Foam pattern surface film forming method for lost foam casting

A technology of foam pattern and film forming method, which is applied in the direction of casting and molding equipment, etc., can solve the problems of high price and long film forming time of film forming materials, and achieve the effects of low cost, reduced film forming time and improved surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1, the sequence includes:

[0023] 1. Film-forming material preparation step: prepare wax-based organic composite material, the mass percentage of its raw material is: paraffin 100%, the rest is 0; wax-based organic composite material has a melting point range of 40°C;

[0024] Then heat and melt the wax-based organic composite material to form a miscible substance at a heating temperature of 60°C;

[0025] 2. Film forming step: completely immerse the unheated foam pattern into the mixed material, take it out after soaking for 5 seconds and slightly shake or shake to remove the excess liquid mixed material, and form a uniform film on the foam pattern after cooling Layer, see image 3 As shown, a smooth thin layer is formed on the surface of the foam mold, and the grooves between the beads of the foam mold are filled.

[0026] In the film forming step, the foam-like foam molding material is expandable polystyrene resin beads.

Embodiment 2

[0027] Example 2, the sequence includes:

[0028] 1. Film-forming material preparation step: prepare wax-based organic composite material, the mass percentage of its raw materials is: ozokerite 80%, stearic acid 15%, polyethylene 5%, and wax-based organic composite material has a melting point of 55°C;

[0029] Then heat and melt the wax-based organic composite material to form a miscible, heating temperature is 70 ℃;

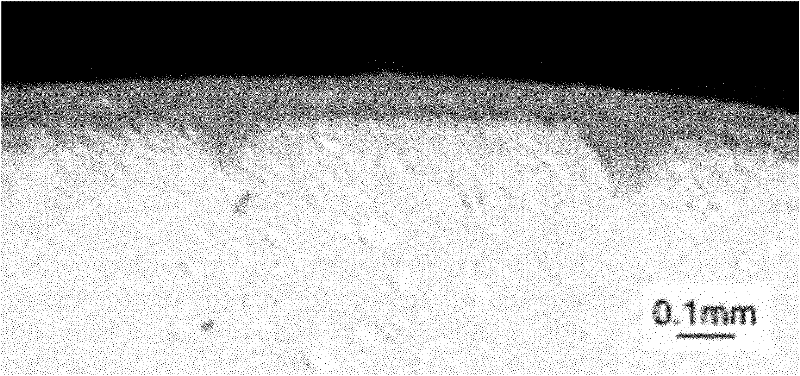

[0030] 2. Film forming step: completely immerse the foam pattern heated at 20°C into the mixed material, take it out after soaking for 35s and slightly shake or shake to remove the excess liquid mixed material, and form a uniform film on the foam pattern after cooling Layer, use the foam pattern to obtain a picture of the shell such as Figure 4 As shown, the surface of the shell is smooth, and the shell is obtained compared with the untreated foam appearance (see figure 2 ) The surface quality is greatly improved.

[0031] In the film forming step, the foam-like foa...

Embodiment 3

[0032] Embodiment 3, the sequence includes:

[0033] 1. Film-forming material preparation steps: prepare wax-based organic composite material, the mass percentage of its raw materials is: Sichuan wax 60%, stearic acid 30%, rosin 10%, and the wax-based organic composite material has a melting point of 70°C;

[0034] Then heat and melt the wax-based organic composite material to form a miscible substance at a heating temperature of 80°C;

[0035] 2. Film forming step: completely immerse the foam pattern heated at 70°C into the mixture, soak it for 60 seconds, take it out and shake or shake it slightly to remove the excess liquid mixture, and form a uniform film on the foam pattern after cooling Layer, the surface roughness Ra of the casting obtained is 1.9 μm.

[0036] In the film forming step, the foam-like foam molding material is expandable polymethyl methacrylate resin beads.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com