Scale remover

A descaling agent and solvent technology, applied in the field of descaling agents, can solve the problems of deteriorating production environment, dangerous configuration, and large removal of parts and product sizes, and achieve the effects of improving the production environment, reducing waste gas treatment, and simple and easy wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

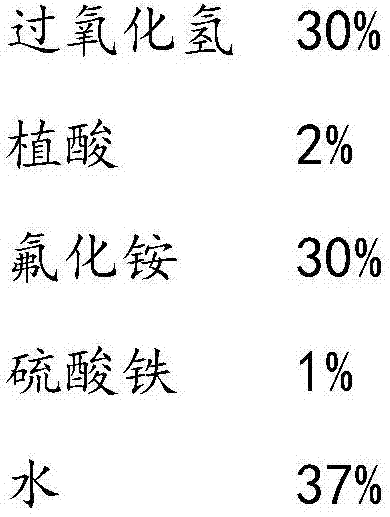

Embodiment 1

[0045] This embodiment provides a descaling agent, including an oxidant, a stabilizer, a builder, a catalyst and a solvent, wherein the oxidant is hydrogen peroxide, the stabilizer is phytic acid, the builder is ammonium fluoride, and the catalyst is iron sulfate , the solvent is water.

[0046] Wherein, the weight percent of each component is respectively:

[0047]

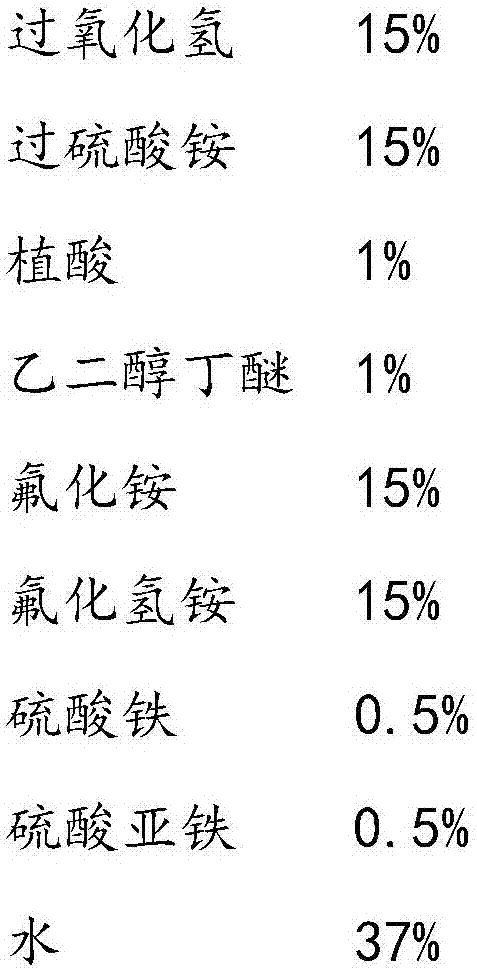

Embodiment 2

[0049] This embodiment provides a kind of descaling agent, comprises oxidizing agent, stabilizing agent, builder, catalyst and solvent, wherein, oxidizing agent is the mixture of hydrogen peroxide and ammonium persulfate, and stabilizing agent is the mixture of phytic acid and ethylene glycol butyl ether. The mixture, the builder is a mixture of ammonium fluoride and ammonium bifluoride, the catalyst is a mixture of ferric sulfate and ferrous sulfate, and the solvent is water.

[0050] Wherein, the weight percent of each component is respectively:

[0051]

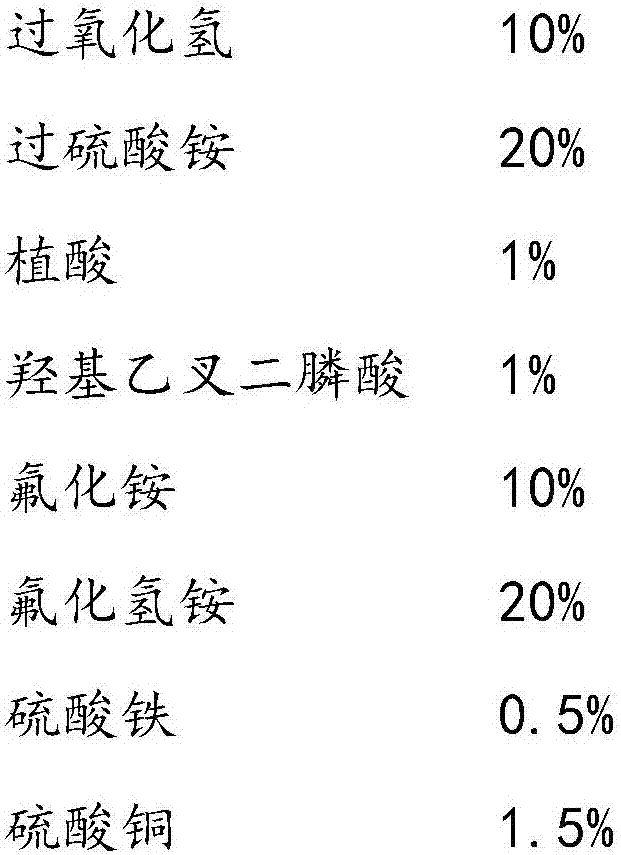

Embodiment 3

[0053] This embodiment provides a kind of descaling agent, comprises oxidant, stabilizer, builder, catalyst and solvent, wherein, oxidant is the mixture of hydrogen peroxide and ammonium persulfate, and stabilizer is phytic acid and hydroxyethylidene diphosphonic acid The mixture, the builder is a mixture of ammonium fluoride and ammonium bifluoride, the catalyst is a mixture of iron sulfate and copper sulfate, and the solvent is water.

[0054] Wherein, the weight percent of each component is respectively:

[0055]

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com