High-efficiency forming device for airbag baffle

A technology for an airbag and a molding device, which is applied to the field of high-efficiency molding devices for airbag baffles, can solve the problems of low manufacturing cost, relatively large friction, easy deformation of products, etc., and achieves simple overall structure, good use stability, and manufacturing cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

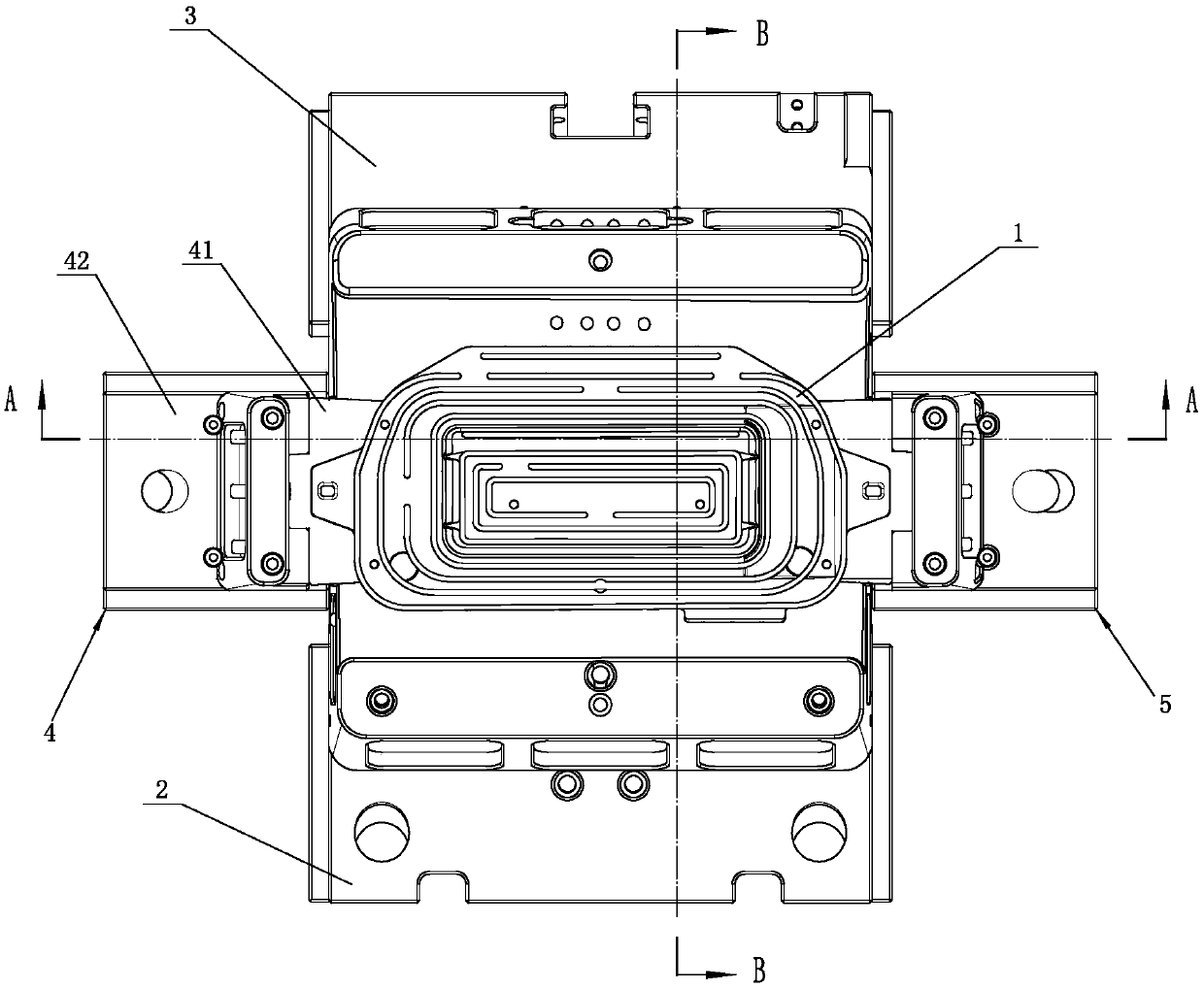

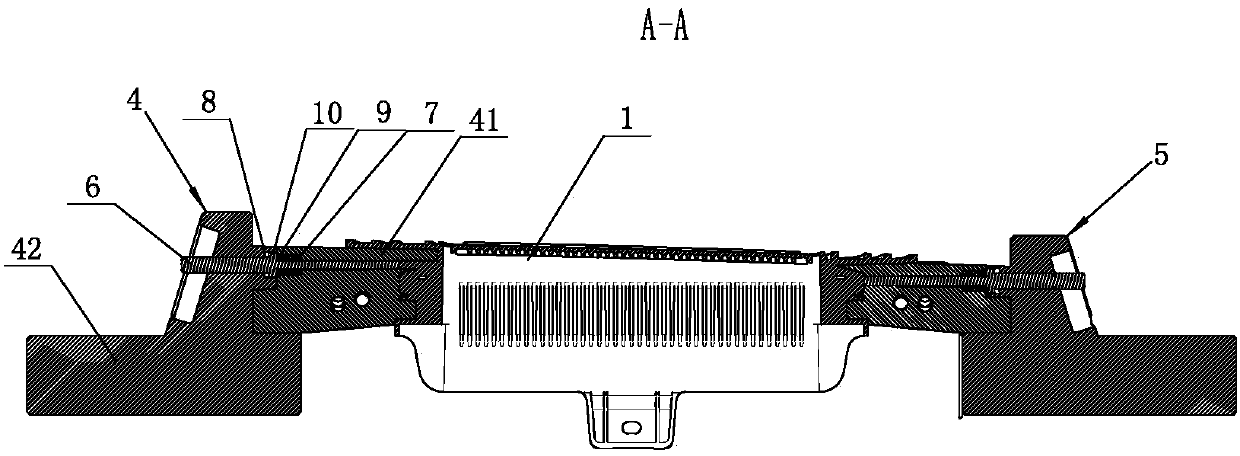

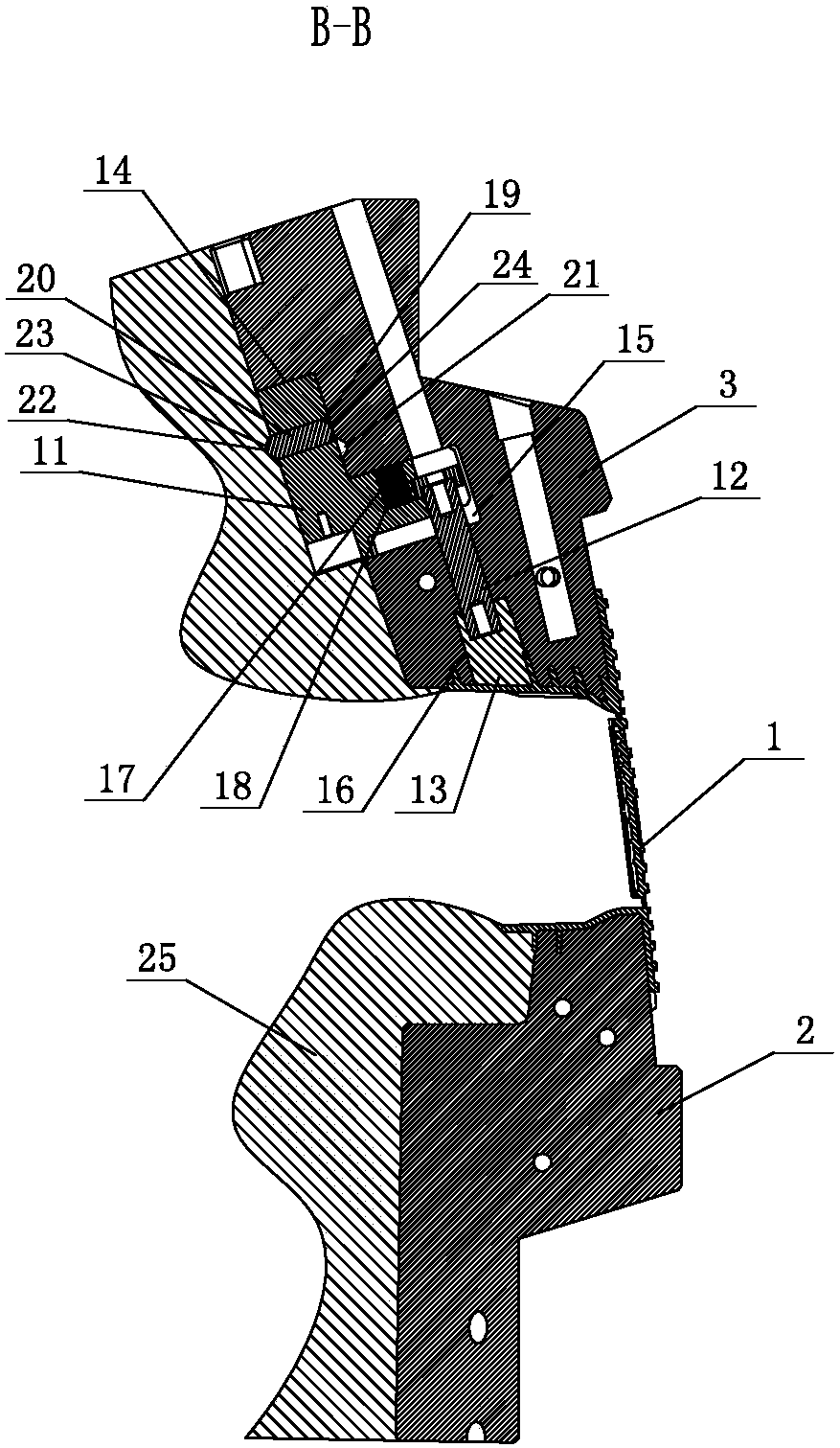

[0020] Such as figure 1 , figure 2 and image 3Shown, a kind of high-efficiency molding device of safety air bag baffle, it comprises fixed mold 25 and front slider 2 on fixed mold 25, rear slider 3, left slider 4 and right slider 5 (certainly also includes other parts , but because it does not involve the invention of the present invention, so it will not be repeated here), the rear slider 3 corresponds to the side of the airbag baffle 1 fabric hinge, and the left slider 4 and the right slider 5 are equipped with At least two thimble mechanisms (this example is three, can also be two, four or five, etc.); said thimble mechanism includes a thimble 6 and a first spring 7, and the reinforcement of the thimble 6 against the side of the fixed mold 25 On the ribs, the left slider 4 is divided into a core-pulling part 41 and a sliding part 42. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com