Helmet cleaning machine

A technology for cleaning machines and safety helmets, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problems of easy breeding of bacteria, unsightly, unhygienic, etc., and achieve simple structure and easy cleaning Thorough, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to facilitate the understanding of the technical solution of the present invention, the technical content thereof will be further described below in conjunction with the accompanying drawings and the way of use.

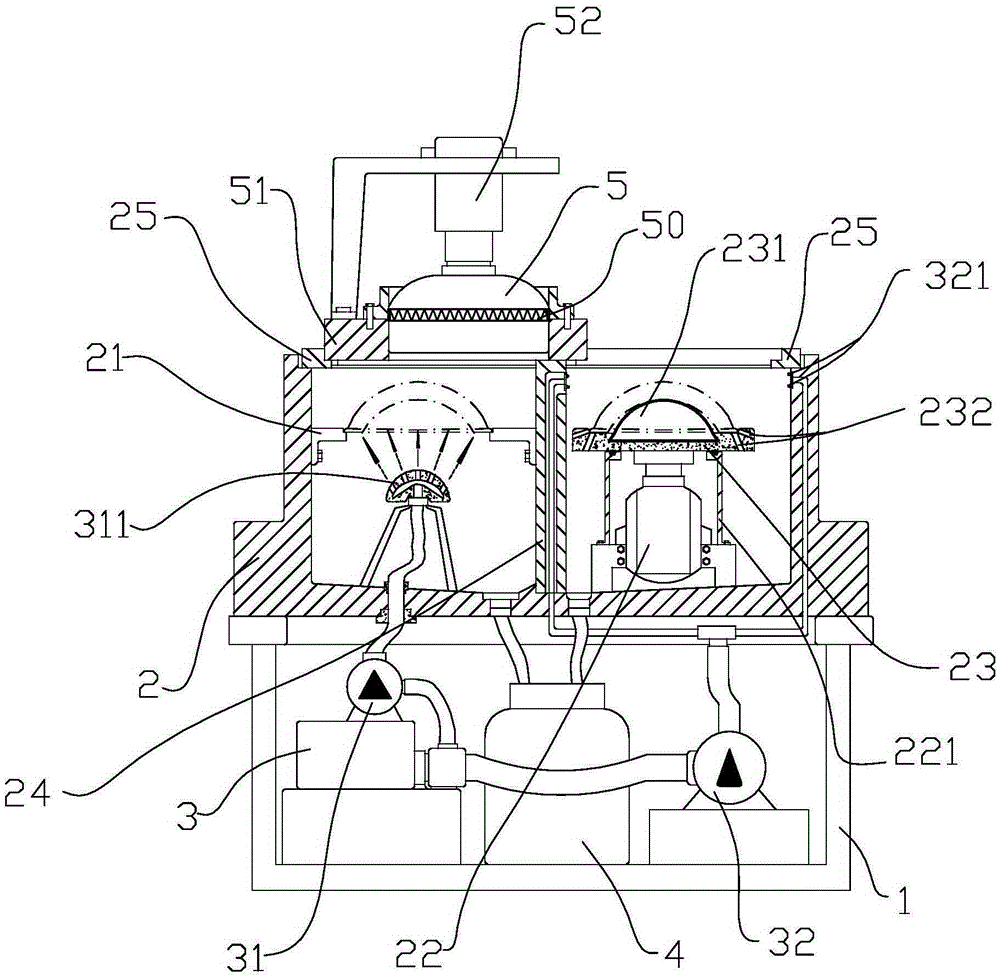

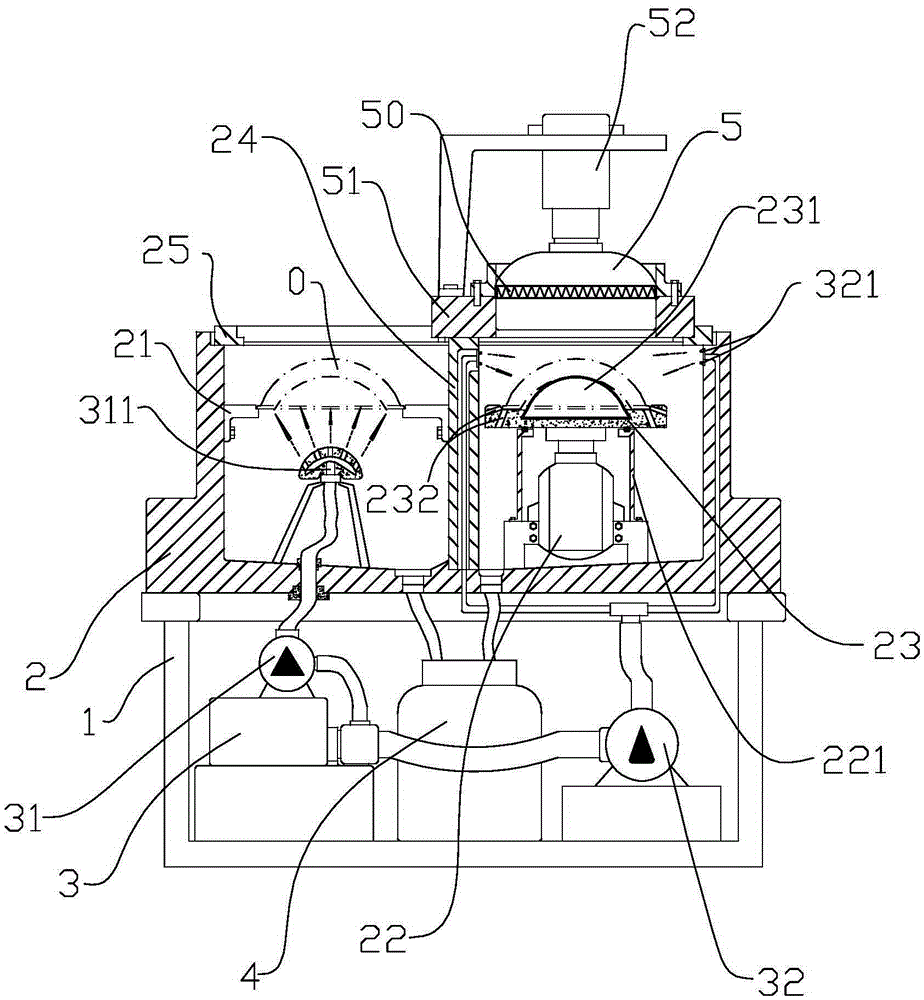

[0050] like Figure 1 to Figure 3 A helmet cleaning machine as shown:

[0051] It includes a frame body 1 , a cleaning chamber 2 , a heater 3 , a high-pressure steam pump 31 , a spray water pump 32 , a waste liquid collection bucket 4 and a cleaning bowl 5 .

[0052] The cleaning chamber 2 is placed on the upper end surface of the frame body 1 . The heater 3 , high-pressure steam pump 31 , spray water pump 32 , and waste liquid collection bucket 3 are placed inside the frame body 1 and located on the lower side of the cleaning chamber 2 .

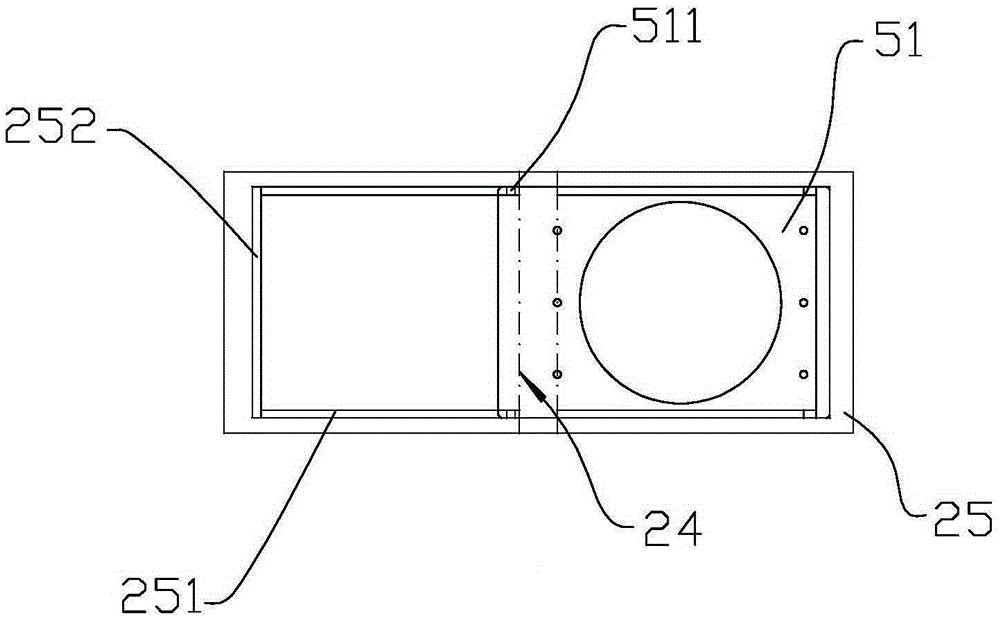

[0053] A partition 24 is arranged in the inner cavity of the cleaning chamber 2 to divide the chamber into two independent chambers, left and right. The bottom wall of the two chambers extends from the left or r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com