Pre-shrinking machine woolen cloth blanket and manufacturing process of same

A production process and pre-shrinking machine technology, applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of increasing the production cost of production enterprises, increasing the manufacturing cost, affecting the setting effect, etc., and prolonging the service life. , not easy to wrinkle, the effect of stable mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

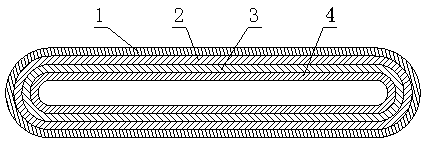

[0024] Such as figure 1 A pre-shrinking machine blanket is shown, which consists of the following four layers from outside to inside: a high temperature resistant fiber layer 1, a wool layer 2, a base fabric layer 3 and a fleece layer 4. in,

[0025] The high temperature resistant fiber layer 1 is composed of four layers of fiber layers fixedly connected, with a square weight of 1000g / m 2 , the thickness is 2.38mm; the high temperature range is 200~230℃.

[0026] The wool layer 2 is composed of six layers fixedly connected, each layer is composed of fine wool strips with a weight content of 40-50% and polyester staple fibers with a weight content of 50-60%, and the square weight of the wool layer is 1500g / m 2 , t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com