Fresh-keeping separating layer cyclically used in rubber tyre manufacturing

A technology of rubber tires and isolation layers is applied in the field of fresh-keeping materials, and achieves the effects of simple manufacturing method, simple and practical product structure, and green environmental protection social value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

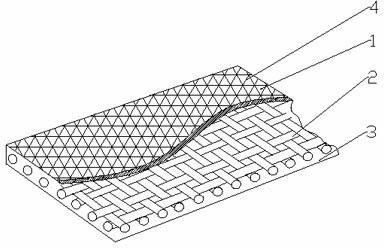

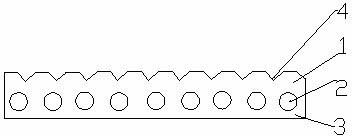

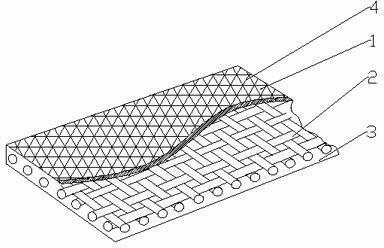

[0011] The plastic surface layers 1 and 2 of the present invention and the plastic braided wire mesh material 3 are the same material, such as polyethylene, polypropylene or other plastic materials. Two different materials can also be used, for example, the surface layer is made of polyethylene, polypropylene and other materials that can be used to make films, while the plastic woven mesh can use other plastic materials that can be drawn differently from the surface layer, but the plastic woven mesh 3 The tensile strength of the material should be higher than that of the plastic surface layer 1 and 2, and the elongation should be lower than that of the plastic surface layer.

Embodiment 2

[0013] The plastic braided wire mesh 3 monofilament of the present invention adopts circular polyethylene monofilament or polypropylene monofilament. When using polyethylene material, then select high-density polyethylene or linear polyethylene relative to the plastic surface layer 1,2. The monofilament diameter of the braided wire mesh 3 is between 0.08 mm and 0.2 mm. The selection of the monofilament center distance, monofilament diameter and monofilament material of the plastic woven wire mesh 3 will be reasonably selected according to different usage occasions. Its purpose is to increase the tensile strength of the fresh-keeping isolation layer, reduce the elongation, and improve the reuse efficiency.

Embodiment 3

[0015] At least one side of the plastic surface layer of the present invention has embossing 4, and the surface of the pressure roller is engraved with a flower shape. When the plastic surface layers 1 and 2 are cured and the middle plastic braided wire mesh 3 is hot-pressed and compounded, the flower-shaped pressure roller will press the plastic surface. Layers 1 and 2 are pressed into an embossed surface. The effect of embossing the fresh-keeping isolation layer is to reduce the contact area between the fresh-keeping isolation layer and the rubber sheet, and facilitate the peeling off of the rubber sheet and the fresh-keeping isolation layer. If the plastic surface layer 1 is embossed 4 on one side, the thickness of the embossed surface layer 1 is slightly thicker than the plastic surface layer plane layer 2. After the thickness of the embossed surface layer 1 is greater than the thickness of one side of the plane surface layer 2, the plastic braided wire mesh 3 can be compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com