Method for hydraulic forming of tee pipe using teflon film local lubrication

A polytetrafluoroethylene, local lubrication technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of long adjustment time, low efficiency, high difficulty, etc., and achieve low cleaning cost, fast operation and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

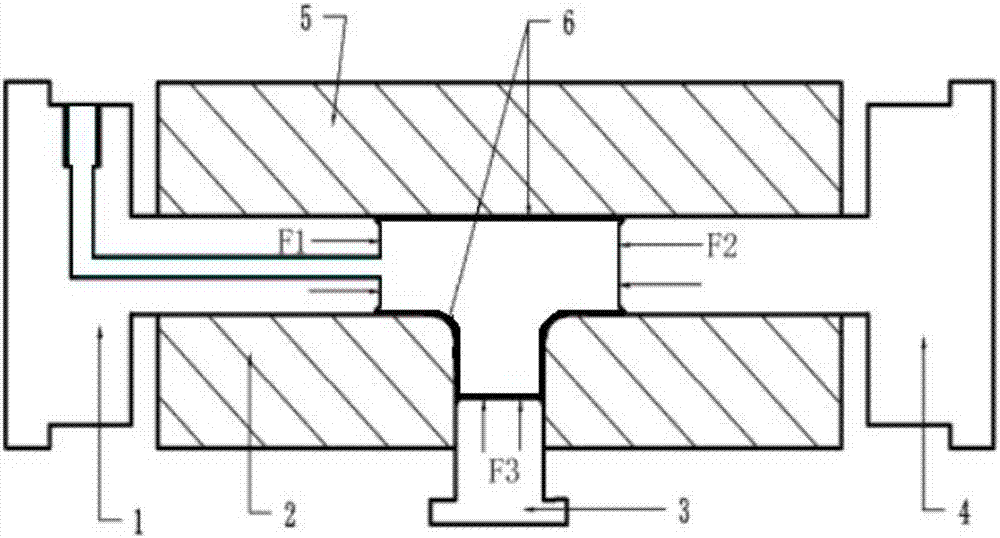

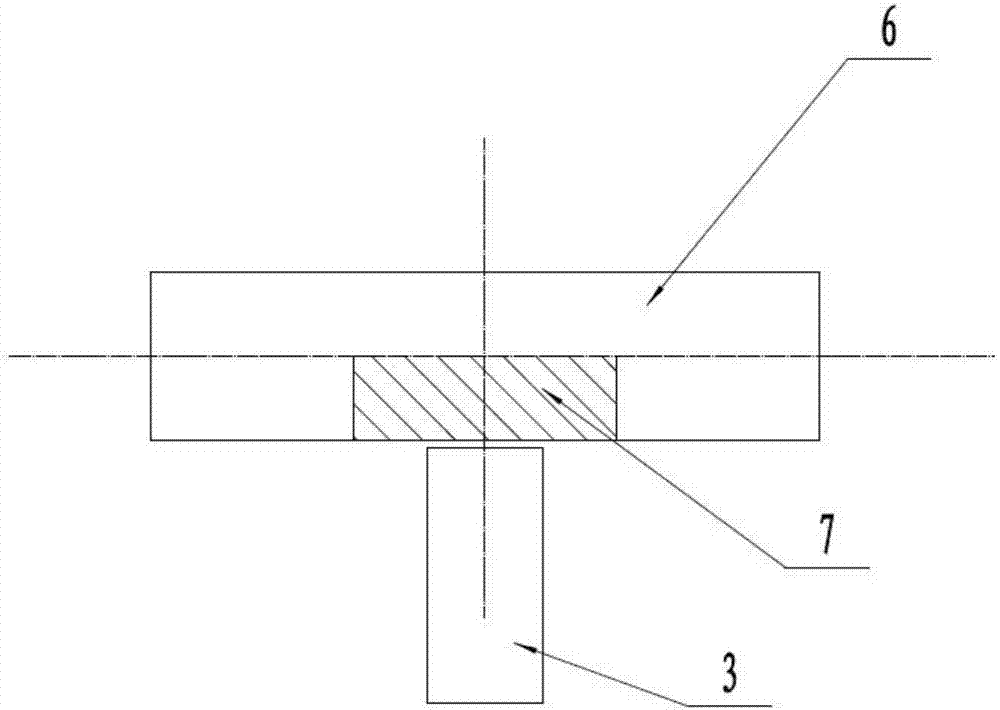

[0036] Such as Figure 1-3 As shown, this embodiment describes in detail the working principle and process of a method for locally lubricating a hydroforming tee pipe using a polytetrafluoroethylene film according to the present invention.

[0037] This embodiment provides a method for partially lubricating a hydroforming tee with a polytetrafluoroethylene film, comprising the following steps:

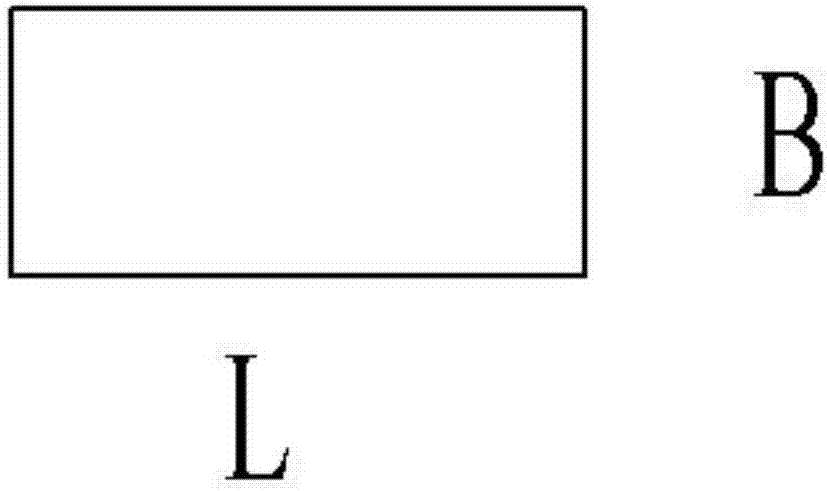

[0038] (1) if figure 1 Shown, design the specification of polytetrafluoroethylene film 7;

[0039] Design polytetrafluoroethylene film 7 is rectangular, and the thickness t of described polytetrafluoroethylene film 7 is 0.02mm, and width B is D1+(10~15) mm, and wherein, D1 is the tee branch pipe diameter; Length L is 1 / 2πD, wherein, D is the diameter of the straight pipe of the tee pipe, and the specific size of the polytetrafluoroethylene film 7 is determined according to the diameters of the branch pipes and straight pipes of the tee pipe to be formed.

[0040] (2) if figure 2 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com