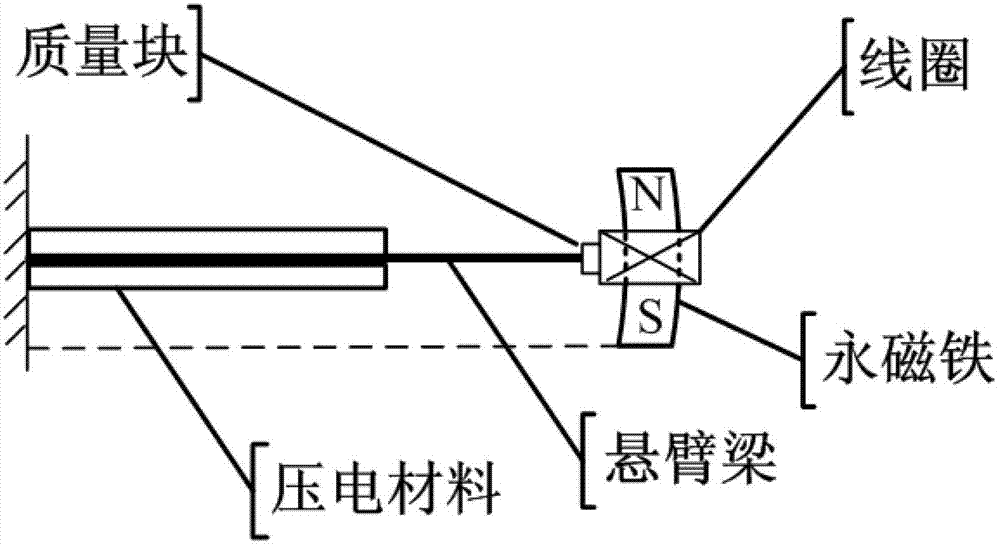

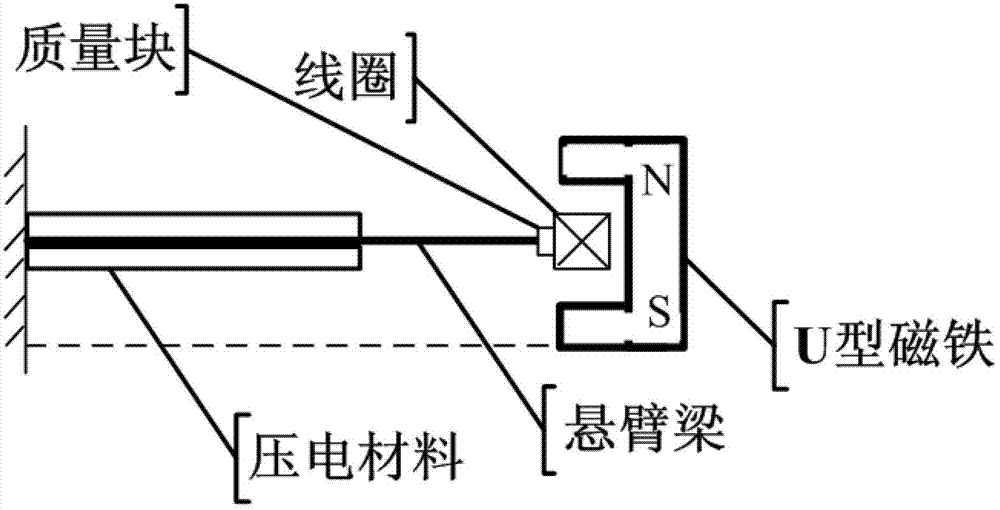

[0071] Embodiment 1: the embodiment in which the elastic member is a cantilever beam

[0072] The elastic component is a cantilever beam, and one end of the cantilever beam is a fixed end that does not produce axial, vertical displacement and rotation. The other end of the cantilever beam is a free end, and the free end can generate a motion perpendicular to the upper and lower surfaces of the cantilever beam. The vibration generated by the outside world and perpendicular to the upper and lower surfaces of the cantilever beam will be captured by the cantilever beam and transmitted to the vibration energy of the cantilever beam structure. Power system.

[0073] Such as figure 2 , 3 , 4, and 5 are examples of micro-power generating structures in which the elastic component is a cantilever beam. The micro-power generation structure includes a cantilever beam. The cantilever beam is usually made of a regular-shaped sheet elastic material, usually made into a rectangular sheet....

Embodiment 2

[0087] Embodiment 2: the embodiment in which the elastic member is a spring

[0088] The said elastic component may be a spring, and one end of said spring is a fixed end. The other end of the spring is a free end, and the free end can produce a movement consistent with the stretching direction of the spring, and the vibration generated by the outside world in the same direction as the stretching direction of the spring will be captured by the spring and transmitted to the vibration energy power generation system of the spring structure.

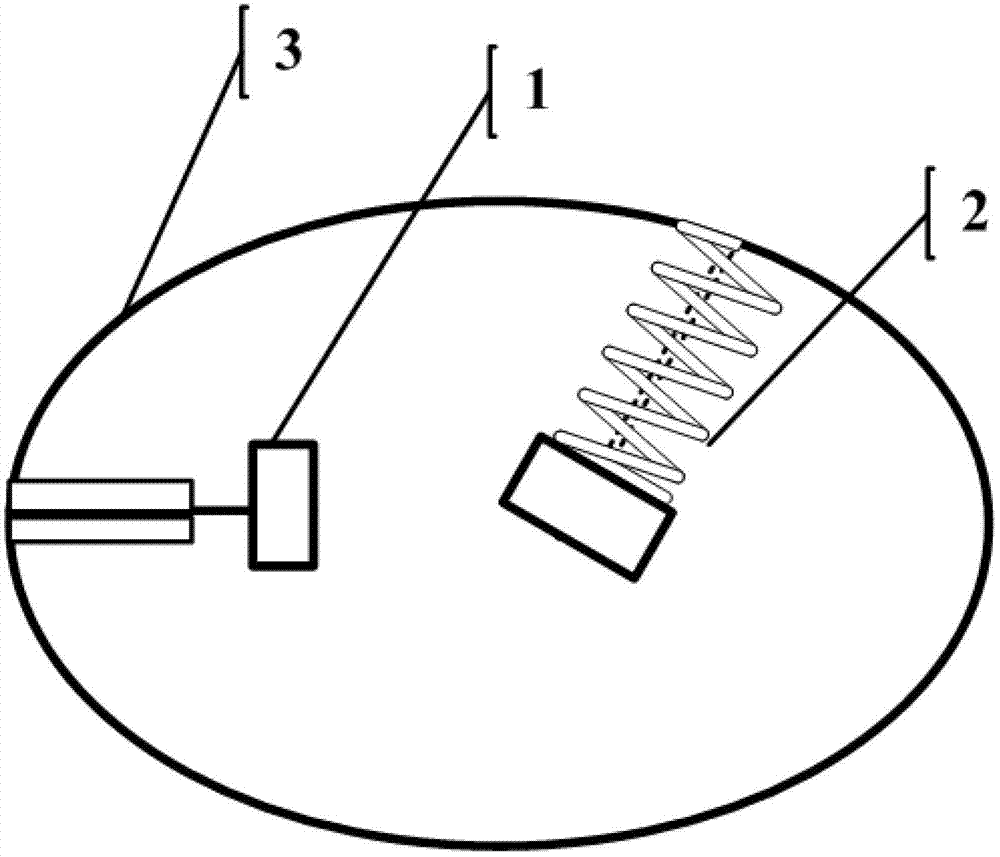

[0089] Such as Figure 6 , 7, 8, and 9 are examples of micro-power generation structures in which the elastic component is a spring. The micro-power generation structure includes a spring, which is usually made of elastic material with regular shape, and its shape can be the same as that of a common spring. The spring is made of a material with a high elastic modulus, which is required to have a good elastic vibration effect and a low Dam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com