Method for producing town pipe gas with liquid light hydrocarbon as material

A light hydrocarbon, liquid technology, applied in the direction of fuel, gas fuel, petroleum industry, etc., can solve the problems that are difficult to avoid international speculative capital, unstable gas production costs, and large fluctuations in price changes, and achieve supervision of technology and resource utilization Maximize and expand the use types and application scope, and the effect of good environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In the embodiment of the present invention, topping oil is used as raw material for mixed gas production, and gas source manufacturers in other regions can also use other liquid light hydrocarbons as raw materials according to their own conditions and production characteristics, so as to solve the problem of hydrocarbon pump startup or operation. cavitation pumping problem.

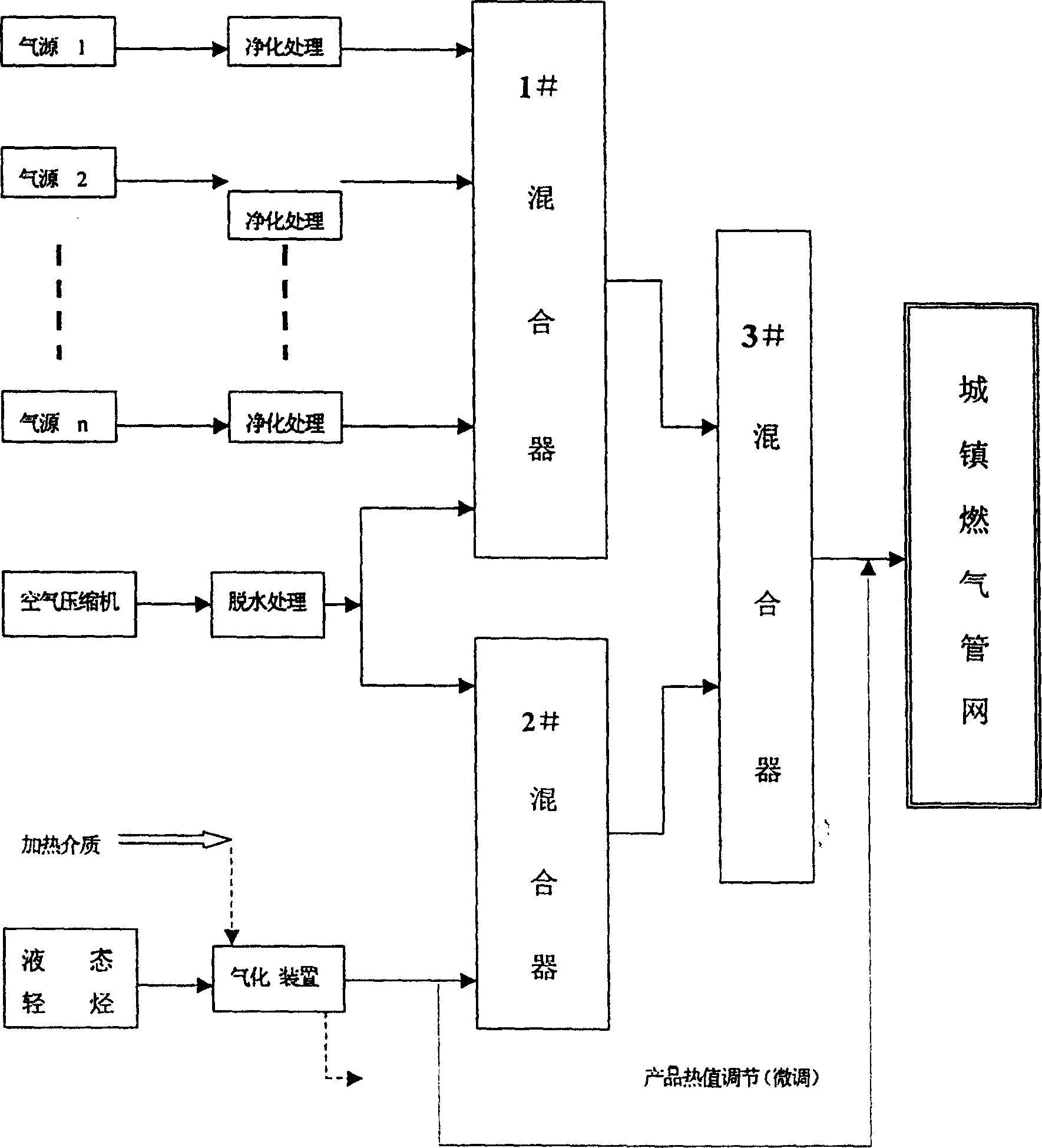

[0020] Such as figure 1 As shown, the topping oil in the raw material tank area is pressurized by the hydrocarbon pump and sent to the gasification device at a constant pressure (0.45MPa), and the excess topping oil is decompressed by the pressure control valve and then returned to the topping oil storage tank. The pressure in the raw material storage tank is related to the topping oil components and the ambient temperature. During the production process, it is generally controlled above 0.1MPa by refluxing high-temperature gas-phase topping oil or adding gas-phase LPG.

[0021] Under the action o...

Embodiment 2

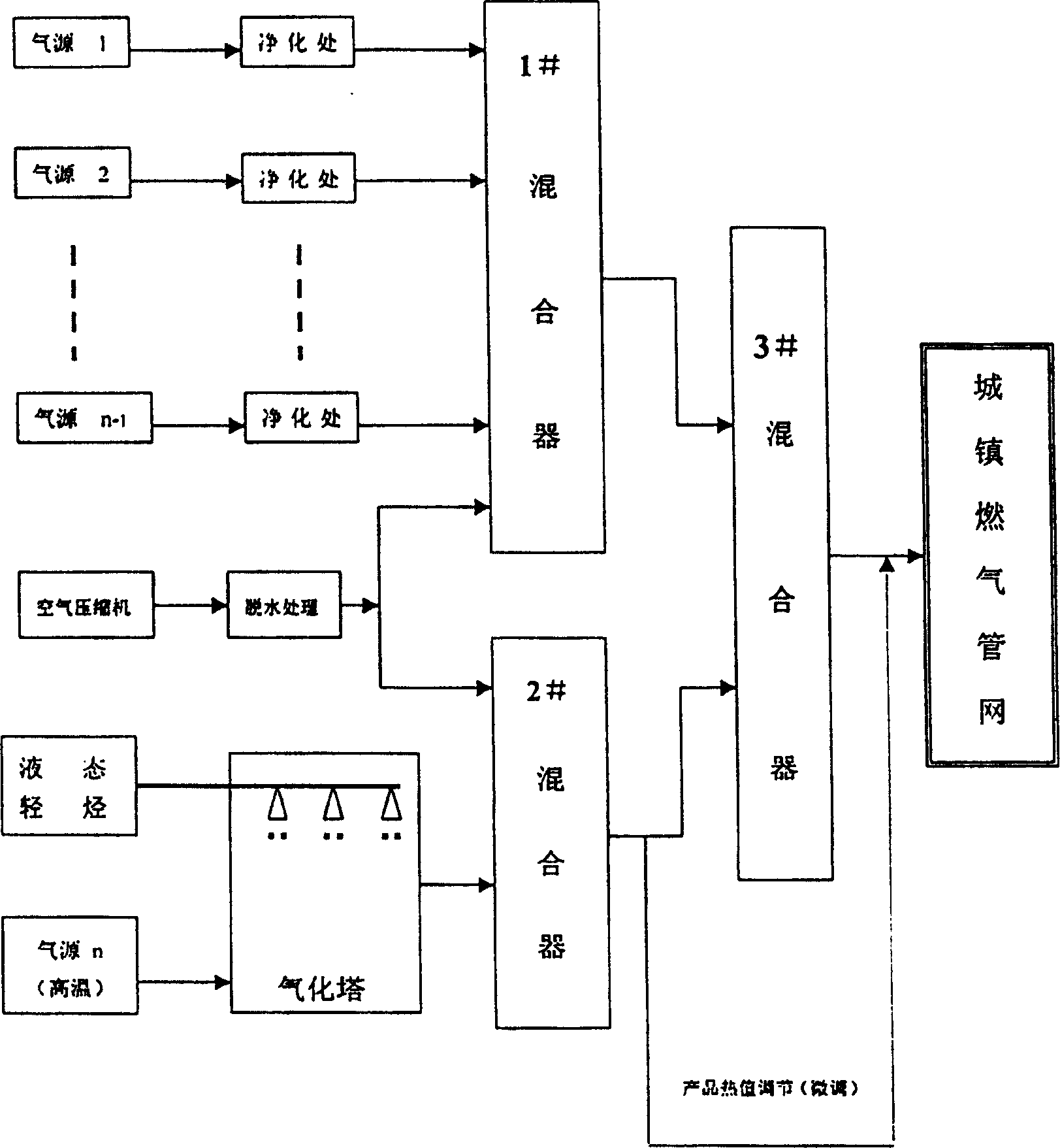

[0039] Such as figure 2 As shown, in this embodiment, mixed gas is produced by directly heating and gasifying topping oil.

[0040] The process flow of this embodiment is basically the same as that of the forced heating method. The difference is that what enters the b mixer is not pure gas phase topping oil (light hydrocarbons), but the mixture of topping oil and a certain gas source (oil-made gas). Mixed gas, liquid light hydrocarbons are vaporized by being heated by a high-temperature gas source (such as CCR reformed gas) in the gasification tower. In addition, the calorific value adjustment (fine-tuning) of the product gas is not achieved by using pure gas-phase light hydrocarbons to increase heat, but by "light hydrocarbons + certain gas source + air" mixed gas.

[0041] This embodiment makes full use of the sensible heat of the gas source n (such as CCR reformed gas), and the liquid-phase topping oil is vaporized by the sensible heat of the reformed gas after spraying i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com