Self-enclosed coaxial equal-angle alternate rotary descaling header device

A technology of descaling headers and alternate rotation, which is applied to spraying devices, workpiece surface treatment equipment, metal rolling, etc., and can solve problems such as cumbersome maintenance work, unstable operation, and easy bursting of high-pressure hoses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

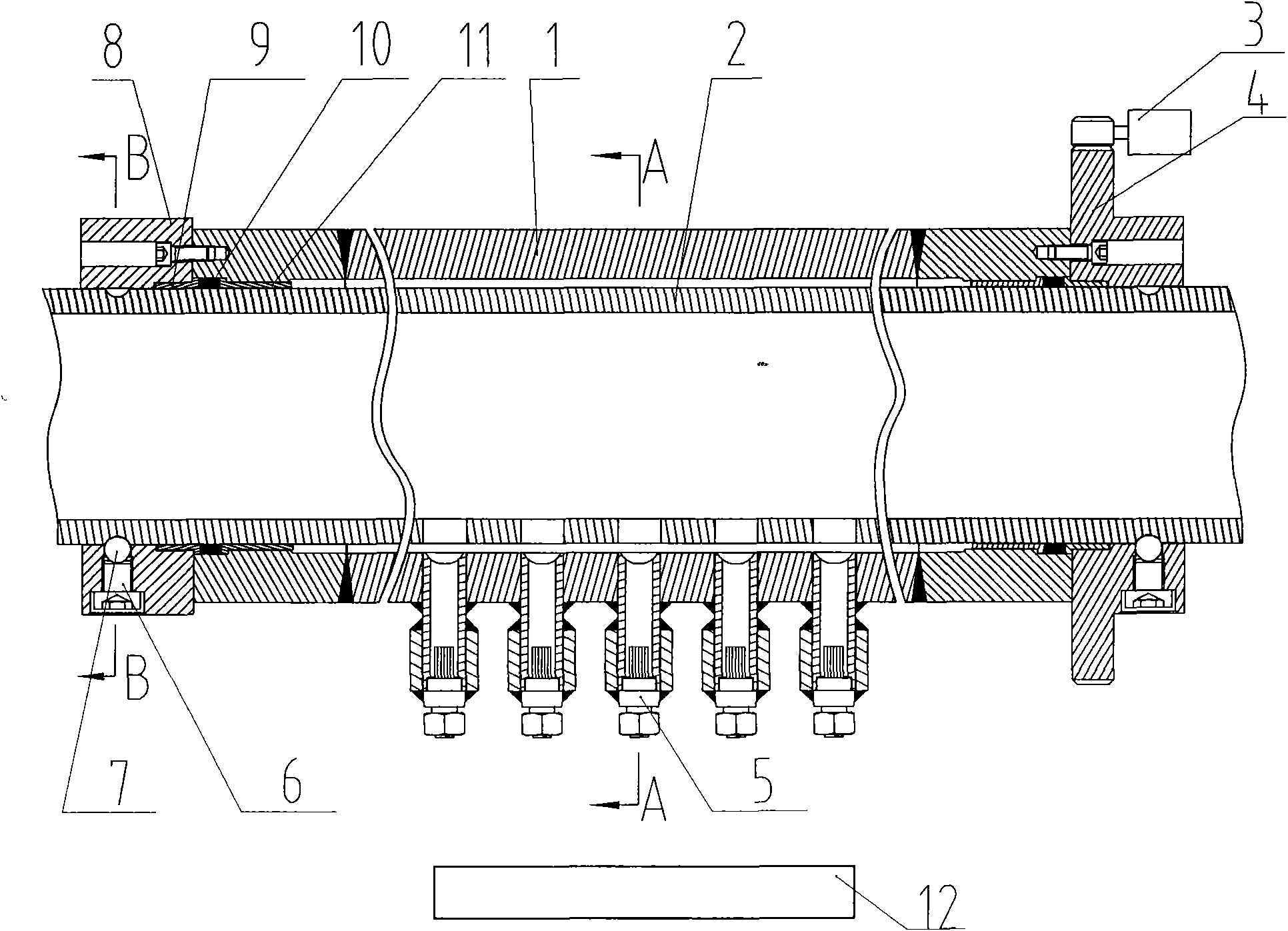

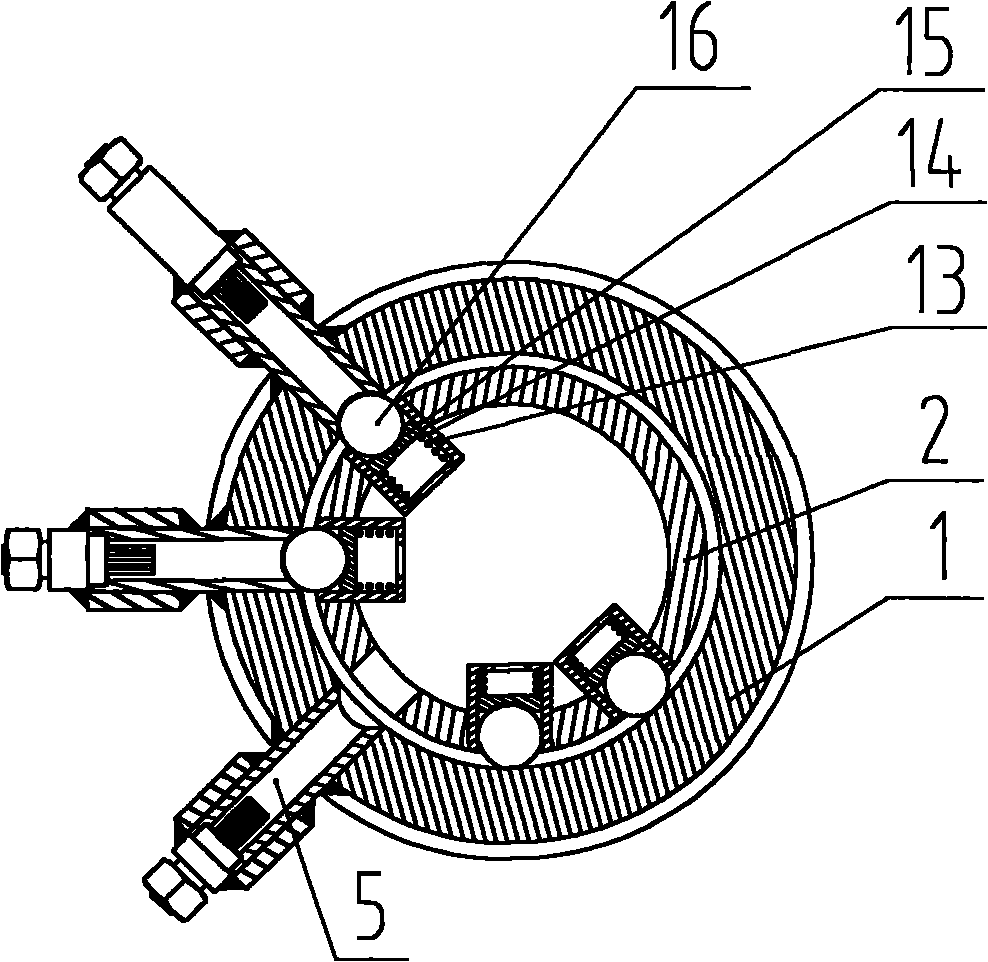

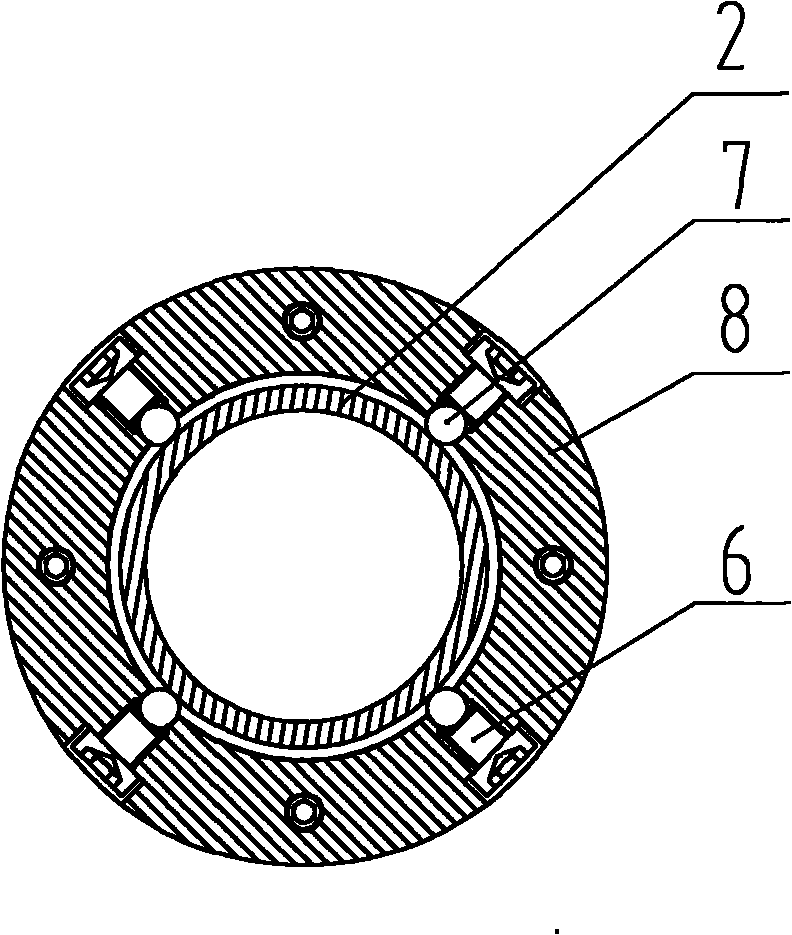

[0017] A self-enclosed coaxial and equal-angle rotating descaling header device, such as figure 1 , Figure 4 , Figure 7 As shown, it includes a header equipped with a nozzle 5, the descaling header is composed of an outer tube 1 and an inner tube 2, the inner tube 2 is installed in the outer tube 1, and the radial direction on the outer tube 1 of the descaling header The nozzle groups arranged in rows are arranged at equal angles, the nozzles 5 of each row of nozzle groups are evenly arranged along the axial direction of the outer tube 1, and the inner tube 2 is set at the position corresponding to a row of normal descaling working nozzles 5 of the outer tube 1. A row of normally open water holes, while the inner pipe 2 is also provided with nozzle closing devices corresponding to the other rows of nozzles 5 of the outer pipe 1, one end of the inner pipe 2 is closed, and the other end is connected to high-pressure water, the inner and outer pipes 2, 1 The two ends between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com