A Simplified Fuel Cell Structure

A fuel cell and single cell technology, applied in the direction of fuel cells, fuel cell groups, fuel cell components, etc., can solve the problems affecting the effective improvement of the stack, increase system complexity, reduce reliability, etc., to improve assembly and Maintenance efficiency, improving volume-specific power density and weight-specific power density, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

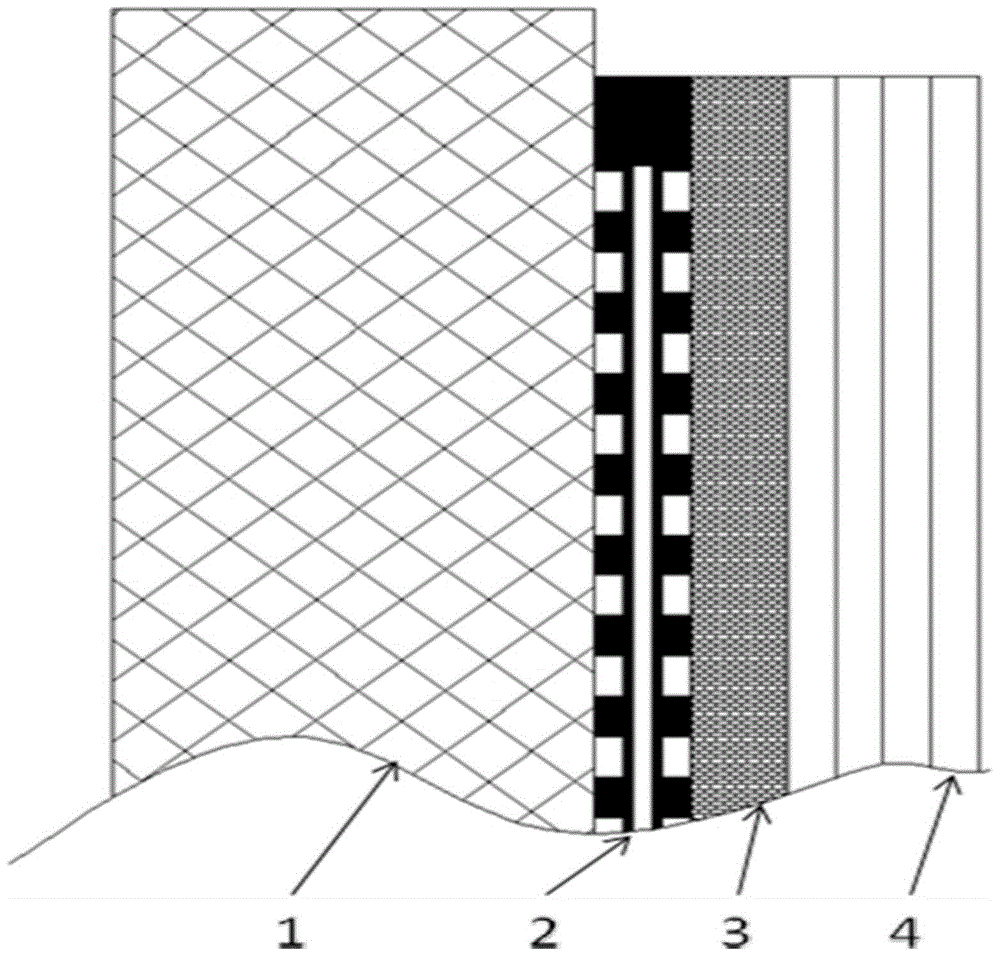

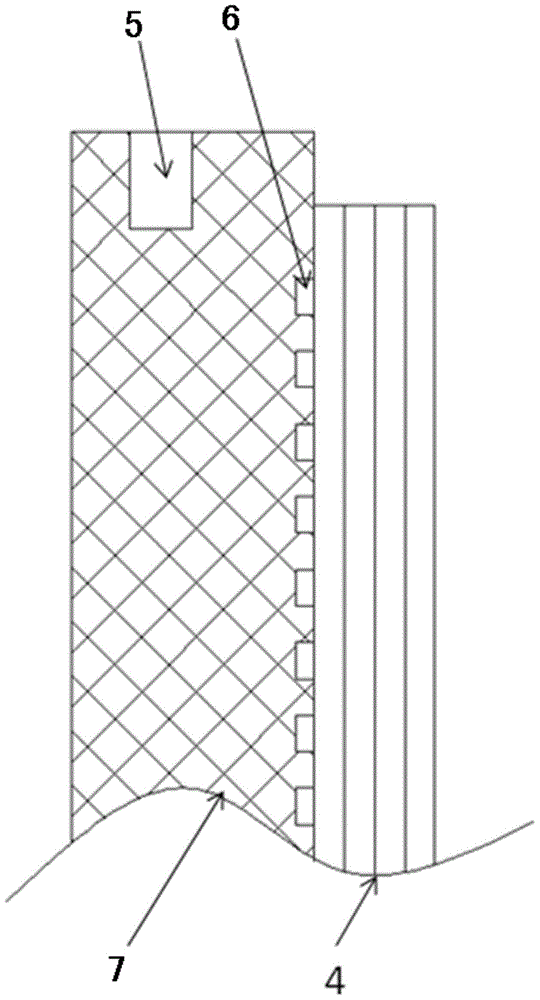

[0016] The simplified fuel cell structure includes an end plate and a multi-section single cell 4, the multi-section single cell 4 is placed between the two end plates, and there is no collector plate 3 and dummy battery 2 between the multi-section single cell 4 and the two end plates, The single cell is directly connected to the two end plates; the end plate is an integrated end plate 7, which is made of conductive material, which is a metal integrated end plate or a carbon fiber integrated end plate, and the end plate is not multi-section The contact surface of the single cell is covered with an insulating layer. The metal integrated end plate includes stainless steel integrated end plate, aluminum alloy integrated end plate, copper integrated end plate or nickel integrated end plate. For stainless steel integrated end plate, copper integrated end plate The insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com