Cleaning liquor and treatment method for removing residual magnesium alloys in die

A technology of cleaning solution and processing method, applied in the field of cleaning solution for removing residual magnesium alloy in molds, can solve problems such as complicated operation, difficult cleaning, mold corrosion, etc., and achieve the effects of low solution cost, easy control, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

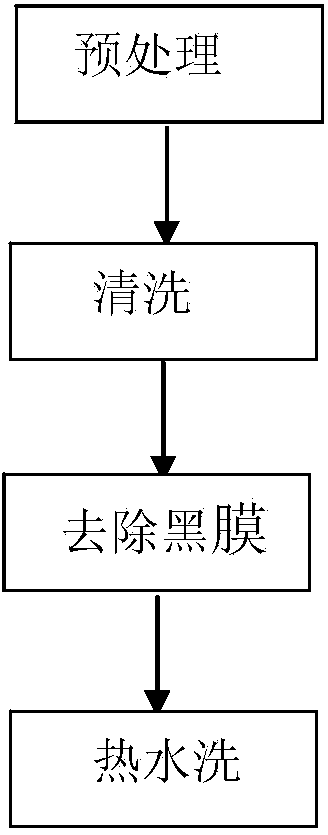

[0027] Firstly, in step (1), the extrusion die is pretreated, for example, using a hammer or other equipment to chisel out or punch out the large magnesium alloy in the split hole, so as to reduce the consumption of the magnesium alloy on the treatment solution.

[0028] Next, in step (2), put the pretreated mold into the prepared cleaning solution to clean the residual magnesium alloy in the mold.

[0029] In this embodiment, the concentration of the solution used to clean the residue in the magnesium alloy mold is 80 ml of hydrochloric acid, 2 g of ammonium citrate, 0.8 g of EDTA, 20 g of corrosion inhibitor, and 880 g of water. The temperature of the cleaning solution is 50°C, and the cleaning time is 1 hour.

[0030] In step (3), rinse the black film on the surface of the cleaned mold with tap water.

[0031] Rinse the black film on the surface of the mold with water, then flush the mold with 100°C hot water for 30 minutes according to step (4), and let the heat generated...

Embodiment 2

[0033] In this embodiment, the treatment method for cleaning the residues in the magnesium alloy mold is the same as that of the first embodiment above. Only the differences from the first embodiment will be described below.

[0034] In this embodiment, in the cleaning treatment of step (2), the concentrations used for cleaning are 100 ml of hydrochloric acid, 4 g of ammonium citrate, 1.2 g of EDTA, 18 g of corrosion inhibitor, and 950 g of water. The temperature of the cleaning solution is 60°C, and the cleaning time is 30 minutes.

[0035] In step (4), the mold is rinsed with hot water, the temperature of the water used is controlled at 80° C., and the time is 40 minutes.

Embodiment 3

[0037] In this embodiment, the concentration of the solution used to clean the residue in the magnesium alloy mold is 60 g of hydrochloric acid, 1 g of ammonium citrate, 0.5 g of EDTA, 1 g of corrosion inhibitor, and 800 g of water. The temperature of the cleaning solution is 100°C, and the cleaning time is 1.5 hours.

[0038] In step (3), rinse the black film on the surface of the cleaned mold with tap water.

[0039] Rinse the black film on the surface of the mold with water, then flush the mold with 100°C hot water for 40 minutes according to step (4), and let the heat generated by the mold dry itself.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com