Preparation process of alloy mold core for high-temperature alloy monocrystal blade precision casting

A single crystal blade and preparation technology, which is applied in other manufacturing equipment/tools, turbines, engine components, etc., can solve the problems of increased production cost of hollow turbine blades, low yield, high scrap rate of alloy mold cores, etc., to achieve deformation Small size, high qualified rate of finished products, small deformation at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

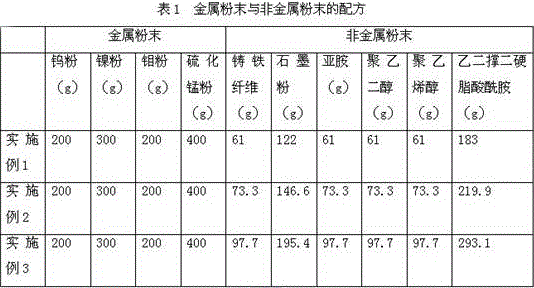

[0042] Embodiment 1-3 The formula of metal powder and non-metal powder is shown in Table 1

[0043]

[0044] According to the above formula, put the metal powder and non-metal powder in a dry mixer and stir them thoroughly for 1 hour, and dry them in a dryer for 3 hours;

[0045] Then, put the fully dried and stirred powder into the acetone solution, and wet mix for 4 hours;

[0046] Next, place the wet-mixed raw materials in an oven and heat to remove the acetone solvent. After the acetone solvent is removed, place the raw materials after the solvent removal in a hopper and heat until the temperature of the raw materials is 130° C.;

[0047] Next, feed the raw material at 130°C into the mold with the heating device through the feeding device;

[0048] Then, start the press, press molding;

[0049] Next, take the formed workpiece out of the mold, because the workpiece has a certain temperature, it can be cut and processed, and then put the mold blank into the CNC equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com