Patents

Literature

53results about How to "Promote structural optimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

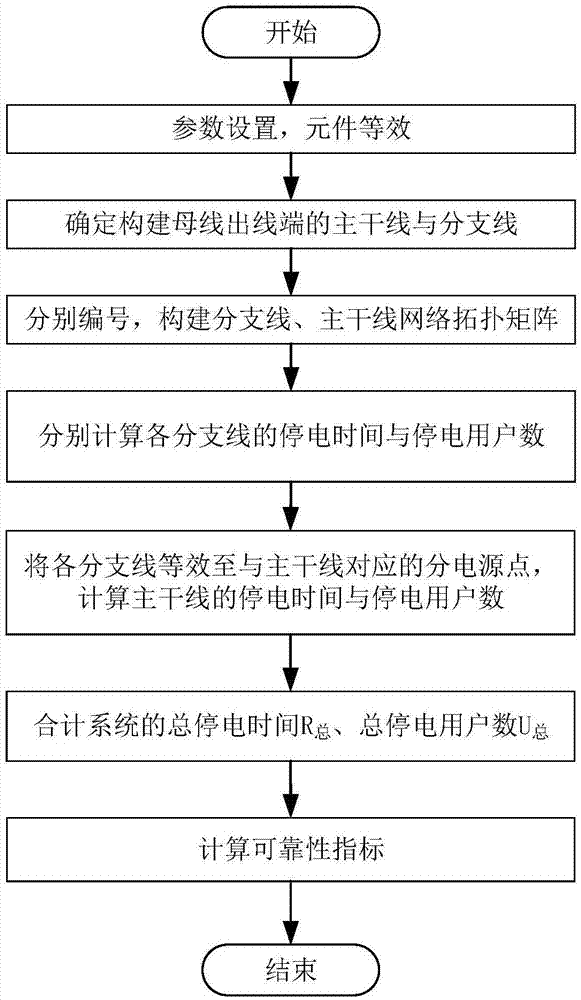

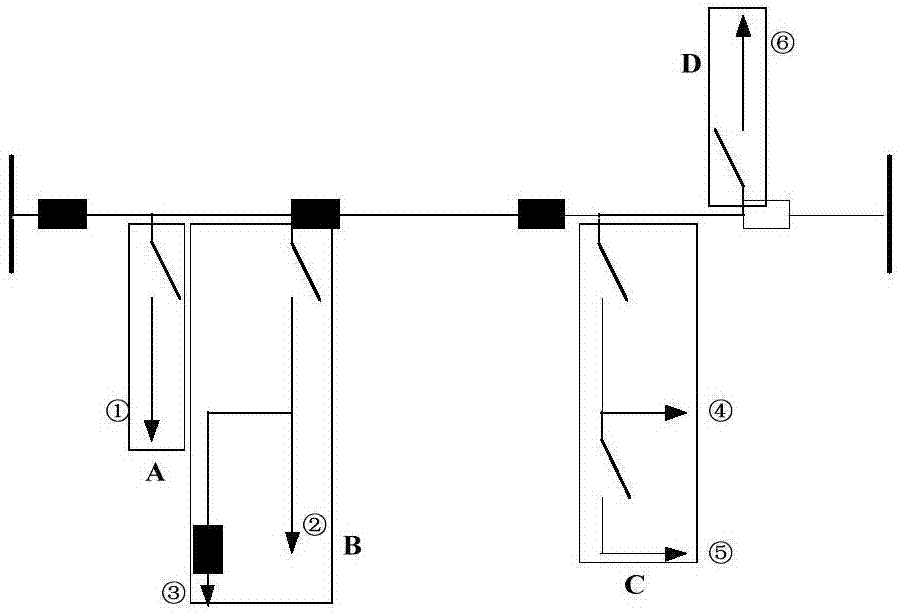

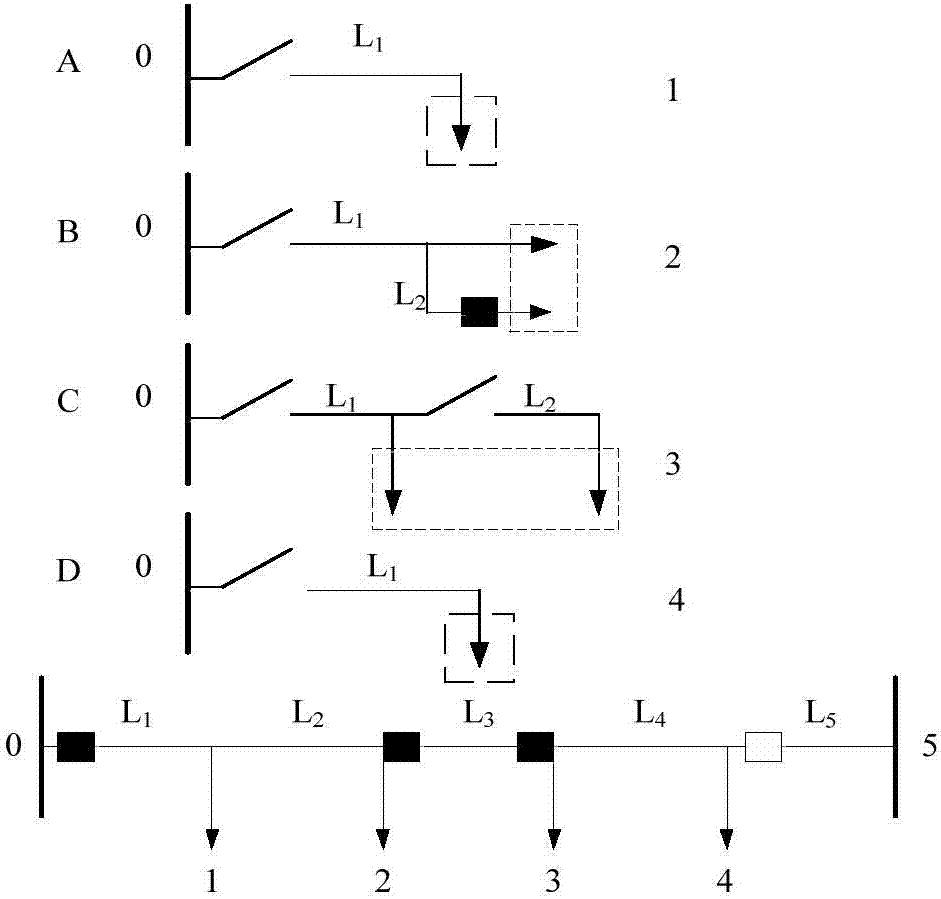

Power supply reliability evaluation method and system

The invention discloses a power supply reliability evaluation method and system. The influences of a power distribution network grid structure on reliability indexes are classified into three categories, namely, links, connections, and mutual influences. Existing reliability evaluation algorithms cannot perform quantitative analysis on the influences on the reliability indexes from the three aspects. The evaluation method of the present invention includes steps of matrix construction, model establishment and index calculation. The matrix construction aims to generate a topology matrix of a power distribution network grid structure; according to the model establishment, a calculation model of the reliability indexes is built through using the topology matrix; and according to an index calculation unit, the calculation model of the reliability indexes is adopted to calculate the reliability indexes, and the influences of the links, connections, and mutual influences on the reliability indexes are expressed in a quantified manner. With the method and system of the invention adopted, the quantitative indexes of power distribution network user reliability analysis and system reliabilityanalysis are realized, and the influences of the links, connections, and mutual influences on the reliability indexes are reflected.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER COMPANY ECONOMIC TECHN INST +4

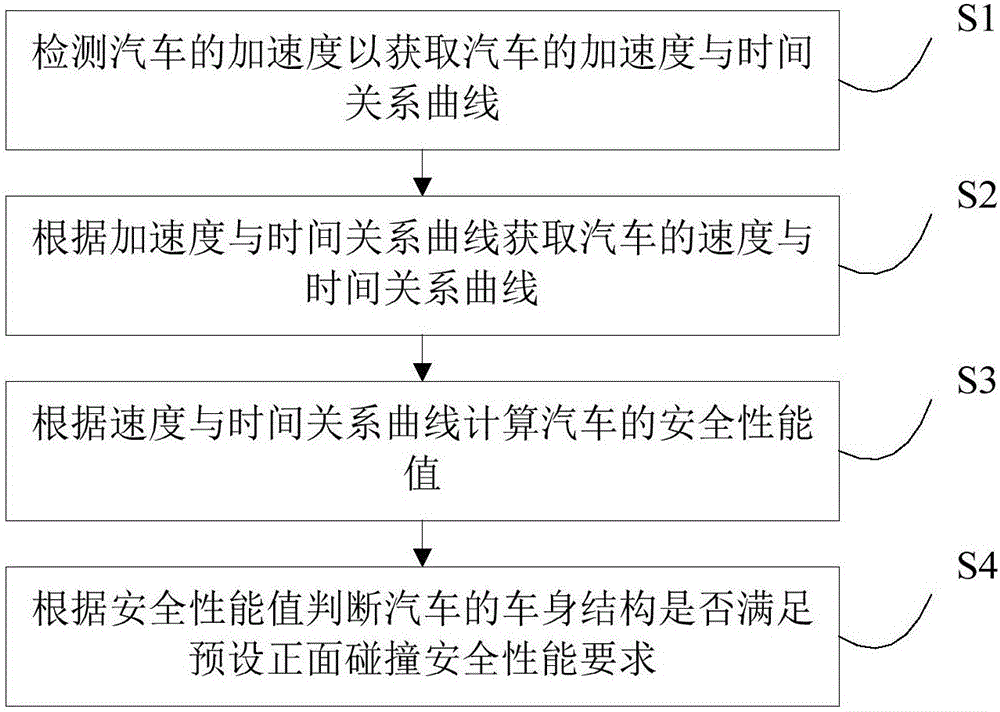

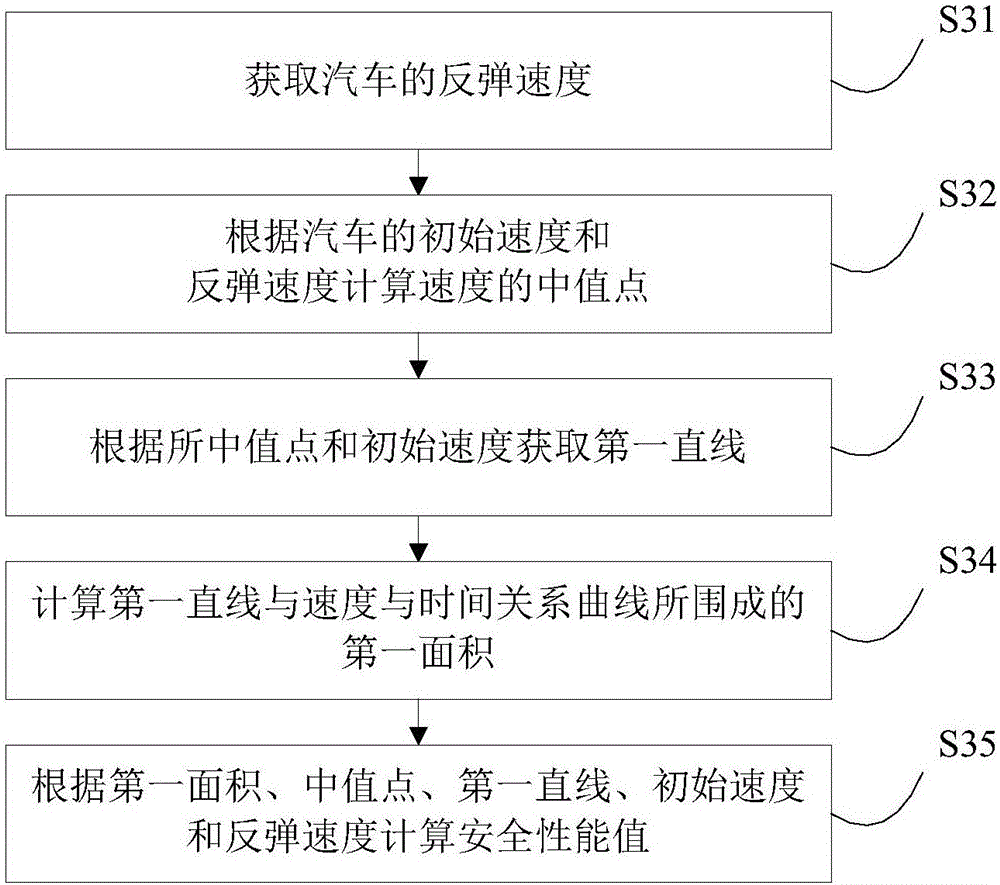

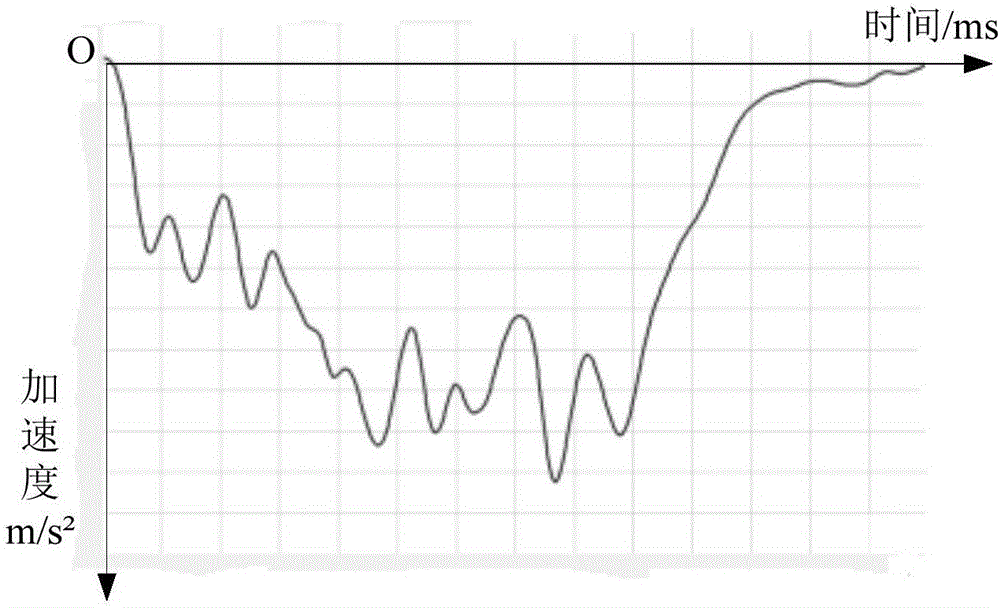

Evaluation method and device of automobile front collision performance

InactiveCN106441941AImprove stabilityPromote structural optimizationVehicle shock testingDevelopment periodAcceleration Unit

The invention discloses an evaluation method and device of automobile front collision performance. The evaluation method includes: detecting acceleration of an automobile to acquire an acceleration and time relation curve of the automobile; calculating and acquiring a speed and time relation curve of the automobile according to the acceleration and time relation curve; calculating a safety value of the automobile according to the speed and time relation curve; judging whether a body structure of the automobile meets preset front collision safety requirements or not according to the safety value. The evaluation method is simple, high in stability, less prone to being affected by single factor, more accurate and more complete in evaluation on rigid barrier-avoiding front collision performance, convenient for optimizing the body structure of the automobile and conducive to shortening development period and lowering number of sample automobiles and development cost.

Owner:BAIC MOTOR CORP LTD

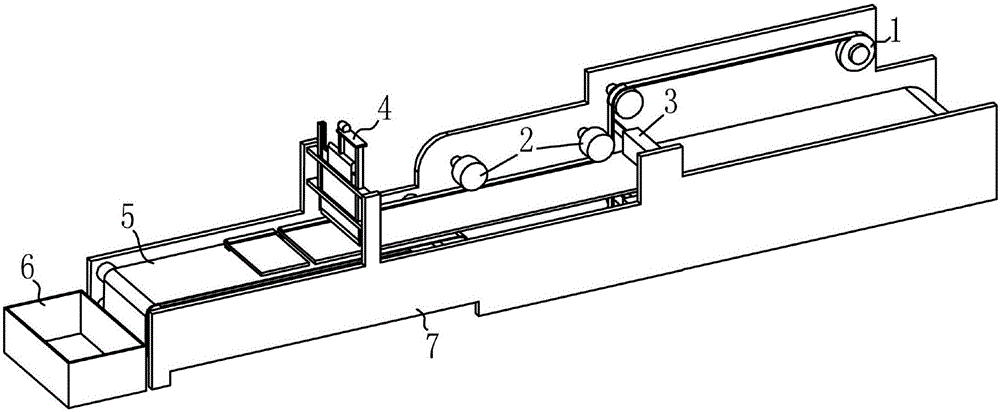

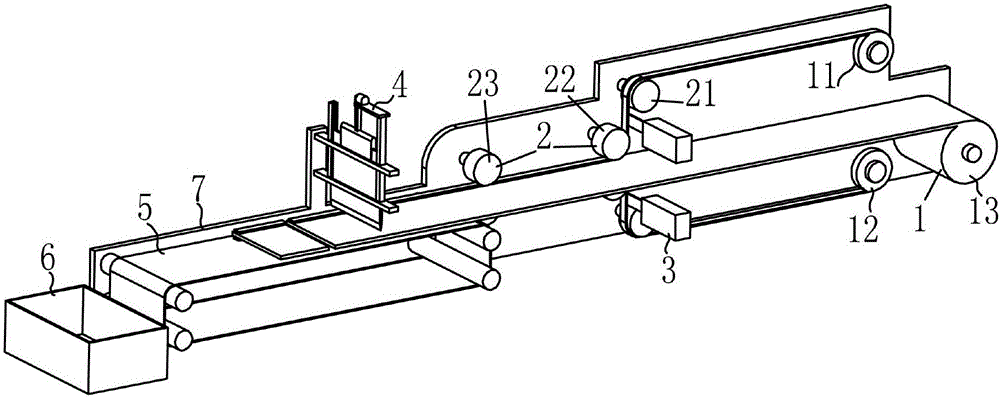

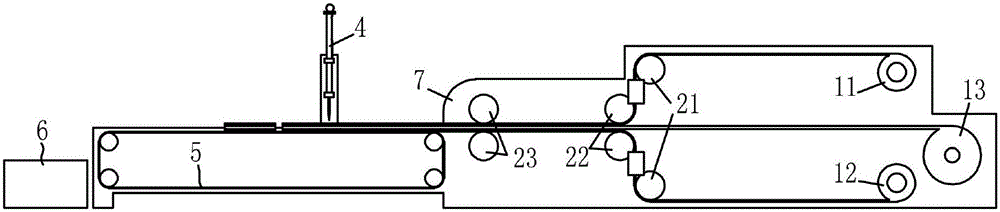

Plastic bag sealing strip mounting equipment

InactiveCN105856631AQuick installationPromote structural optimizationEnvelopes/bags making machineryDrive motorEngineering

The invention relates to the field of plastic bag manufacturing, in particular to a plastic bag sealing strip installation equipment, which includes a material supply roll, a drive roller set, a glue coating device, a cutting device, a conveyor belt, a collection box and a frame, and the material supply roll is located at At the far right end of the frame, the material supply roll is used to supply the plastic film and sealing strip to be processed, and the drive roller group is located on the left side of the material supply roll; between the drive roller sets, there is a coating for bonding the seal strip and the plastic bag. glue device; the cutting device is located above the conveyor belt, and the cutting device includes a cutter, a fixed frame, a connecting rod mechanism and a drive motor; the fixed frame is fixed on the frame, and a chute is arranged on the fixed frame; Both sides are located in the chute. The present invention adopts the method of assembly line, can realize the rapid installation of the plastic bag sealing strip, has better equipment structure optimization, and lower cost.

Owner:胡承平

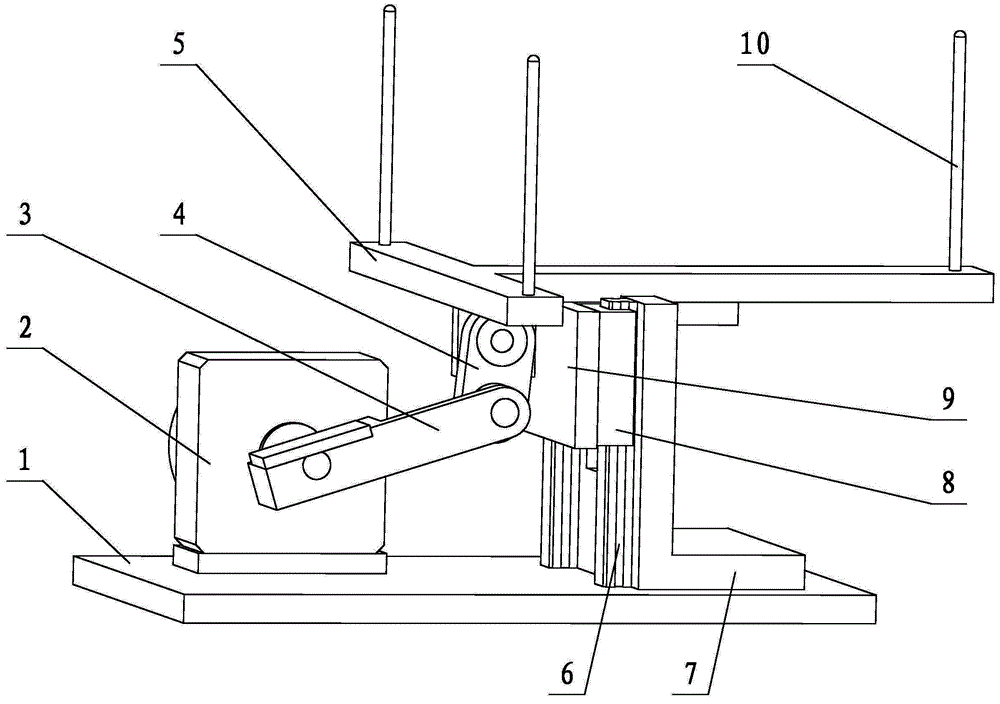

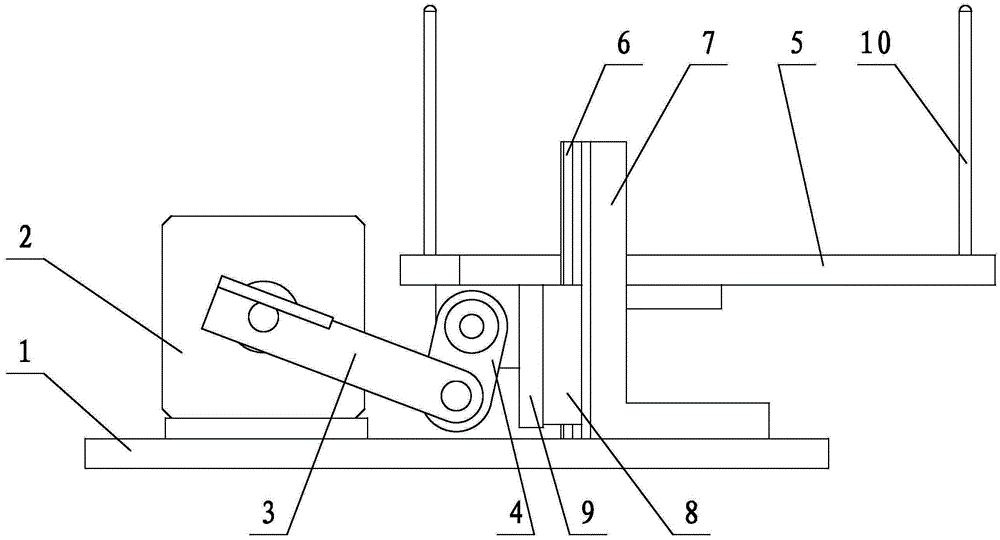

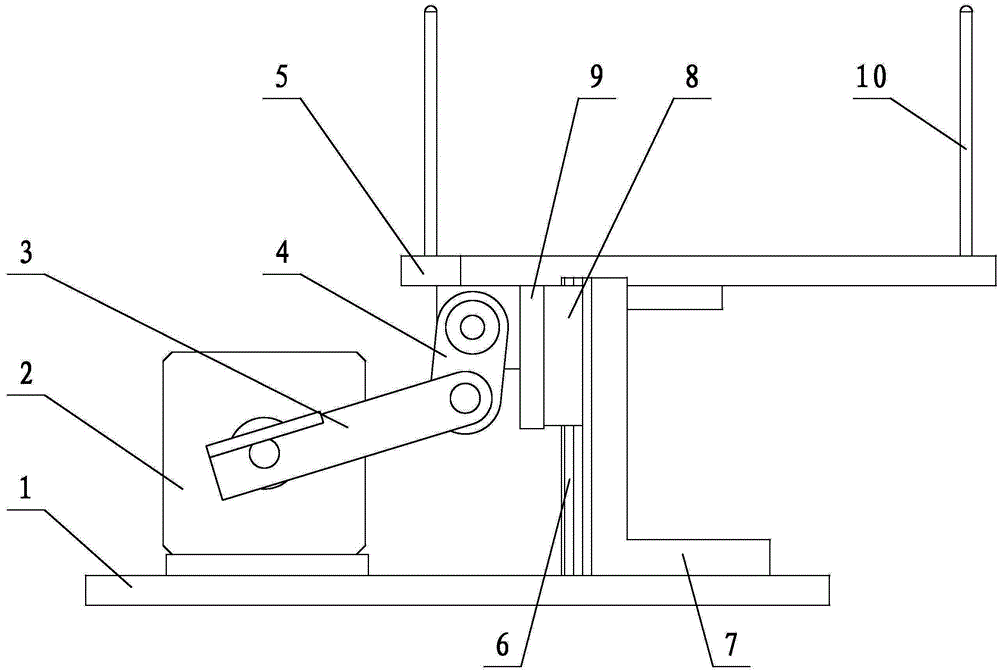

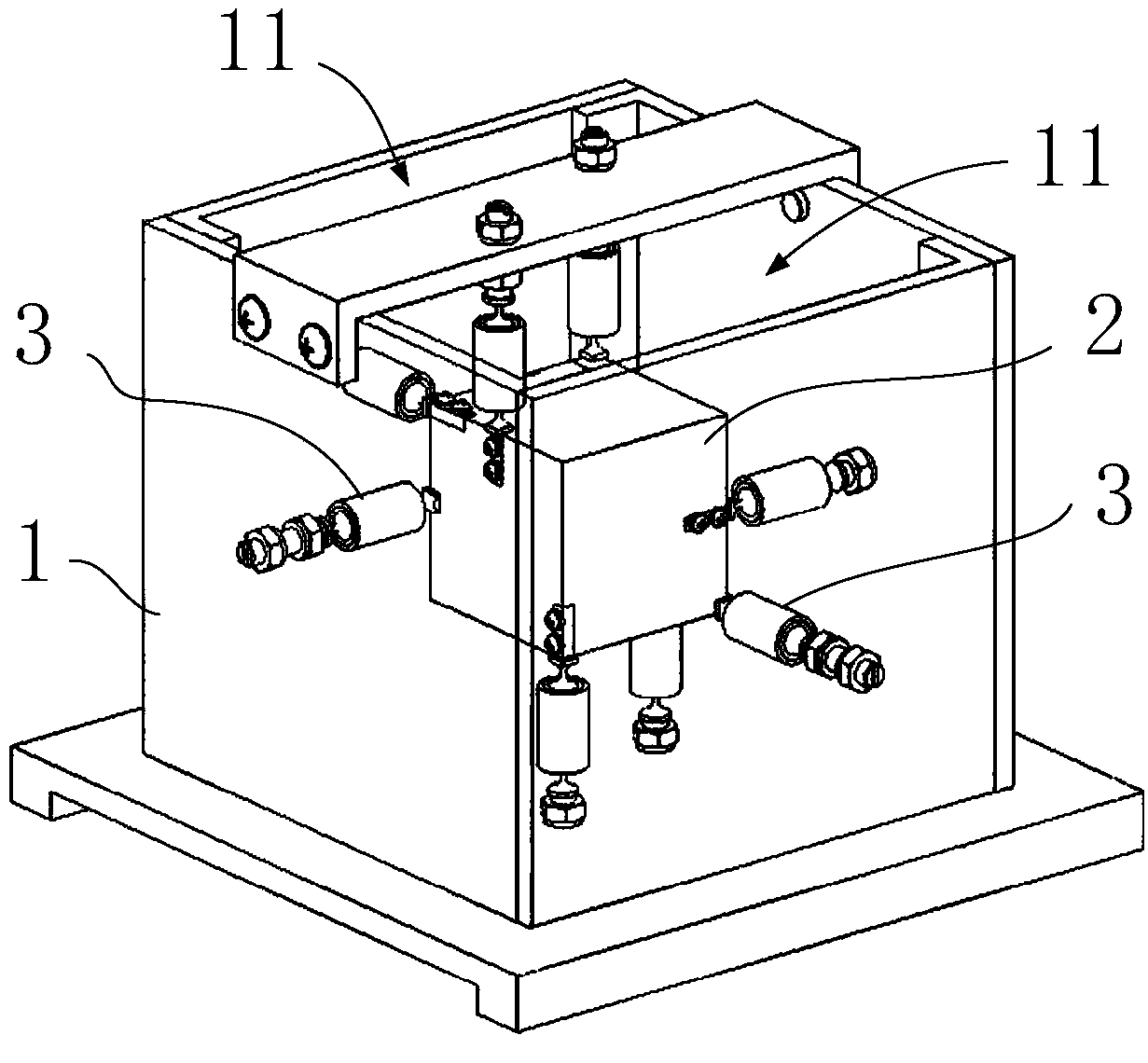

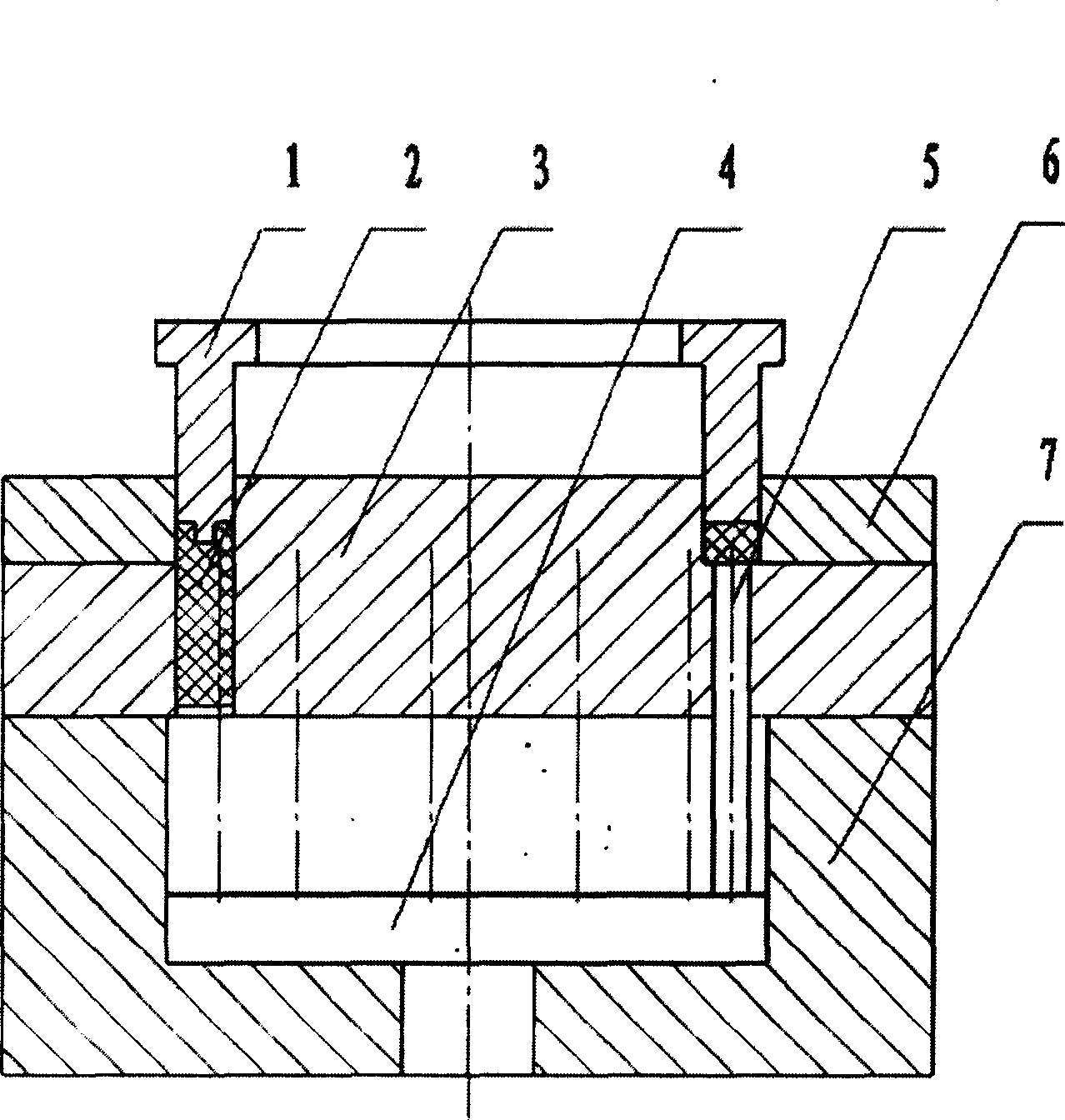

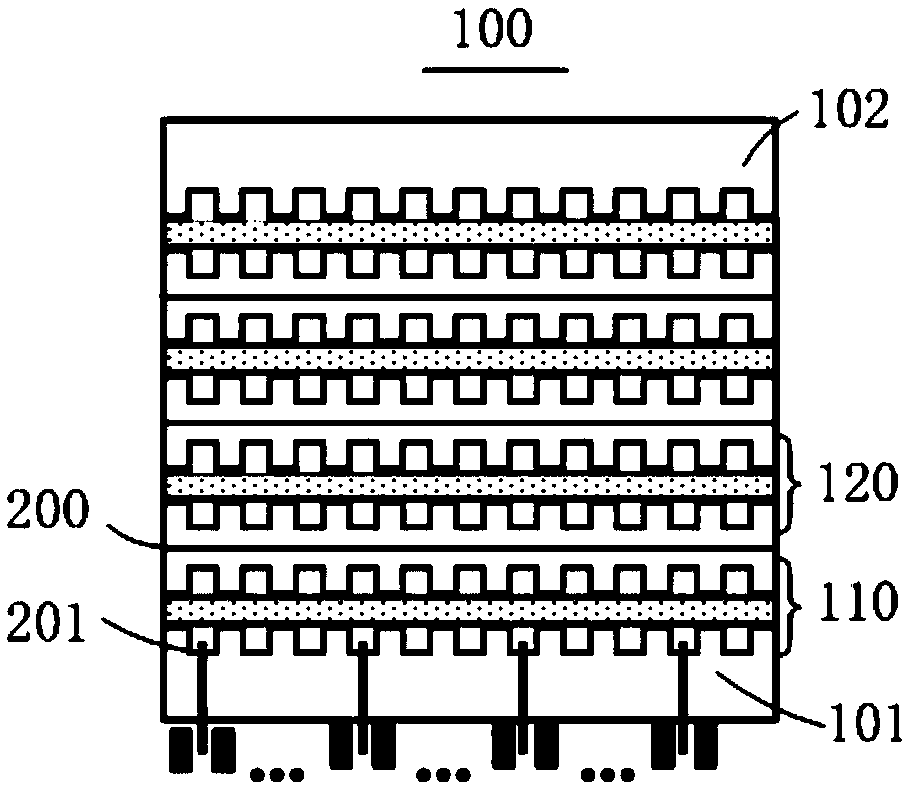

Compact type wafer lifting mechanism

ActiveCN104576471ASmall structure sizeSave spaceSemiconductor/solid-state device manufacturingConveyor partsManipulatorEngineering

The invention relates to equipment for carrying wafers during the manufacturing of semiconductors, particularly to a compact type wafer lifting mechanism for lifting the wafers when the wafers are taken by mechanical hands. The compact type wafer lifting mechanism comprises a base, a swinging air cylinder, a swinging rod, a connecting rod and a wafer holder carrying the wafers, wherein the swinging air cylinder is mounted on the base, one end of the swinging rod is connected with a rotating shaft of the swinging air cylinder, the other end of the swinging rod is connected with the wafer holder through the connecting rod, the swinging air cylinder drives the swinging rod to swing, and drives the connecting rod through the swinging rod so as to drive the wafer frame carrying the wafers to ascend and descend. According to the invention, the swinging air cylinder drives the swinging rod to rotate so as to drive the wafer holder and the wafers to ascend and descend through the connecting rod. Under the situation of the same wafer lifting distance, compared with the conventional wafer lifting mechanism driven by a straight-rod air cylinder, the compact type wafer lifting mechanism disclosed by the invention has the advantages that the structural size is relatively smaller in the wafer moving direction, the space occupied by the mechanism in the wafer moving direction can be saved, and the mechanism disclosed by the invention is beneficial to structural optimization.

Owner:SHENYANG KINGSEMI CO LTD

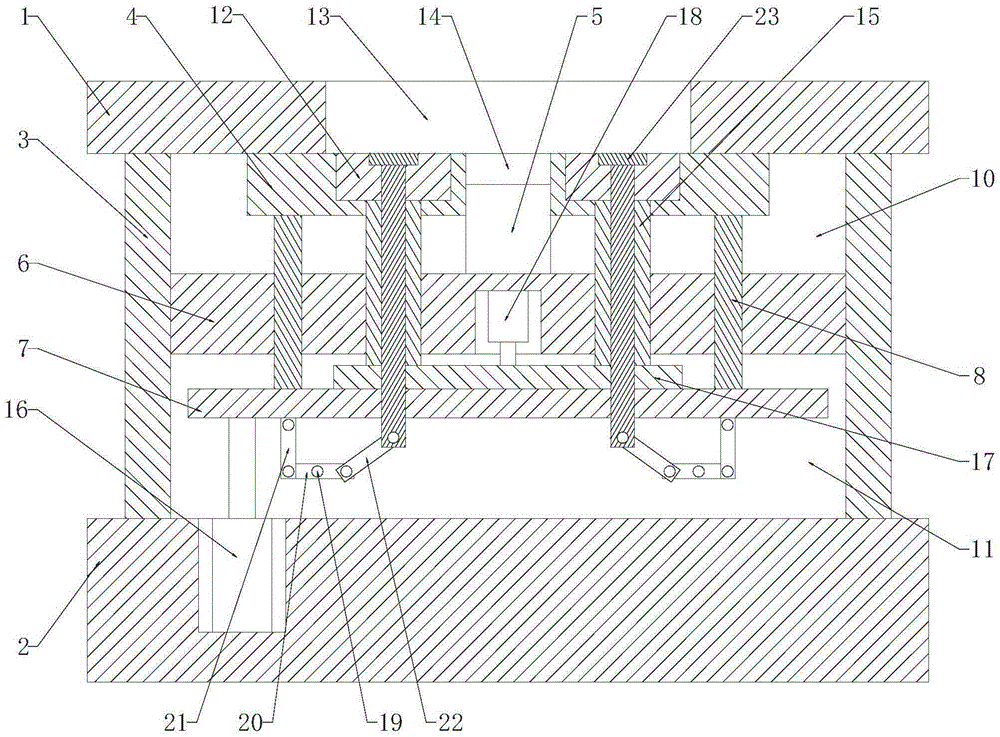

Mold for auto parts processing

The invention discloses a mold for auto parts processing. The mold for the auto parts processing comprises a male mold and a female mold which is matched with the male mold correspondingly. The male mold comprises an upper fixed seat, a lower fixed seat and a supporting ring seat. The upper fixing seat is provided with a first through opening; a first molding plate and a second molding plate are arranged in an upper chamber; a first connecting rod is fixedly connected with the lower end of the first molding plate; and a kicker pin is arranged in the first connecting rod in an up-down moving mode. A second connecting rod is fixedly connected with the lower end of the second molding plate; the male mold also comprises a first driving device which controls the first connecting rod to move up and down, a second driving device which controls the second connecting rod to move up and down and a linkage which controls the kicker pin to move on the opposite direction according moving of the second connecting rod. The injection mold for the auto parts divides demoulding into two stages, so that the occurrence of finished products breakage can be effectively avoided during demoulding. Therefore, the successful rate of demoulding is increased.

Owner:CHONGQING SHENGSHUN TECH

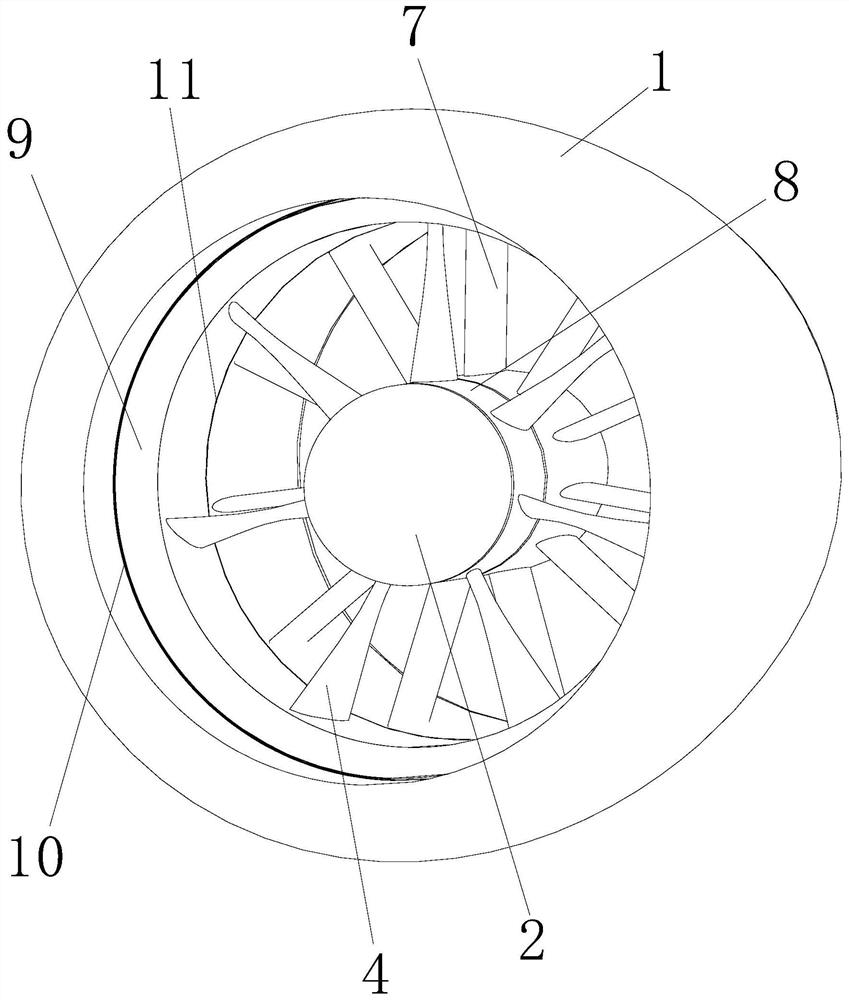

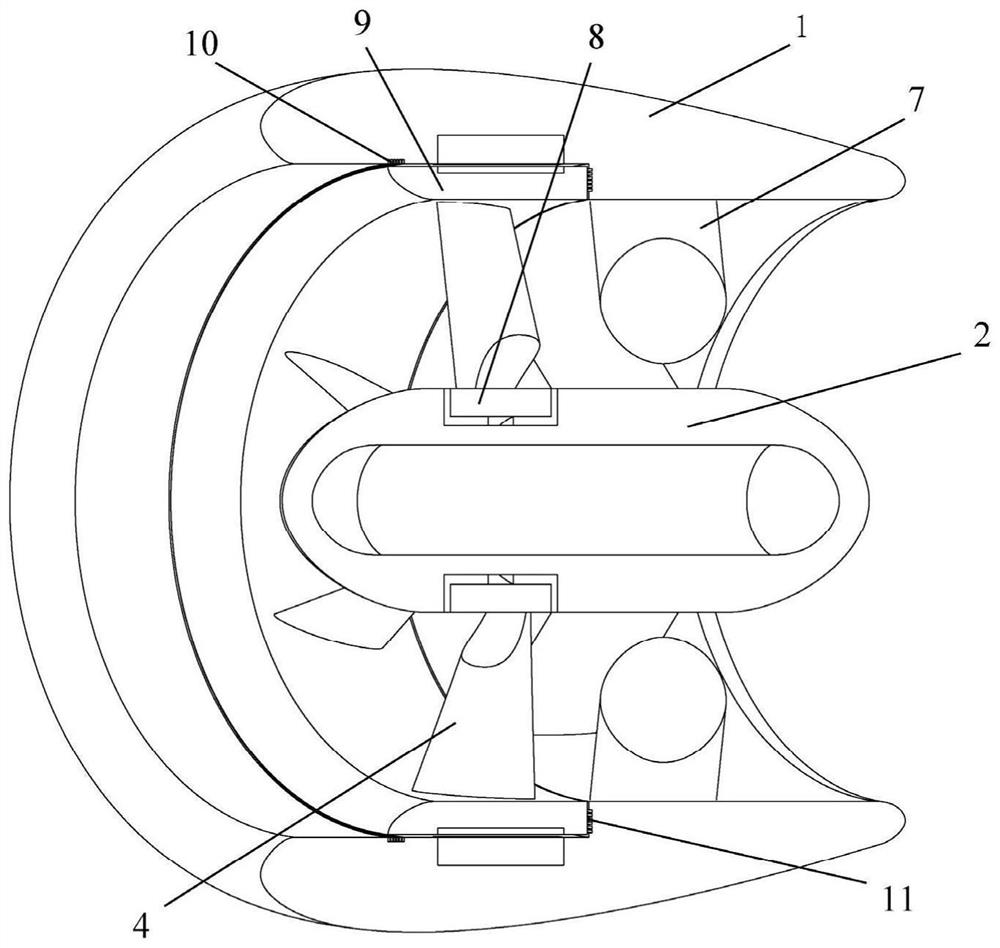

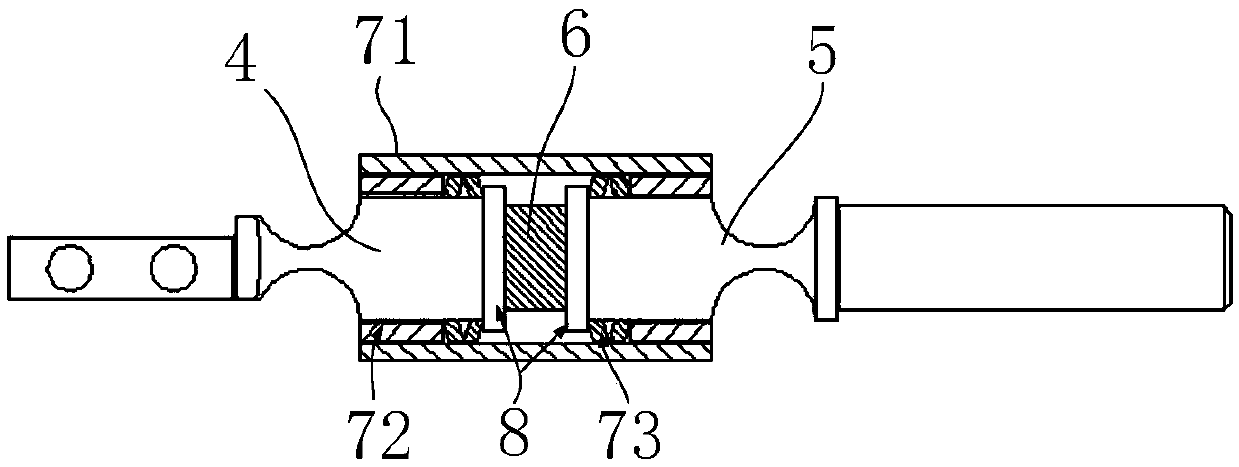

Rim driving propeller with dummy shaft structure

ActiveCN114056529ALow flow resistanceReduce radial thicknessPropulsive elementsImpellerFriction loss

The invention discloses a rim driving propeller with a dummy shaft structure, which comprises an annular guide pipe, a dummy shaft is coaxially arranged in the annular guide pipe, a bearing is coaxially and fixedly sleeved outside the dummy shaft, an impeller is coaxially and fixedly sleeved outside the bearing, and a rim motor rotor is coaxially and fixedly sleeved outside the outer edge of the impeller. The rim motor stator matching the rim motor rotor is coaxially embedded in the inner wall of the annular guide pipe, and a rear guide vane with the outer edge connected to the inner wall of the annular guide pipe is coaxially and fixedly arranged at the position, located behind the bearing, outside the dummy shaft in a sleeving mode. According to the invention, the space structure of the dummy shaft under the large hub ratio scale of the impeller is reasonably utilized, and the bearing is arranged at the hub, which means that the diameter is smaller, the linear speed is smaller during working, and the friction loss is reduced; and meanwhile, only the rim motor stator is placed in the annular guide pipe, the structural form is simpler, the radial thickness of the annular guide pipe is reduced, structural optimization of the annular guide pipe is more facilitated, and the flow resistance during working of the pump-jet propeller is reduced.

Owner:XIAN UNIV OF TECH

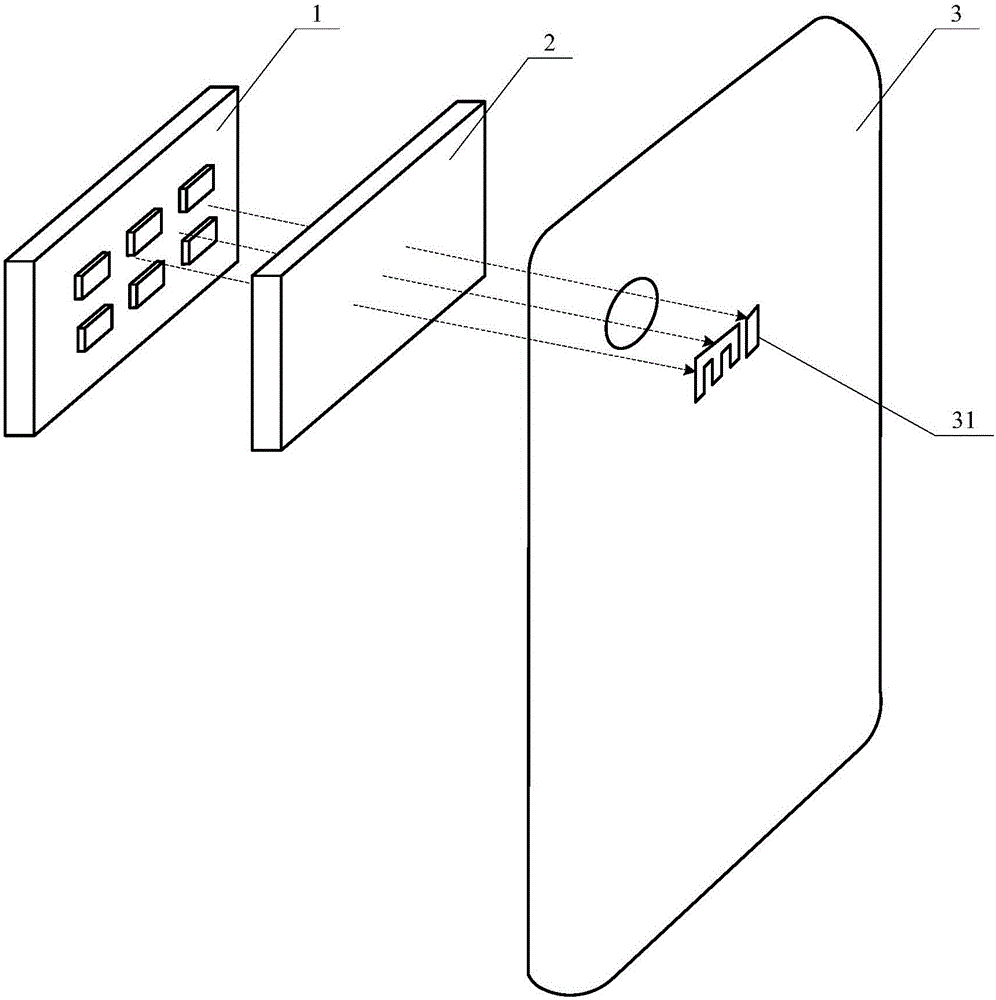

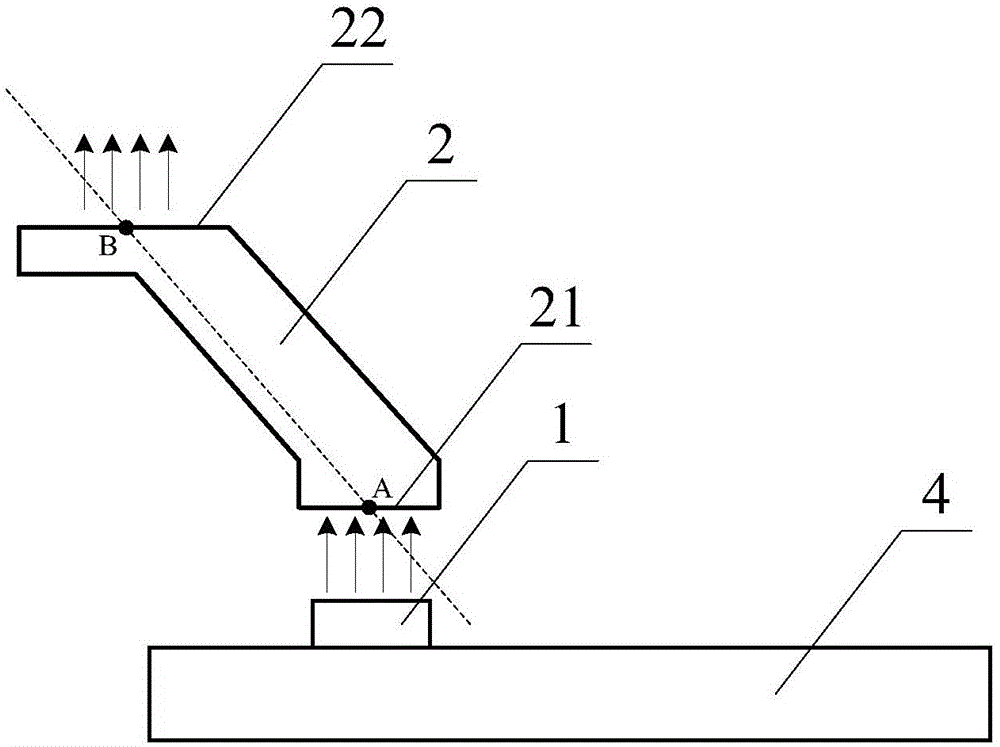

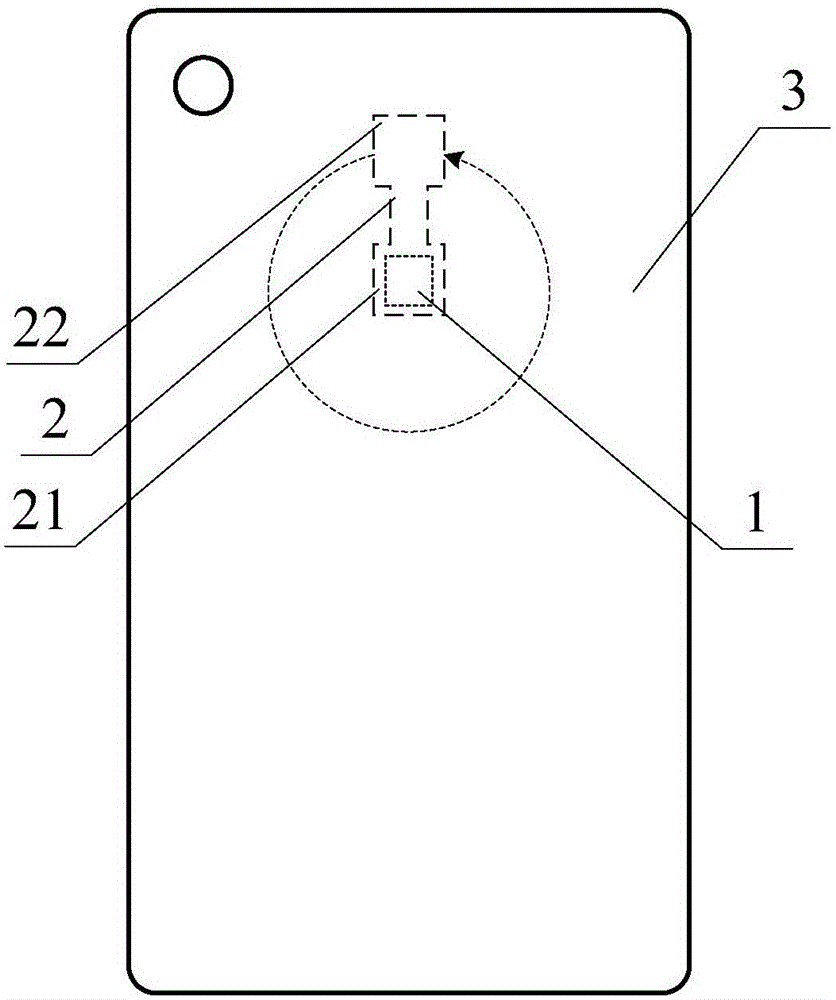

Light guide structure, indicator lamp structure and electronic device

InactiveCN105674212AReduce relevanceFacilitate structural optimizationMechanical apparatusLight guides detailsOptoelectronicsLight guide

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

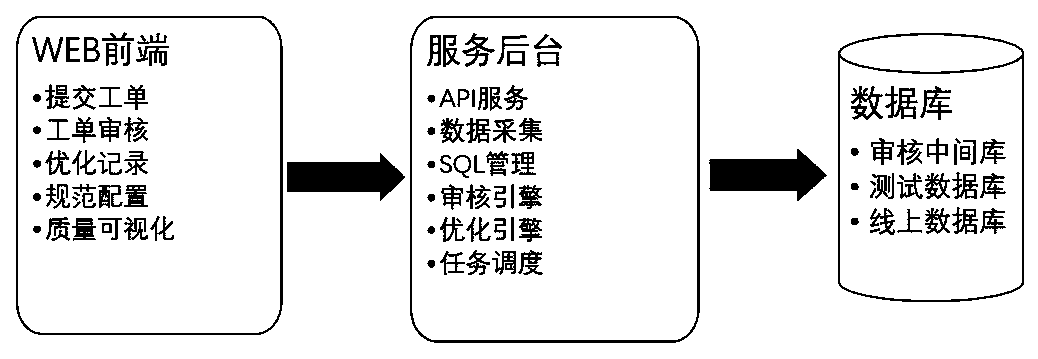

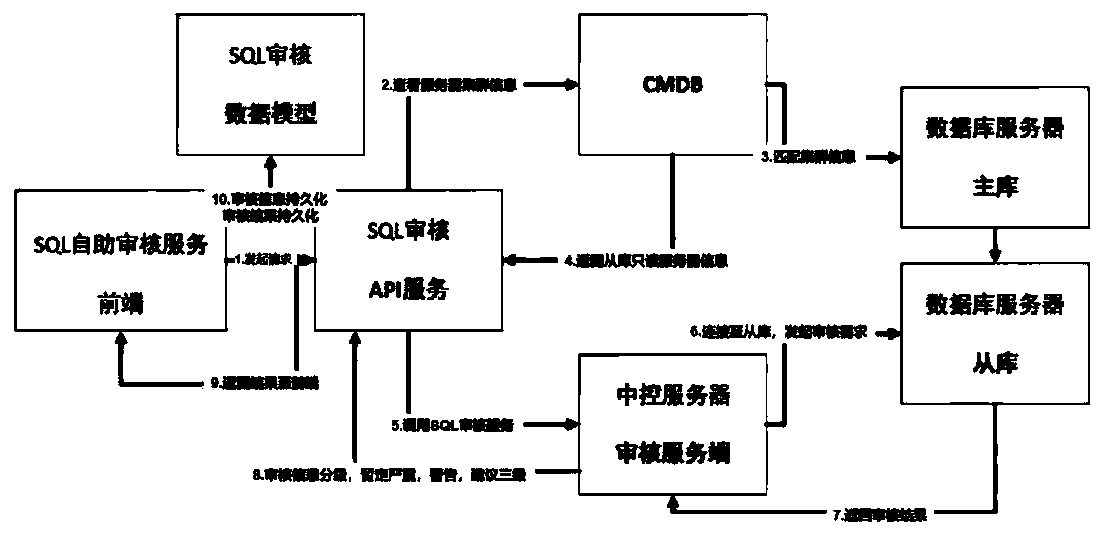

Multi-dimensional comprehensive database SQL auditing and optimizing method and system

ActiveCN111078675AExpedited reviewPromote structural optimizationSpecial data processing applicationsDatabase design/maintainanceSynthetic dataData acquisition

The invention relates to the technical field of SQL databases, in particular to a multi-dimensional comprehensive database SQL auditing and optimizing method and system. The system comprises a WEB front end, a service background and a database, the WEB front end comprises a work order submitting module, a work order auditing module, an optimization recording module, a standard configuration moduleand a quality visualization module. The service background comprises an API service module, a data acquisition module, an SQL management module, an auditing engine module, an optimization engine module and a task scheduling module. The database comprises an audit intermediate library module, a test database module and an online database module, the SQL audit speed, the database structure optimization speed and the SQL optimization speed can be greatly increased, the daily work pressure of database DBA is reduced, and the influence of SQL performance hidden danger on the online environment iseffectively prevented.

Owner:绿城科技产业服务集团有限公司

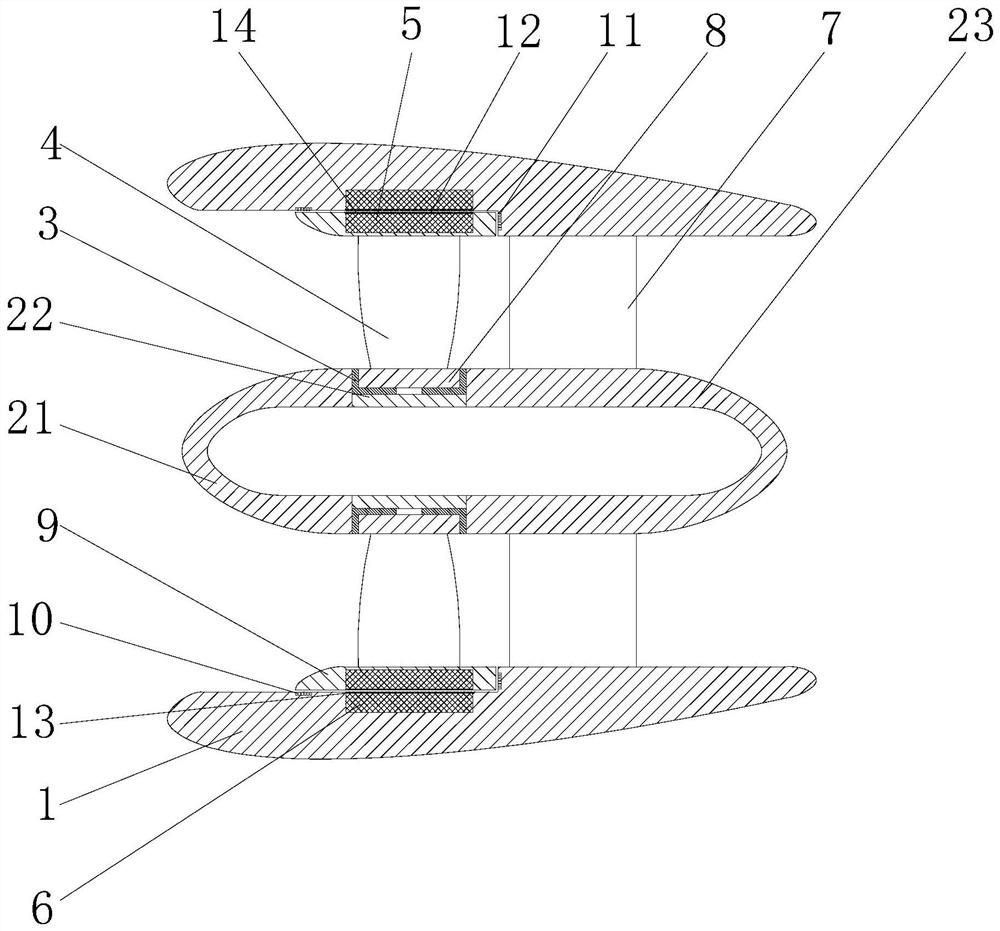

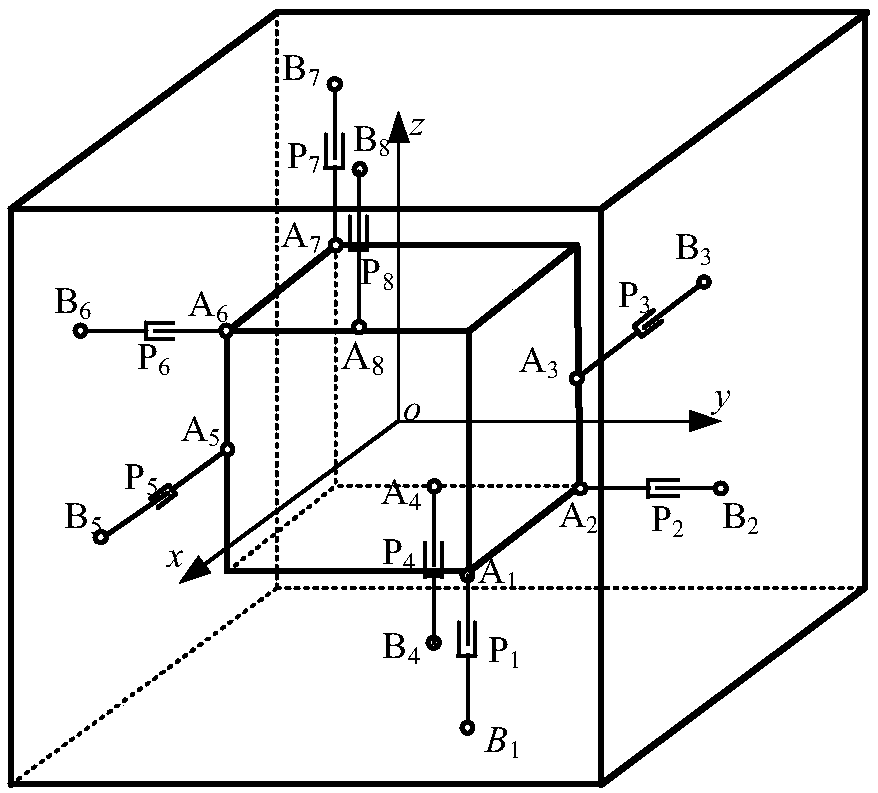

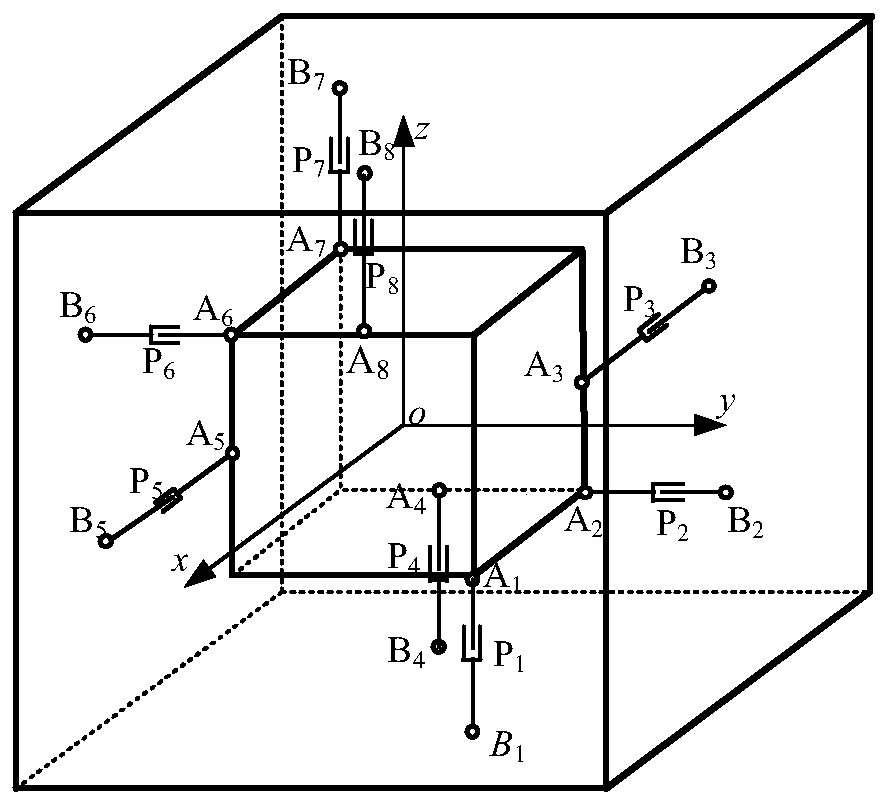

Pre-tightened parallel six-dimensionality acceleration sensor and measuring and sensitivity analyzing method thereof

InactiveCN108802427ASimple structureIncrease stiffnessAcceleration measurement using interia forcesTesting/calibration of speed/acceleration/shock measurement devicesProblem solveMeasurement precision

The invention discloses a pre-tightened parallel six-dimensionality acceleration sensor and a measuring and sensitivity analyzing method thereof. An eight-branch-chain parallel mechanism is adopted asan elastic body structure of the sensor, so that the sensor has higher rigidity and higher load bearing capacity; pre-tightening force can be applied on piezoelectric ceramic through a pre-tighteningdevice, so that after pre-tightening, the sensor can effectively avoid output signal distortion of the piezoelectric ceramic, and the sensor has higher measuring accuracy. The measuring method can realize real-time measuring of six-dimensionality acceleration by only compiling a program in a computer in advance. By the sensitivity analyzing method, a force coordination equation is established bydigging an inherent constraint relation in a sensor parallel mechanism, statically indeterminate solving of a sensitivity model of the sensor is converted into statically determinate problem solving,then an analytical expression of sensitivity of the sensor is acquired through derivation, so that theoretical guidance is provided for structural optimization design of subsequent sensors.

Owner:NANJING FORESTRY UNIV

High-magnesium composite sinter and production method thereof

The invention relates to high-magnesium composite sinter and a production method thereof. A high-magnesium fluxing agent and other raw materials are prepared, optimized and then sintered in a sinter bed, so that the problems that in terms of existing high-magnesium sinter production, resource utilization and mineral generation are unreasonable, the yield is low, the strength is low, the return mine rate is high, and the solid fuel consumption is high are solved. The high-magnesium composite sinter is formed by crushing and mixing sinter of upper and lower layer structures. With composite calcium ferrite as the main binder phase, the upper layer of sinter is formed by sintering a material A, wherein MgO accounts for not greater than 1.8%, and Al2O3 accounts for not greater than 2.0%; and the lower layer of sinter is formed by sintering a material B, and the content of MgO of the lower layer of sinter is greater than that of the MgO of the upper layer of sinter. The material A comprises72-90% of iron-containing mineral powder raw materials, 7-20% of a low-magnesium fluxing agent and 3-8% of a solid fuel; and the material B comprises 0-90% of sinter, 0-70% of sintering return mine and 10-100% of a high-magnesium fluxing agent. The high-magnesium composite sinter is good in comprehensive metallurgical performance, the blast furnace burden structure can be optimized easily, and theslag mobility and desulfuration and dealkalization effects can be improved.

Owner:胡明意

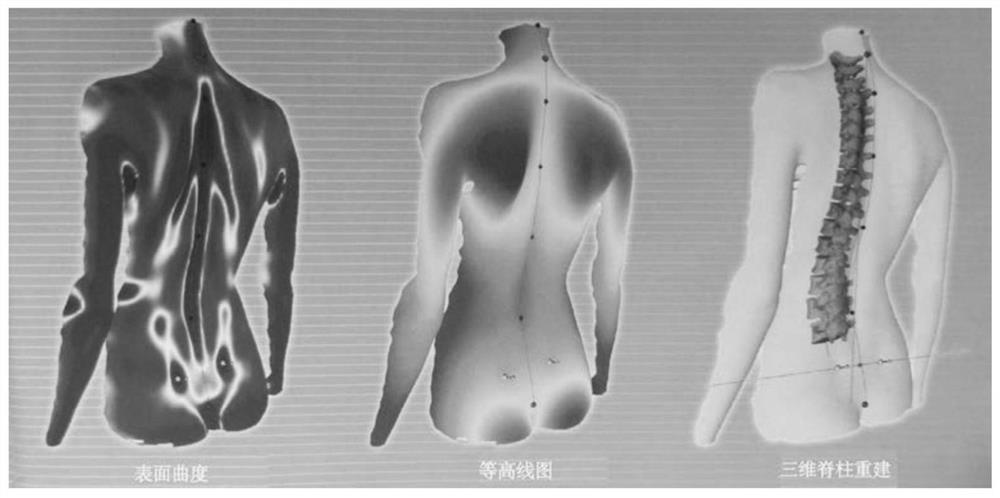

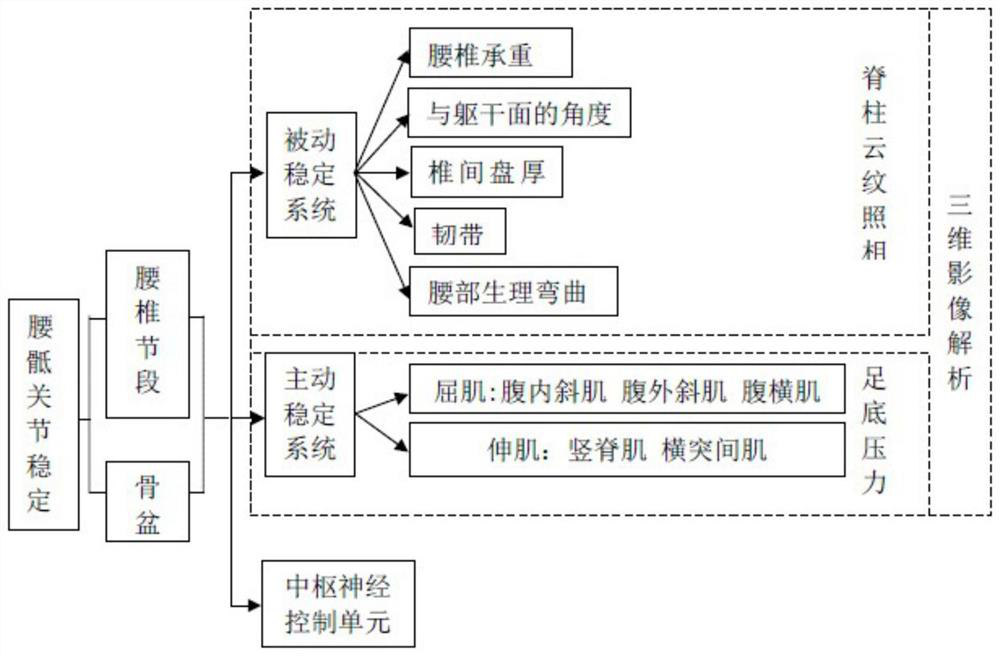

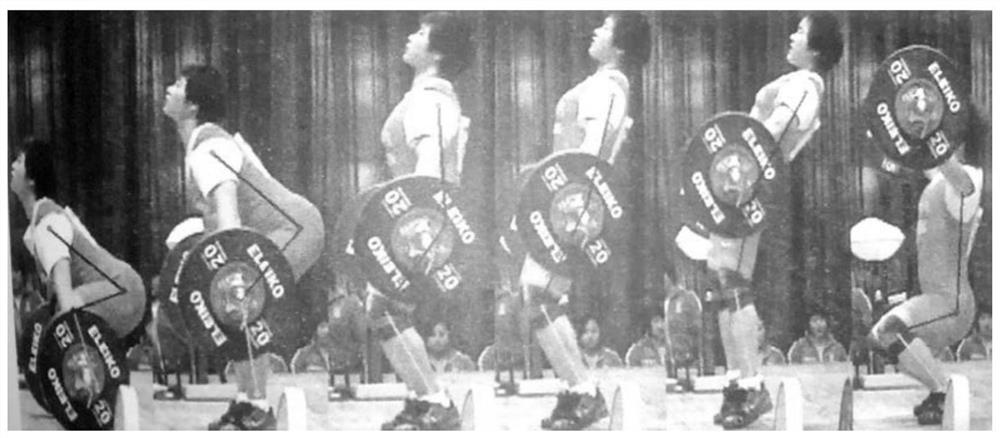

Female weightlifting athlete lumbosacral joint biomechanical analysis method based on numerical simulation

PendingCN112489762AGuaranteed universal applicabilityGuaranteed accuracyMedical simulationPhysical therapies and activitiesAnatomical structuresSpinal column

The invention relates to a female weightlifting athlete lumbosacral joint biomechanical analysis method based on numerical simulation; the method comprises the steps: selecting a plurality of female weightlifting athletes as to-be-tested athletes, and screening a target athlete according to spine form data; monitoring in the whole weightlifting process of the target athlete, and establishing a weightlifting action model; conducting static spine CT scanning on the target athlete, and establishing a finite element model of the lumbosacral joint according to a scanning result, finally performingnumerical simulation analysis to generate an analysis result. Modeling and numerical simulation analysis are specially carried out on lumbosacral joints of female weightlifting athletes to obtain stress change conditions of anatomical structures such as joints, muscles and soft tissues in the weightlifting movement process, so that structural optimization is carried out on weightlifting actions ofthe female weightlifting athletes, the competitive ability is improved, movement injuries are avoided, the safety of the female weightlifting athletes is improved, and guidance opinions are providedfor exercise rehabilitation.

Owner:宋雅伟

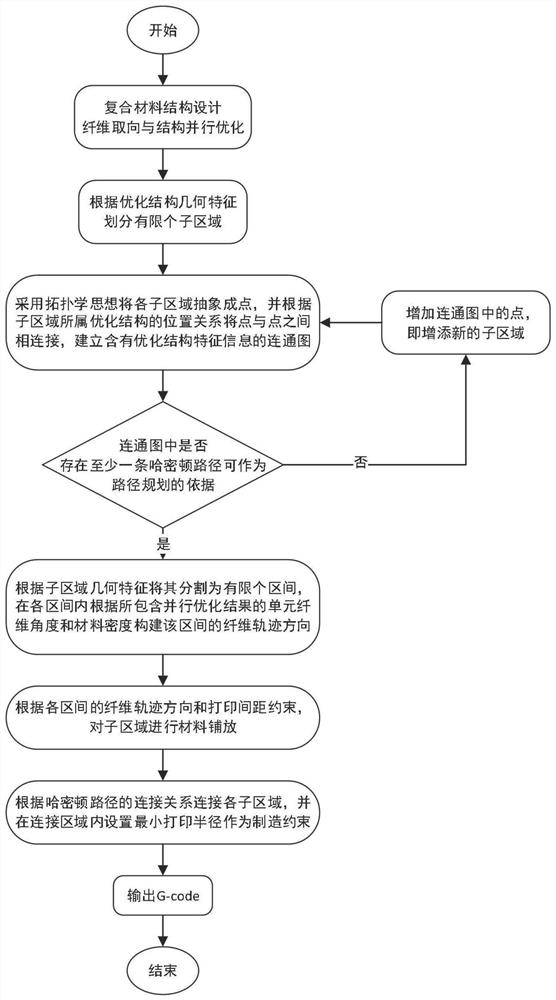

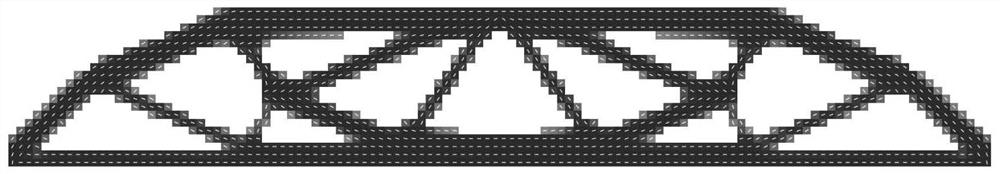

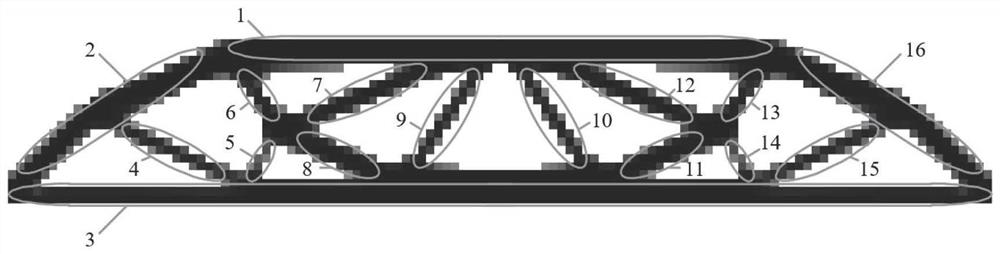

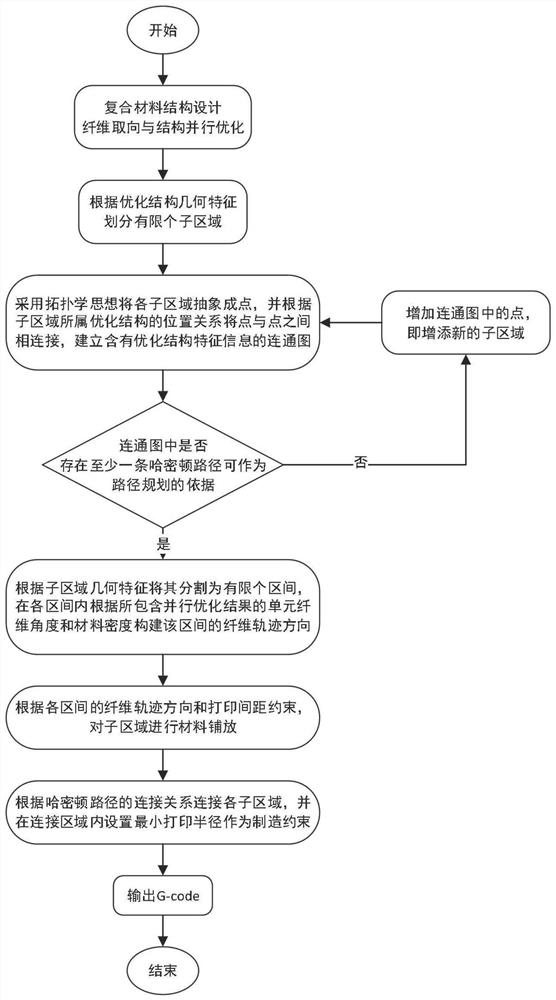

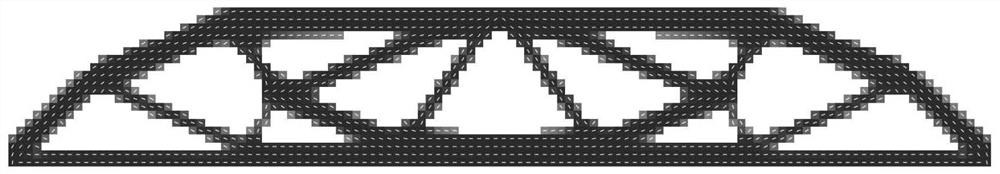

Continuous fiber 3D printing path planning method capable of achieving fiber orientation and structure parallel optimization

ActiveCN113442441AGive full play to the advantages of mechanical propertiesImprove printing efficiencyAdditive manufacturing apparatusDesign optimisation/simulationFiber-reinforced compositeFiber orientation

The invention discloses a continuous fiber 3D printing path planning method capable of achieving fiber orientation and structure parallel optimization. The method comprises the steps that a fiber orientation and composite material structure parallel optimization model is constructed, material density and a fiber angle serve as design variables, and the material density and the fiber angle are filtered to obtain a fiber orientation and composite material structure parallel optimization structure; a complex optimization structure is dispersed into a structure in a simple geometrical shape, each sub-region is abstracted into points by adopting a topology thought, the points are connected according to a position relation of an optimization structure to which the sub-regions belong, a connected graph containing optimization structure feature information is formed, and path planning classified into a Hamiltonian path for searching in the connected graph; a material density value is taken as a weight factor of the fiber angle to obtain a fiber track direction in each sub-region of the optimized structure; and printing paths of the sub-regions are connected in sequence according to a Hamiltonian path to generate a printing code. The anisotropic mechanical property of a continuous fiber reinforced composite material is exerted, and the requirement of the 3D printing process is met.

Owner:XI AN JIAOTONG UNIV

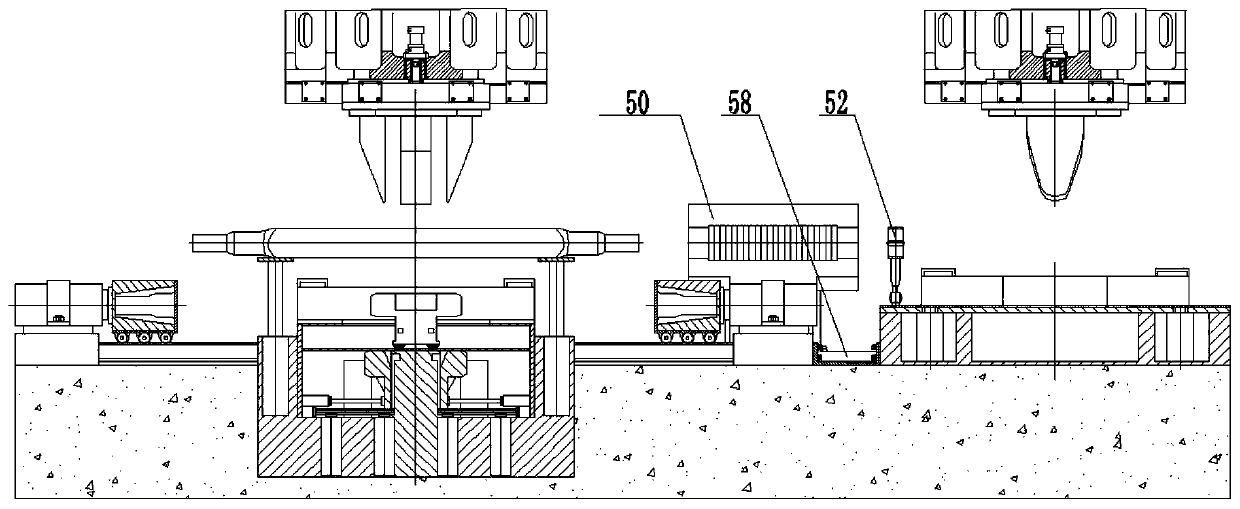

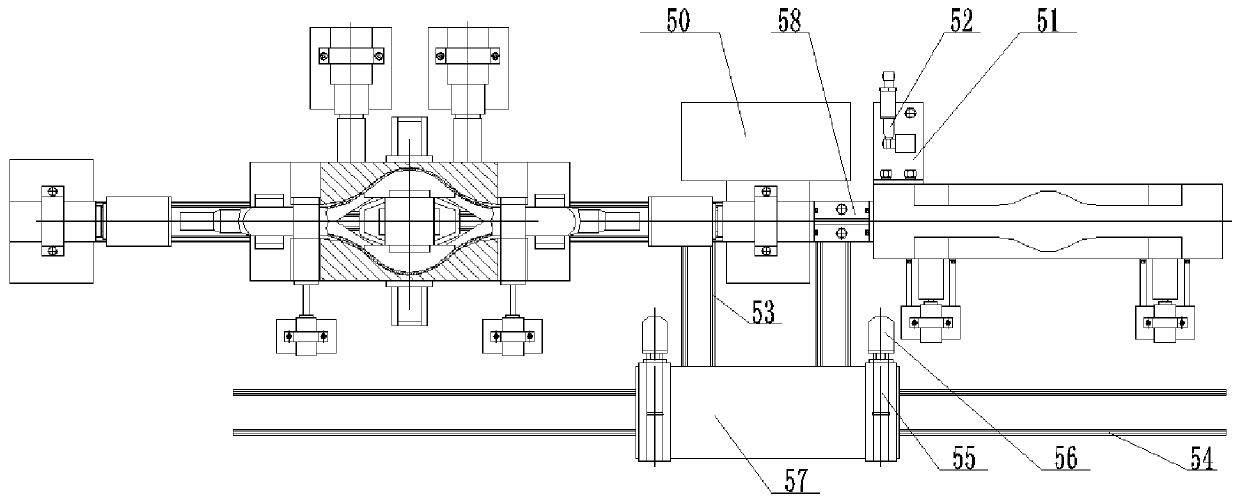

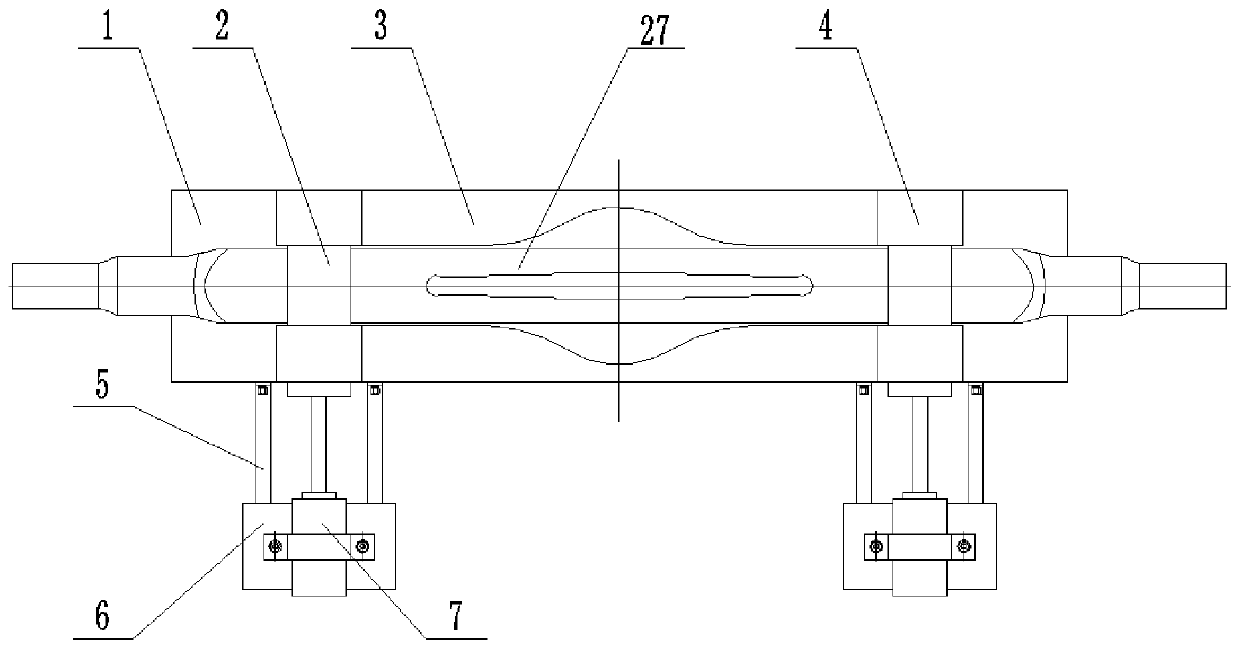

Forming equipment of medium-thick-wall integral automobile drive axle shell axle arch

PendingCN110038969AReasonable structureSmooth connectionShaping toolsMetal working apparatusEngineeringThick wall

The invention discloses a forming equipment of a medium-thick-wall integral automobile drive axle shell axle arch. The forming equipment comprises a wedge pre-expanding forming mechanism, a core moldexpanding forming mechanism, a semi-closed heating furnace, an industrial robot mechanism and a transportation mechanism, the core mold expanding forming mechanism is positioned on the left side of the wedge pre-expanding forming mechanism, the core mold expanding forming mechanism is connected with the wedge pre-expanding forming mechanism through a connecting seat, the side, close to the wedge pre-expanding forming mechanism, of the core mold expanding forming mechanism is provided with the semi-closed heating furnace through a semi-closed heating furnace support, the side, close to the wedge pre-expanding forming mechanism, of the semi-closed heating furnace is provided with the industrial robot mechanism, and the transportation mechanism is arranged on the other side of the core mold expanding and forming mechanism and the other side of the wedge pre-expanding forming mechanism. The forming equipment can obviously improve the stress state of the expanding region, so that the bending transition position of the medium-thick-wall axle shell axle arch and the straight arm is better formed, and the shape and size precision of the axle arch is greatly improved.

Owner:NORTH CHINA INST OF SCI & TECH

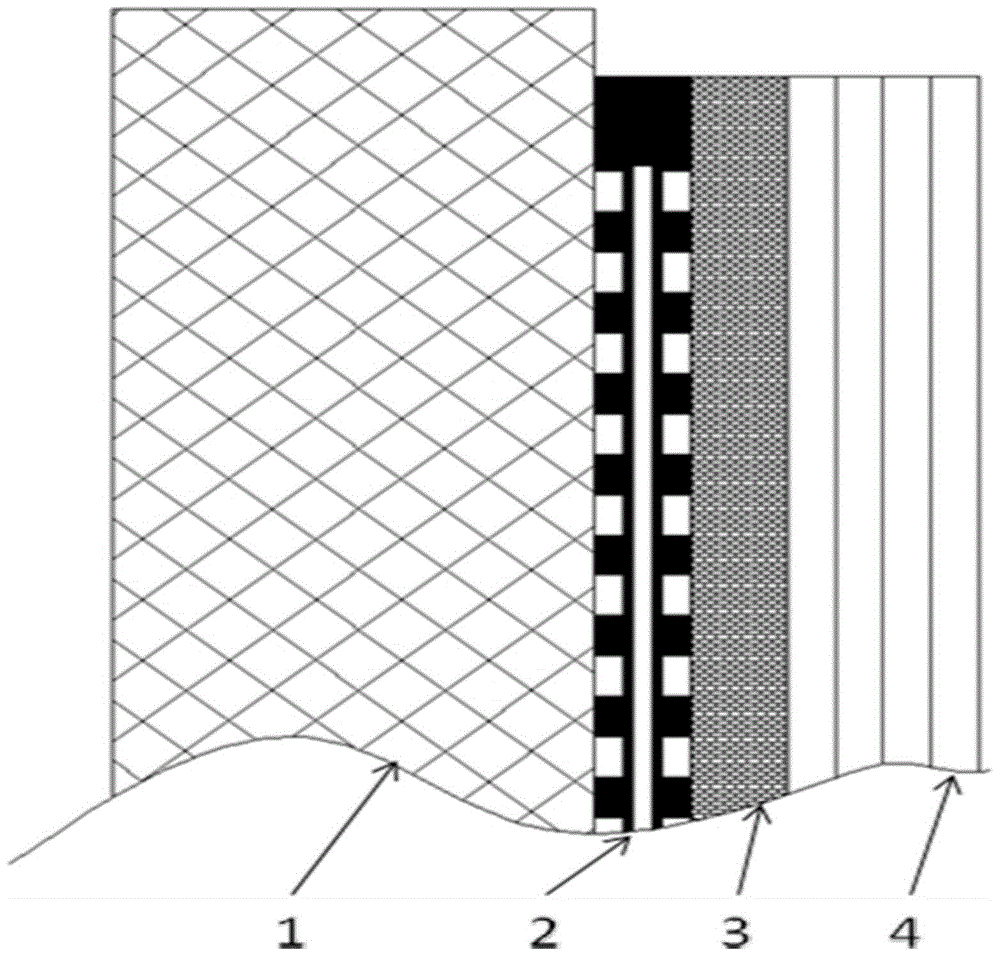

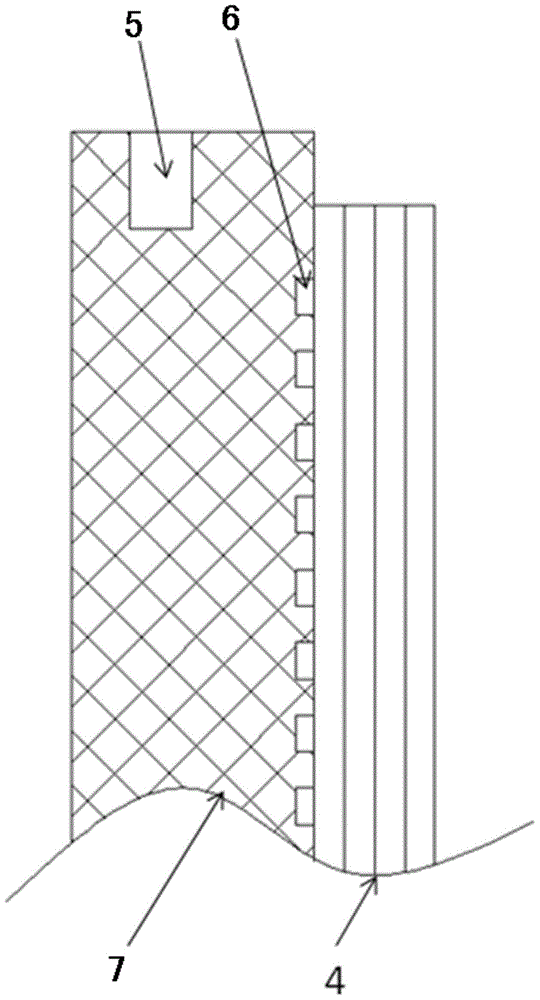

A Simplified Fuel Cell Structure

ActiveCN103633346BReduce volumeReduce weightFuel cells groupingFuel cell detailsFuel cellsConductive materials

A simplified fuel cell structure comprises integrated end plates and a multi-section monocell; a collector plate and a fake cell are arranged between the multi-section monocell and the two integrated end plates; the integrated end plates are made of a conductive material; one surface, which is not in contact with the multi-section monocell, of each end plate made of the conductive material is subjected to insulation treatment, and a hydrogen flow passage, an air flow passage and a cooling liquid flow passage are processed on one surface, in contact with the multi-section monocell, of each end plate and are isolated through sealant lines; a connector for line outgoing of a positive / negative pole outgoing line of a galvanic pile is processed on a side surface of each end plate. The simplified fuel cell structure has the benefits that the integrated end plates integrate the functions of the end plates, the collector plate and the fake cell, the size and the weight of the galvanic pile are reduced, and the volume ratio power density and the weight ratio power density of the galvanic pile are improved helpfully; the number of galvanic pile components is reduced, the galvanic pile structure is simplified, the reliability is improved, and the assembly and maintenance efficiency of the galvanic pile is improved; the function of edge effect of the 'fake cell' of the galvanic pile can be adjusted only by changing the structure of a fluid field of the end plate, so that structural improvement is facilitated.

Owner:SUNRISE POWER CO LTD

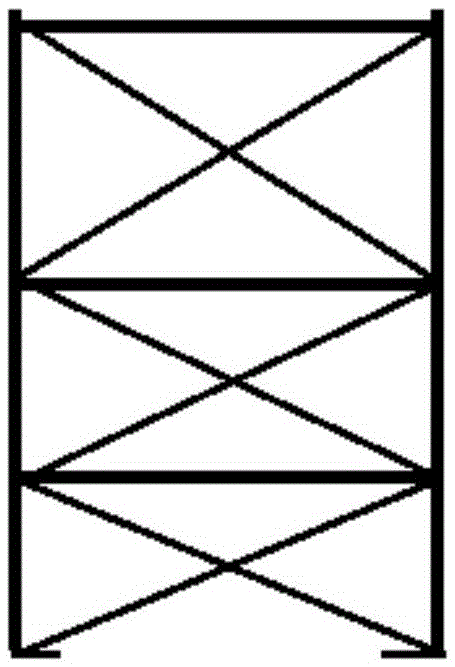

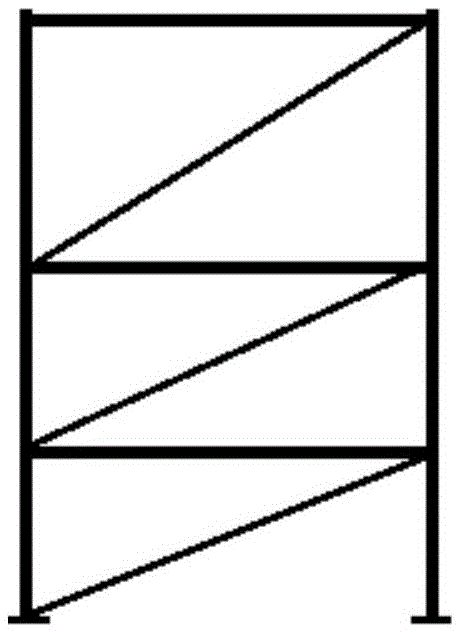

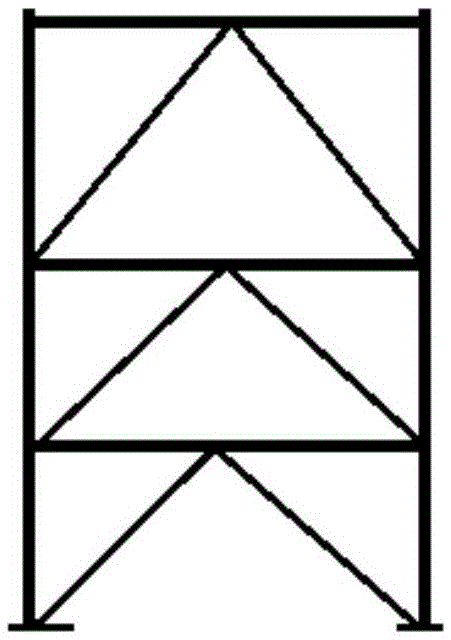

Buckling-restrained brace arranged in cross mode, building with buckling-restrained brace and application

InactiveCN105625594AReduce material usageSave steelShock proofingBuckling-restrained braceEngineering

The invention relates to a buckling-restrained brace arranged in a cross mode, a building with the buckling-restrained brace and application. The buckling-restrained brace arranged in the cross mode mainly comprises a first stress component and a second stress component. The first stress component and the second stress component are each provided with a stress main pipe. The middle section of each stress main pipe is provided with a protruding part. The inner side of the protruding part of each stress main pipe is fixedly connected with an inner restraining casing pipe, and the outer side of the protruding part of each stress main pipe is fixedly connected with an outer restraining casing pipe. The protruding parts of the two stress main pipes are fixedly connected to form an X-shaped structure. According to the buckling-restrained brace arranged in the cross mode, the building with the buckling-restrained brace and the application, the cross-sectional area and the length of the protruding parts of the stress main pipes can be adjusted, the ratio of the strength to the stiffness of the bracing components is changed conveniently, and structure optimization is achieved.

Owner:SHANDONG UNIV

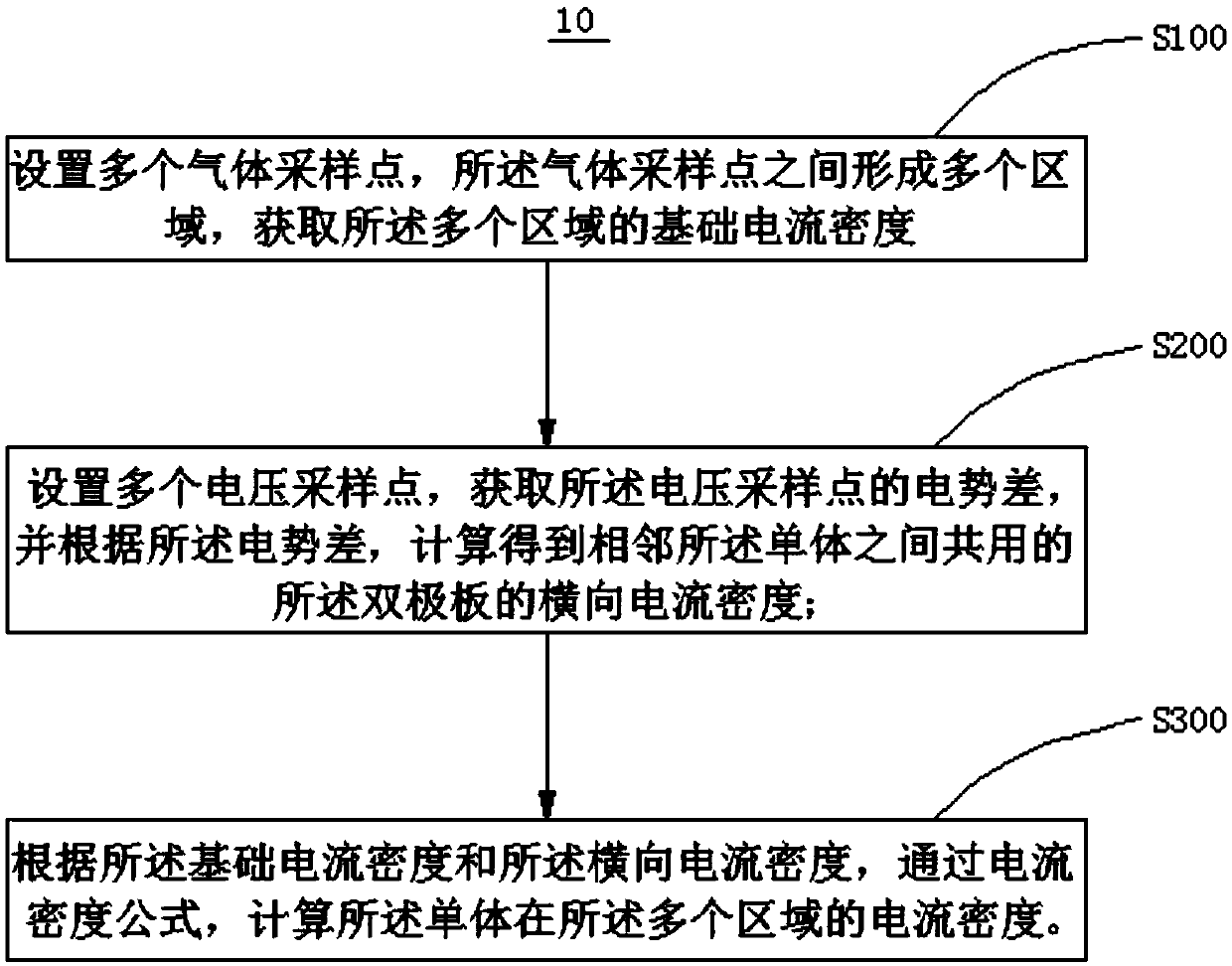

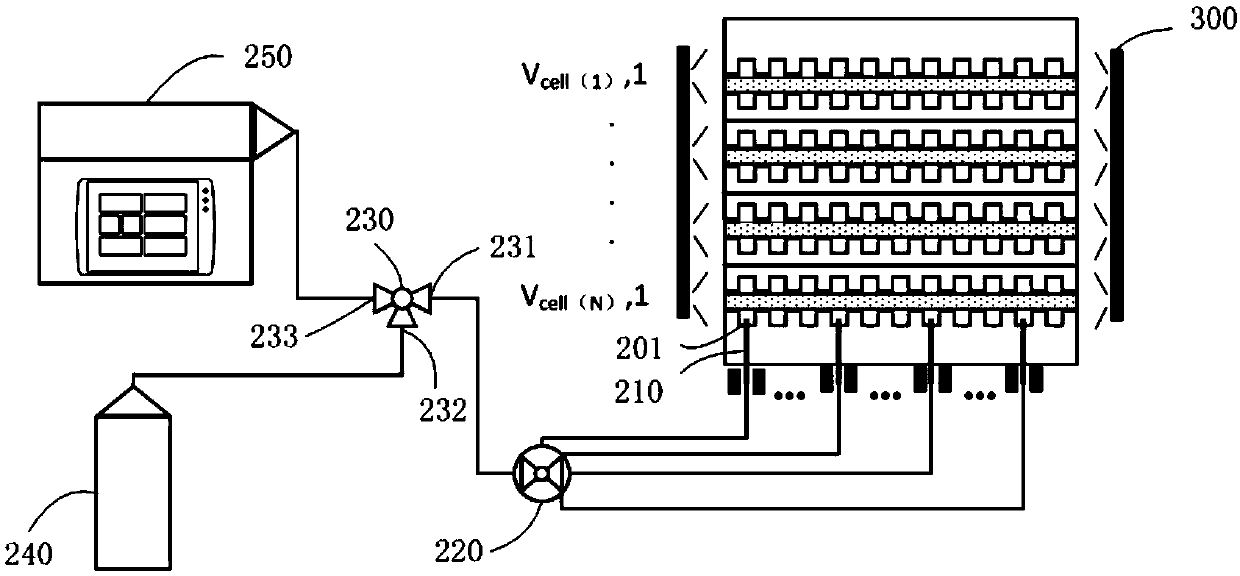

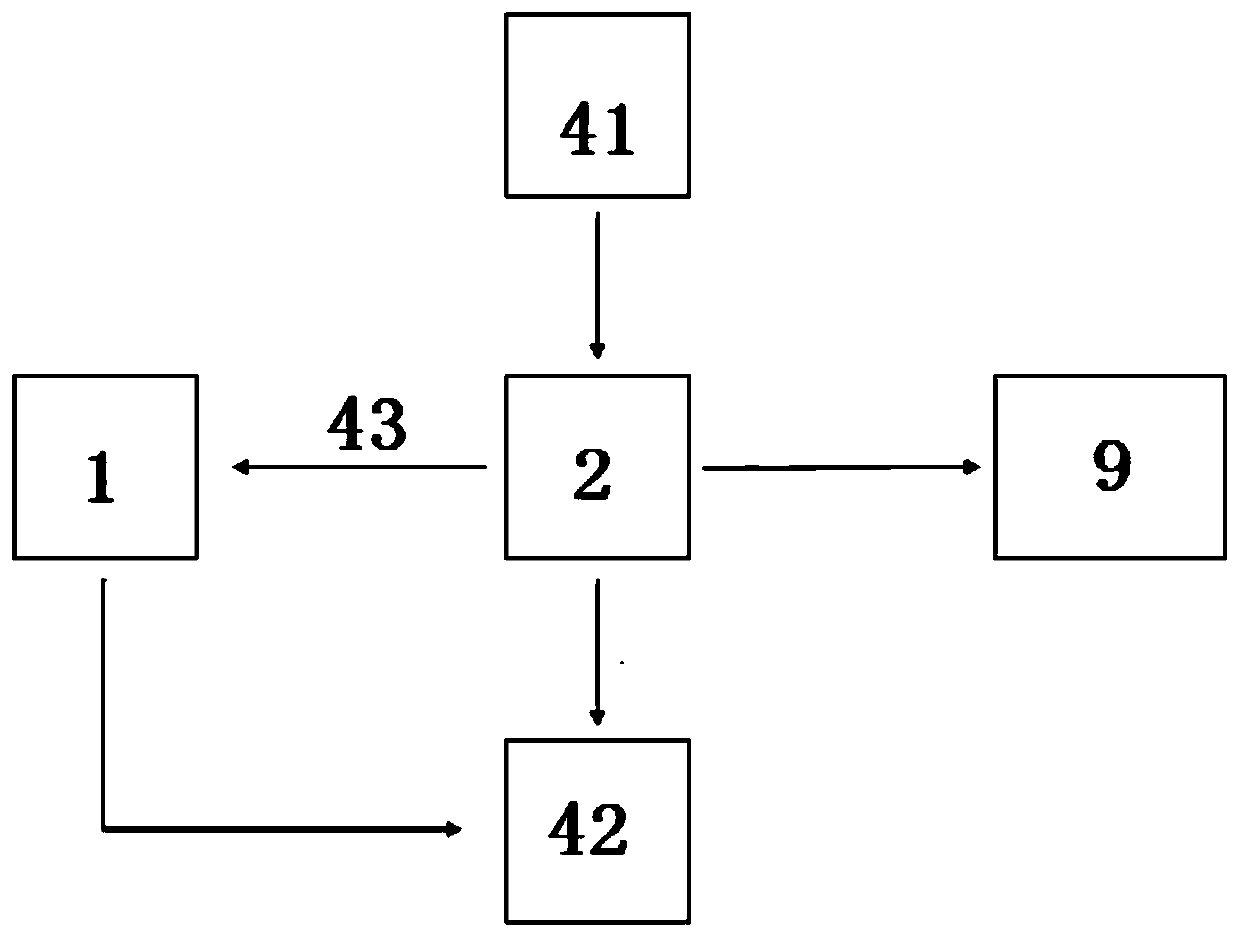

Multipoint analysis method for fuel cell

ActiveCN109669135APromote structural optimizationImprove accuracyElectrical testingPower flowFuel cells

The invention relates to a multipoint analysis method for a fuel cell. The multipoint analysis method for the fuel cell comprises the following steps: acquiring base current density of a first singlecell connected with a fuel cell cathode by a gas sampling method; then acquiring potential of a second single cell to obtain transverse current density of a bipolar plate where an anode of a second single cell is positioned; and finally, calculating current density of the second single cell in each second area according to the base current density and the transverse current density. According to the multipoint analysis method for the fuel cell, the current density distribution condition of each single cell can be obtained under the condition of not damaging an internal structure of the fuel cell. The performance condition of each single cell is judged according to the current density distribution condition of each single cell. The multipoint analysis method for the fuel cell is favorable for improving the accuracy of design evaluation of a fuel cell stack and further promotes structure optimization of the fuel cell.

Owner:TSINGHUA UNIV +1

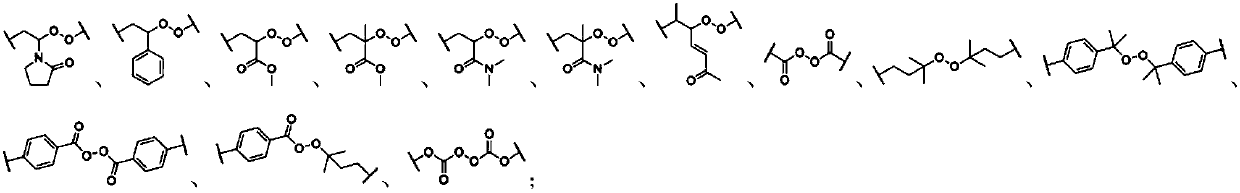

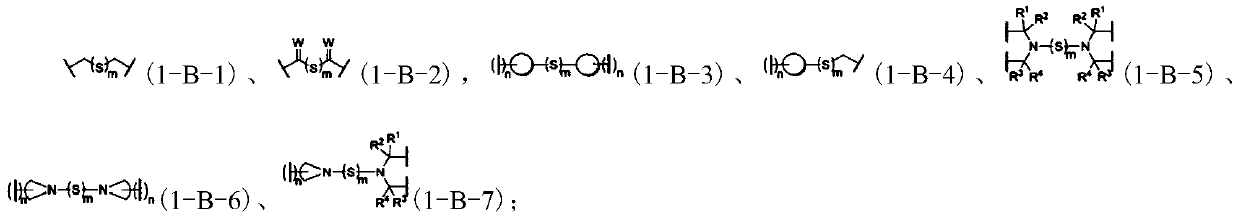

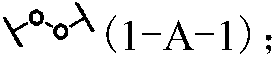

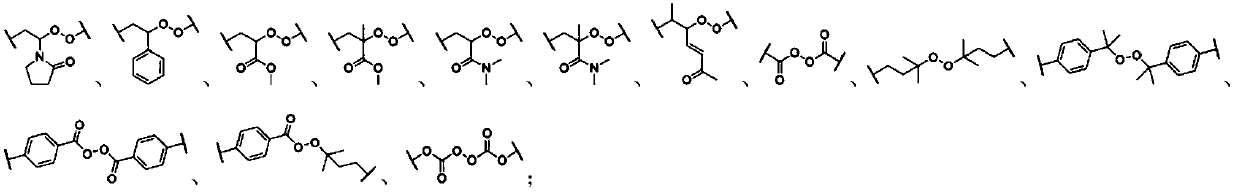

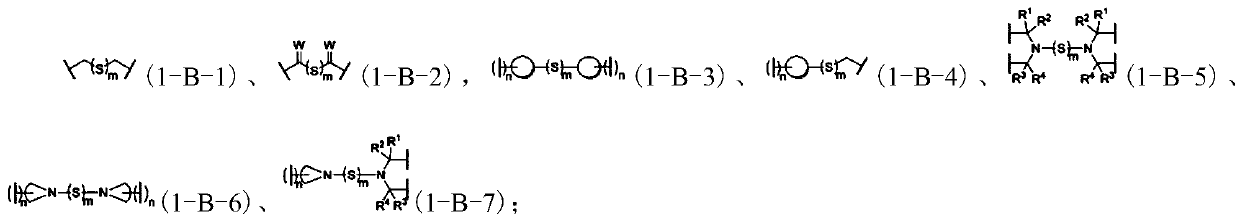

Force-induced responsive polymer with single hybrid network structure

PendingCN111378181AImprove structural stabilityImprove mechanical propertiesPolymer scienceRepair material

The invention discloses a force-induced responsive polymer with a single hybrid network structure. Only one cross-linked network is contained, non-dynamic covalent bond covalent cross-linking and non-covalent cross-linking are contained at the same time, the cross-linking degree of the non-dynamic covalent bond covalent cross-linking is above a gel point, and the cross-linked network contains at least two force-sensitive groups; under the action of mechanical force, the force-sensitive groups are subjected to chemical and / or physical changes, and force-induced response is achieved. The singlehybrid network structure provides good structural stability and mechanical properties for the polymer; based on the force-induced responsiveness of the force-sensitive groups, the detection, monitoring and warning effects on the stress, deformation, damage and failure processes are obtained; the non-covalent dynamics of the non-covalent cross-linking may provide self-healing performance. The force-induced responsive polymer can be applied to a stress sensing material, a self-repairing material, a tough material, a shape memory material, a toy material, a functional coating material, an intelligent sensor, a binding material, a plugging material and the like.

Owner:厦门天策材料科技有限公司

Force-induced responsive cross-linked polymer with multiple networks

PendingCN111378171AImprove structural stabilityImprove mechanical propertiesPolymer scienceRepair material

The invention discloses a force-induced responsive cross-linked polymer with multiple networks. The force-induced responsive cross-linked polymer comprises at least two cross-linked networks and a force-sensitive group, wherein the cross-linking degree of non-dynamic covalent bond covalent cross-linking in at least one cross-linked network is above the gel point; under the action of mechanical force, the force-sensitive group is subjected to chemical and / or physical changes, and force-induced response is achieved. The multi-network structure provides good structural stability and mechanical properties for the polymer; based on the force-induced responsiveness of the force-sensitive group, detection, monitoring and warning effects can be provided for the stress, deformation, structural damage and failure processes of the polymer. The force-induced responsive polymer contains at least two force-sensitive groups, so that rich force-responsive properties can be obtained. The force-inducedresponsive cross-linked polymer can be applied to a stress sensing material, a self-repairing material, a tough material, a shape memory material, a toy material, a functional coating material, an intelligent sensor, a binding material, a plugging material and the like.

Owner:厦门天策材料科技有限公司

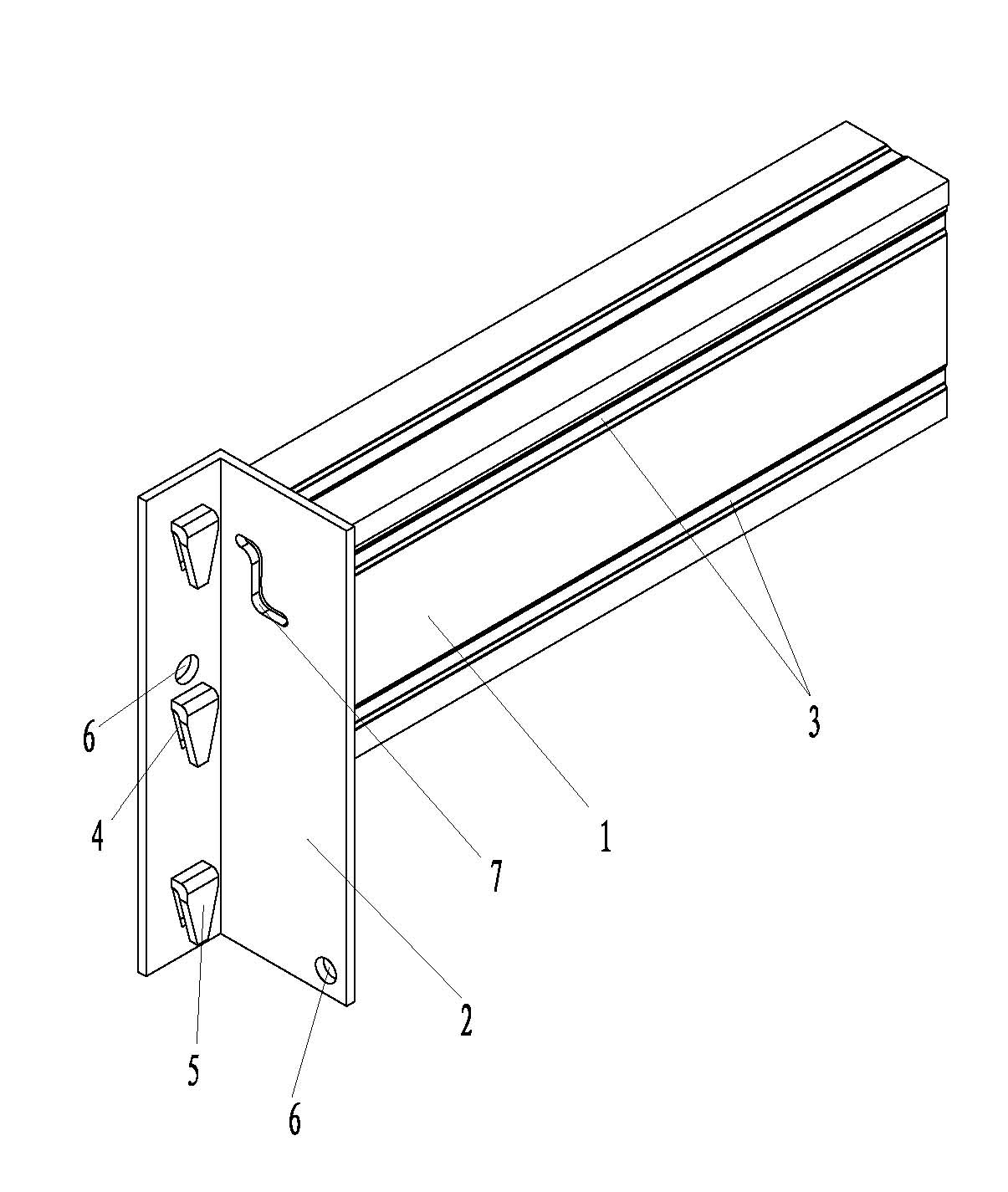

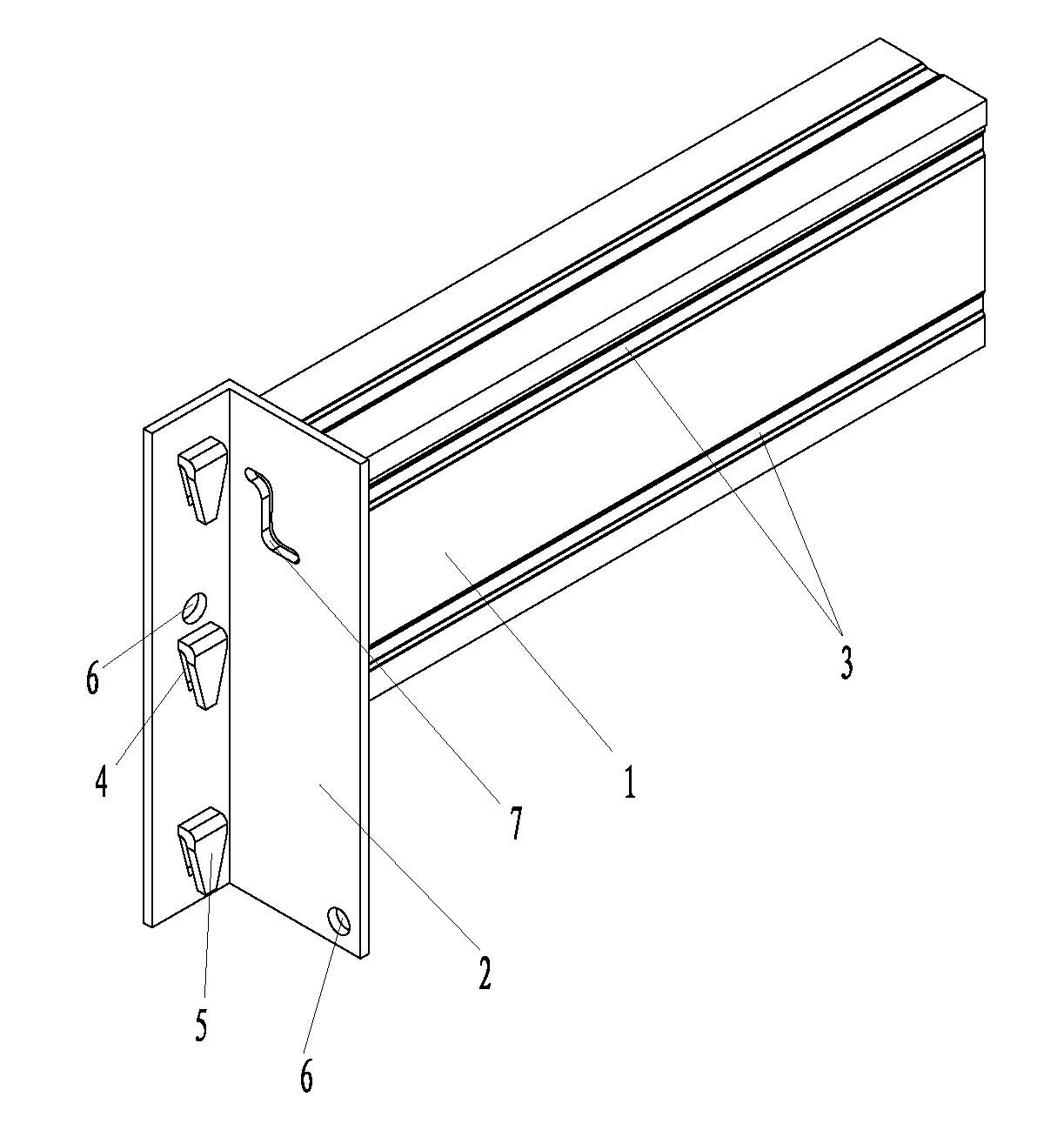

Thickened hanging piece for crossbeam

InactiveCN102090815AIncrease bite forceEnsure that the force reaches the standardShow shelvesShow hangersStress conditionsEngineering

The invention relates to the technical field of goods shelf connection, in particular to a thickened hanging piece for a crossbeam. The hanging piece comprises a fastening plate, wherein, the section of the fastening plate is in an 'L' shape; one edge of the fastening plate is equipped with a hanging piece hole; the edge of the hanging piece hole is equipped with the hanging piece; and the width of one end of the hanging piece connected with the edge of the hanging piece hole is greater than that of a hanging end of the hanging piece. The thickened hanging piece has the beneficial effects that the hanging piece is set to be a shape with a big end and a small end, which increases biting force for fastening the hanging piece with an upright column or the crossbeam and meanwhile reduces frictional resistance so as to improve safety performance, reduce stress hidden danger and realize product structural optimization and promotion under the conditions of reasonable material selection and suitable cost; and hanging teeth of the hanging piece can be fully combined with stressed points of the upright column during the assembly process, which ensures that stress condition of the crossbeam reaches the standard within a design load-bearing range.

Owner:GUANGDONG WEITELONG TECH CO LTD

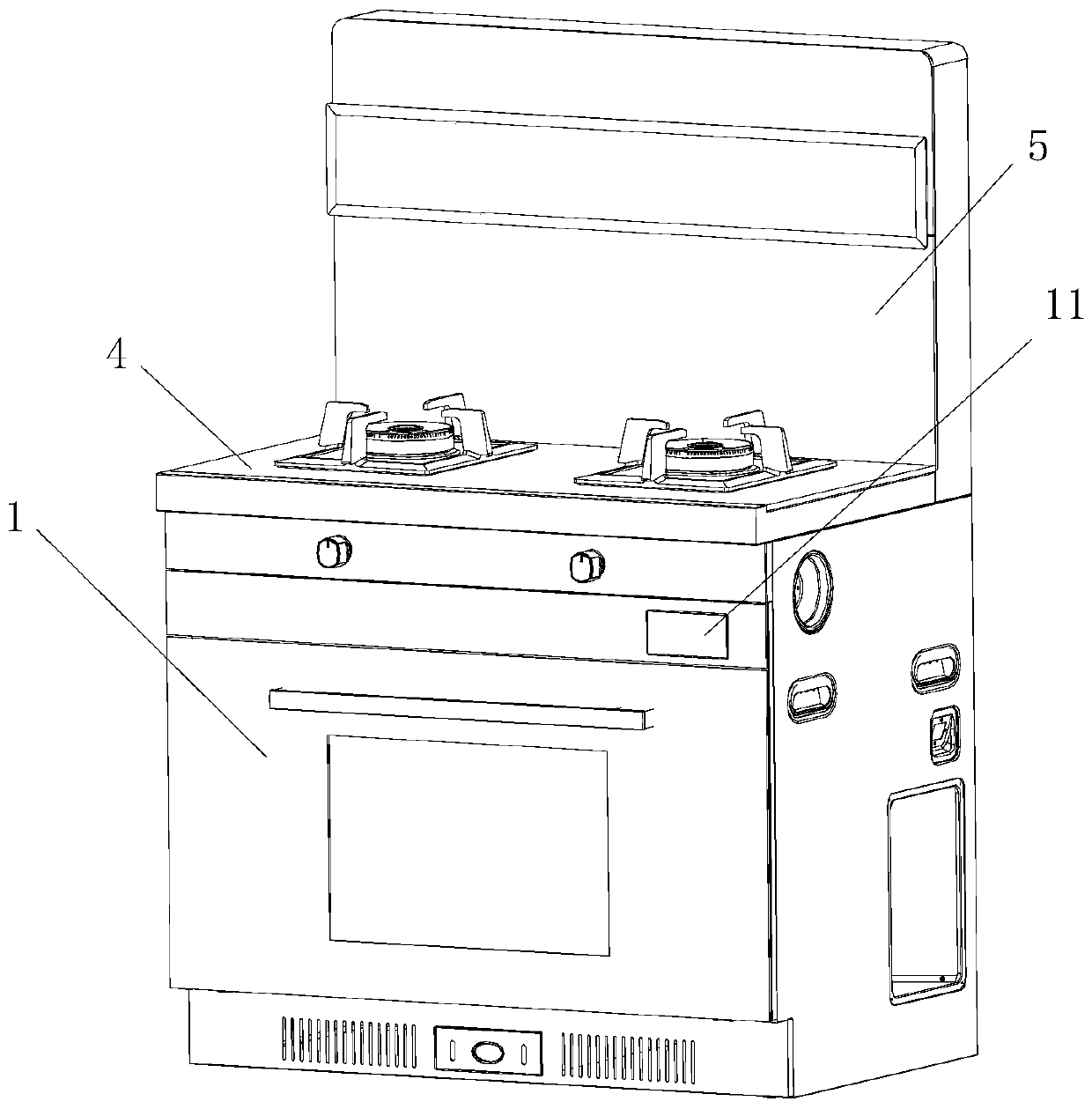

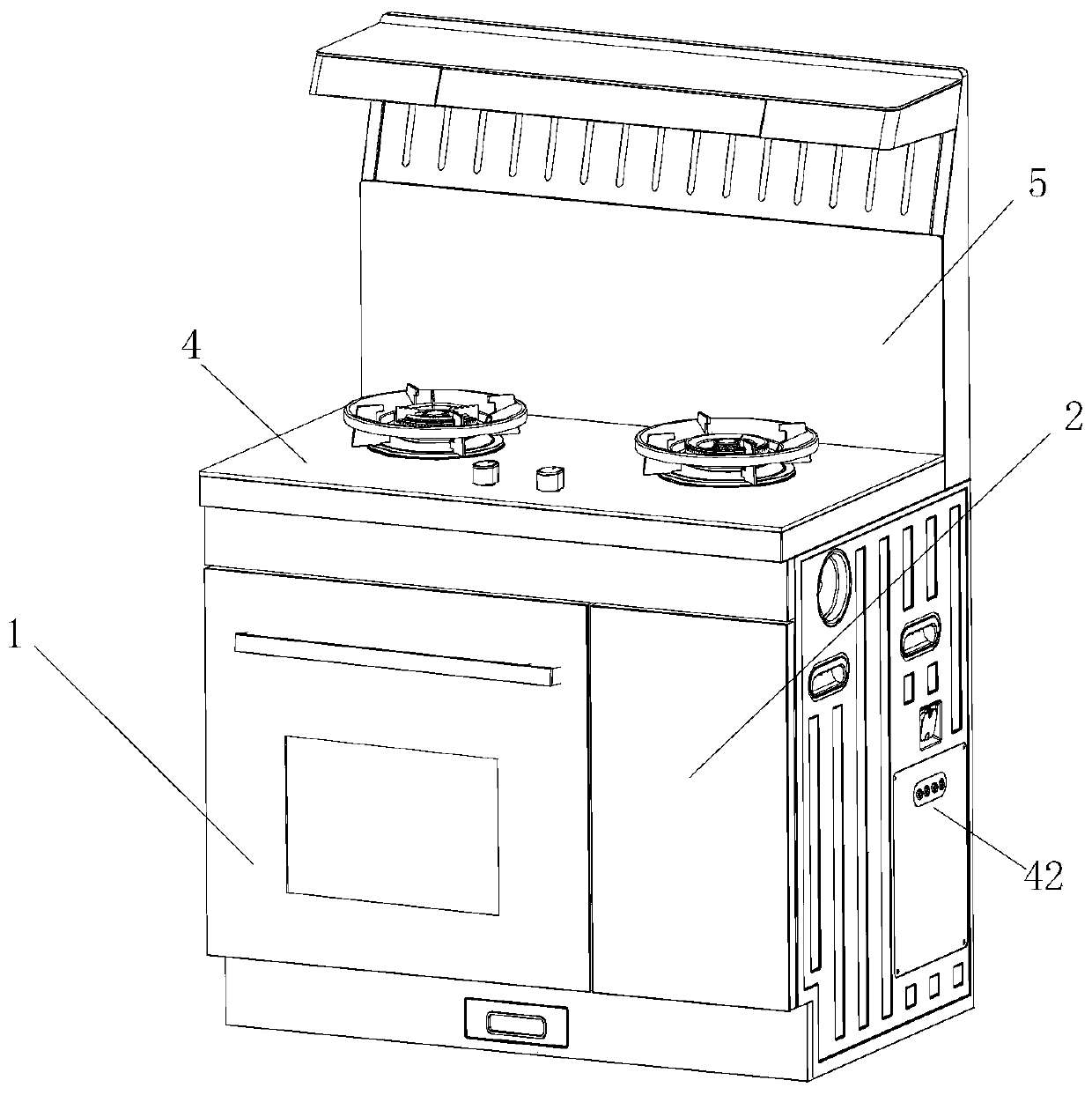

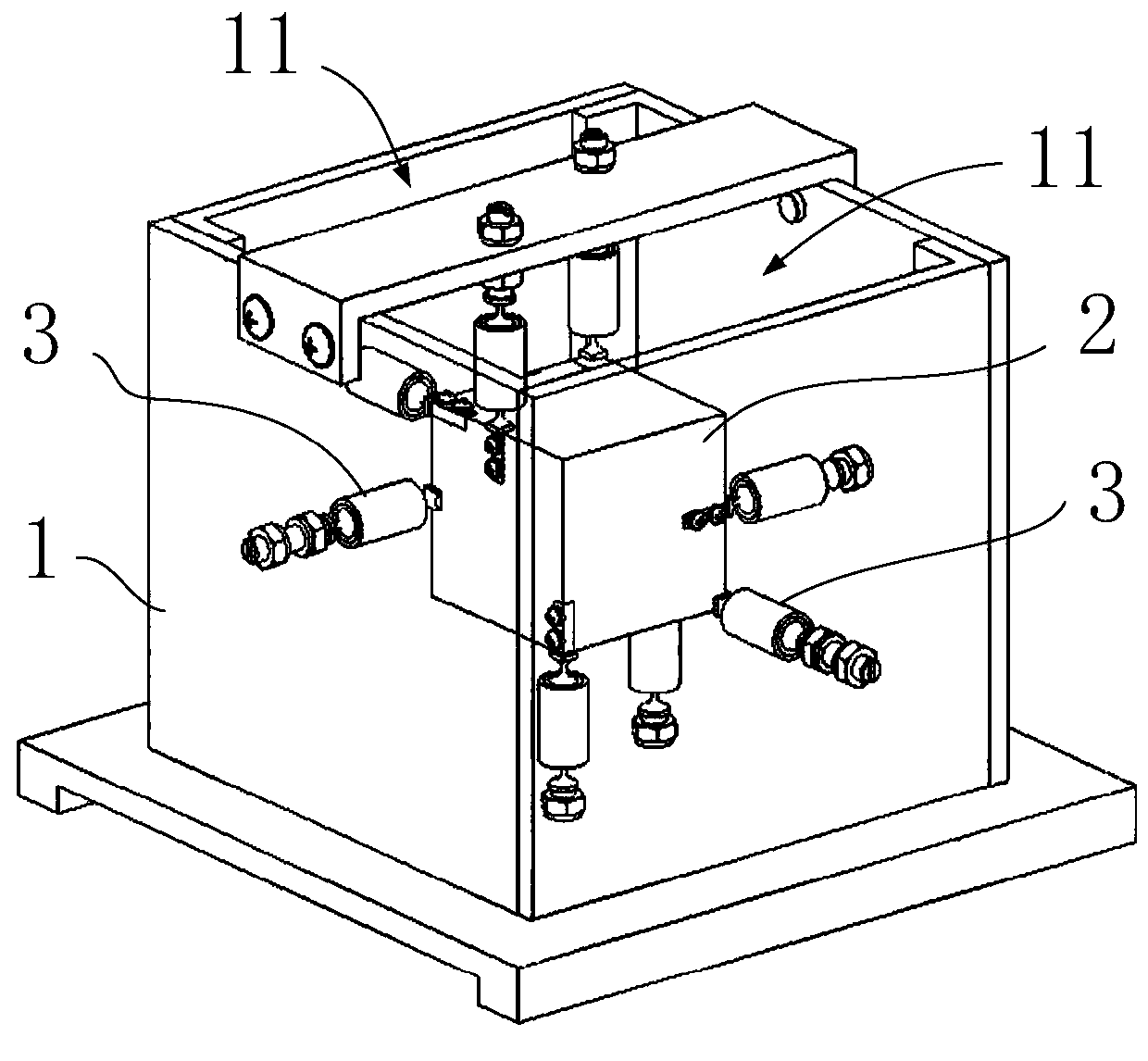

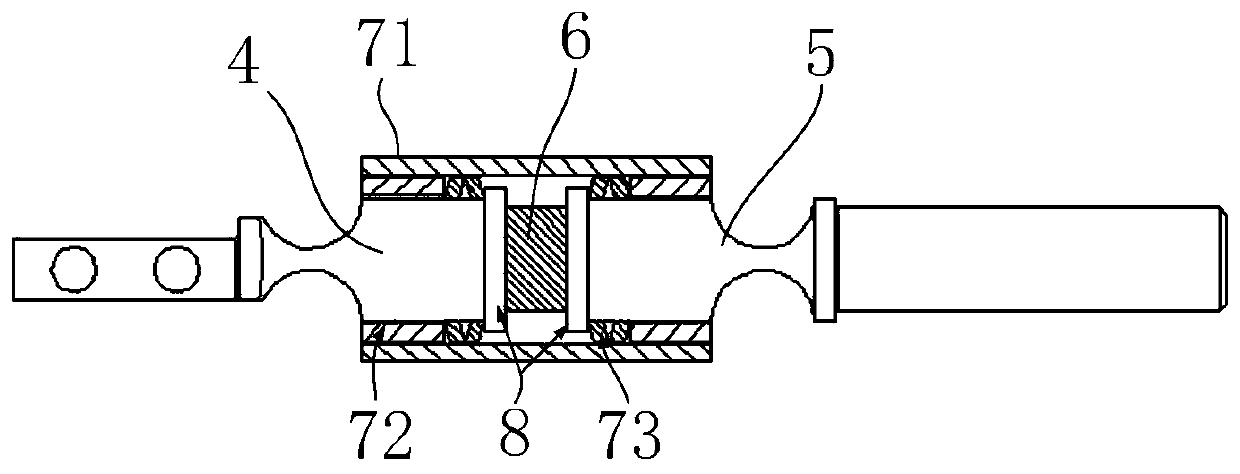

Integrated stove

InactiveCN111351081ALow costEnhanced interconnectionDomestic stoves or rangesSteam generation heating methodsThermodynamicsSteam cooking

The invention discloses an integrated stove, which comprises a steam cooking module, a steam washing module (6) and a common steam generator (10), wherein the common steam generator can be switched between a low heating power state or a high heating power state, in the low power state, the common steam generator generates a water vapor mixture and delivers the mixture to the steam washing module at least, and in the high heating power state, the common steam generator generates high temperature steam and delivers the steam to the steam cooking module at least. In the integrated stove providedby the invention, a plurality of function modules share one steam generator, so the interconnection of the modules is strengthened, the use of at least one steam generator is reduced, and steam with different temperatures, humidity and other parameter performances can be generated to meet different needs, and further the purified water can be accessed to the steam cooking module and the steam washing module through the water purifying module, so the generation of boiler scale and the deposition of heavy metal ions on a food surface can be reduced, the cooking quality is improved, and the performance and grade of an integrated stove product can be improved.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

Preloaded Parallel Six-Dimensional Acceleration Sensor and Its Measurement and Sensitivity Analysis Method

InactiveCN108802427BPromote structural optimizationEasy to productizeAcceleration measurement using interia forcesTesting/calibration of speed/acceleration/shock measurement devicesStatically indeterminateStructural engineering

The invention discloses a pre-tightened parallel six-dimensional acceleration sensor, a measuring method and a sensitivity analysis method thereof. The sensor adopts an eight-chain parallel mechanism as the elastic body structure of the sensor, which has higher rigidity and greater load-bearing capacity; the pre-tightening force can be applied to the piezoelectric ceramics through the pre-tightening device, and after the pre-tightening, the sensor can effectively The problem of distortion of the piezoelectric ceramic output signal is avoided, so that the sensor has better measurement accuracy. This measurement method can realize the real-time measurement of six-dimensional acceleration only by writing a program in the computer in advance, and its sensitivity analysis method excavates the inherent constraint relationship in the parallel mechanism of the sensor, establishes the force coordination equation, and makes the sensitivity model of the sensor hyperstatically indeterminate The solution of the problem is transformed into the solution of the statically indeterminate problem, so as to derive the analytical expression of the sensitivity of the sensor, which provides theoretical guidance for the subsequent structural optimization design of the sensor.

Owner:NANJING FORESTRY UNIV

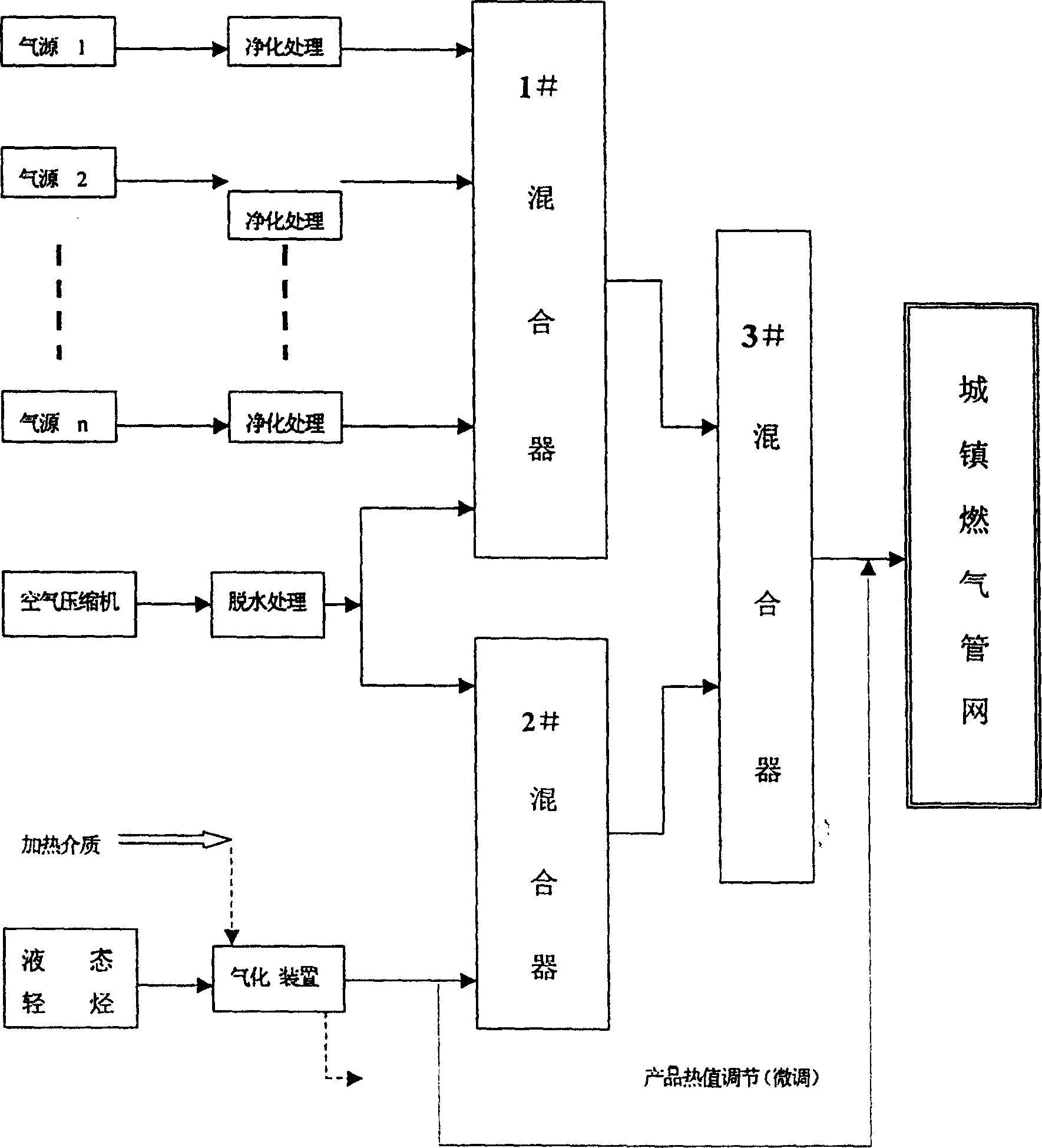

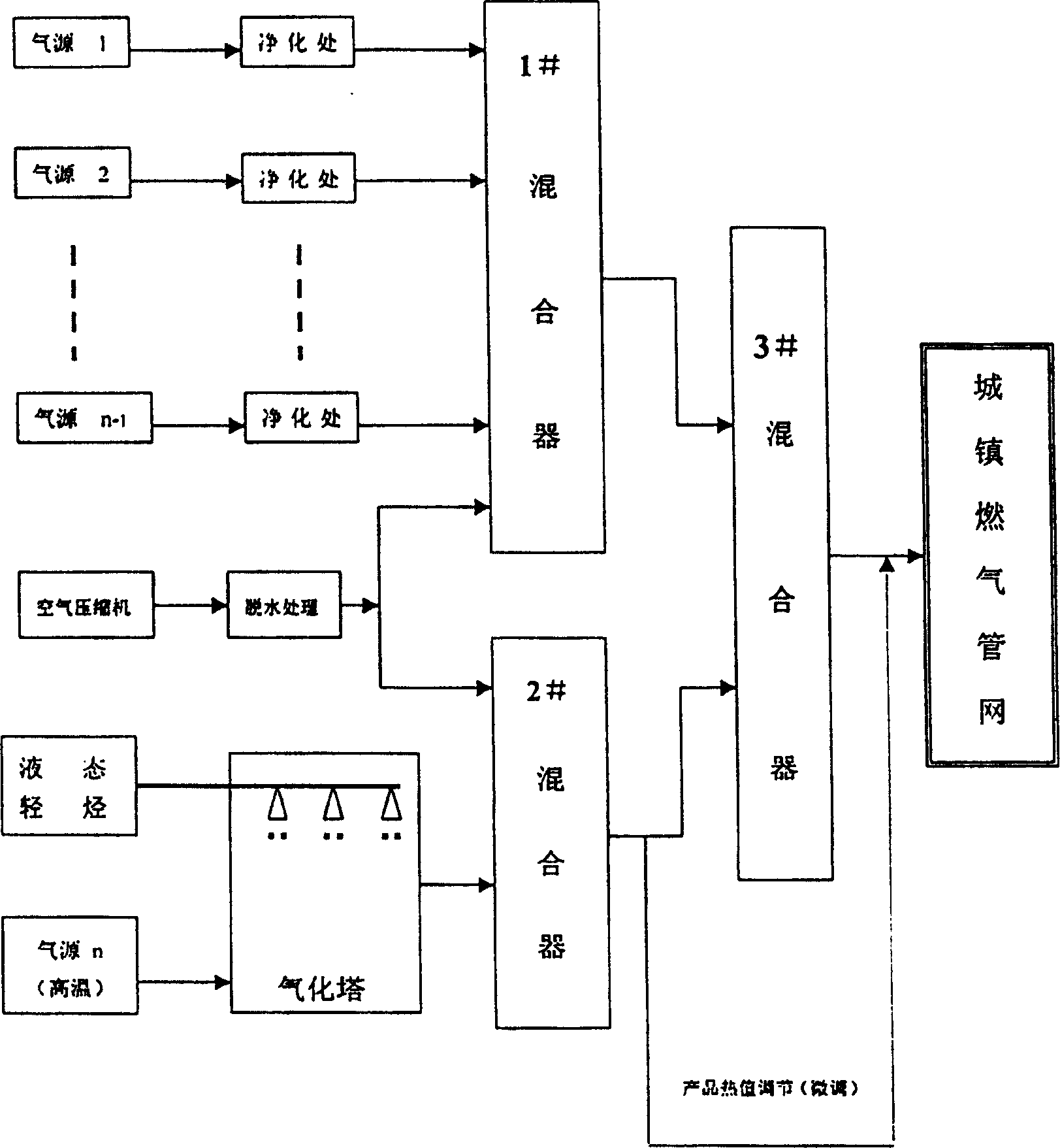

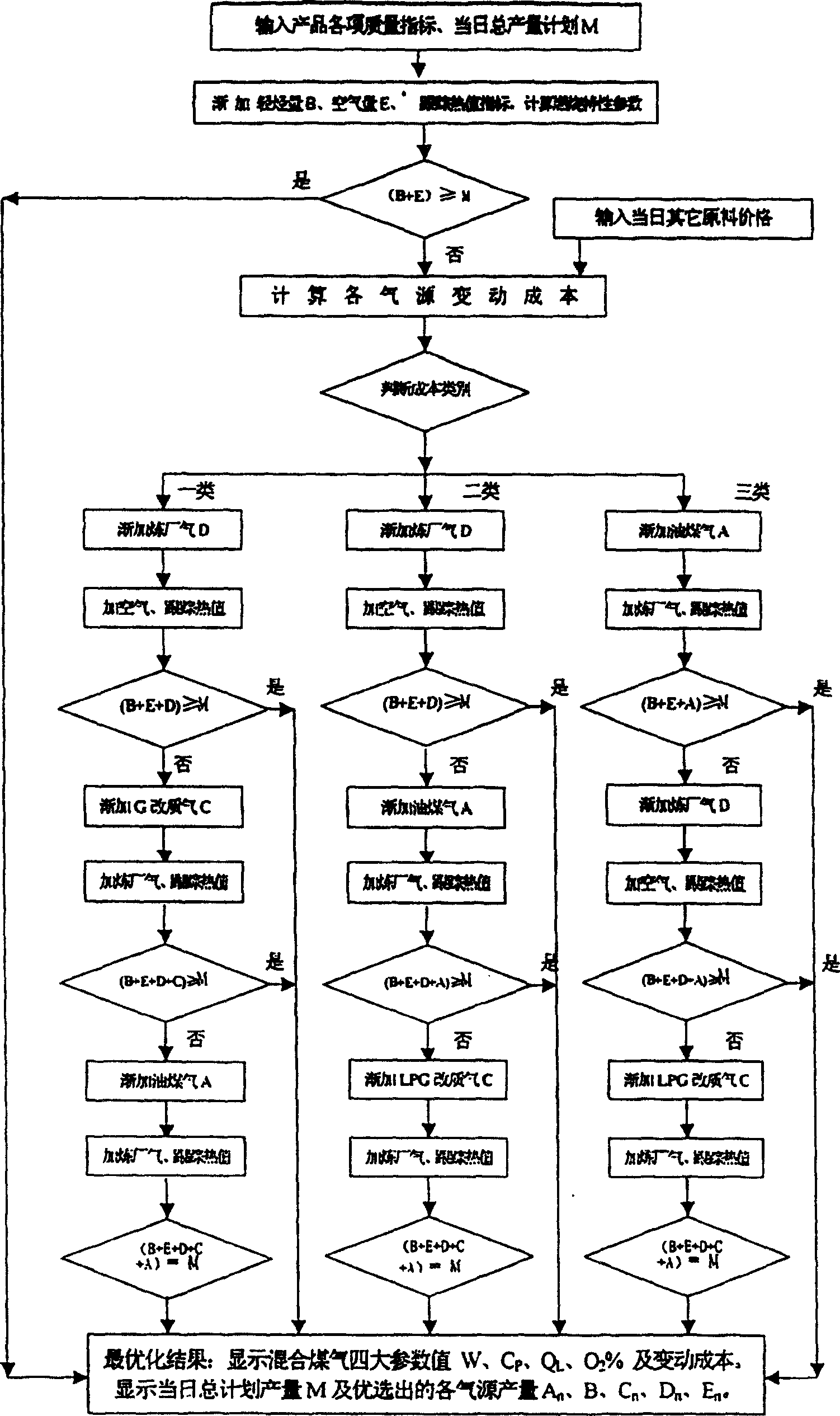

Method for producing town pipe gas with liquid light hydrocarbon as material

InactiveCN1240813CEmission reductionImprove the level of comprehensive utilizationGaseous fuelsHydrocarbon mixturesGas phase

The invention discloses a process for preparing pipe-line coal gas by using liquid hydrocarbons as raw material comprising the steps of, pressurizing the hydrocarbon mixture of liquid hydrocarbons and LPG, subjecting to heating and gasification, loading vaporized hydrocarbon mixture to mixer b and mixing with a large quantity of air, purifying and disposing the air supply with combustion value and dew-point temperature lower than the gas phase lighter hydrocarbons and mixing in mixer a, charging air, further mixing gas in mixer a with gas in mixer b in mixer c.

Owner:GUANGZHOU GAS

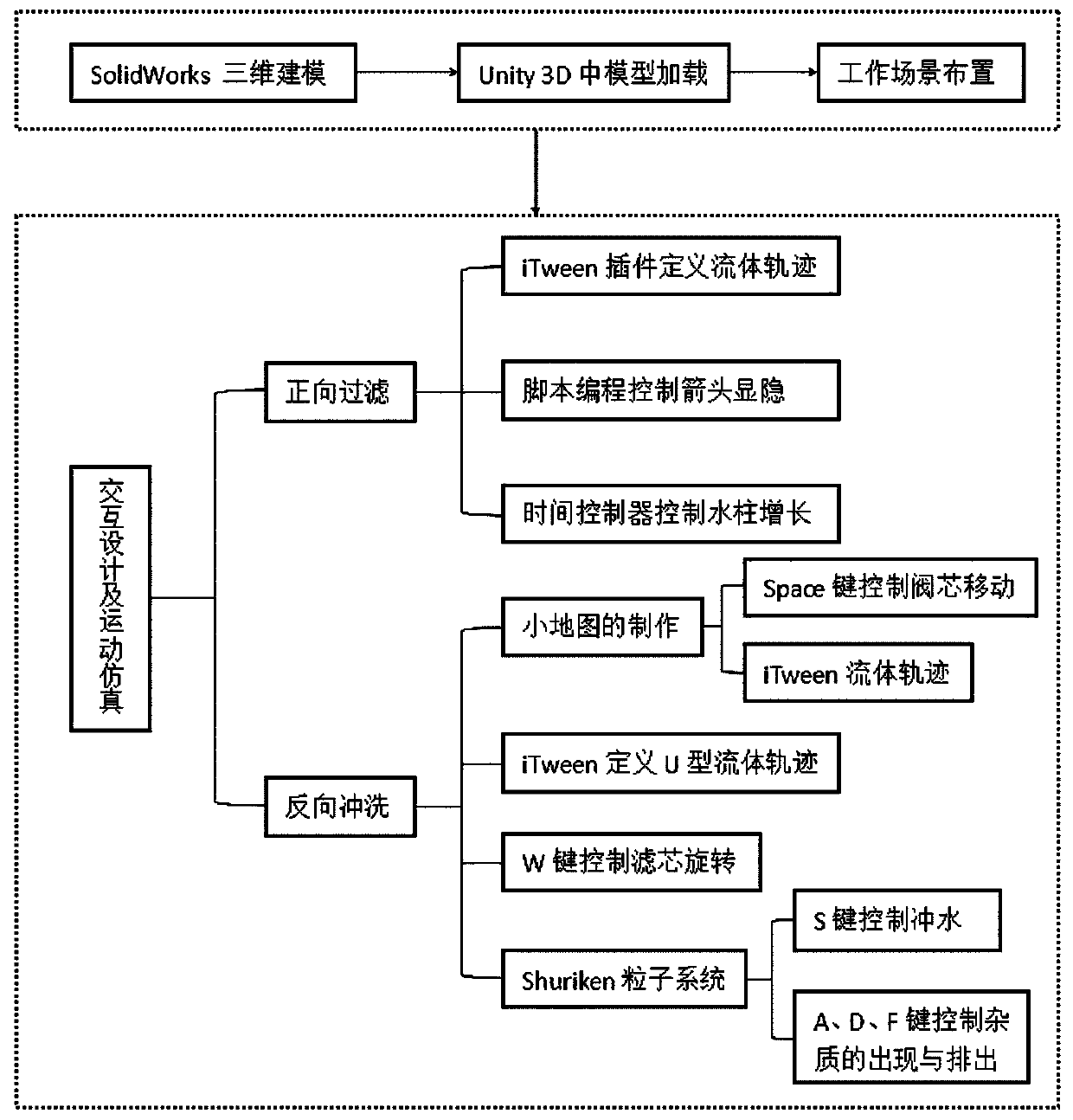

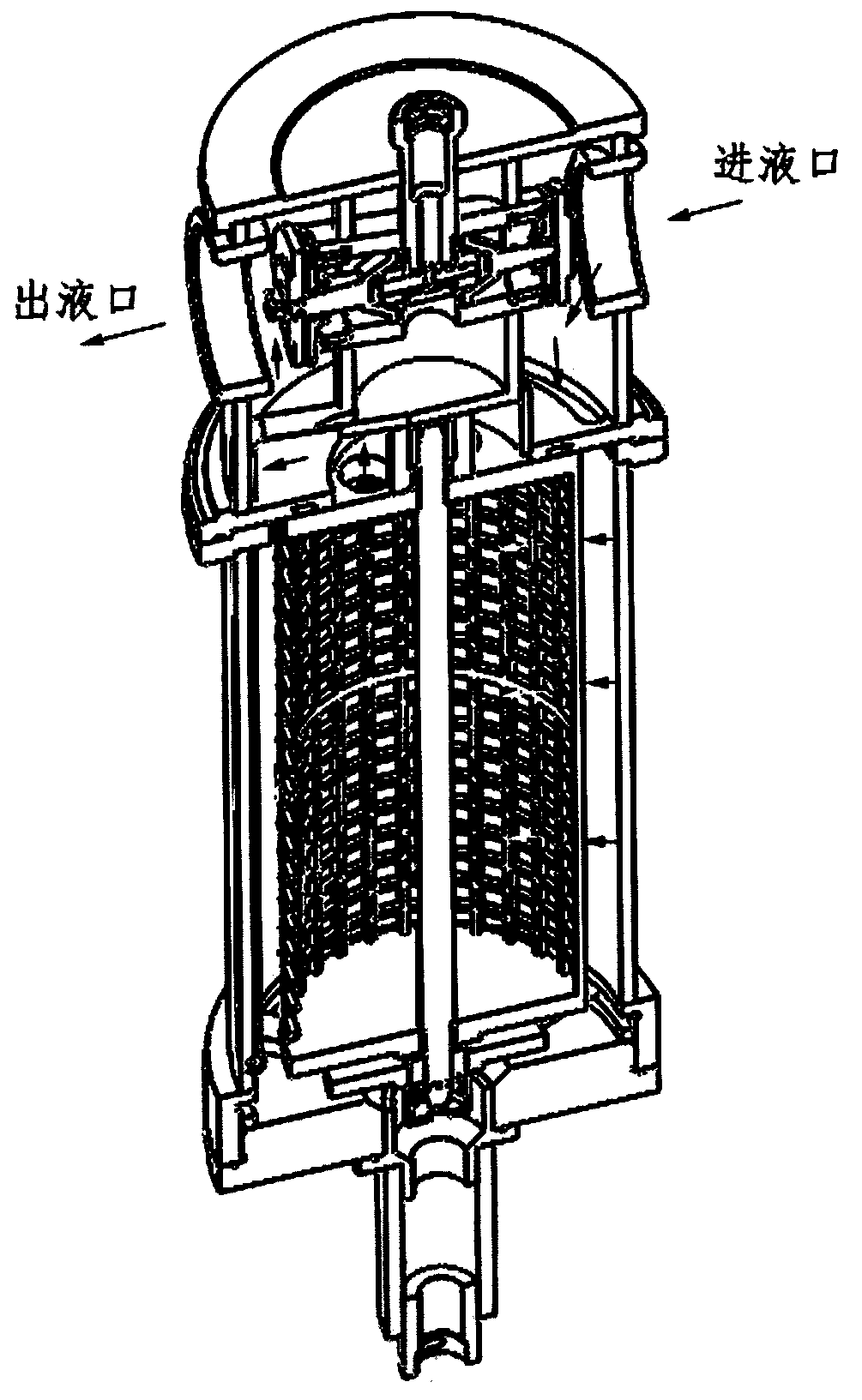

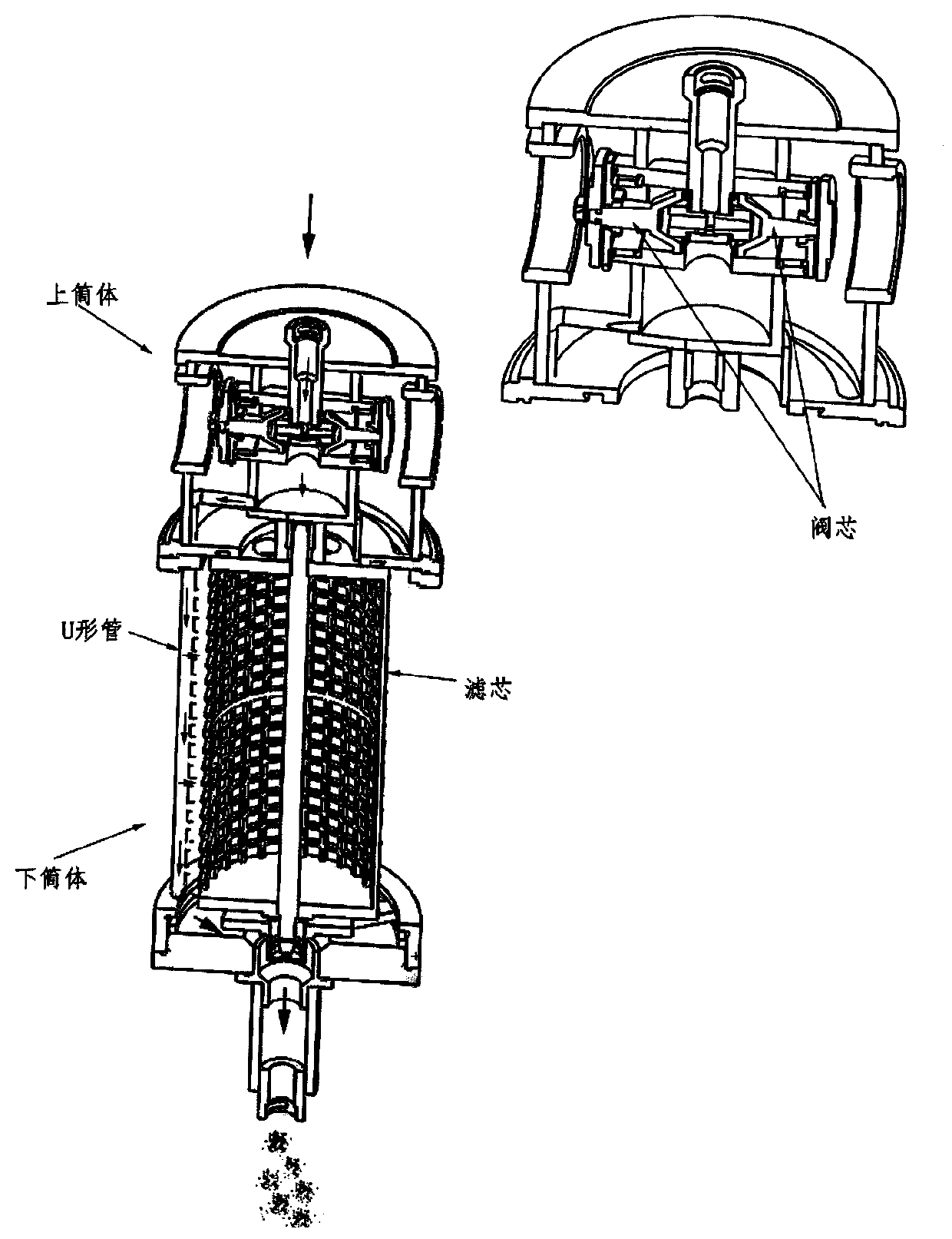

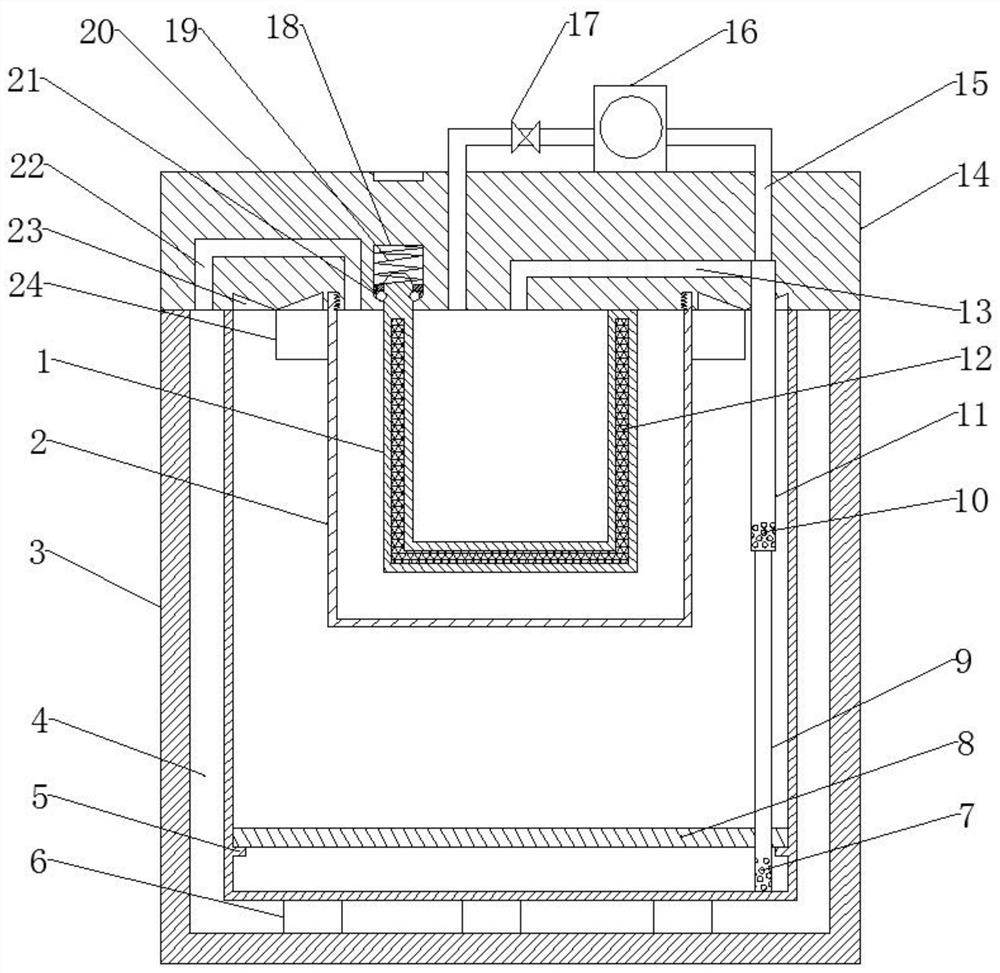

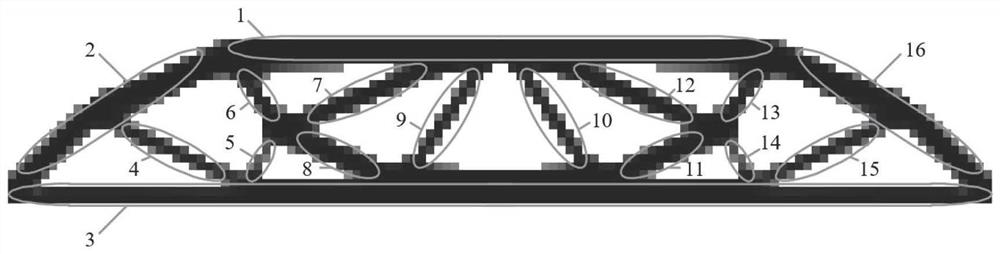

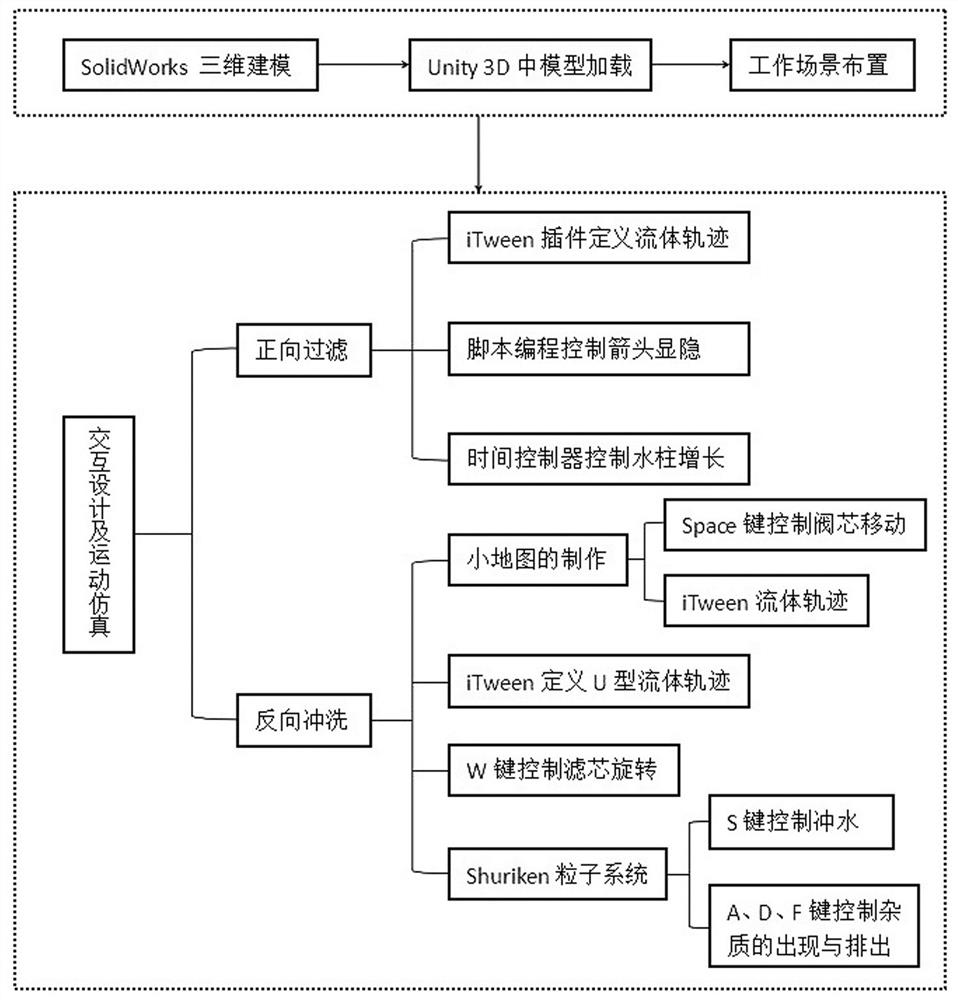

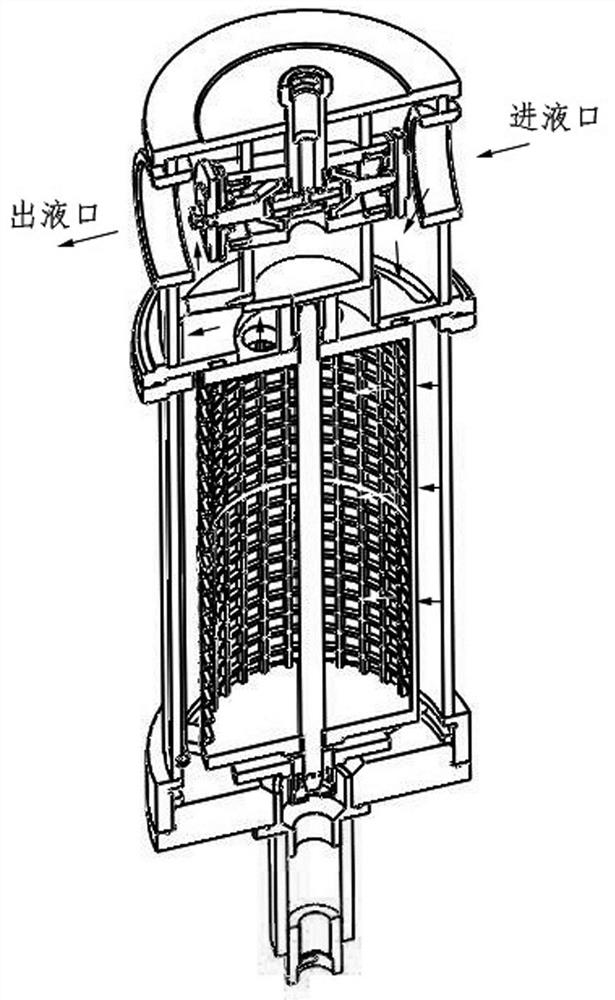

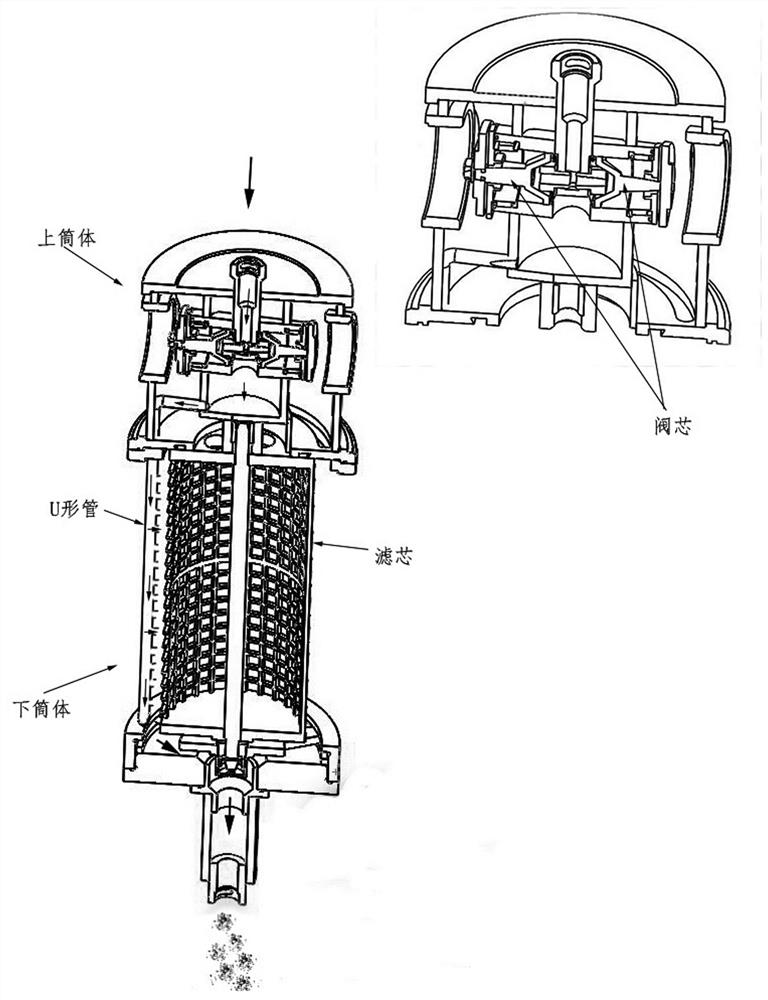

Interactive virtual-reality simulation method for backwash filter

ActiveCN109701309ASimulation smoothPromote structural optimizationSpecial data processing applicationsStationary filtering element filtersStop timeThree dimensional model

The invention belongs to the technical field of simulation methods, and specifically relates to an interactive virtual-reality simulation method for a backwash filter. The interactive virtual-realitysimulation method comprises the following steps: S1, modeling: establishing a three-dimensional model of the backwash filter; S2, loading: loading the filter model in Unity; and S3, interactive designing and motion simulation: 1) the virtual scene of normal-flow filtration: defining the trajectory of a fluid with an iTween plugin; controlling dominance and recessiveness of an arrow indicating thetrajectory of a filtered fluid through C# script programming; and controlling the starting and stopping time of filling of a filter element with a liquid through compiling of a time controller; and 2)the virtual scene of back washing: amplifying the local effect of a filter through small map functions; defining the trajectory of a backwash fluid with the iTween plugin; controlling the movement ofa valve element and a filter element with scripts; creating backwash water and impurities; and compiling the scripts, and controlling the process of simulation with an external device. The interactive virtual-reality simulation method provided by the invention can reflect the characteristics, morphology and layout of elements in an actual scene in a realistic, vivid and accurate way.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

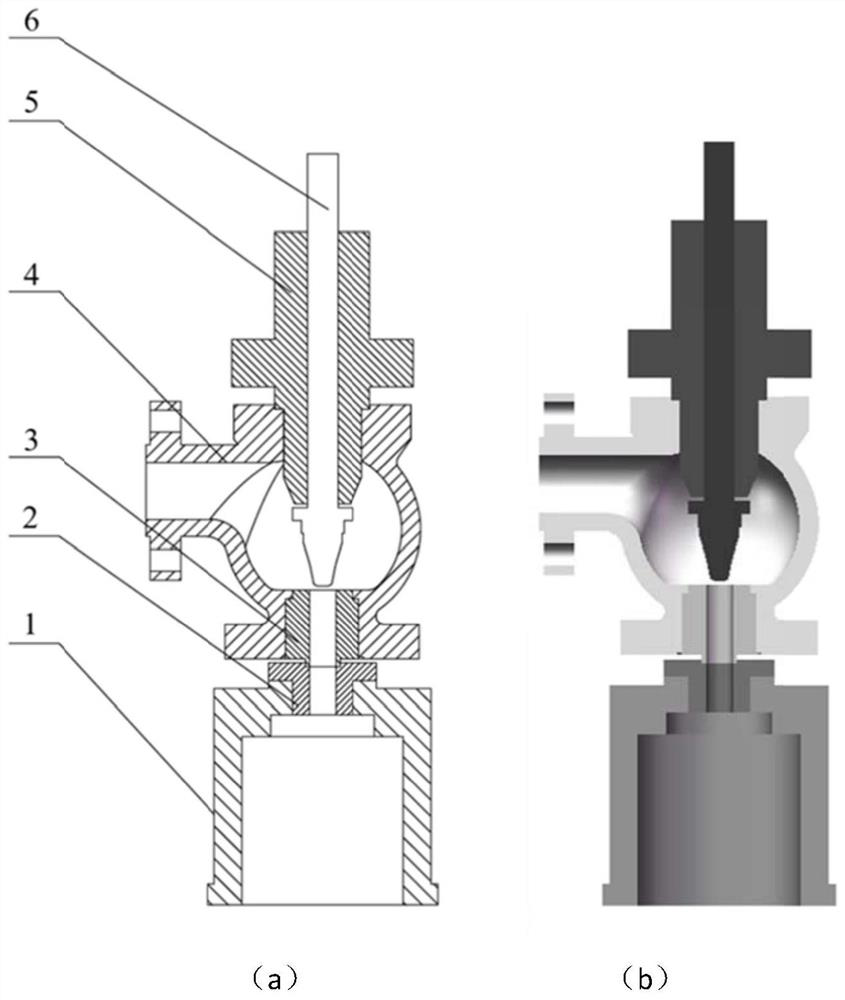

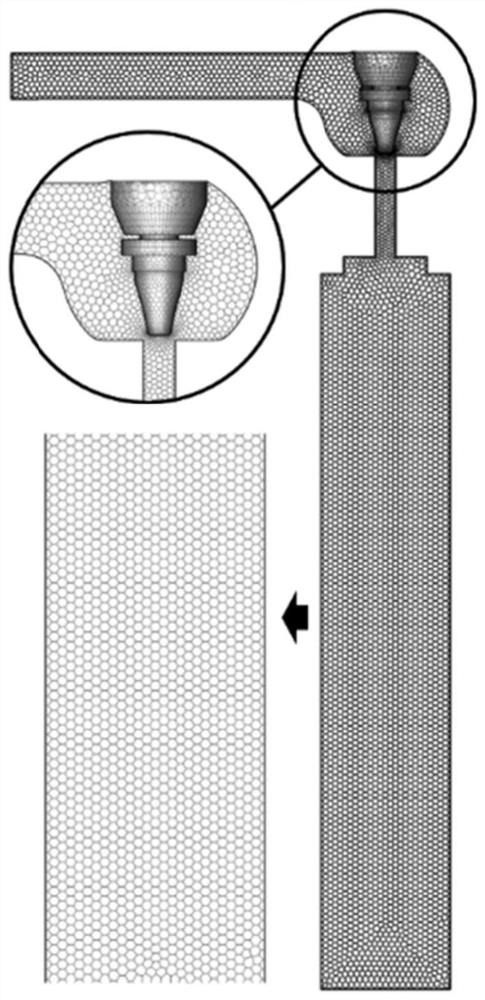

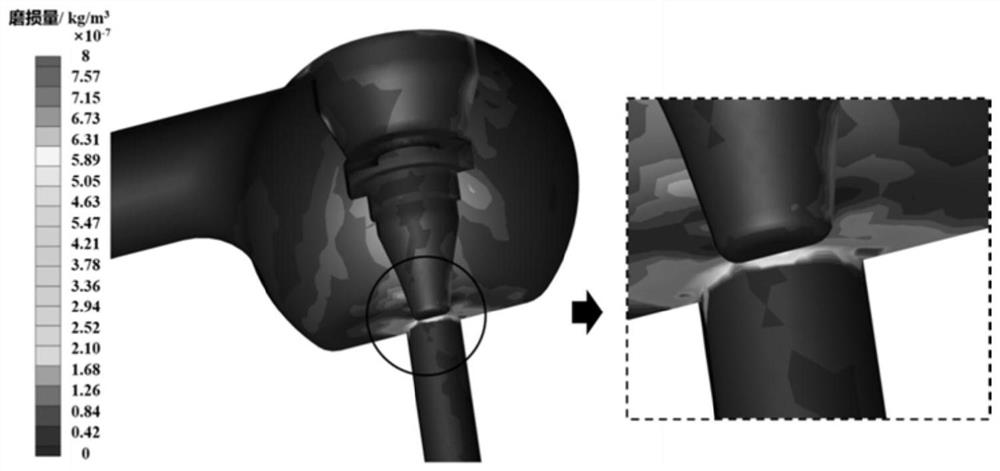

Valve body wall thickness lightweight design method based on erosive wear

ActiveCN113722850ASimple designPromote structural optimizationGeometric CADDesign optimisation/simulationEngineeringDimensional modeling

The invention discloses a valve body wall thickness lightweight design method based on erosive wear, which comprises the following steps of: firstly, performing three-dimensional modeling according to a design file of a valve, establishing a complete valve solid model, and extracting a flow channel of the valve to establish a valve internal flow channel model; carrying out flow field calculation in the valve by utilizing computational fluid mechanics software through grid division and a numerical simulation method; through post-processing of a calculation result, achieving visualization of a flow field of the valve body, and determining a wear area and a non-wear area in the valve; and through quantitative definition of parameters of a non-wear area of the valve body, setting experimental points, and performing structural optimization on the valve body. According to the method, the redundant wall thickness of the valve body can be preferably removed, the mass of the valve body is reduced, tedious and complex theoretical calculation and experimental correction are avoided, the design process of the valve body is greatly simplified, and a new thought is provided for lightweight design of the valve body.

Owner:ZHEJIANG UNIV

A kind of high-magnesium composite sinter and its production method

The invention relates to high-magnesium composite sinter and a production method thereof. A high-magnesium fluxing agent and other raw materials are prepared, optimized and then sintered in a sinter bed, so that the problems that in terms of existing high-magnesium sinter production, resource utilization and mineral generation are unreasonable, the yield is low, the strength is low, the return mine rate is high, and the solid fuel consumption is high are solved. The high-magnesium composite sinter is formed by crushing and mixing sinter of upper and lower layer structures. With composite calcium ferrite as the main binder phase, the upper layer of sinter is formed by sintering a material A, wherein MgO accounts for not greater than 1.8%, and Al2O3 accounts for not greater than 2.0%; and the lower layer of sinter is formed by sintering a material B, and the content of MgO of the lower layer of sinter is greater than that of the MgO of the upper layer of sinter. The material A comprises72-90% of iron-containing mineral powder raw materials, 7-20% of a low-magnesium fluxing agent and 3-8% of a solid fuel; and the material B comprises 0-90% of sinter, 0-70% of sintering return mine and 10-100% of a high-magnesium fluxing agent. The high-magnesium composite sinter is good in comprehensive metallurgical performance, the blast furnace burden structure can be optimized easily, and theslag mobility and desulfuration and dealkalization effects can be improved.

Owner:胡明意

Dynamic extraction device for raw materials of burn-scald film-spraying medicament

InactiveCN112494971AMany integrated functionsRegulating pressureEvaporator accessoriesFiltration circuitsThermodynamicsProcess engineering

The invention discloses a dynamic extraction device for raw materials of a burn-scald film-spraying medicament in the field of medicament component extraction equipment. The dynamic extraction devicecomprises an extraction kettle, the upper end of the extraction kettle is connected with a top cover, a steam kettle is arranged on the inner side of the extraction kettle, a concentration kettle is arranged on the inner side of the steam kettle, and the steam kettle and the concentration kettle are both detachably connected to the top cover. A steam channel for communicating the steam kettle withthe extraction kettle, a steam return channel for communicating the concentration kettle with the extraction kettle and an extraction channel are arranged in the top cover, interlayers are arranged in the side wall and the bottom wall of the concentration kettle, and heating mechanisms are arranged in the interlayers. The problems that existing dynamic extraction equipment is large in size and cannot be suitable for being used in laboratories can be solved.

Owner:CHONGQING MEDICAL & PHARMA COLLEGE

Continuous fiber 3D printing path planning method based on parallel optimization of fiber orientation and structure

ActiveCN113442441BGive full play to the advantages of mechanical propertiesImprove printing efficiencyAdditive manufacturing apparatusDesign optimisation/simulationProcess engineeringFiber-reinforced composite

A continuous fiber 3D printing path planning method for parallel optimization of fiber orientation and structure, constructs a parallel optimization model of fiber orientation and composite material structure, takes material density and fiber angle as design variables, and filters them to obtain parallel optimization of fiber orientation and composite material structure Structure: discretize the complex optimized structure into a structure of simple geometric shapes, use topology to abstract each sub-region into points, and connect the points according to the positional relationship of the optimized structure to which the sub-region belongs to form a connection containing the characteristic information of the optimized structure Graph, the path planning is classified as finding the Hamiltonian path in the connected graph; the material density value is used as the weight factor of the fiber angle to obtain the direction of the fiber trajectory in each sub-region of the optimized structure; the sub-region printing paths are sequentially connected according to the Hamiltonian path , to generate a printing code; the invention exerts the anisotropic mechanical properties of the continuous fiber reinforced composite material and meets the requirements of the 3D printing process.

Owner:深圳云疆智造科技有限公司

An Interactive Virtual Reality Simulation Method for Backwashing Filters

ActiveCN109701309BPromote structural optimizationImprove quality controlDesign optimisation/simulationStationary filtering element filtersInteraction designModelSim

The invention belongs to the technical field of simulation methods, and in particular relates to an interactive virtual reality simulation method for a backwash filter, comprising the following steps: S1, modeling: establishing a three-dimensional model of the backwash filter: S2, loading: loading the filter in Unity Model; S3, interaction design and motion simulation, 1) Forward filtering virtual scene: use iTween plug-in to define the fluid trajectory; use C# script programming to control the visibility of the arrow indicating the filtration fluid trajectory; write a time controller to control the liquid filling filter element 2) Backwash virtual scene: Use the mini-map function to zoom in on the local effect on the filter; use the iTween plug-in to define the trajectory of the backwash fluid; scripts to control the movement of the spool and filter element; create backwash water and impurities; Write a script to control the simulation process from an external device. It can truly, vividly and accurately reflect the characteristics, shape and layout of elements in the actual scene.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

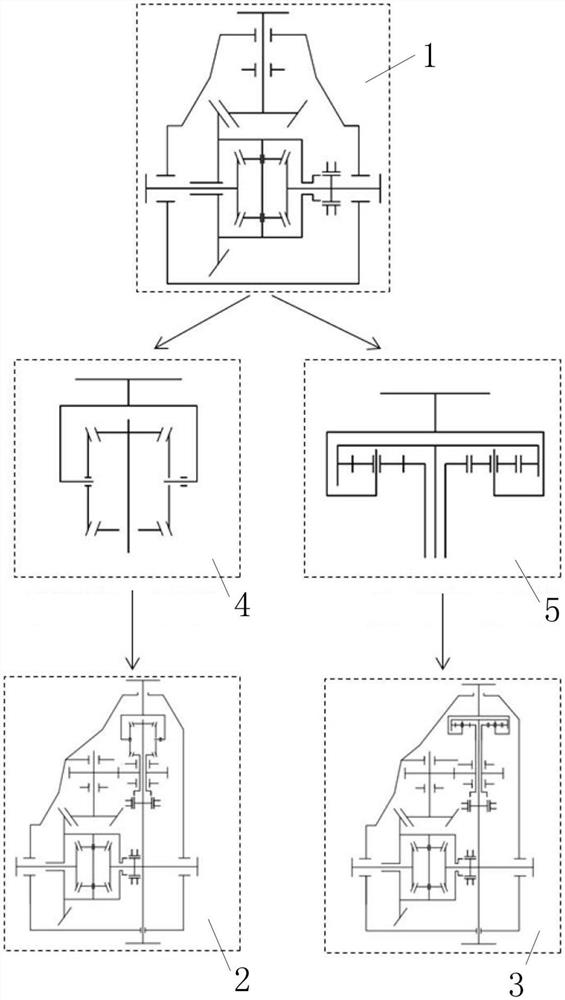

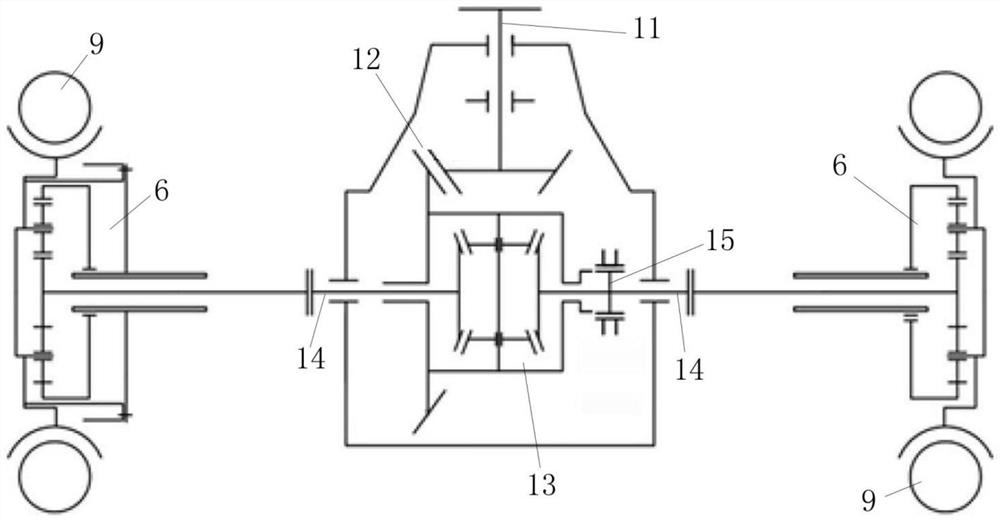

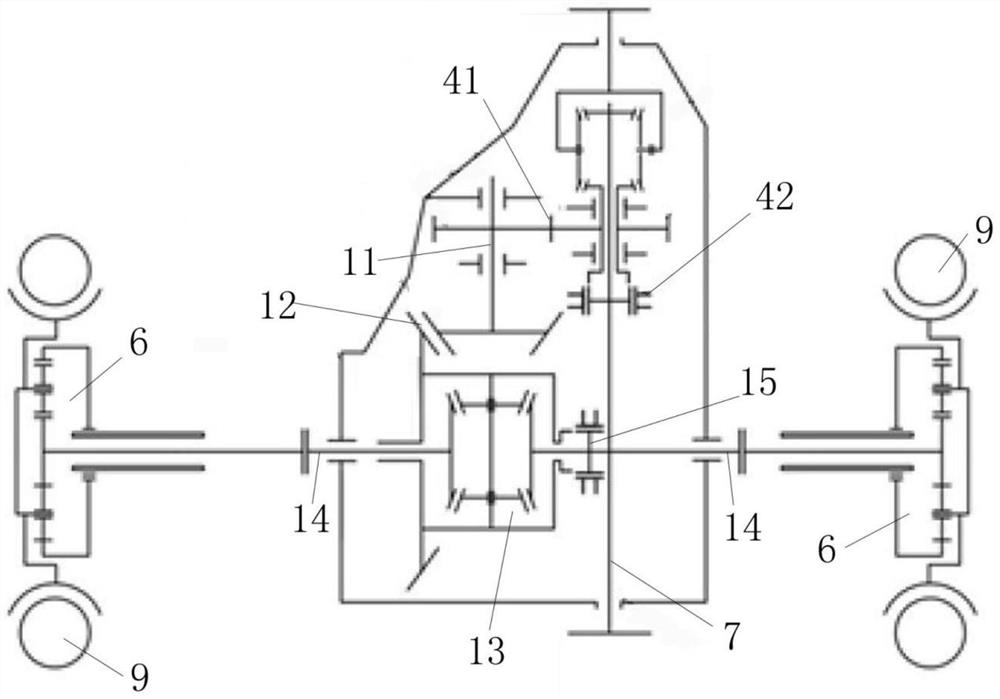

Modularized disconnected type drive axle and all-terrain crane

PendingCN114380193AVarious formsPromote structural optimizationGearingTravelling gearTransfer caseControl engineering

The invention discloses a modularized disconnected type drive axle and an all-terrain crane in the technical field of cranes, the modularized disconnected type drive axle comprises a main reduction module and a wheel side module, and the input end of the main reduction module is in transmission connection with the output end of a transfer case; the output end of the main reduction module is in transmission connection with the input end of the wheel side module; the wheel side modules are in transmission connection with wheels; the main reduction module comprises at least one of a non-through main reduction module, a through main reduction module and a triple drive through main reduction module; the wheel side module comprises one of a first wheel side module, a second wheel side module and a third wheel side module, and the speed ratio of the first wheel side module is larger than the speed ratio of the second wheel side module and smaller than the speed ratio of the third wheel side module. The modular design of the drive axle for the all-terrain crane is achieved, the drive axle has more forms, and the adaptability to the axle is higher.

Owner:JIANGSU ADVANCED CONSTR MASCH INNOVATION CENT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com