Valve body wall thickness lightweight design method based on erosive wear

A lightweight design and valve body technology, applied in the direction of constraint-based CAD, computer-aided design, design optimization/simulation, etc., can solve problems such as valve lightweight design, flow field and structure field optimization methods, etc. Achieve the effects of avoiding theoretical calculation and experimental correction, improving design, and simplifying the design process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

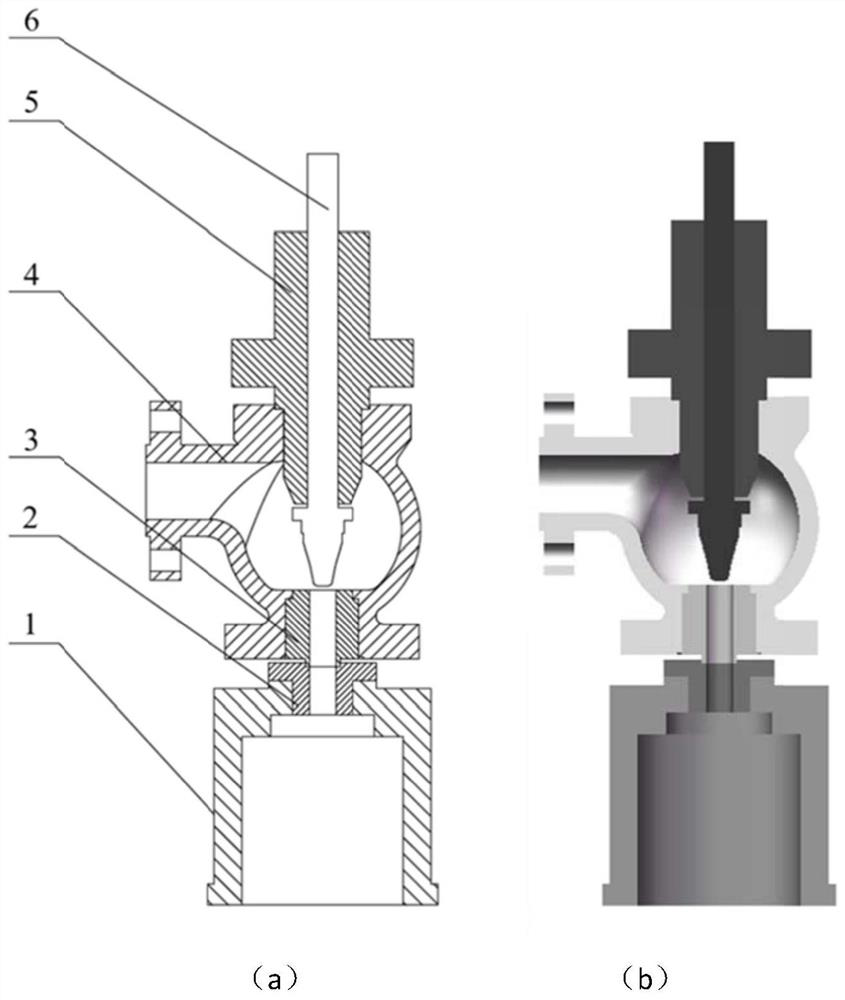

[0050] S1: According to the design documents of the valve, the valve entity model of the valve to be optimized is constructed by 3D modeling software. The valve to be optimized used in this embodiment is a black water angle valve for coal chemical industry. Such as figure 1 As shown in (a), the black water angle valve is composed of valve seat 1, lower bushing 2, upper bushing 3, valve body 4, valve cover 5 and integral valve core 6. Since the structure of the valve body is symmetrical about the longitudinal section plane of the valve body, a 1 / 2 valve body model symmetrical about the section plane can be established, and the established valve entity model is as follows figure 1 (b) shown.

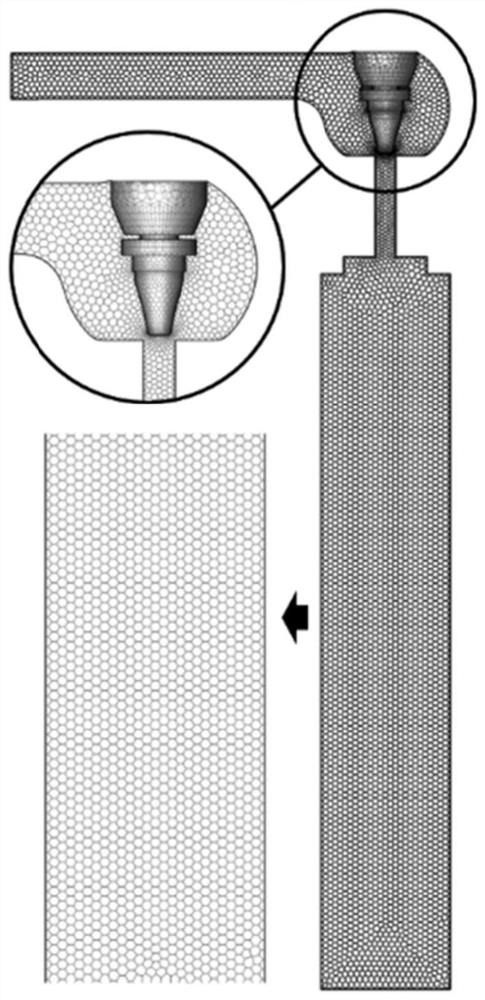

[0051] S2: According to the obtained valve entity model, extract the internal flow channel model of the valve, the steps are as follows: Create a solid geometry in the 3D modeling software Solidworks as the matrix, so that the matrix contains the currently constructed black water angle v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com