Injection mold for auto parts

A technology for injection molds and auto parts, applied in the field of auto parts processing, can solve problems such as broken parts and unsmooth demoulding, so as to avoid the breakage of finished products and improve the success rate of demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

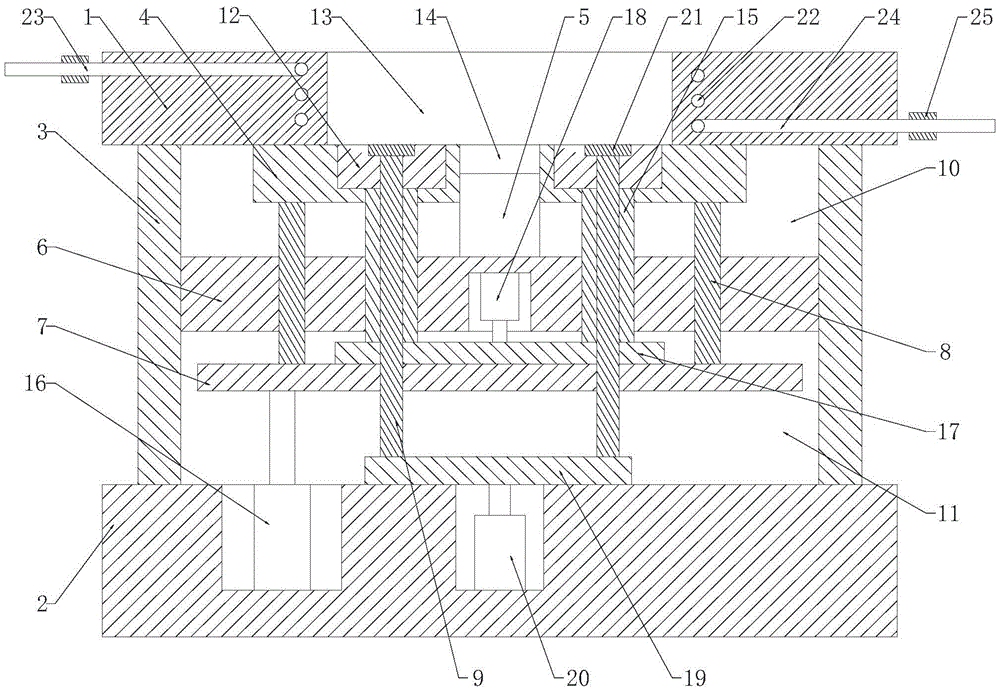

[0026] Such as figure 1 As shown, an injection mold for auto parts includes a male mold and a female mold corresponding to the male mold; the male mold includes an upper holder 1, a lower holder 2 located below the upper holder 1, and the upper and lower ends respectively The supporting ring seat 3 connected with the upper fixing seat 1 and the lower fixing seat 2, the upper fixing seat 1, the lower fixing seat 2 and the supporting ring seat 3 jointly form a movable cavity, and the upper fixing seat 1 is provided with a cooling water pipe, and the cooling water pipe includes The spiral cooling section 22, the water inlet section 23 communicating with the water inlet end of the cooling section 22, and the water outlet section 24 communicating with the water outlet end of the cooling section 22, and the upper fixed seat 1 is also provided with a valve that communicates with the movable chamber and is located in the cooling section. The first opening in the area surrounded by 22;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com