Patents

Literature

43results about How to "Does not affect dimensional accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for treating surface of magnesium or alloy thereof

This invention provides a method of surface treatment for magnesium or its alloy, which comprises the following steps: first, degreasing the surface of works, then immersing magnesium or its alloy into the treatment fluid and stirring the solution, the immersed temperature is indoor temperature, the immersed time is 0.5-10min. Said treatment fluid comprises 0.5%-10% oxalic acid, 0.5%-15% phosphorus acid, 1%-10% ammonium acid fluoride, 1%-3% inhibitor, 0.0005%-0.001% humectant by mass percent,and deionized water which is residual. Said inhibitor is one or more than of thiourea, hexamethylenetetramine and citric acid, and its proportioning is optional. Said humectant is sodium dodecyl sulfonate, OP-10 or carbowax. The invention has the merits such as high processing speed, simple process, less depletion and environmental protection.

Owner:SOUTHEAST UNIV

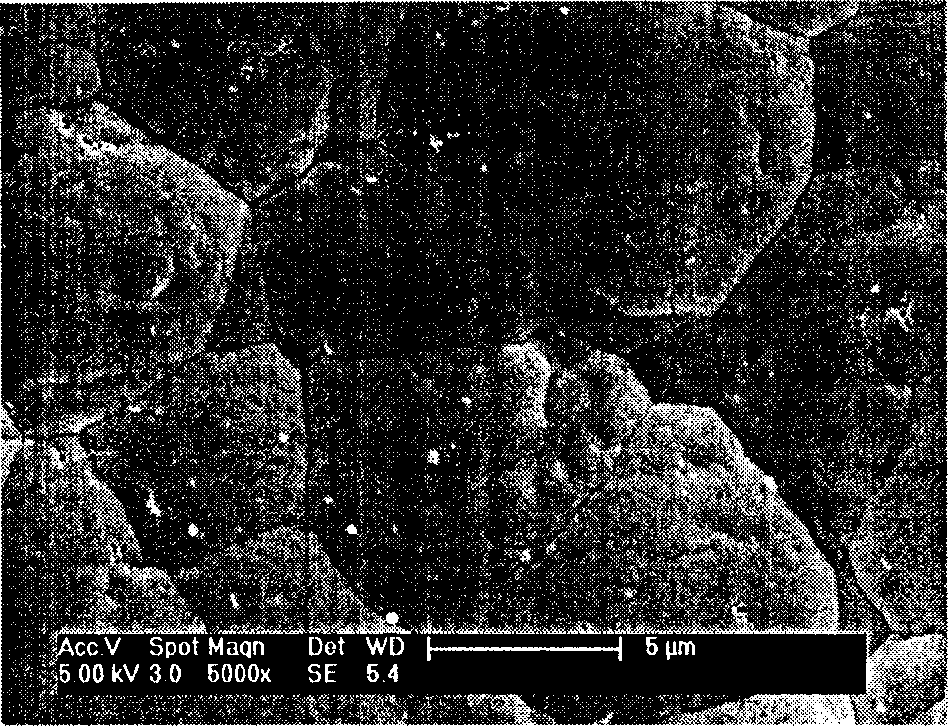

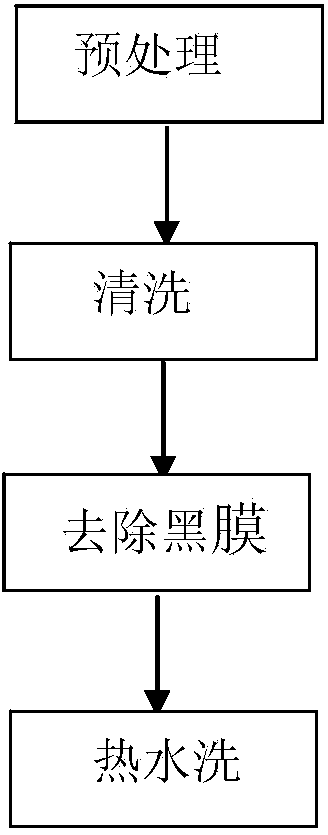

Cleaning liquor and treatment method for removing residual magnesium alloys in die

The invention provides cleaning liquor for removing residual magnesium alloys in a die. The cleaning liquor comprises the following components in percentage by weight: 60-240g of hydrochloric acid, 1-10g of ammonium citrate, 0.5-2g of EDTA (Ethylene Diamine Tetraacetic Acid), 5-55g of a corrosion inhibitor and 750-950g of water. Meanwhile, the invention provides a treatment method for cleaning the residual magnesium alloys by using the cleaning liquor according to the following four steps: pretreatment, cleaning, removing black films and washing by hot water. The cleaning liquor and treatment method have the benefits that damages cannot caused to the die and no influence is made on dimensional precision of the die, and configuration and operating method are simple and feasible, so that the surface roughness Ra1.0-1.5 of the die is effectively guaranteed. Referring to standards of GB8923-1988 Rusting Grade on Surface of Steel Products and Derusting Grade before Coating, according to the method, the surface rusting condition of the die is improved from grade D to grade A, and the grade Sa 3 of compressed-air blast cleaning is realized, so that one grade is raised relative to that of existing die cleaning liquor in the existing market.

Owner:TIANJIN DONGYI MAGNESIUM PROD +1

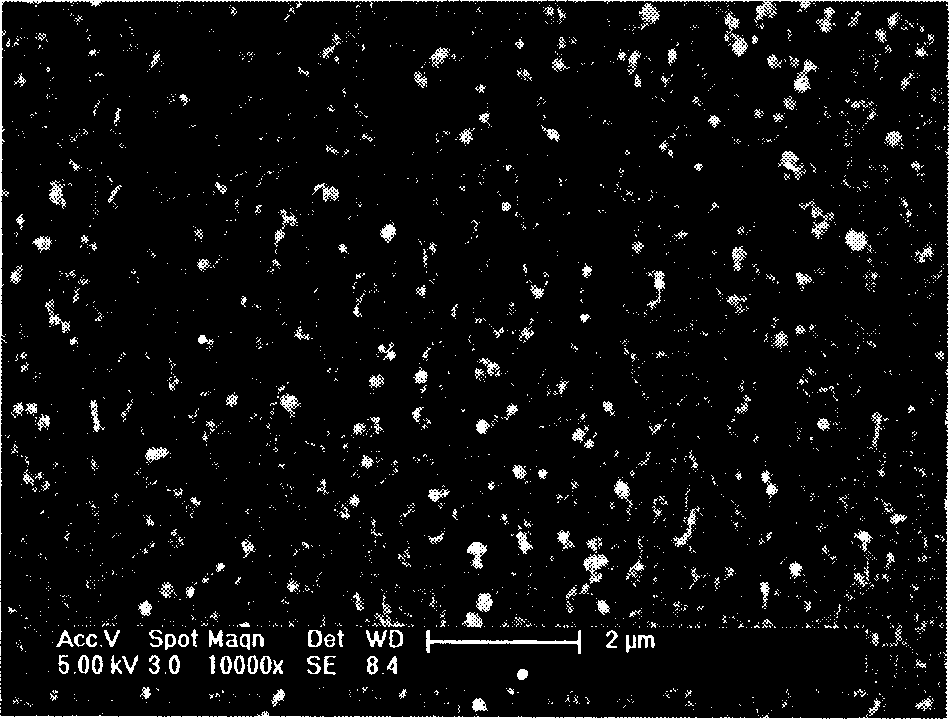

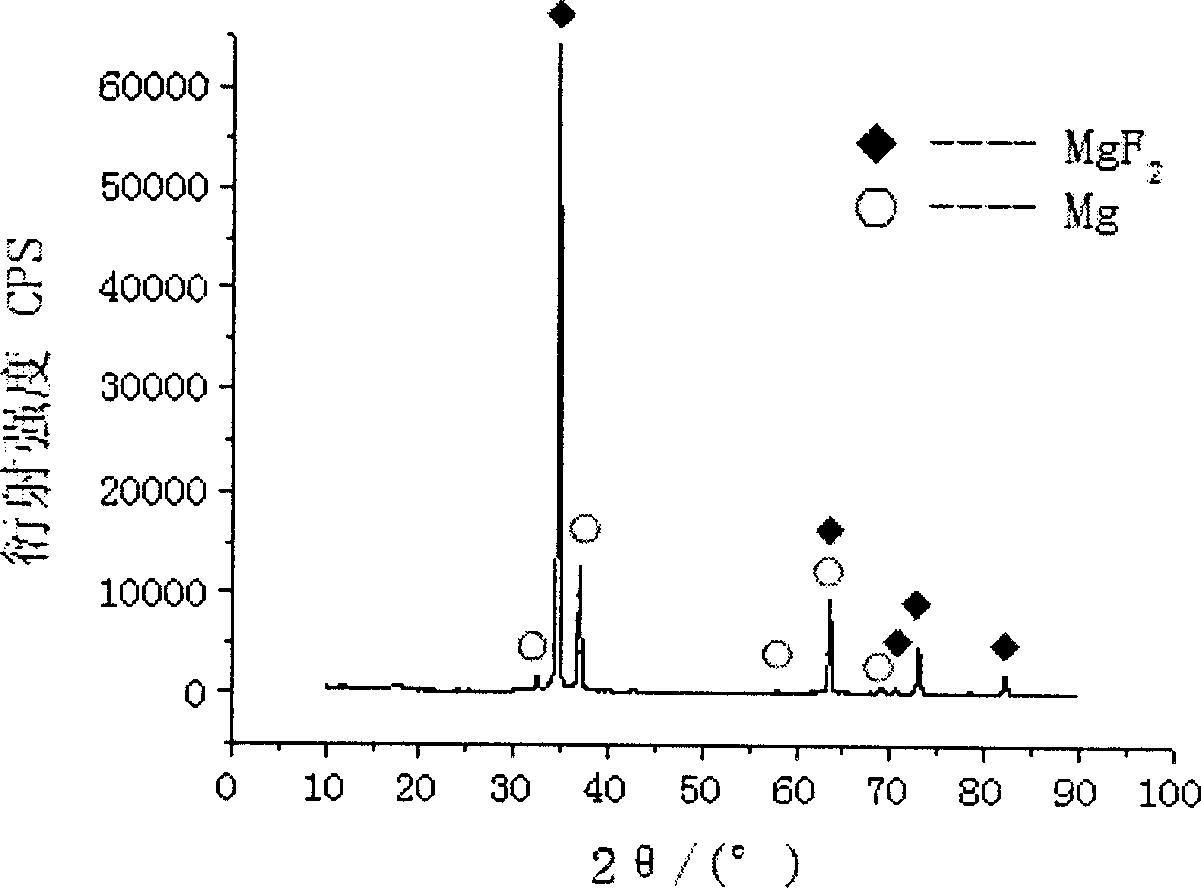

Composition for magnesium alloy surface activation

ActiveCN101205609ASignificant corrosionWash thoroughlyMetallic material coating processesCarboxylic acidBiological activation

The invention discloses a complex for magnesium alloy surface activation. The complex comprises inorganic acid, organic phosphonic acid, surfactant and oxidizer, and is characterized in that: the complex also comprises organic carboxylic acid and corrosion-inhibition agent. The complex for magnesium alloy surface activation provided by the invention can ensure that the residue on the surface of the magnesium alloy is completely cleaned; at the same time, the complex can not cause remarkable corrosion effect to the magnesium alloy, has more lasting activation effect; the activated magnesium alloy has smooth and luminant surface, and has no influence on the size accuracy of workpieces. And the complex provided by the invention does not contain the substances harmful to the human body and the environment such as Cr, F and so on, and has no pollution to the human body and the environment.

Owner:南通江海港建设工程有限公司

Drawing lubricant for titanium and titanium alloy tubes and application method of such drawing lubricant

ActiveCN106811277AImprove bindingReduce frictionLubricant compositionSodium phosphatesSurface cleaning

The invention belongs to the field of lubricating materials and application thereof and discloses a drawing lubricant for titanium and titanium alloy tubes and an application method of such drawing lubricant. The drawing lubricant comprises 1) any two of glass powder, graphite fluoride and boron nitride, 2) any two of borax, sodium phosphate and sodium fluoride, and 3) water. A lubricating treatment process includes subjecting the titanium and titanium alloy tubes to surface cleaning, conducting oxidizing annealing, spraying, drying and drawing practically to enable the surface roughness of drawn products to be below Ra 0.8 micrometers. The drawing lubricant has the advantages that a lubricating coating is formed on the surfaces of titanium and titanium alloy blanks through the drawing lubricant, so that lubricating conditions between the tube blanks and drawing dies are improved effectively, adhesion between the blanks and the dies is prevented, the service lives of the dies are prolonged and the tube surface quality is improved.

Owner:GRIMAT ENG INST CO LTD

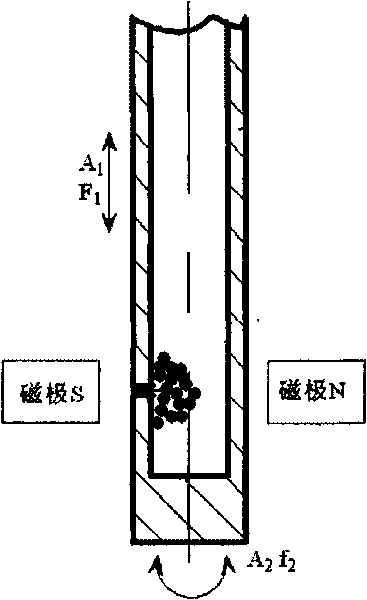

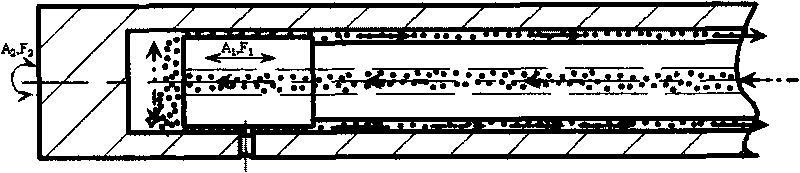

Grinding material vibration porous deburring process

The invention relates to a grinding material vibration porous deburring process. Vibration energy is attached to a grinding tool or a ground workpiece to vibrate the grinding tool or the workpiece at a certain frequency and amplitude in a grinding direction, and a dissociative grinding material is put on the surface of the roughly processed workpiece to complete deburring or finishing processing. Cured vibration parameters include: torsional vibration parameters: A2=1mm and F2=10Hz; and axial vibration parameters: A1=0, F1=0 and a magnetic grinding material. Liquid grinding material vibration grinding test parameters: torsional vibration parameters: A2=0 and F2=0; axial vibration parameters: A1=0.4mm and F1=20Hz; and a liquid grinding material. The invention has the advantages that the grinding material vibration porous deburring process is an improved grinding method for vibrating the grinding tool or the workpiece in the traditional grinding processing, has simple operation, significant effect, high efficiency and low cost, belongs to ultra fine grinding, has minimal impact on the size precision of the inner conical surface and the outer conical surface of a nozzle and has high processing efficiency.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

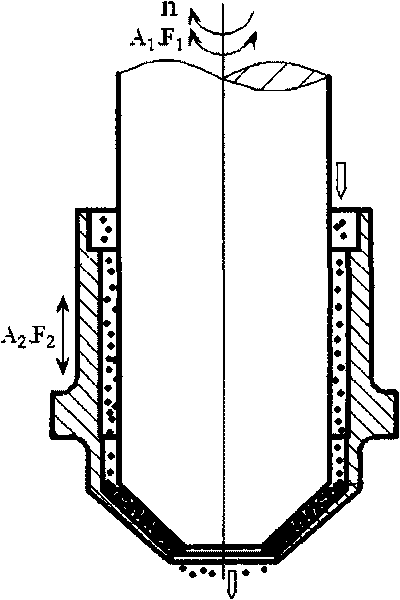

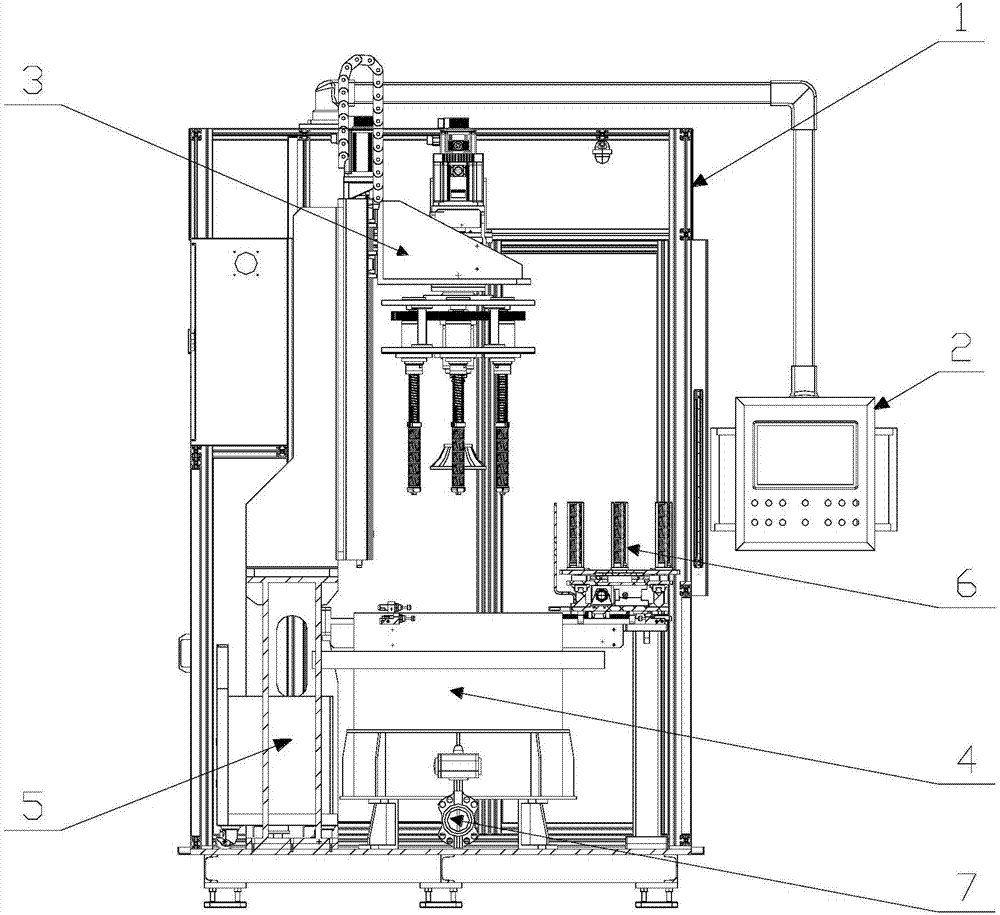

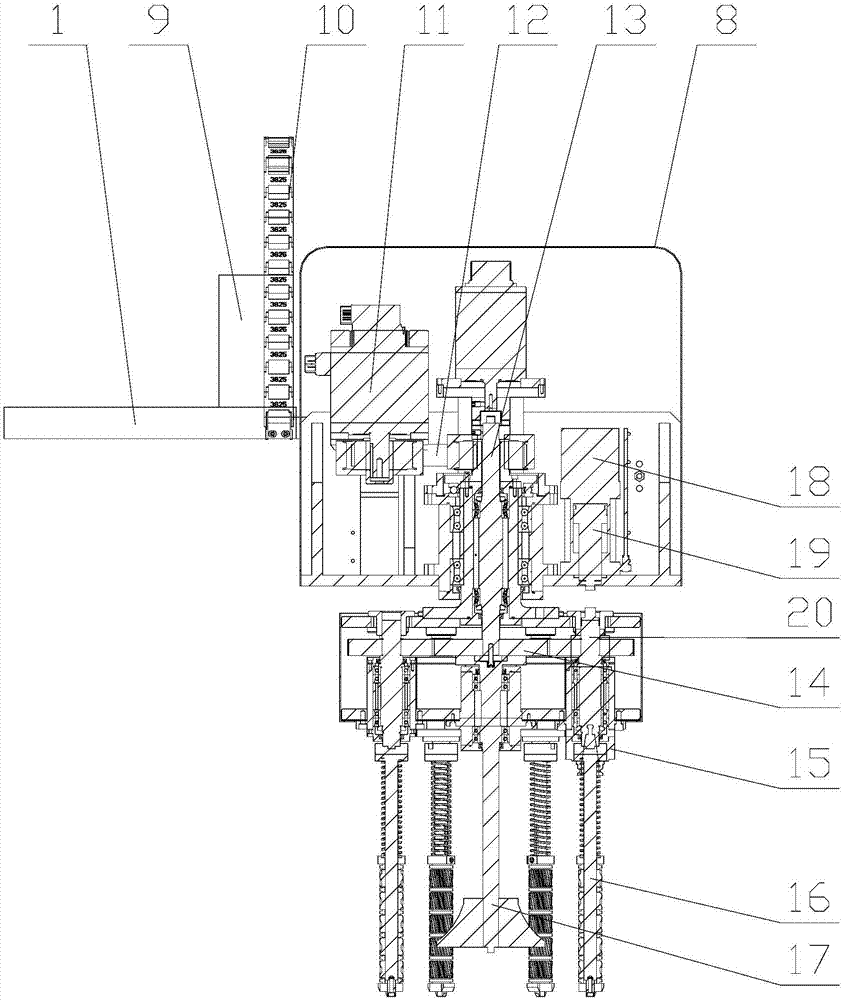

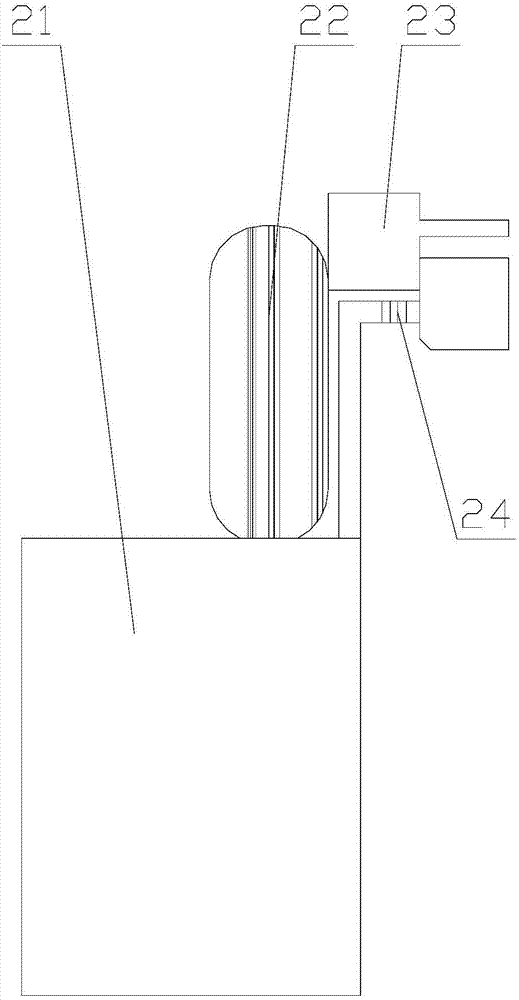

Deburring, grinding and polishing integrated ultra-fine processing machine

PendingCN107511737ADoes not affect dimensional accuracyExtended service lifeEdge grinding machinesGrinding drivesMachineFiltration mechanism

The invention relates to a deburring, grinding and polishing integrated ultra-fine processing machine. The machine comprising a frame, wherein a control box is arranged on the frame; a planetary mechanism is arranged inside the frame; a storage tank is arranged below the planetary mechanism; a grinding fluid filling and circulating filtration mechanism is arranged at one side of the storage tank; and a work fixture is arranged at the other side of the storage tank. The deburring, grinding and polishing integrated ultra-fine processing machine has the advantages that no chemical pollution, dust pollution or noise pollution is generated by adopting physical methods; precise positioning can be carried out through a positioning rod and impact damage is avoided during a cleaning process; meanwhile, all-directional three-dimensional deburring and cleaning can be realized through the planetary mechanism, the surface finish of a part can be increased through the grinding fluid filling and circulating filtration mechanism and the surface of the part is cooled and hardened to improve the service life of the part; and the machine adopts intelligent control to realize high efficiency and low cost and can be connected to a track type production line and a robot to realize the automatic production and reduce the labor cost.

Owner:李涛

Lubricant used for swing and rolling forming and use method thereof

The invention relates to a lubricant used for swing and rolling forming of tantalum and tantalum alloy parts and a use method thereof. The lubricant contains the components: (1) any two of molybdenum disulfide, graphite and boron nitride, (2) any one or two of borax, ceresin wax, silica and sodium sulfate and (3) water. The lubricating treatment process comprises the following steps of surface cleaning, preheating, spraying and drying. The lubricant and the use method thereof can meet the demand of carrying out severe deformation swing and rolling forming on tantalum and tantalum alloy blanks, thereby effectively reducing the friction between blanks and moulds; products have high surface quality, and the service lives of the moulds are long.

Owner:GRIMAT ENG INST CO LTD

Nano graphite modified powdery demolding agent for valve casting

ActiveCN104959528AHigh temperature resistanceWith wear resistanceFoundry mouldsFoundry coresGraphiteBeef Tallow

The invention discloses a nano graphite modified powdery demolding agent for valve casting and relates to the technical field of demolding agent production. The nano graphite modified powdery demolding agent is prepared by the following raw materials in part by mass: 60-70 parts of polyethylene wax powder, 15-18 parts of nano graphite powder, 12-15 parts of calcined kaolin, 10-13 parts of cork powder, 8-10 parts of titanium dioxide, 6-9 parts of beef tallow, 5-7 parts of silica micropowder, 4-6 parts of carboxymethyl chitosan, 3-4 parts of concentrated hydrochloric acid, 2-3 parts of dodecanedioic acid, 40-45 parts of normal heptane, 25-30 parts of methylbenzene and 60-70 parts of water. The nano graphite improved powdery demolding agent is good in demolding effect, demolding can be implemented after a valve is fully cooled and shaped, size accuracy and surface quality of the valve are not affected, and the nano graphite improved powdery demolding agent is long in service life.

Owner:HEXIAN KEJIA VALVE CASTING

Foam pattern surface film forming method for lost foam casting

InactiveCN101954445AImprove surface qualityDoes not affect dimensional accuracyFoundry moulding apparatusWaxMetallurgy

The invention relates to a foam pattern surface film forming method for lost foam casting, belonging to a lost foam casting method, and solving the problems that the film forming matter of the current foam pattern surface film forming method has longer film forming time and high cost. The method of the invention comprises the following steps: (1) a film forming matter preparing step: preparing a wax-based organic composite material of which the raw materials in mass percent are as follows: 60%-100% of wax, 0%-40% of stearic acid and 0%-10% of additives, wherein the range of melting point of the wax-based organic composite material is 40 DEG C-70 DEG C, and then heating to meld the composite material to form mixture; and (2) a film forming step: completely soaking the foam pattern into the mixture and soaking for 5-60s, and then taking out and slightly shaking or whipping to remove the excess liquid mixture, and after cooling, an even film layer is formed on the foam pattern. The invention has simple operation, short film forming time and lower cost, and can greatly improve the surface quality of the foam pattern, thereby improving the surface qualities of a mold shell and casting, and realizing large-scale industrial production.

Owner:HUAZHONG UNIV OF SCI & TECH

Wear-resistant ceramic roller and preparation method thereof

InactiveCN111575568AReasonable structural designImprove wear resistanceMetallic material coating processesPolyvinyl alcoholAdhesive

The invention discloses a wear-resistant ceramic roller and a preparation method thereof. The ceramic roller comprises a roller core and a wear-resistant layer from inside to outside, and the roller core is prepared from the following components of, in parts by mass, 70 to 80 parts of ceramic particles, 20 to 30 parts of a metal matrix, 15 to 20 parts of active elements and 1 to 5 parts of an adhesive, wherein the ceramic particles are prepared from the following components of, in parts by mass, 80 to 85 parts of Al2O3, 10 to 15 parts of ZrO2 and 1 to 5 parts of polyvinyl alcohol; the metal matrix is prepared from the following components of, in parts by mass, 20 to 15 parts of Cr, 2.0 to 2.5 parts of C, 1.0 to 2.2 parts of Ni, 1.0 to 1.5 parts of Mo, 0.5 to 1.0 part of Mn, 0.2 to 0.6 partof Si, 0 to 0.1 part of P, 0 to 0.05 part of S and the balance of Fe; and the wear-resistant layer is prepared from the following components of, in parts by mass, 85 to 95 parts of Fe55 powder and 5to 15 parts of TiC particles. According to the wear-resistant ceramic roller and the preparation method thereof, the formula is reasonable, the preparation method is simple, the cost is low, the yieldis high, large-scale batch production is easy to realize, and the prepared ceramic roller has the advantages of good wear resistance, long service life and wide application prospect.

Owner:徐州华焰特种陶瓷有限公司

Nano bentonite improved pasty demolding agent for valve casting

The invention discloses a nano bentonite improved pasty demolding agent for valve casting and relates to the technical field of demolding agent production. The nano bentonite improved pasty demolding agent is prepared by the following raw materials in part by mass: 70-80 parts of methyl silicone oil, 12-15 parts of nano bentonite, 15-18 parts of zeolite powder, 10-14 parts of calcium carboante, 8-11 parts of lard, 6-9 parts of mica powder, 3-5 parts of abietic acid, 2-4 parts of laurel wax, 1-2 parts of alkyl naphthalene sulfonate, 2-4 parts of concentrated nitric acid, 10-12 parts of methyl ethyl ketone, 20-30 parts of alcohol and 50-60 parts of water. The nano bentonite improved pasty demolding agent is good in demolding effect, demolding can be implemented after a valve is fully cooled and shaped, size accuracy and surface quality of the valve are not affected, and the nano bentonite improved pasty demolding agent is long in service life.

Owner:HEXIAN KEJIA VALVE CASTING

Nano titanium dioxide improved pasty demolding agent for valve casting

The invention discloses a nano titanium dioxide improved pasty demolding agent for valve casting and relates to the technical field of demolding agent production. The nano titanium dioxide improved pasty demolding agent is prepared by, by mass, 70-80 parts of methyl silicone oil, 15-20 parts of nano titanium dioxide, 12-15 parts of talcum powder, 10-13 parts of diatomite, 8-10 parts of gas-phase silica, 6-9 parts of abietic acid, 5-8 parts of vaseline, 4-6 parts of alkyl naphthalene sulfonate, 3-5 parts of lard, 2-4 parts of concentrated nitric acid, 10-12 parts of methyl ethyl ketone, 20-30 parts of alcohol and 50-60 parts of water. The nano titanium dioxide improved pasty demolding agent is good in demolding effect, demolding can be realized after a valve is fulled cooled and shaped without having influence on size accuracy and surface quality of the valve, and the nano titanium dioxide improved pasty demolding agent is long in service life.

Owner:HEXIAN KEJIA VALVE CASTING

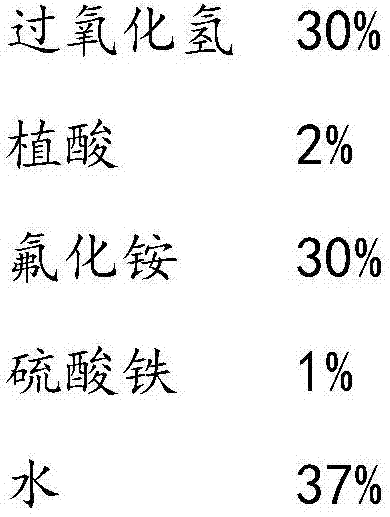

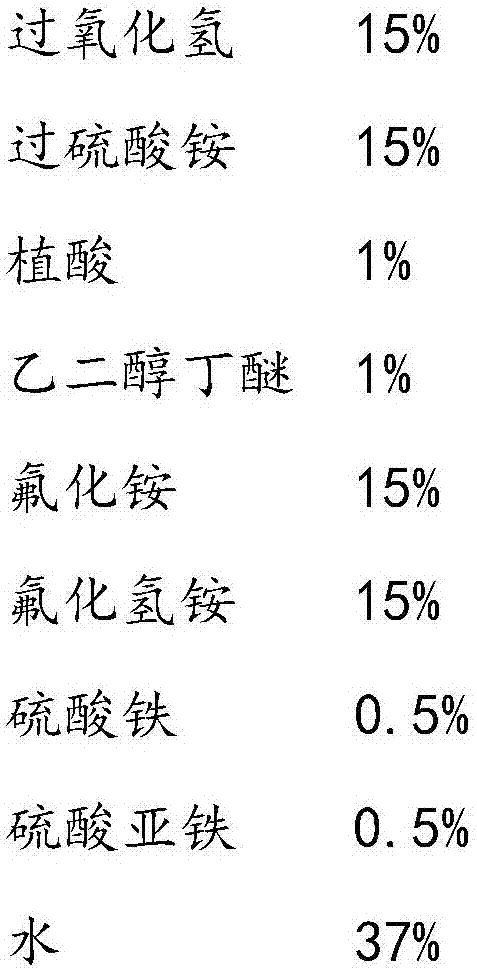

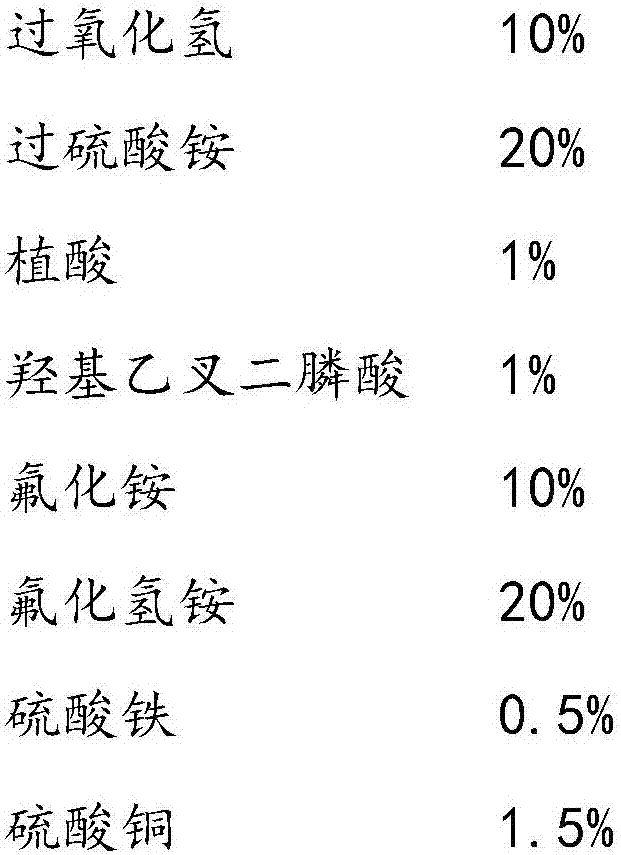

Scale remover

InactiveCN107254682AGood descaling effectDoes not affect dimensional accuracySolventAmmonium bifluoride

The invention provides a scale remover and belongs to the technical field of electroplating. The scale remover comprises an oxidizing agent, a stabilizer, a catalyst, a builder and a solvent. The oxidizing agent is selected from at least one of hydrogen peroxide or sodium persulfate; the stabilizer is selected from at least one of phytic acid or ethylene glycol butyl ether or hydroxyethylidene diphosphonic acid; and the builder is selected from at least one of ammonium fluoride or ammonium bifluoride or hydrofluoric acid. No strong oxidative acid such as nitric acid or the small amount of the strong oxidative acid is added into the scale remover, corrosivity is not significant, an aluminum alloy is not corroded, and the dimensional precision of the aluminum alloy is not affected. Meanwhile, phosphorus discharging is avoided, and waste water treatment is simple and easy. Discharging of pale brown smog such as nitrogen oxides is also avoided, the production environment is improved, and waste gas treatment is reduced.

Owner:深圳市威通科技有限公司

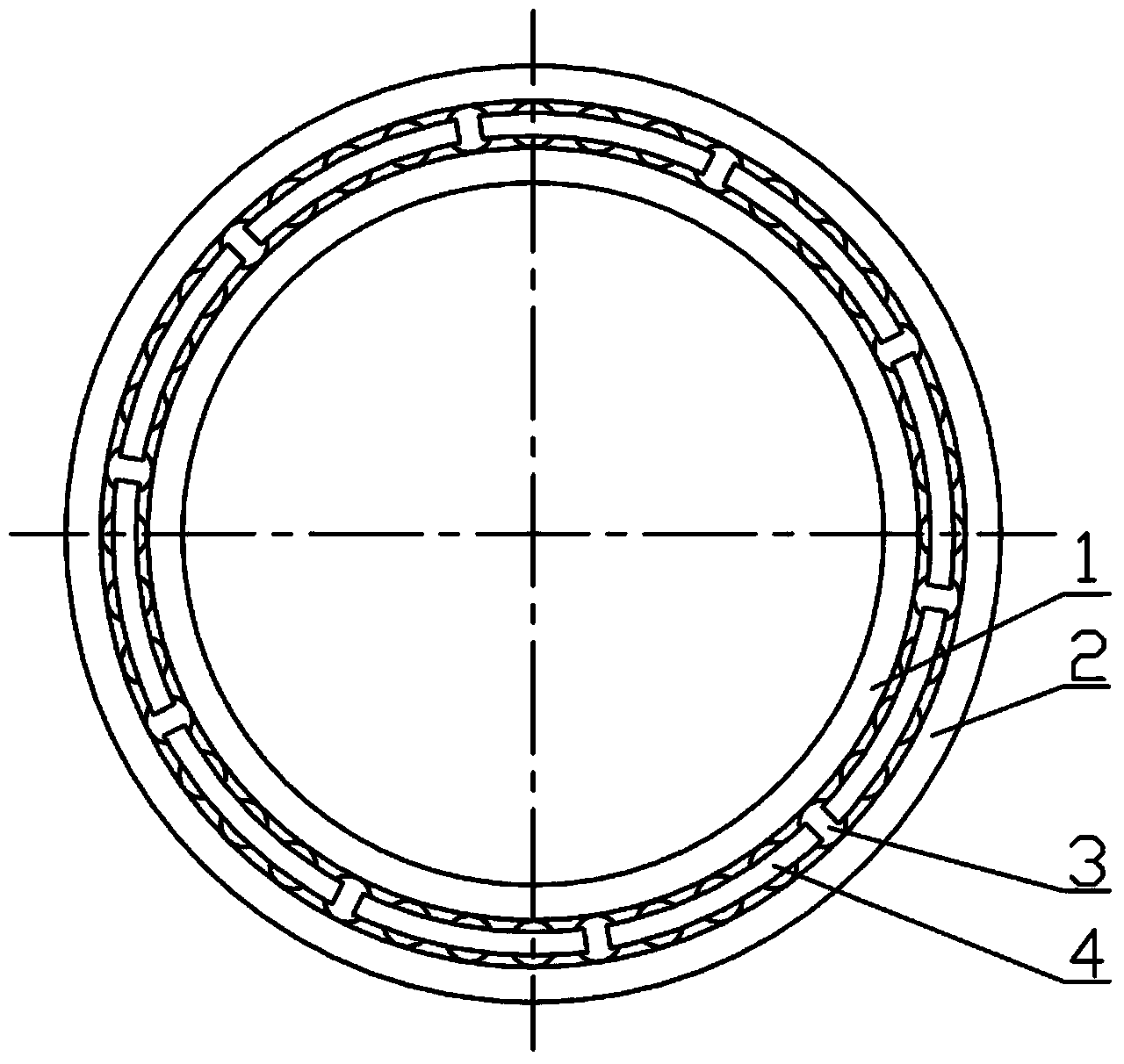

Solid lubrication thin-wall bearing with segmented self-lubricating holder

InactiveCN103758872AReduce irregular frictionSmooth runningBearing componentsComposite filmSpecial design

The invention discloses a solid lubrication thin-wall bearing with a segmented self-lubricating holder. The solid lubrication thin-wall bearing comprises an outer ring and an inner ring for solid lubrication treatment, balls and the holder consisting of a plurality of arc segments. The solid lubrication thin-wall bearing has the characteristics in that the segmented holder is adopted to successfully solve the problems that a bearing with an integral holder structure operates unstably and is likely to cause whistler; a bearing channel adopts a sputtering MoS2 base composite film to serve as an initial lubricating film of the bearing, the holder is made of a self-lubricating material and can provide continuous transfer lubrication to the bearing, and thus the service life of the bearing is prolonged. According to the invention, through special design of the holder, the solid lubrication of the thin wall bearing is successfully realized. The thin-wall bearing disclosed by the invention has the advantages of being convenient to install and use, operating stably, having no whistler and having a long service life. The solid lubrication thin-wall bearing can be used for rotating support of equipment such as robots and manipulators with thin-wall bearings, and particularly equipment with special requirements on temperature range or use environment.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Acid copper direct-electroplating solution for iron part

The invention discloses an acid copper direct-electroplating solution for an iron part. The acid copper direct-electroplating solution contains a basic solution capable of providing cupric ions, a complexing agent, a corrosion inhibitor and a reducing agent, wherein the complexing agent is one or more of tartaric acid, citric acid, etidronic acid and ethylenediaminetetramethylene phosphoric acid; the corrosion inhibitor is thiourea and / or allylthiourea; the reducing agent is formaldehyde and / or glyoxylic acid. The acid copper direct-electroplating solution for the iron part is free of a harmful substance cyanide for copper pre-plating, a copper pre-plating procedure is eliminated, and the iron part can directly be electroplated with copper to form a copper-plated layer which is strong in bonding strength, bright and compact on the surface of the iron part; moreover, compared with an iron substrate easily corroded by high-concentration sulfuric acid in a bright acid copper plating solution, the corrosion inhibitor of the acid copper direct-electroplating solution has the advantages that the iron part can be well protected, the iron part is prevented from being greatly corroded, and the influence on the dimensional accuracy of the iron part is eliminated.

Owner:崇辉半导体(深圳)有限公司

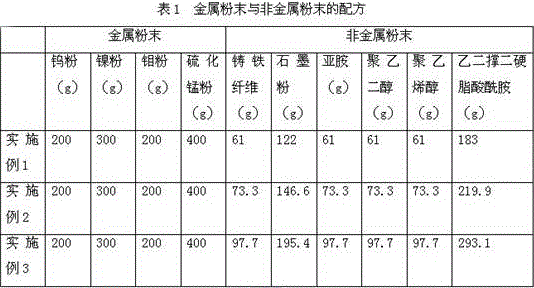

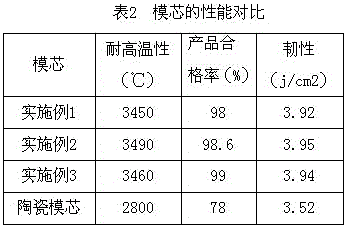

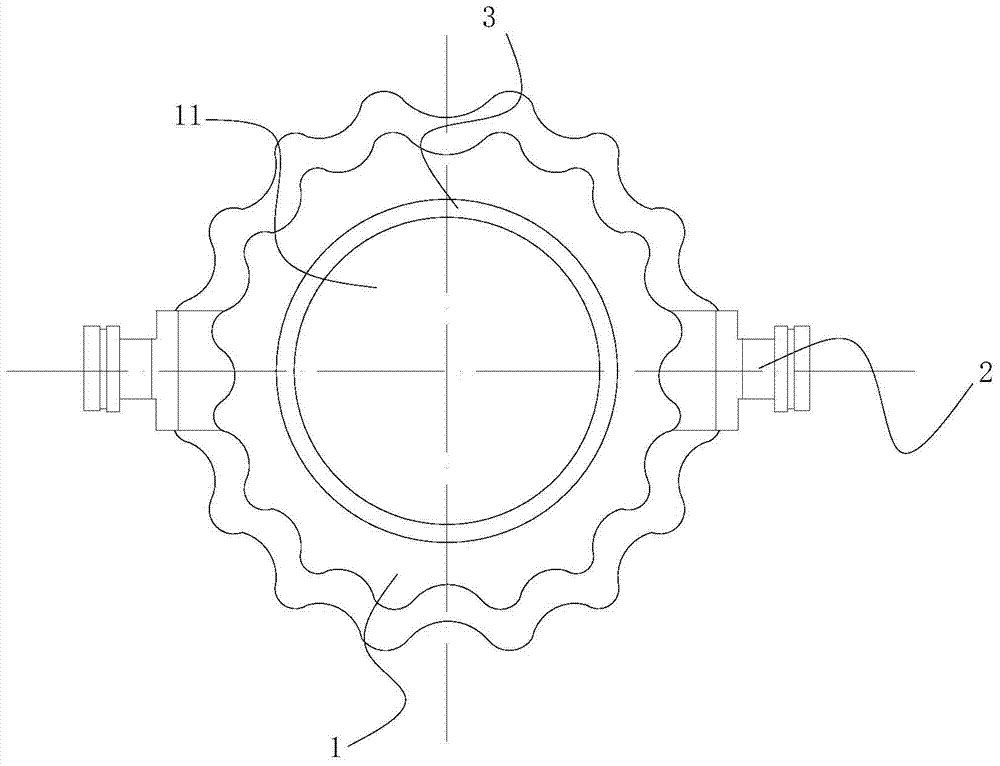

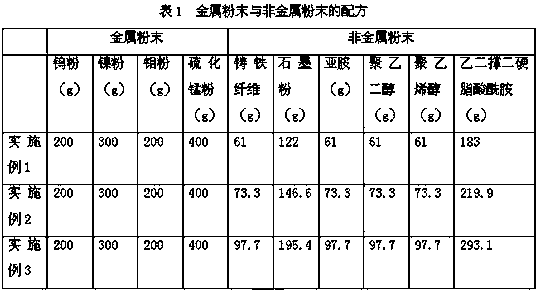

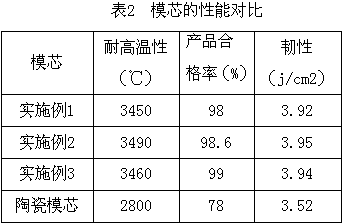

Preparation process of alloy mold core for high-temperature alloy monocrystal blade precision casting

ActiveCN106001553AImprove the success rate of demouldingImprove pass rateTurbinesOther manufacturing equipments/toolsNumerical controlFiber

The invention discloses a preparation process of an alloy mold core for high-temperature alloy monocrystal blade precision casting. Raw materials of the alloy mold core comprise metal powder and nonmetal powder; the metal powder is mainly prepared from cast iron fibers, tungsten powder, nickel powder, molybdenum powder and manganese sulfide powder in a mixed manner; and the nonmetal powder is mainly prepared from graphite powder, imine, polyethylene glycol, polyvinyl alcohol and ethylene bis stearamide in a mixed manner. The preparation process of the alloy mold core includes the following steps that the metal powder and the nonmetal powder are mixed in the proportion of 5:2; then the mixed powder is thrown into an acetone solution; an acetone solvent is removed in a heating manner; heating continues till 130 DEG C, and the mixture is fed into a mold to be pressed and formed; next, a machined mold blank is placed into a vacuum furnace to be subjected to degreasing, and sintering and forming are performed through hot pressing; and finally, the formed product is placed in a numerical control electrolytic machine tool to be subjected to precise electrolytic machining, and the alloy mold core is acquired. The alloy mold core acquired through the method is high in percent of pass of finished products, and the product is resistant to high temperature.

Owner:李庆

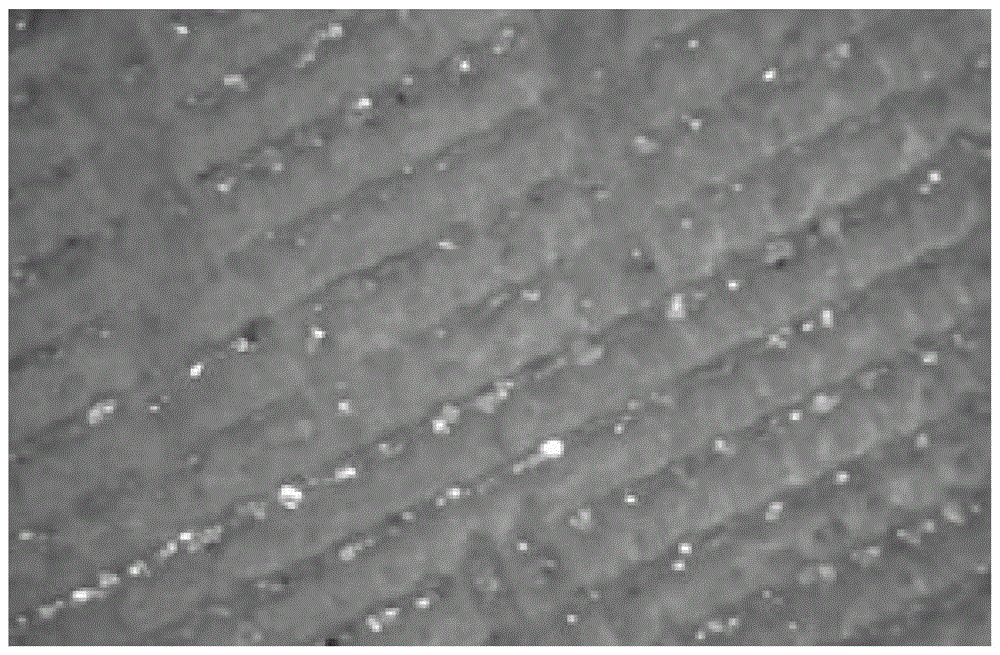

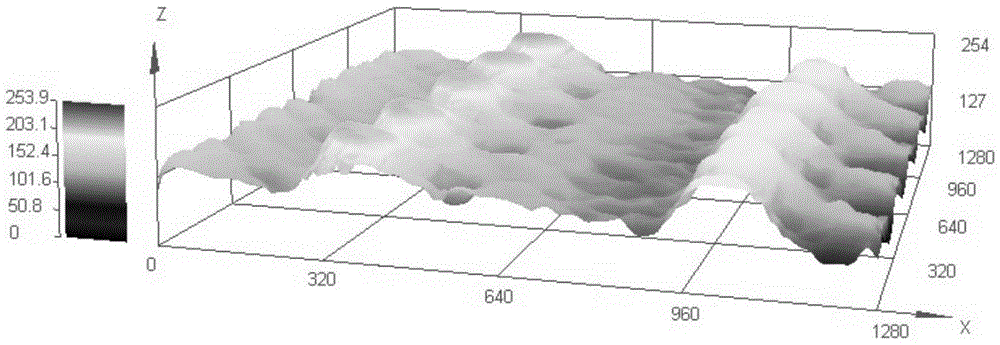

Roughness-controllable polishing method for stereolithographic resin prototype models

ActiveCN103433853AImprove surface accuracyReduce work intensityPolishing compositions with abrasivesParticle flowDimensional precision

The invention discloses a roughness-controllable polishing method for stereolithographic resin prototype models. According to the invention, the fluid of a prepared chemical etching abrasive particle flow is used on abrasive particle flow equipment for respective polishing of the stereolithographic resin prototype models; then distilled water or deionized water is used for cleaning, surface roughness of the obtained stereolithographic resin prototype models is reduced to Ra 0.8 to 2 mu m from original Ra 8.0 to 20.0 mu m, surface roughness is uniform, texture is regular, postprocessing of the stereolithographic resin prototype models is realized, operation is simple, and labor intensity is reduced. The polishing method eliminates step effects of the stereolithographic resin prototype models, improves surface precision of the resin prototype models and does not influence dimensional precision of the resin prototype models.

Owner:XI AN JIAOTONG UNIV +1

Discharging burr removal processing method for plasma tip

The invention relates to the technical field of copper base alloy manufacturing, in particular to a discharging burr removal processing method for a plasma tip. The method comprises the following steps of 1, a hanging process; 2, a cleaning process before polishing; 3, a plasma polishing process, wherein a workpiece obtained after the cleaning process and a hanging toll are placed in a plasma tankfor plasma polishing, wherein the working voltage in the plasma is 200-400 V, the concentration of the plasma is 30-80 g / L, the working temperature of the plasma is 30-90 DEG C, and the working timeis 30-50 seconds; the plasma is 30 millimeters or above, and 5-7 kilograms of polishing salt is added and dissolved in water; 4, a cleaning process after polishing; 5, a drying process; 6, a taking-down process. According to the discharging burr removal processing method for the plasma tip, the aims of reducing the cost, improving the production efficiency and product quality and the like are achieved.

Owner:DEQING TIANMA BEARING CO LTD

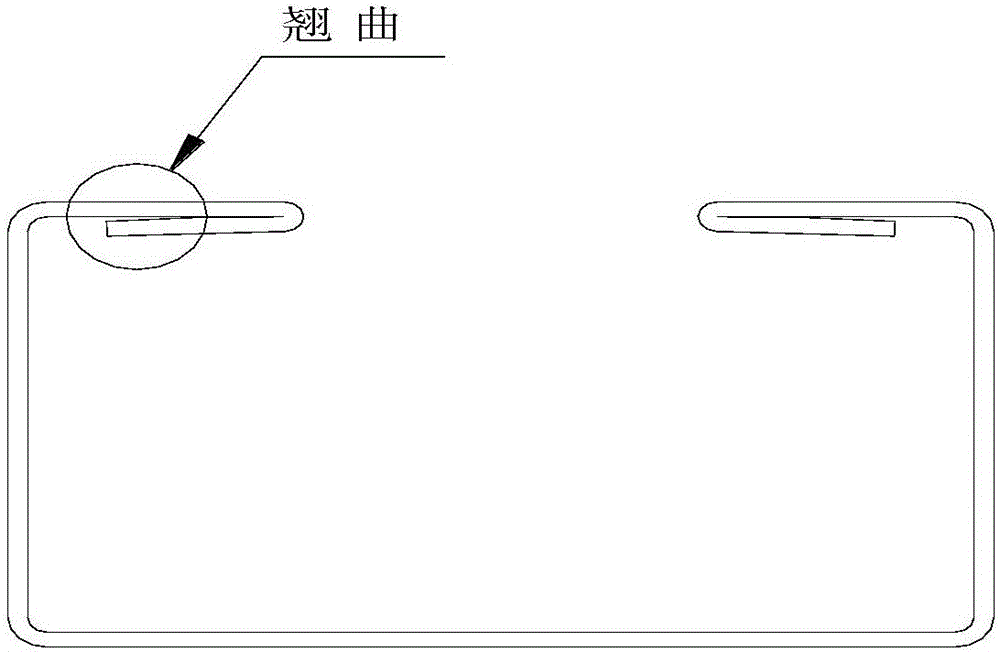

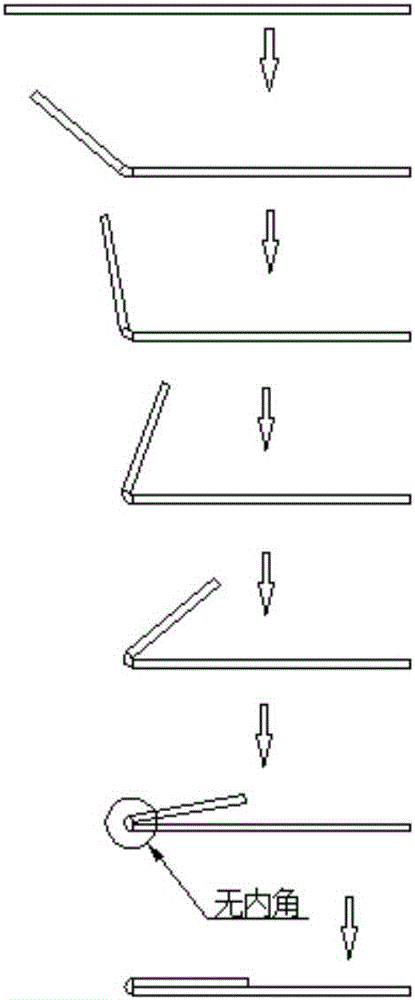

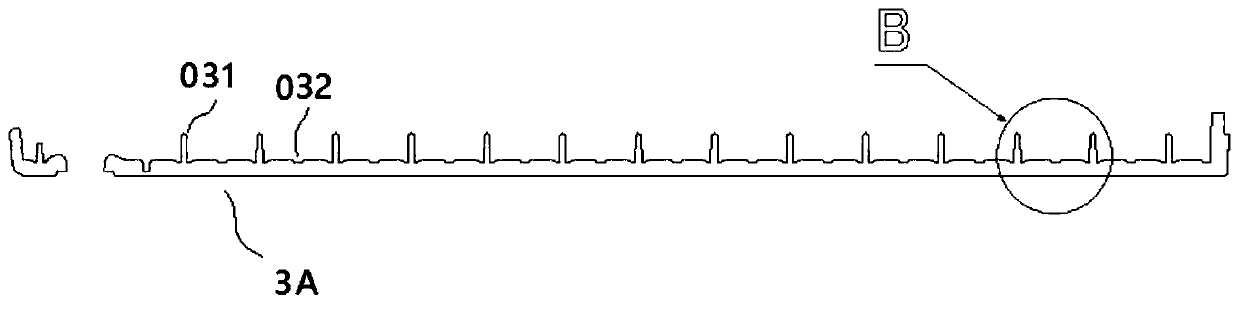

Design technology for producing side-stacked section materials

ActiveCN106424264ASolve the phenomenon of overlapping edge warpingSolve the phenomenon of edge warpingMature technologyEngineering

The invention discloses a design technology for producing side-stacked section materials. Through rolling of an upper roller and a lower roller, bending deformation of the section materials in a hole pattern of a roller of each pass is carried out according to the preset angle, the numerical values of circular beads of the section materials are increased in the deformation process, the section materials keep a large circular bead before final side-stacking formation, approximate-parallelism rolling of the two sides of the section materials is completed, and filleted corners are flattened after rolling is completed. The internal stress of the circular beads of deformation is basically released in the last pass but one, finally sides of the large circular bead compensate for the two sides of the small circular bead through material compensation, and therefore the dimensional accuracy is not influenced, the side warping problem is effectively solved, and a mature technology improvement is realized.

Owner:山东华舜达冷弯科技有限公司

Washing method of seal head

The invention relates to a washing method of a seal head. The washing method of the seal head is characterized by comprising the following steps: (1) spraying an organic builder to the seal head, and standing for 30 minutes under the temperature of 20 to 45 DEG C, and then flushing with clean water; (2) soaking the seal head in 3% of sodium borate solution; and (3) soaking the seal head in a composite surfactant. The washing method of the seal head has the advantages of being simple and convenient to operate, lasting in effect, convenient to use and maintain, high in washing quality, high in efficiency, and high in technique compatibility; the washed part surface is clean; the size accuracy and surface state of a part are not influenced; the washing method is nontoxic, free of irritant gas, and does not damage the body health of operators.

Owner:QINGDAO XUSHENG HEAD

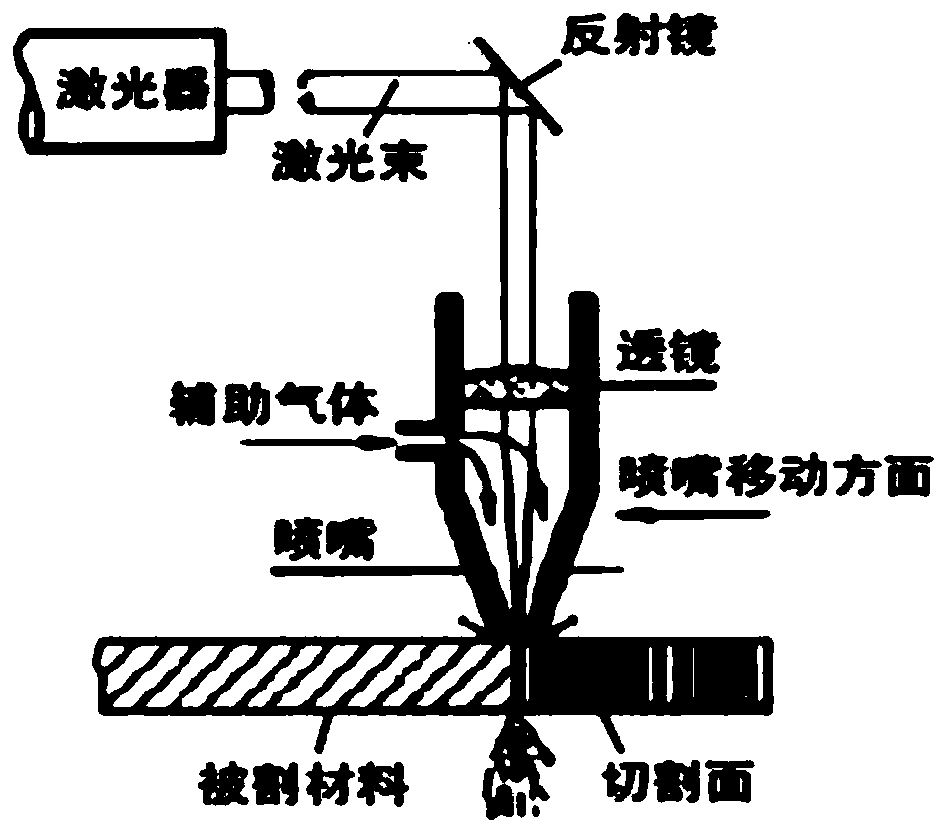

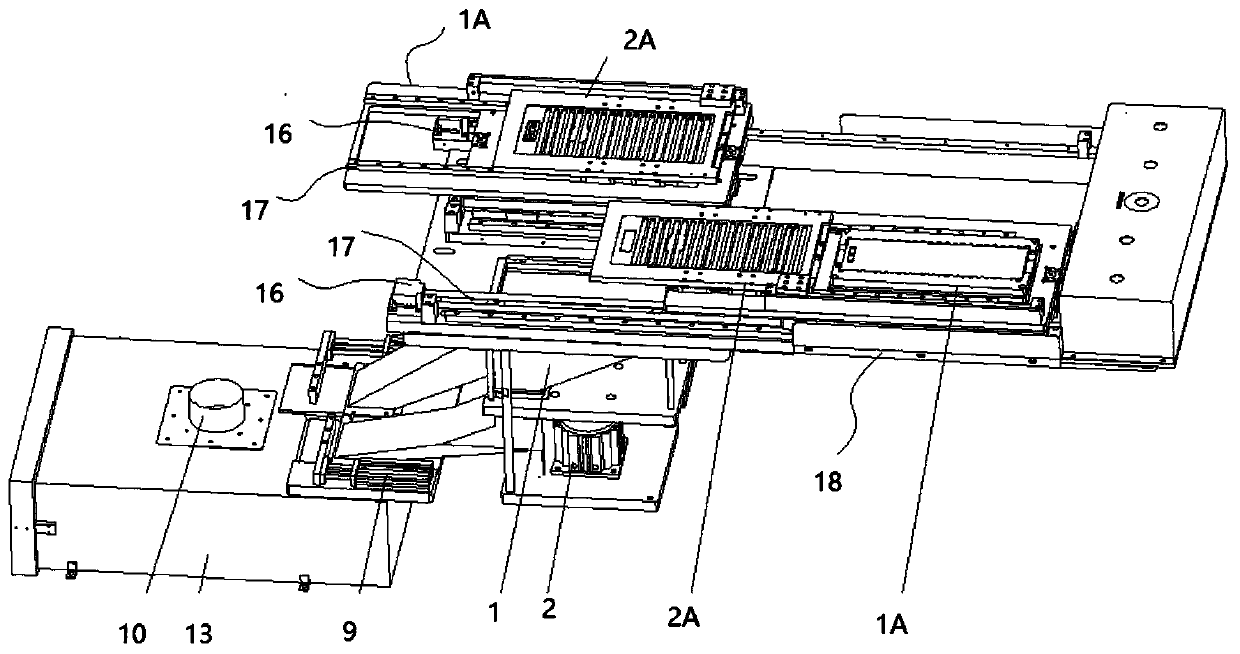

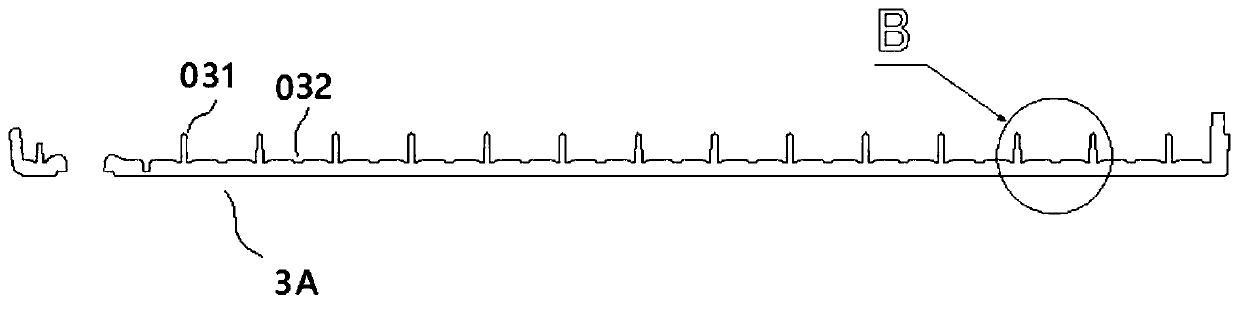

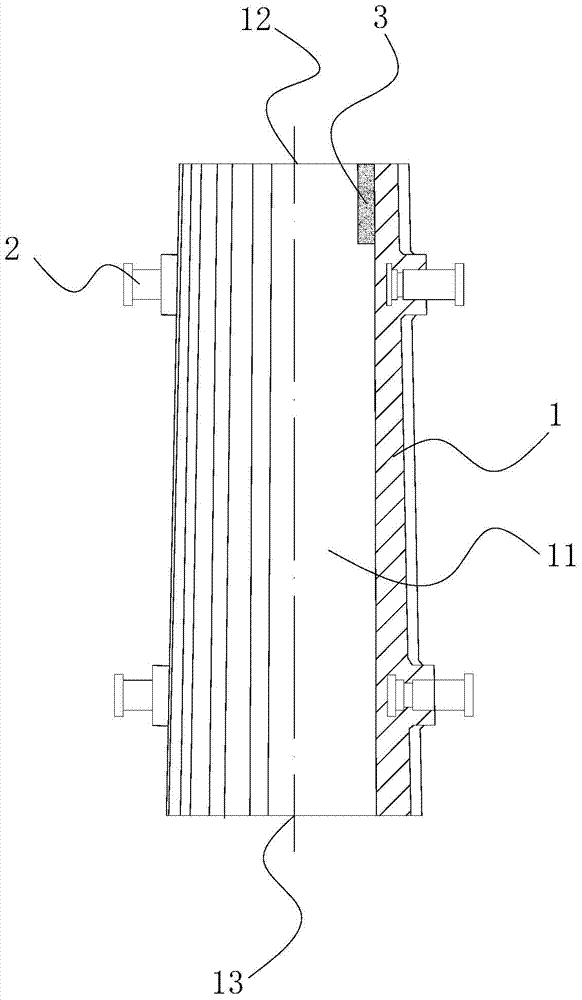

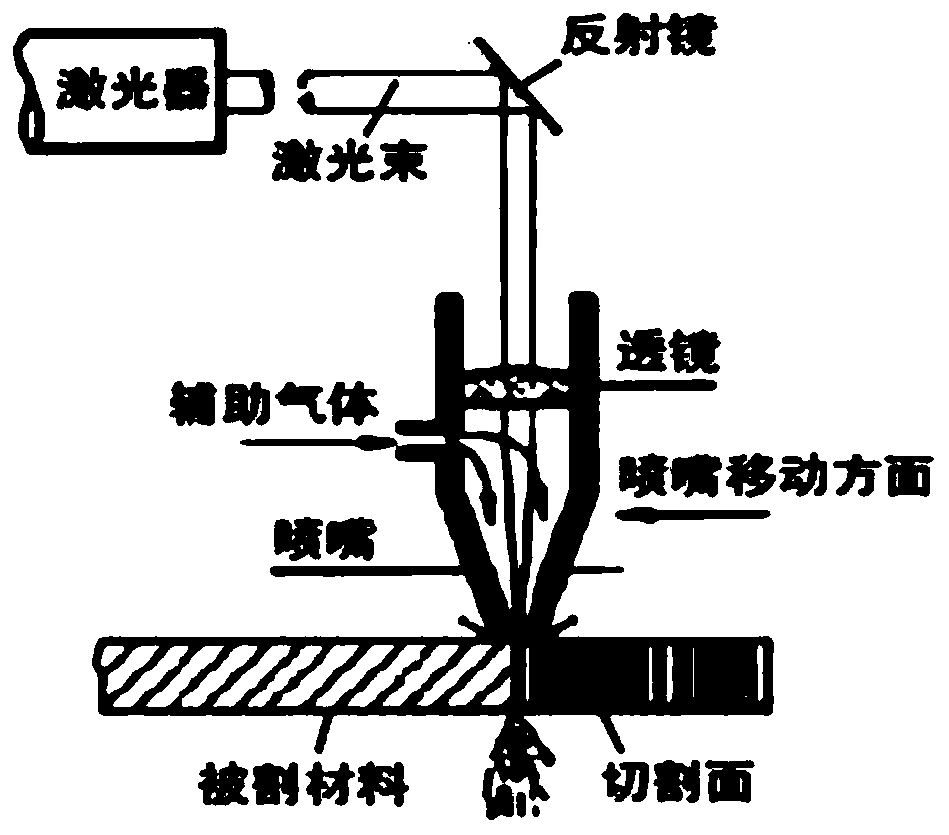

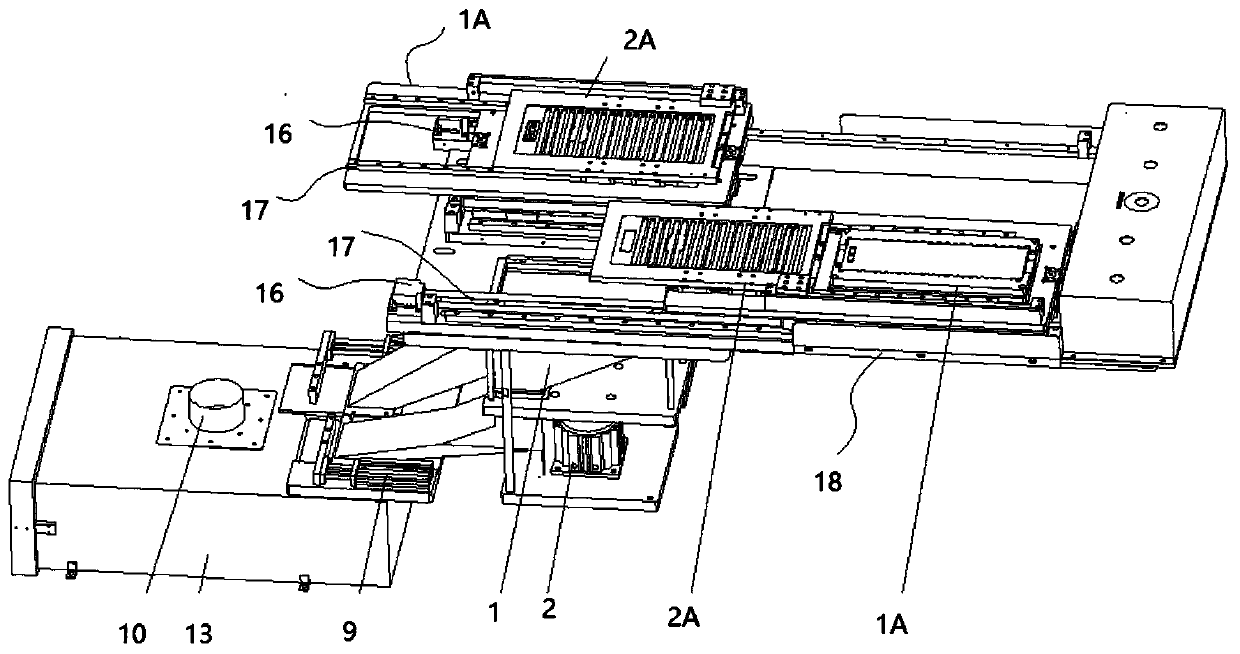

Collecting mechanism for automotive interior laser cutting and cutting method thereof

ActiveCN110977192APrevent overflowAvoid separationLaser beam welding apparatusElectric machineryLaser cutting

The invention discloses a collecting mechanism for automotive interior laser cutting. The collecting mechanism comprises a laser device, cutting jigs, a special material taking device and a waste gascollecting device connected with the cutting jigs; the collecting mechanism comprises the two cutting jigs of the left cutting jig and the right cutting jig, namely the left station and the right station, and the cutting jigs are arranged on jig bases 18 through sliding rails 17; and sliding rail motors 16 are arranged on the sliding rails 17, so that the cutting jigs slide on the rails to realizeseamless connection between the jigs and a waste material collecting hopper 1. According to the collecting mechanism for the automotive interior laser cutting, the application of laser cutting in PCand ABS plastic product cutting is achieved, the problem that a plastic product is difficult to cut by laser is solved, and after the process is adopted, a product notch is bright and clean, the slagadhering amount at the bottom is extremely small, and no smoke and dust exist on the surface of the product; a laser hot melting area is obviously reduced, and the amount of cutting smoke and dust isobviously reduced; and the developed jigs are convenient for fixing the product, and improving the precision, so that good product machining precision is obtained, and the error of the product is + / -0.03 mm.

Owner:南京上美冠丰塑胶有限公司

Round steel ingot mold and round steel ingot manufacturing method

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Preparation process of alloy mold core for high-temperature alloy single crystal blade precision casting

ActiveCN106001553BImprove the success rate of demouldingImprove pass rateTurbinesOther manufacturing equipments/toolsFiberNumerical control

Owner:李庆

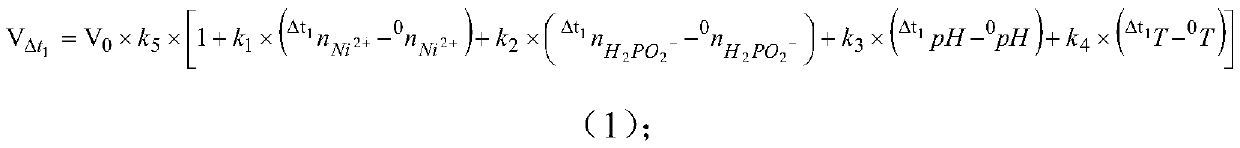

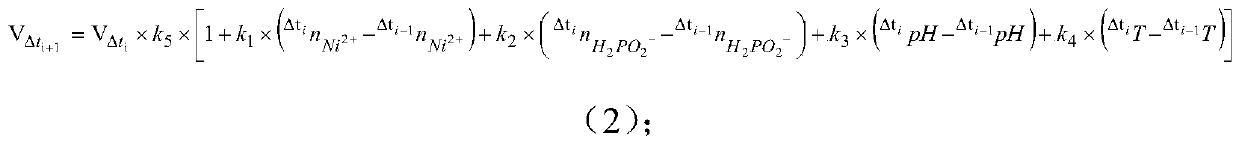

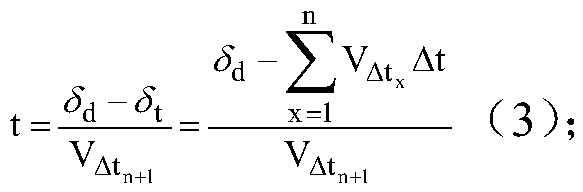

A method for accurately controlling the thickness of an electroless plating layer and a method for preparing a wear-resistant screen

InactiveCN108441845BDoes not affect dimensional accuracyHigh dimensional accuracyLiquid/solution decomposition chemical coatingChemical platingMathematical model

The invention relates to a method for precisely controlling the thickness of an electroless plating layer and a preparation method for a wear-resistant screen, belonging to the field of electroless plating. The method for accurately controlling the thickness of the electroless plating layer of the present invention accurately measures and calculates the plating speed and controls the plating time by establishing a mathematical model and performing iterative calculation on parameters such as the concentration of reactants in the plating process. The method realizes the use of computer programs to control the electroless plating process, establishes the mathematical model of the plating speed and the remaining time of plating by detecting the reactant concentration, pH value, temperature and other parameters that affect the chemical plating process, and uses the iterative calculation principle to accurately calculate the plating Speed, precise control of plating time, so as to achieve the purpose of precise control of coating thickness. The method can control the thickness error of the electroless plating layer within the range of ±0.0002mm, and significantly improves the manufacturing precision of the electroless plating product.

Owner:HENAN INST OF SCI & TECH

Composition for magnesium alloy surface activation

ActiveCN101205609BSignificant corrosionWash thoroughlyMetallic material coating processesCarboxylic acidBiological activation

The invention discloses a complex for magnesium alloy surface activation. The complex comprises inorganic acid, organic phosphonic acid, surfactant and oxidizer, and is characterized in that: the complex also comprises organic carboxylic acid and corrosion-inhibition agent. The complex for magnesium alloy surface activation provided by the invention can ensure that the residue on the surface of the magnesium alloy is completely cleaned; at the same time, the complex can not cause remarkable corrosion effect to the magnesium alloy, has more lasting activation effect; the activated magnesium alloy has smooth and luminant surface, and has no influence on the size accuracy of workpieces. And the complex provided by the invention does not contain the substances harmful to the human body and the environment such as Cr, F and so on, and has no pollution to the human body and the environment.

Owner:南通江海港建设工程有限公司

Foam pattern surface film forming method for lost foam casting

InactiveCN101954445BImprove surface qualityDoes not affect dimensional accuracyFoundry moulding apparatusMetallurgyStearic acid

The invention relates to a foam pattern surface film forming method for lost foam casting, belonging to a lost foam casting method, and solving the problems that the film forming matter of the current foam pattern surface film forming method has longer film forming time and high cost. The method of the invention comprises the following steps: (1) a film forming matter preparing step: preparing a wax-based organic composite material of which the raw materials in mass percent are as follows: 60%-100% of wax, 0%-40% of stearic acid and 0%-10% of additives, wherein the range of melting point of the wax-based organic composite material is 40 DEG C-70 DEG C, and then heating to meld the composite material to form mixture; and (2) a film forming step: completely soaking the foam pattern into themixture and soaking for 5-60s, and then taking out and slightly shaking or whipping to remove the excess liquid mixture, and after cooling, an even film layer is formed on the foam pattern. The invention has simple operation, short film forming time and lower cost, and can greatly improve the surface quality of the foam pattern, thereby improving the surface qualities of a mold shell and casting,and realizing large-scale industrial production.

Owner:HUAZHONG UNIV OF SCI & TECH

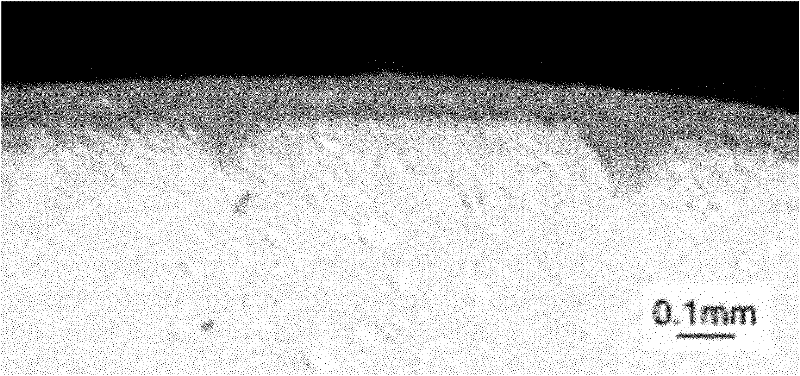

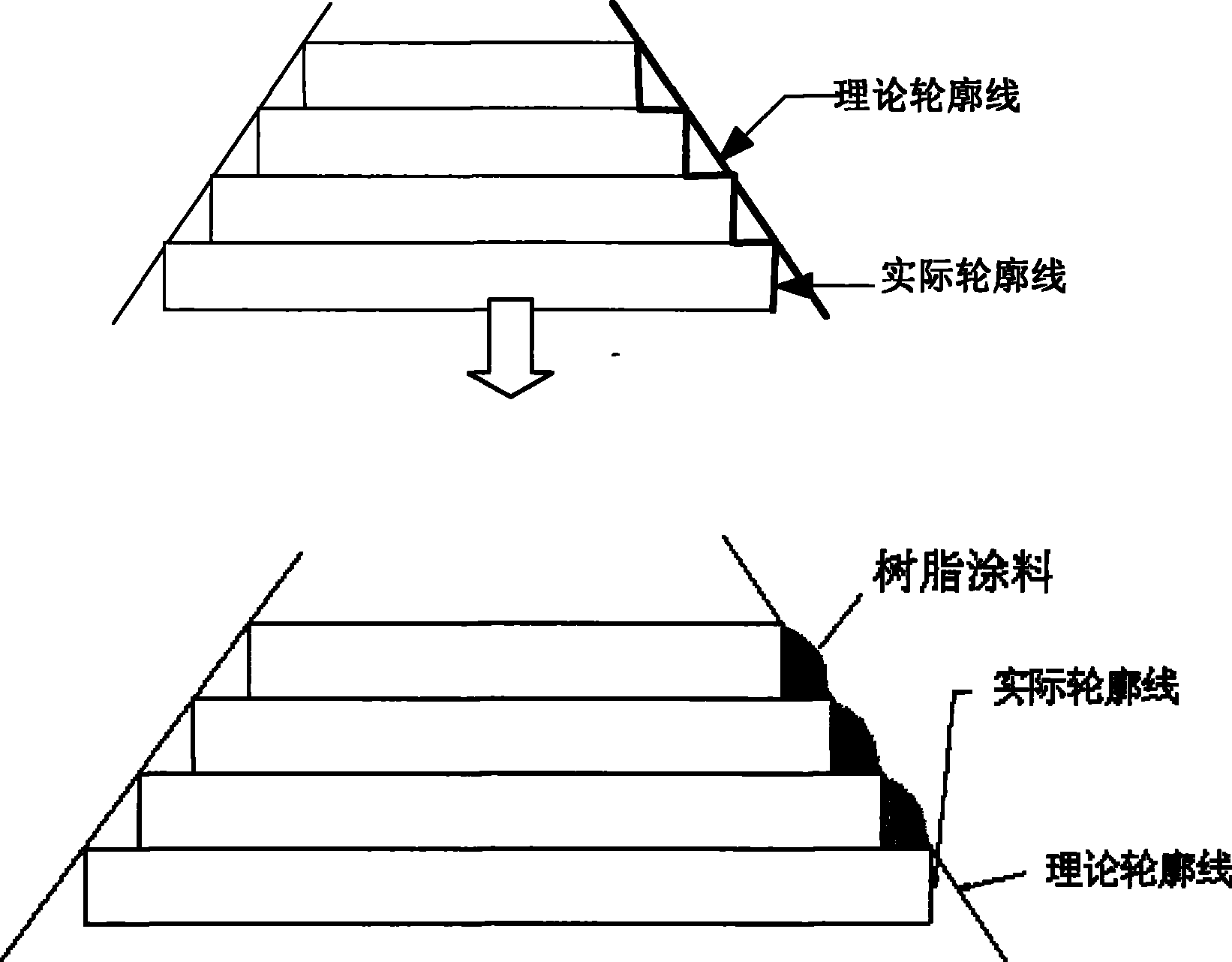

Method for reducing light-cured rapid prototype component surface roughness

InactiveCN101081388BDoes not affect dimensional accuracyEliminate the step effectPretreated surfacesCoatingsDiluentSurface roughness

The present invention discloses one kind of physical and chemical method to lower the surface roughness of stereo optically cured body. The method includes the following steps: compounding resin paint through adding surfactant not more than 0.1 %, active diluent in 5-30 % and leveling agent not more than 1 % into resin and regulating the viscosity of the resin paint to 0.25-0.70 Pa.S; and coatingthe resin paint to the surface of the body to form homogeneous coating of thickness within 300 micron, so as to reduce the roughness from 6-15 micron to 3 micron. The method can eliminate the step effect of stereo optically curing, and has excellent application foreground.

Owner:XI AN JIAOTONG UNIV

A Polishing Method of Light Curing Forming Resin Prototype with Controllable Roughness

InactiveCN103433853BImprove surface accuracyReduce work intensityPolishing compositions with abrasivesParticle flowDistilled water

The invention discloses a roughness-controllable polishing method for stereolithographic resin prototype models. According to the invention, the fluid of a prepared chemical etching abrasive particle flow is used on abrasive particle flow equipment for respective polishing of the stereolithographic resin prototype models; then distilled water or deionized water is used for cleaning, surface roughness of the obtained stereolithographic resin prototype models is reduced to Ra 0.8 to 2 mu m from original Ra 8.0 to 20.0 mu m, surface roughness is uniform, texture is regular, postprocessing of the stereolithographic resin prototype models is realized, operation is simple, and labor intensity is reduced. The polishing method eliminates step effects of the stereolithographic resin prototype models, improves surface precision of the resin prototype models and does not influence dimensional precision of the resin prototype models.

Owner:XI AN JIAOTONG UNIV +1

A laser cutting collection mechanism for automobile interior decoration and its cutting method

ActiveCN110977192BAchieve isolationPrevent overflowLaser beam welding apparatusWaste collectionElectric machinery

The invention discloses a laser cutting and collecting mechanism for automobile interior decoration, which includes a laser, a cutting jig, a special reclaimer and a waste gas collection device connected with the cutting jig, including two sets of cutting jigs, a left cutting jig and a right cutting jig. The fixture is the left station and the right station. The cutting fixture is set on the fixture base (18) through the slide rail (17). The slide rail (17) is provided with a slide rail motor (16) to realize the cutting fixture Sliding on the track realizes the seamless connection of the jig and the waste collection bucket (1). The invention realizes the application of laser cutting in the cutting of PC+ABS plastic products, and solves the problem that the laser is difficult to cut plastic products. The area is significantly smaller, and the amount of cutting smoke and dust is significantly reduced; the developed jig is convenient for product fixing; the accuracy is improved: the product processing accuracy is very good, and the error of the product is + / ‑0.03mm.

Owner:南京上美冠丰塑胶有限公司

Surface roughness reduction method of light-cured rapid prototype based on atomization technology

The invention discloses an atomization technology-based light-cured rapid prototyping product surface roughness reducing method. The method adopting a liquid wax emulsion as a raw material comprises the following steps: heating the material, and atomizing to form uniform atomization environment in an atomization box; placing a light-cured rapid prototyping product in the atomization box, and uniformly coating the internal and external cavity surfaces of the light-cured rapid prototyping product with the atomized wax emulsion for a certain time, taking out he light-cured rapid prototyping product, heating the light-cured rapid prototyping product in an oven, and drying to remove water in the emulsion to form an extremely thin coating on the internal and external cavity surfaces of the light-cured rapid prototyping product. The coating can eliminate a step effect generated through a light curing rapid molding technology and reduce the surface roughness of the light-cured rapid prototyping product. The method is simple to operate, is especially suitable for the surface quality improvement of the light-cured rapid prototyping product with a complex internal and external cavity structure, does not affect the dimensional accuracy of the light-cured rapid prototyping product, and has a wide application prospect.

Owner:XI AN JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com