Solid lubrication thin-wall bearing with segmented self-lubricating holder

A technology of solid lubrication and thin-walled bearings, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as large friction torque, howling sound, and unstable operation, and achieve small friction torque and reduce friction , the effect of smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

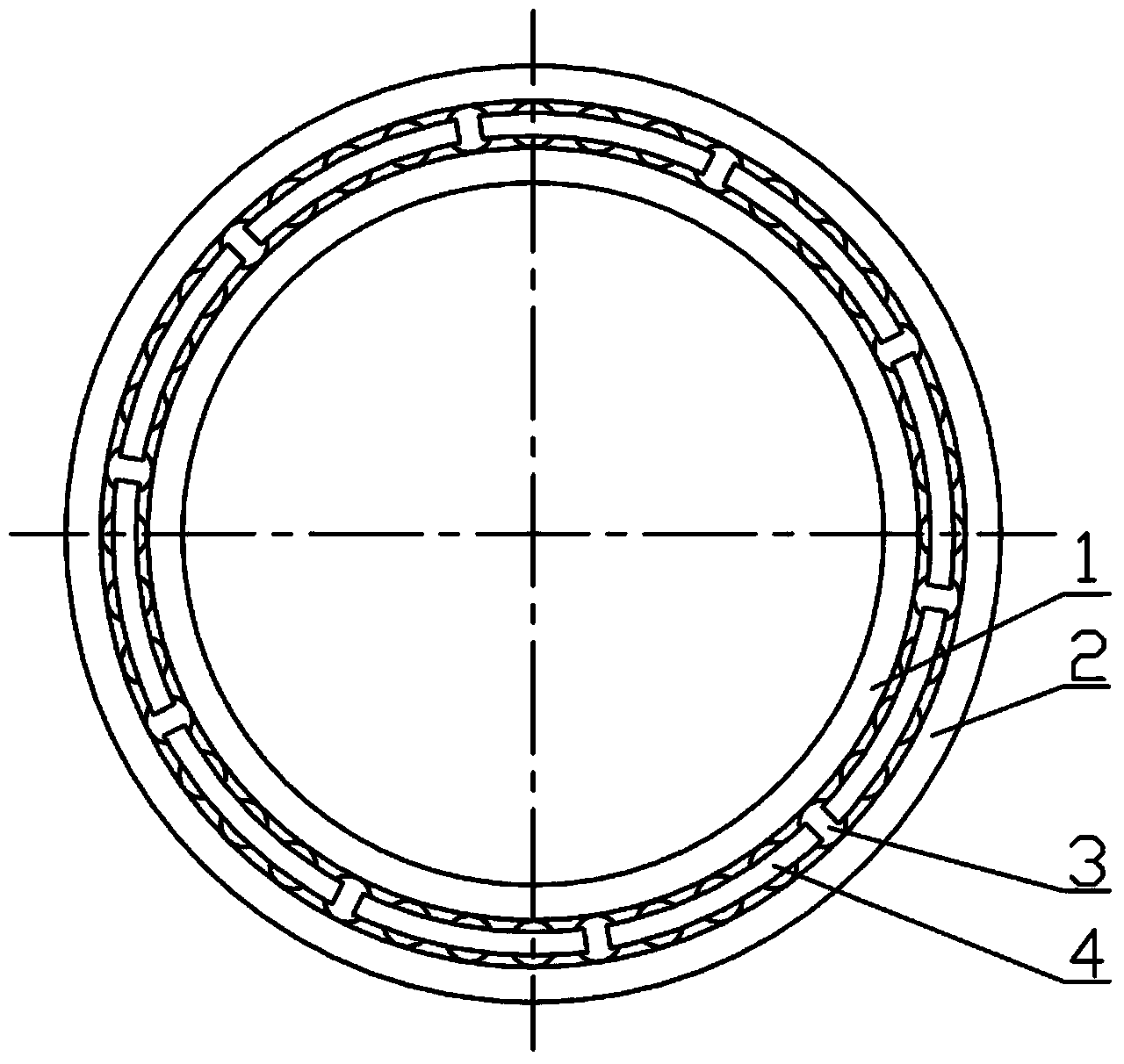

[0020] Such as figure 1 As shown, the specific implementation technical solution of the present invention is: a solid lubricated thin-walled bearing with a segmented self-lubricating cage, including an inner ring 1, an outer ring 2, a ball 3 and a cage;

[0021] Wherein, the cage is composed of multiple arc sections 4 equally divided on the same circumference, and more than three pocket holes are evenly distributed on the arc surface of the arc section 4, and the cross-sections at both ends of the arc section 4 There is a semi-circular groove in the upper processing;

[0022] The connection relationship is that: multiple sections of the arc section 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com