Collecting mechanism for automotive interior laser cutting and cutting method thereof

A collection mechanism and laser cutting technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as rough incision, equipment that cannot meet production requirements, white smoke and inaccurate product positioning, and achieve cutting quality assurance , reduce thermal effects, increase the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

[0062] Aspects of the invention are described in this disclosure with reference to the accompanying drawings, which show a number of illustrated embodiments. Embodiments of the present disclosure are not necessarily intended to include all aspects of the invention. It should be appreciated that the various concepts and embodiments described above, as well as those described in more detail below, can be implemented in any of numerous ways.

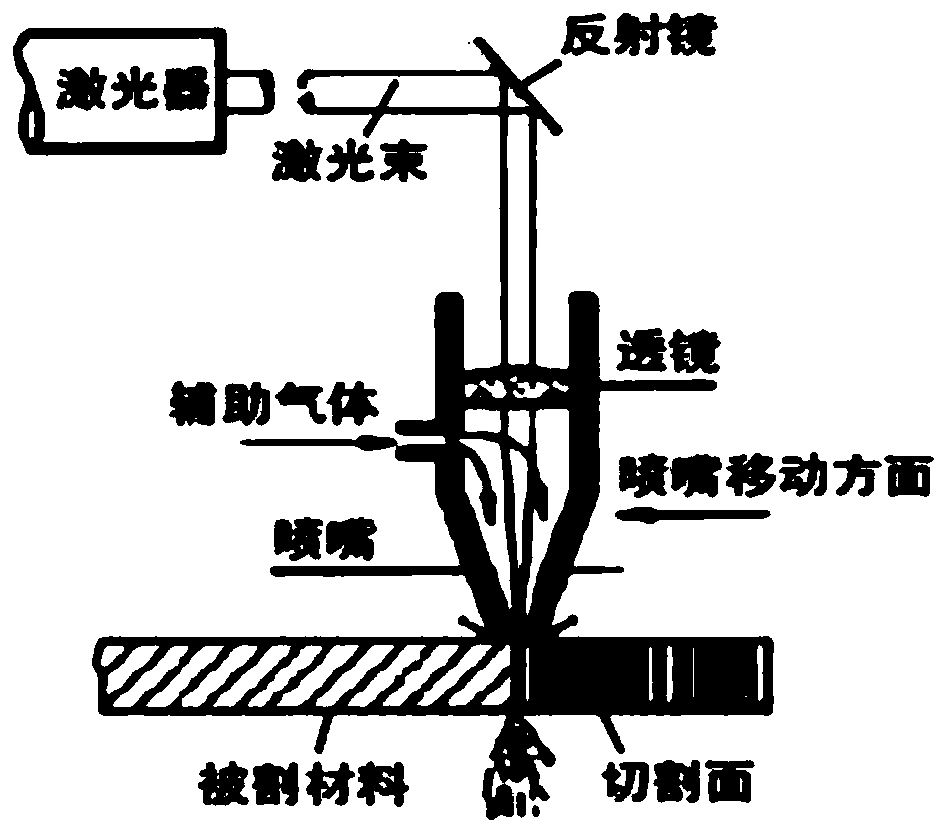

[0063] Such as figure 1 As shown, the laser passes through the laser speed and reflector and lens, as well as the auxiliary gas, and cuts in the cutting product through the nozzle.

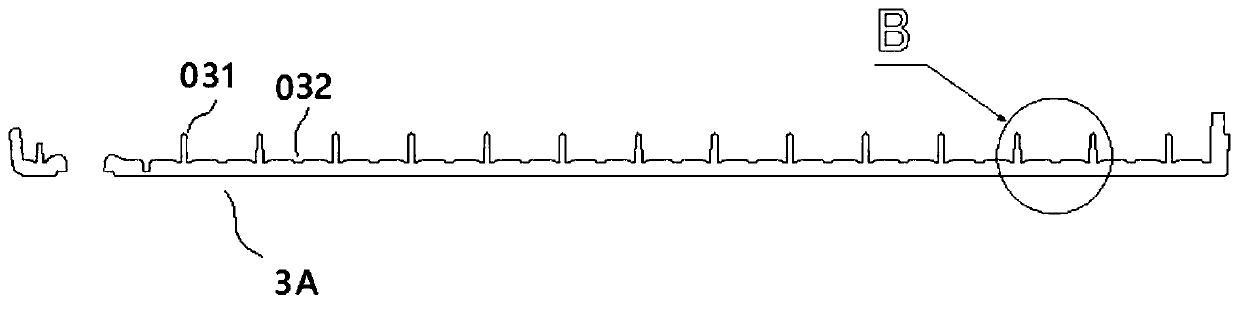

[0064] Such as image 3 with 4 , In order to obtain a good cutting thickness and improve the target product, a 0.5mm cutting groove is provided on the reverse side of the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com