Patents

Literature

88 results about "Grinding test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Apley grind test or Apley test is used to evaluate individuals for problems in the meniscus of the knee. The Apley grind test has a reported sensitivity of 97% and a specificity of 87%.

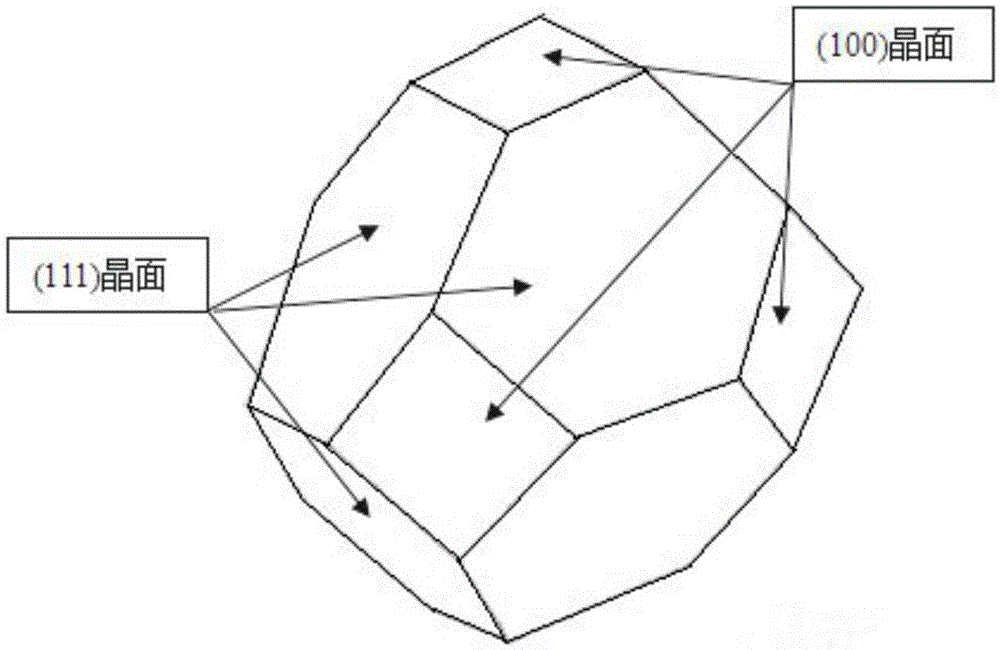

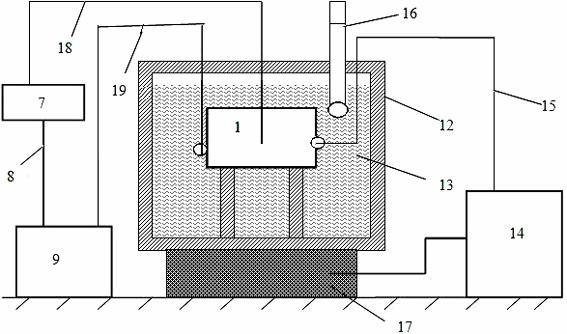

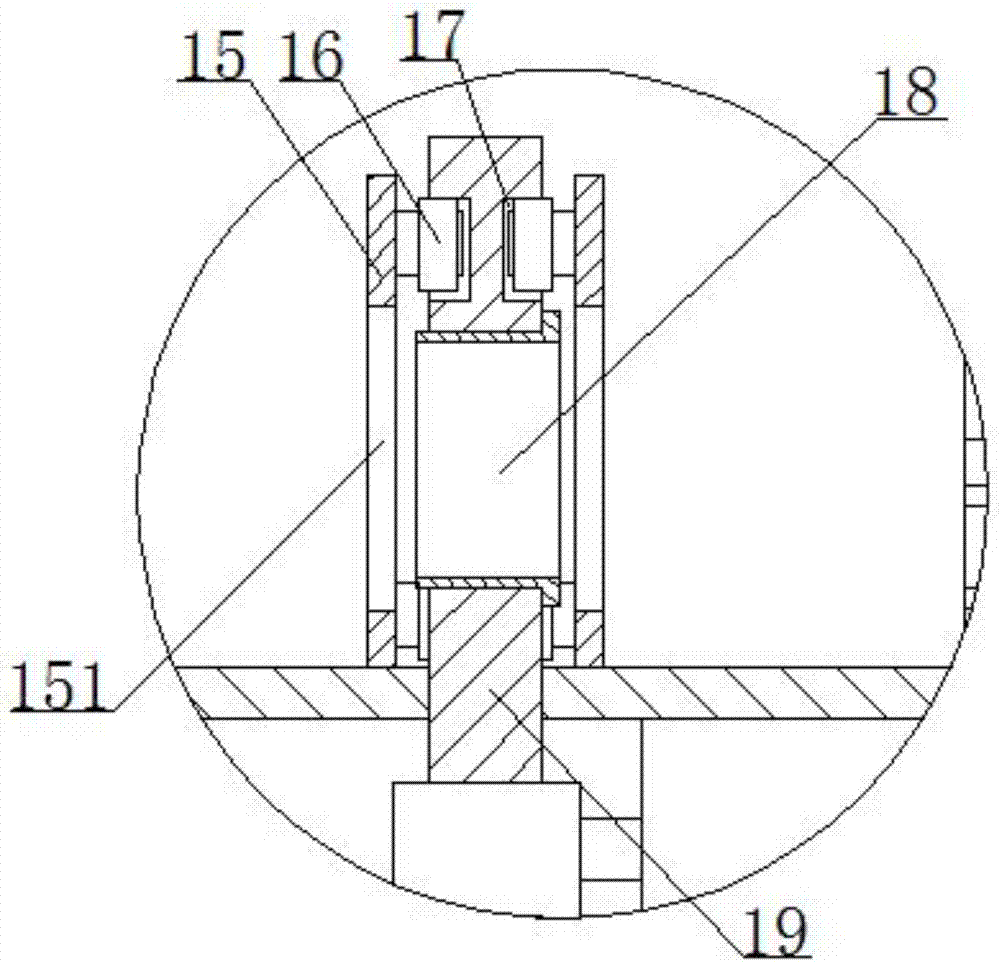

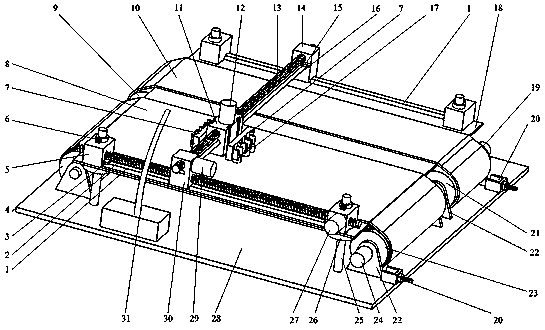

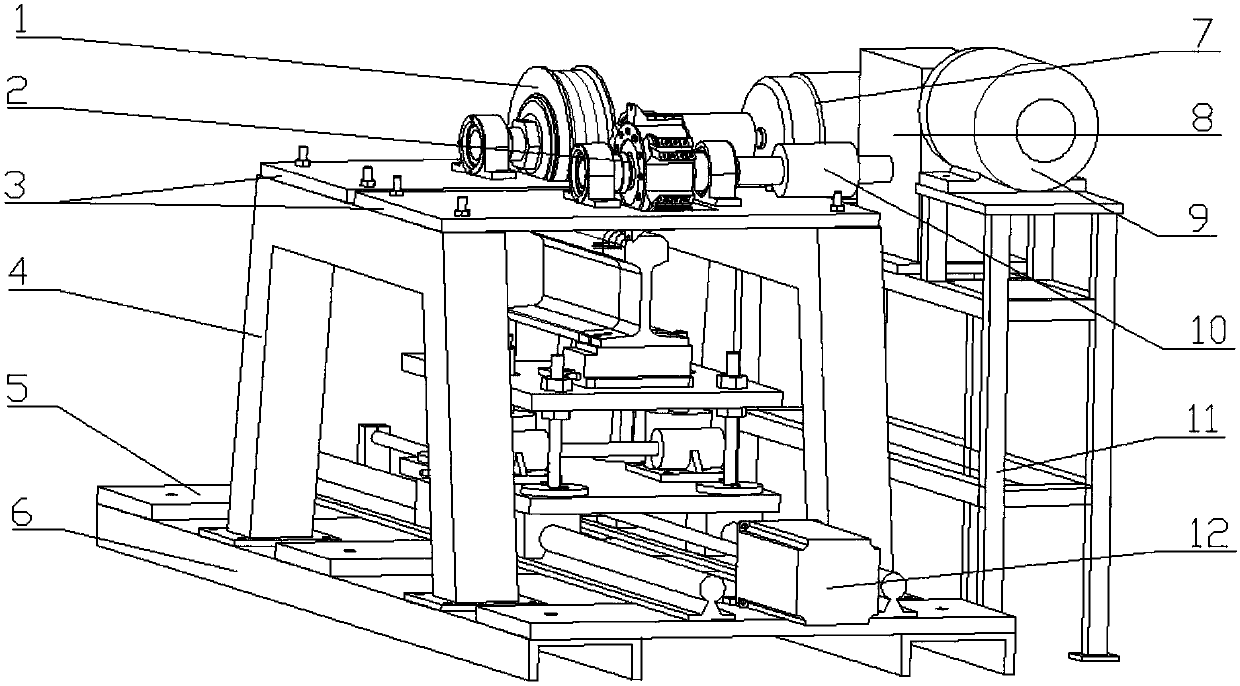

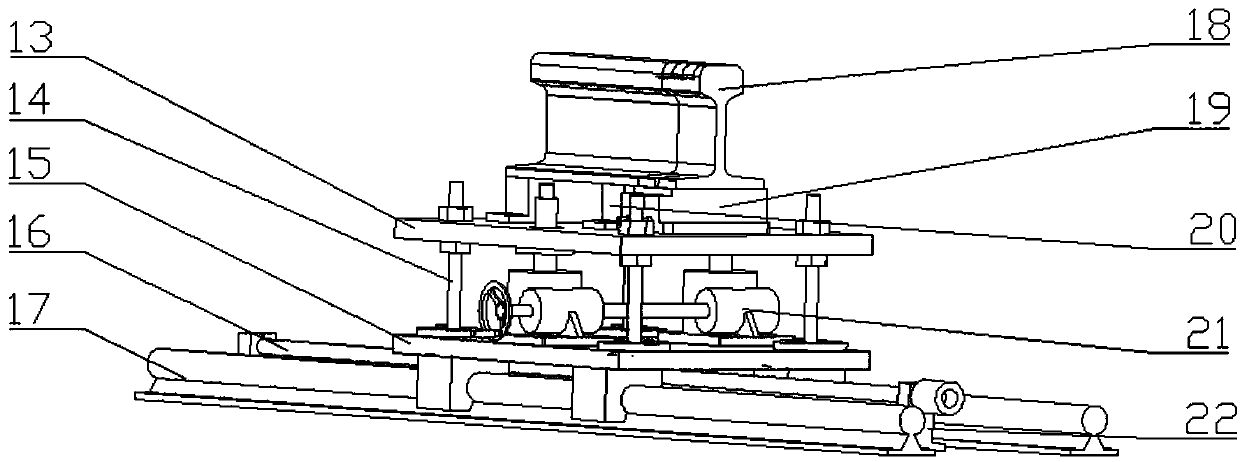

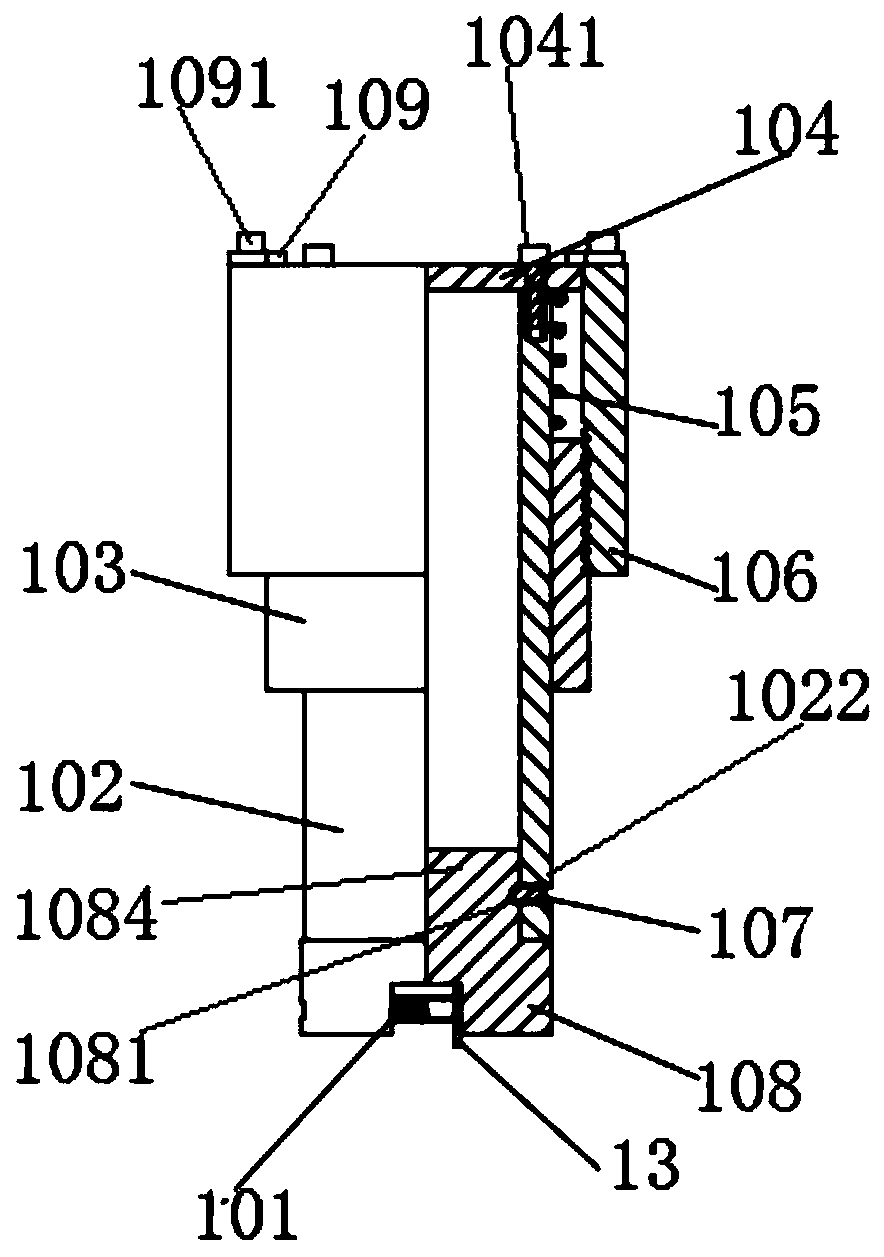

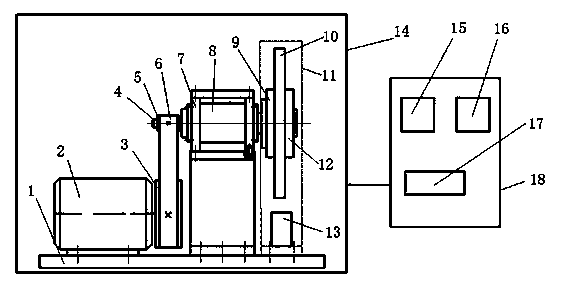

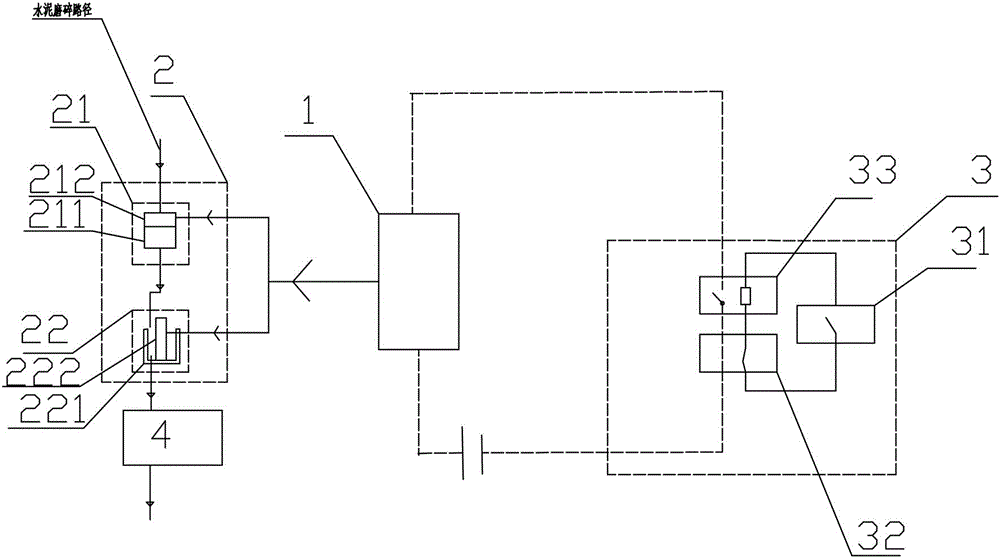

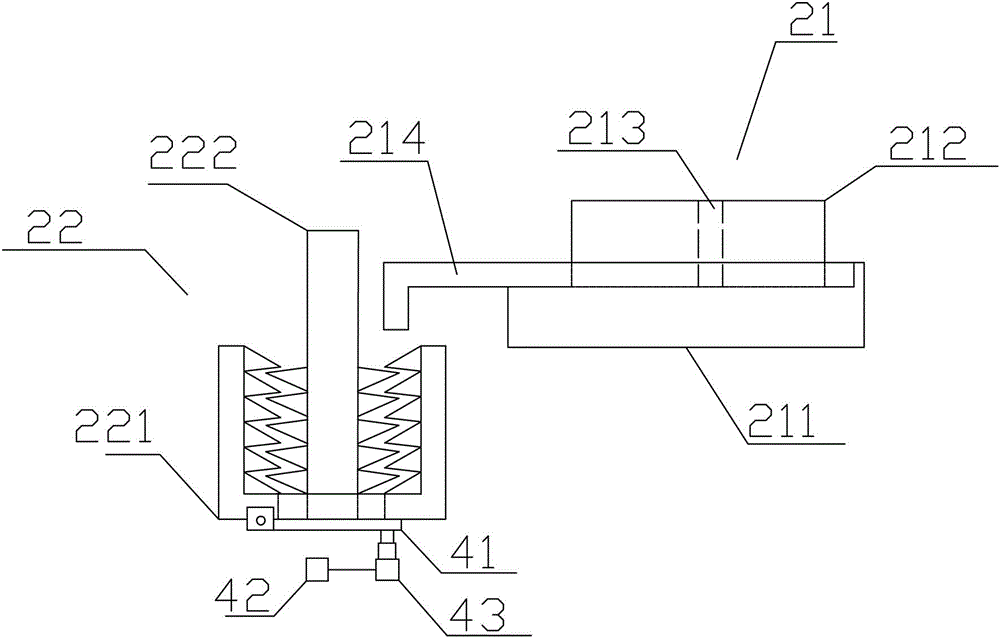

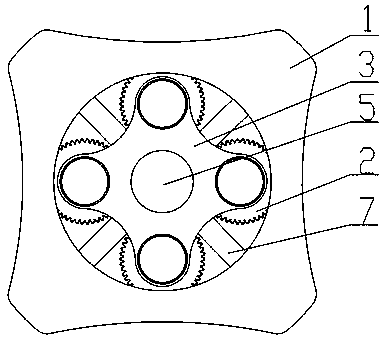

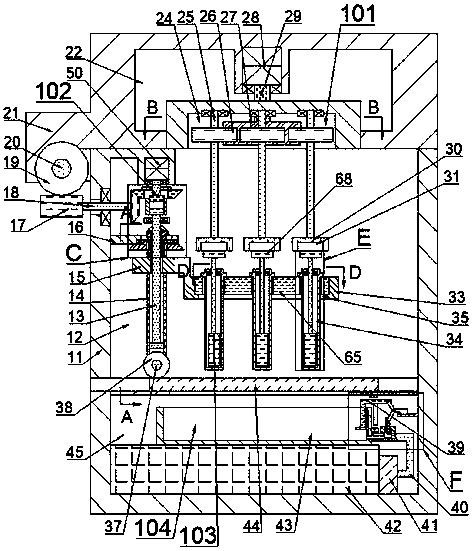

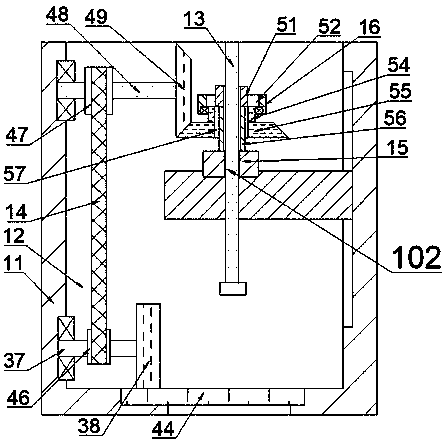

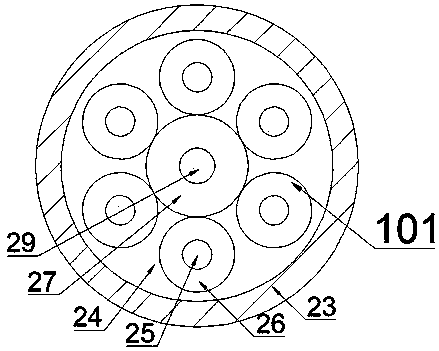

Abrasive particle pose controllable grinding test platform and abrasive particle pose controllable grinding test method for single abrasive particles

ActiveCN105158098AEasy accessSolve the problem of large differences in the results of repeated experimentsInvestigating abrasion/wear resistanceGrinding testMaterial removal

The invention discloses an abrasive particle pose controllable grinding test platform and an abrasive particle pose controllable grinding test method for single abrasive particles. The abrasive particle pose controllable grinding test platform comprises an abrasive particle pose controllable grinding wheel for the single abrasive particles and an acoustic emission measuring system. A block with the abrasive particles is arranged on the abrasive particle pose controllable grinding wheel for the single abrasive particles, and a balance block without the abrasive particles is arranged on the abrasive particle pose controllable grinding wheel and is symmetrical to the block with the abrasive particles; the abrasive particles are in contact with an abrasive particle braze welding platform on the top of a mandrel during braze welding; the acoustic emission measuring system comprises an acoustic emission sensor, a power amplifier, a data acquisition card and a computer. The abrasive particle pose controllable grinding test platform and the abrasive particle pose controllable grinding test method have the advantages that abrasive particle pose and cutting forms can be constrained, grinding procedures can be monitored, and accordingly technical support can be provided for further studying material removal mechanisms during grinding and abrasion conditions of the abrasive particles.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

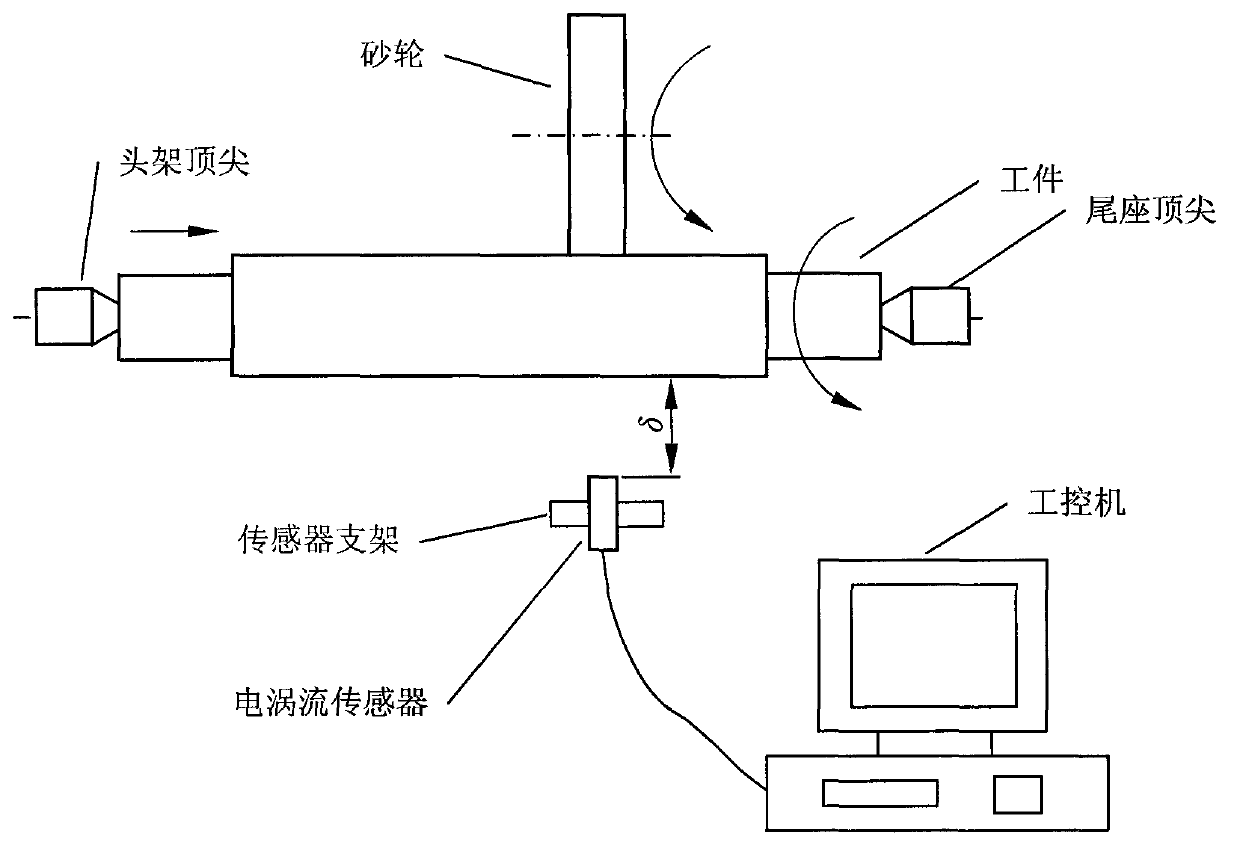

Method and device for detecting cylindrical grinding surface roughness through data fusion technology

InactiveCN103659602AImprove completenessImprove efficiencyGrinding feed controlUsing electrical meansProcess systemsGrinding test

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

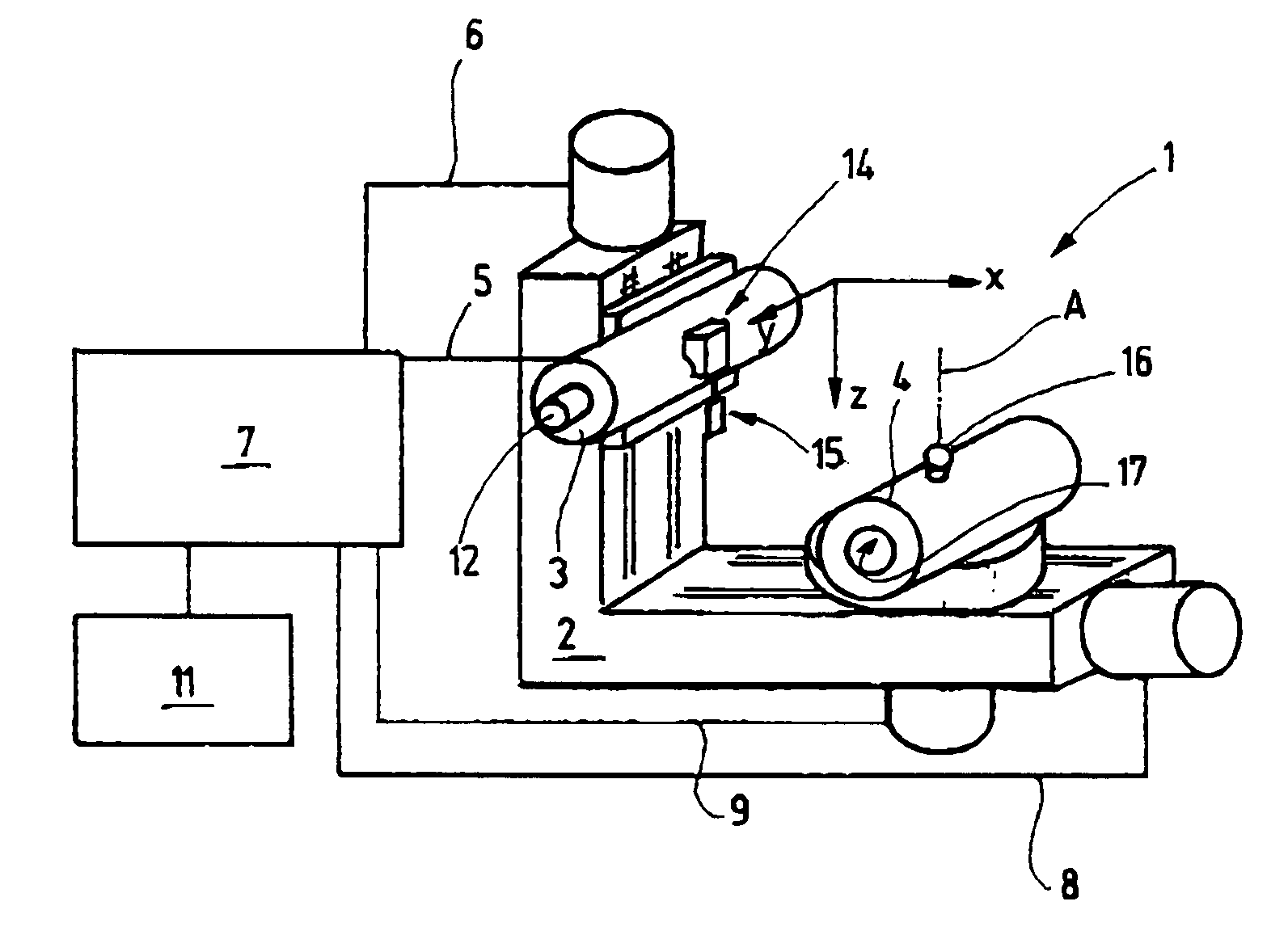

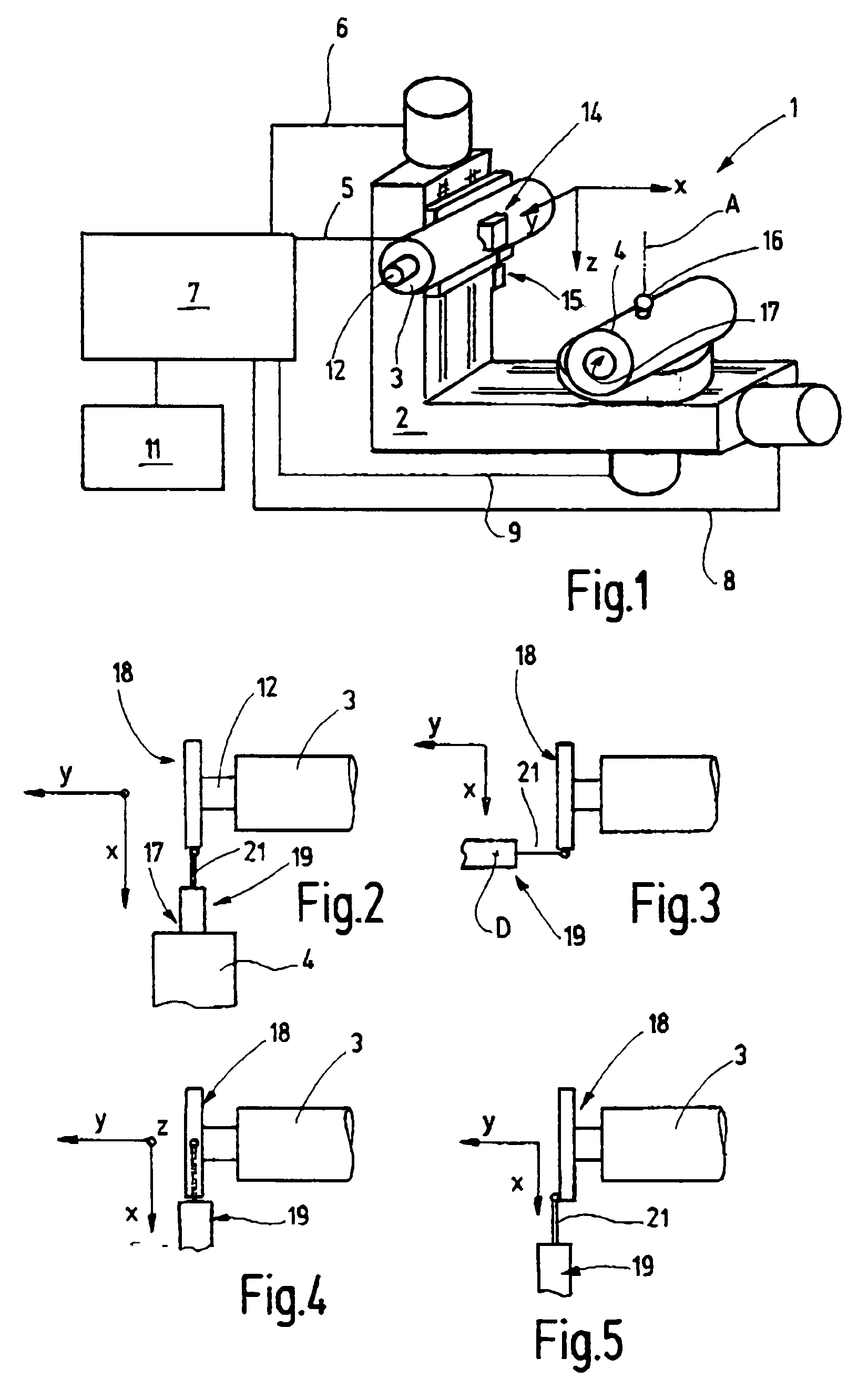

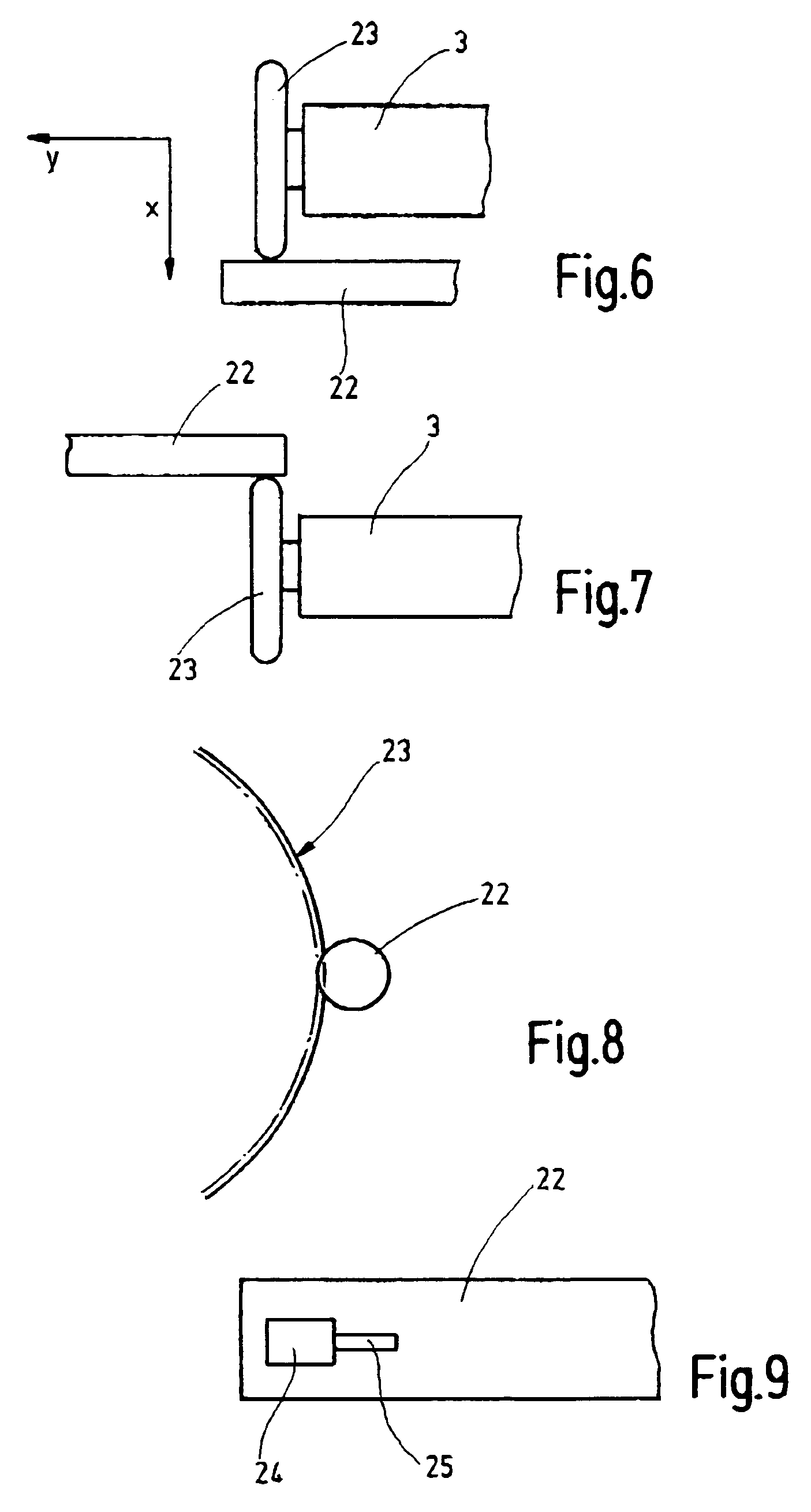

Calibration procedures and such using an erosion and grinding machine

A method for calibration of grinding and / or erosion machines assumes an initial calibration process and corresponding re-calibration processes. Calibration of the machine is performed with a reference piece and a reference tracer in an initial calibration process. Grinding tests follow the first tracing process from all directions during which tests deviations are determined and made ineffective with the iterative procedure. The machine-internal measuring system is calibrated immediately after performing the machining tests and thereby immediately after the initial referencing of the machining apparatus whereby the machine tracer and a test piece is traced from all coordinate directions and the resulting position values are stored. Subsequent re-calibrations supply measured values, which are compared to the stored values whereby correction values are determined then from the deviations for additional machining of workpieces.

Owner:WALTER MASCHINENBAU GMBH

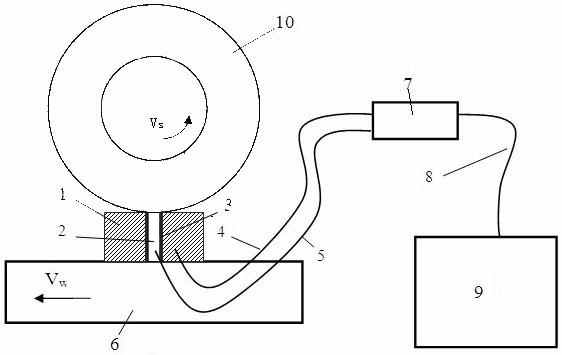

Method for measuring temperature of grinding region of surface grinding

InactiveCN102501173AAccurate measurementAvoid Grinding BurnsThermometers using electric/magnetic elementsGrinding feed controlShielded cableThermodynamics

The invention relates to a method for measuring the temperature of a grinding region of surface grinding. The method comprises the following steps: (1), making a thermocouple temperature sensor, (2), calibrating the thermocouple temperature sensor, and (3), measuring the temperature of the grinding region. During the grinding process, firstly a wire I and a wire II are connected into a collection card with a cold-end compensation function and a computer, then the grinding test is carried out after setting the rotation speed (Vs) of a grinding wheel and the rotation speed (Vw) of a working table, the top part of a ground work piece and the top part of a constantan sheet as thermocouple material are mutually lapped or welded together to form a thermocouple node, and finally the detected value of temperature of the grinding region is displayed and recorded by the computer through the shielded-type collection card with a cold-end compensation function and a shielded cable. The method can measure the temperature of the grinding region relatively and accurately when the work piece is ground by a surface grinding machine, and can protect the work piece from grinding burn and large residual stress by optimizing the process parameters of the surface grinding operation. The method has significance of improving quality of ground surface of the work piece and increasing the grinding efficiency.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

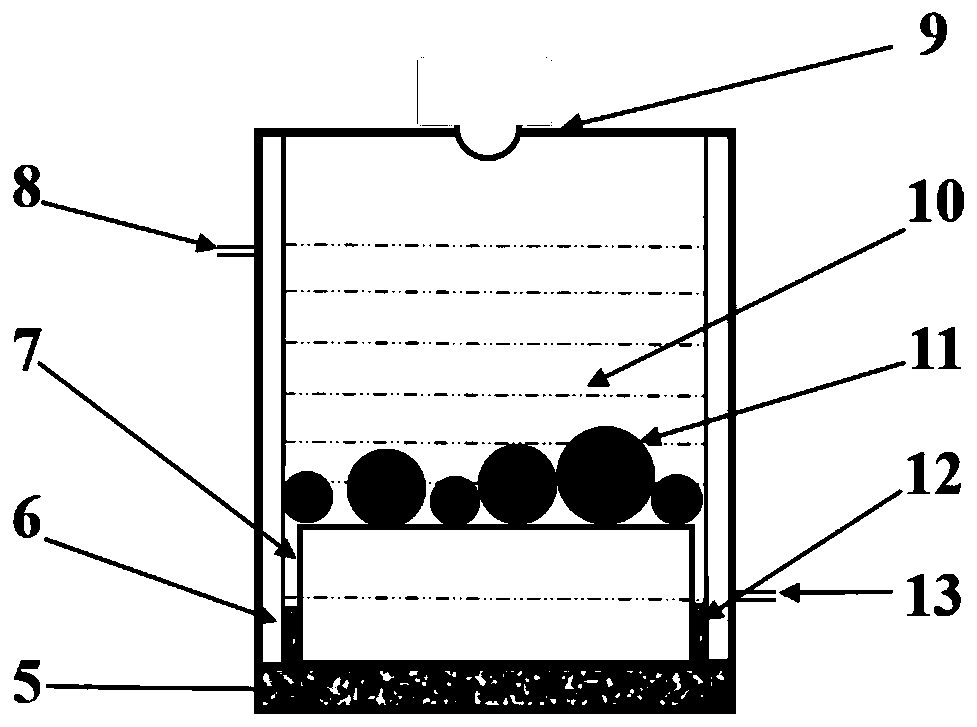

Marine concrete impacting and grinding test device and test method thereof

PendingCN109916756ASimple structureEasy to operateInvestigating abrasion/wear resistanceTemperature controlImpeller

The invention relates to a marine concrete impacting and grinding test device and a test method thereof. The test device comprises a test container for accommodating simulated seawater and a test piece, a temperature control device for controlling a test environment temperature in the test container, a stirring device for driving a water flow and simulating wave washing, and a communication tube for being connected with the test container and the temperature control device. The test piece is arranged in the test container. When the test device is in use, the test container is filled with an artificial sea water solution. An impacting and grinding medium is paved on the upper surface of the test piece; and stirring impellers of the stirring device are arranged in the test container. The test device having a simple structure is operated conveniently. The development and study of the anti-impacting anti-grinding performance evaluation method of the cement-based material and the novel material of the marine concrete under effects of multiple coupling factors in an actual marine environment, especially in a splash zone can be simulated and promoted. The test device and the test method have characteristics of wide application range, real marine environment simulation, energy conservation, and environment protection and the like.

Owner:WUHAN UNIV OF TECH

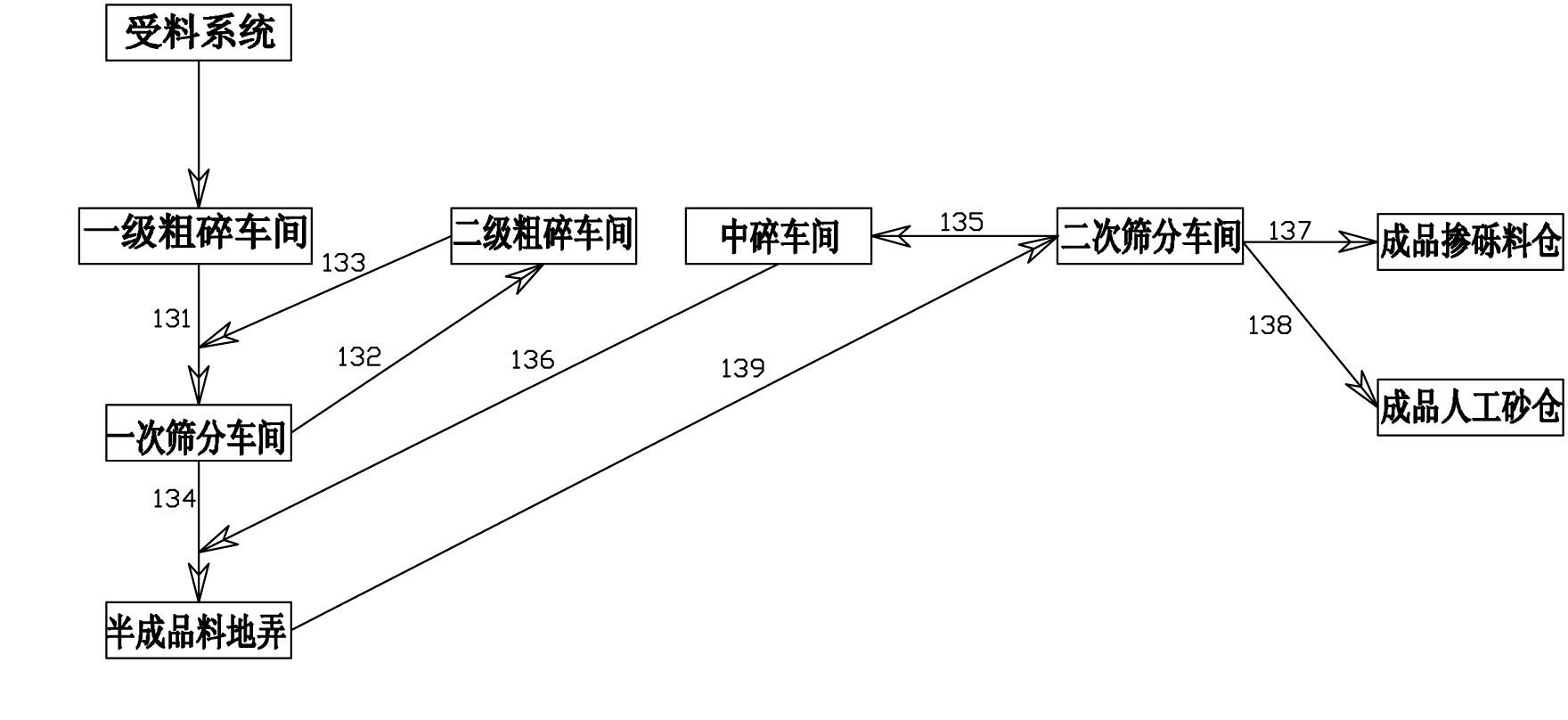

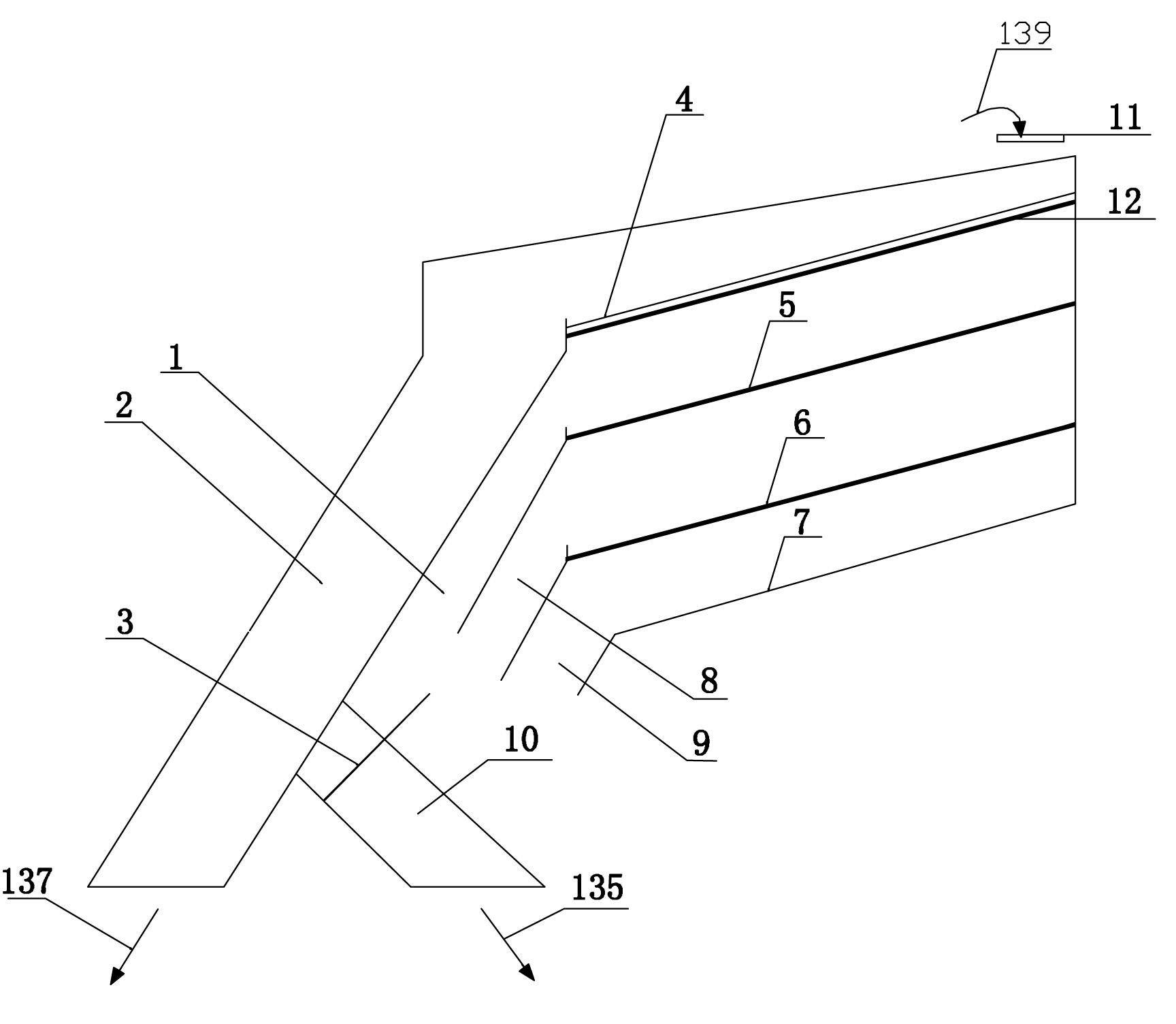

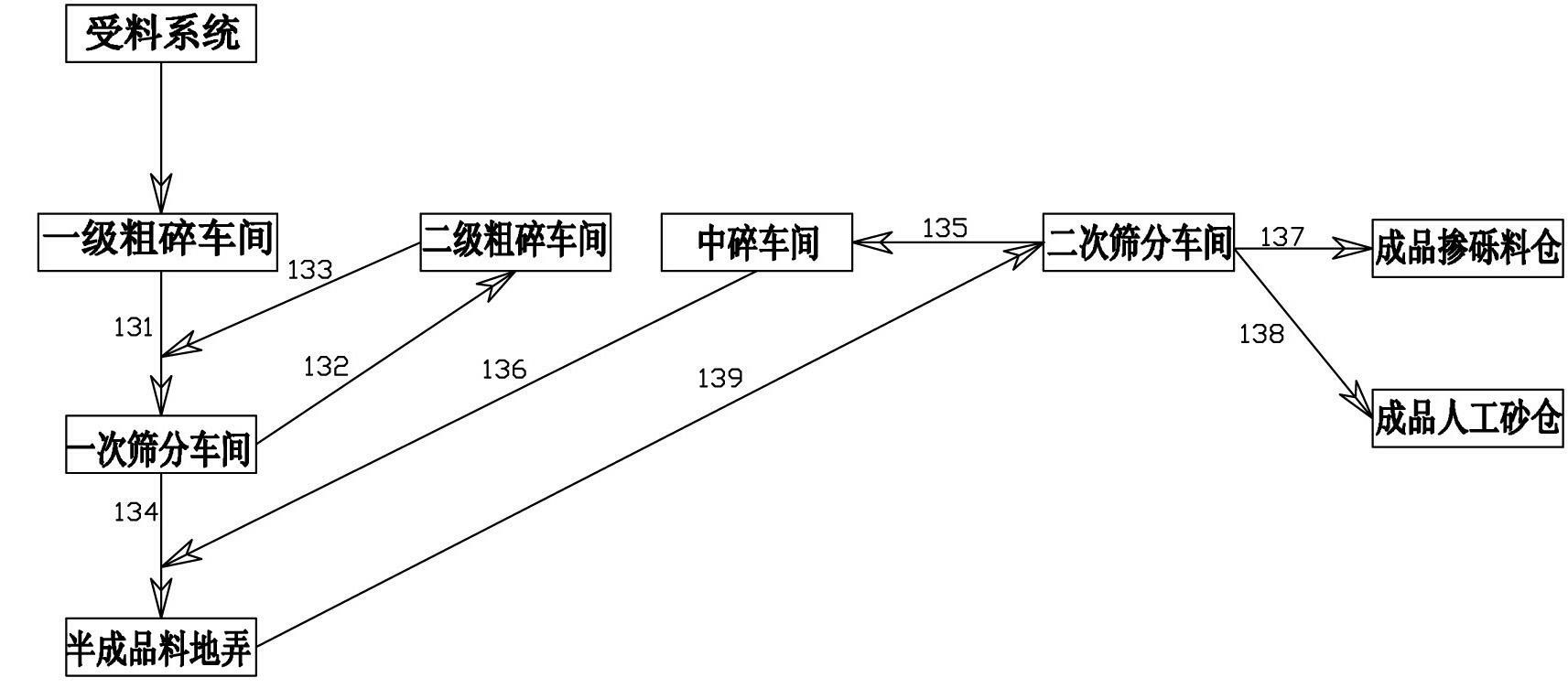

Gravel doped grinding system for anti-leakage wall and preparation method thereof

ActiveCN102152398AGuaranteed continuityReduce occupancyArtificial islandsUnderwater structuresGrinding testEngineering

The invention discloses a gravel doped grinding system for an anti-leakage wall and a preparation method thereof. The preparation method comprises: 1) arranging a 5mm blockage screen on the upper part of a shunt screen in a re-screening workshop, forming a shunt groove on a chute at an discharge hole of the screen, and arranging a shunt plug board on the shunt groove; 2) shunting part of the mixture into an intermediate crushing workshop by adjusting the opening degree of the shunt plug board so as to increase the content of intermediate stone and the content of gravel; and 3) sampling a gravel doped finished product from a warehouse, performing a grinding test, adjusting the height of the shunt plug board and the opening degree of a discharge hole of a crushing system according to the result of the grinding test until the grinding meets the designed requirements. By the above steps, the gravel doped material for the anti-leakage wall which meets the requirements on the designed grinding is prepared at one time. The system and the method have the advantages of reducing occupied area, shrinking the production period and improving the production efficiency.

Owner:中国葛洲坝集团建设工程有限公司

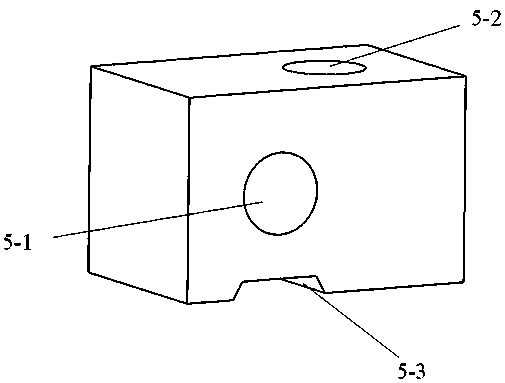

Electric wire and cable abrasion resistance detection equipment applicable to multiple experimental environments

PendingCN107478532ACompact structureEasy to useInvestigating abrasion/wear resistanceGrinding testEngineering

The invention provides electric wire and cable abrasion resistance detection equipment applicable to multiple experimental environments. The electric wire and cable abrasion resistance detection equipment comprises a scraping and grinding test unit, wherein the scraping and grinding test unit comprises a clamping seat, the clamping seat comprises one upper pressure plate which can be turned over as well as opened and closed, and a through hole is formed in the middle part of the upper pressure plate; the upper end of the upper pressure plate is fixedly connected with two sliding seats, and a slidable push rod is erected between the two sliding seats; and a scraping knife which can horizontally reciprocate is fixedly connected with the middle part of the lower end of the push rod and extends into the through hole. The electric wire and cable abrasion resistance detection equipment has the advantages that the middle part of an electric wire and cable is fixed by virtue of the scraping and grinding test unit located at the middle part, so that a common test unit and a hole test unit which are arranged at two sides do not influence each other during operation; a removable grinding sleeve is adopted, so that the electric wire and cable abrasion resistance detection equipment can be conveniently maintained; and the scraping knife is arranged on the upper pressure plate of the clamping seat, so that the scraping knife can be applicable to electric wires and cables with different outer diameters, and the universality of the electric wire and cable abrasion resistance detection equipment is enhanced.

Owner:TIANJIN DAILY PROSPERITY SCI & TECH GROUP

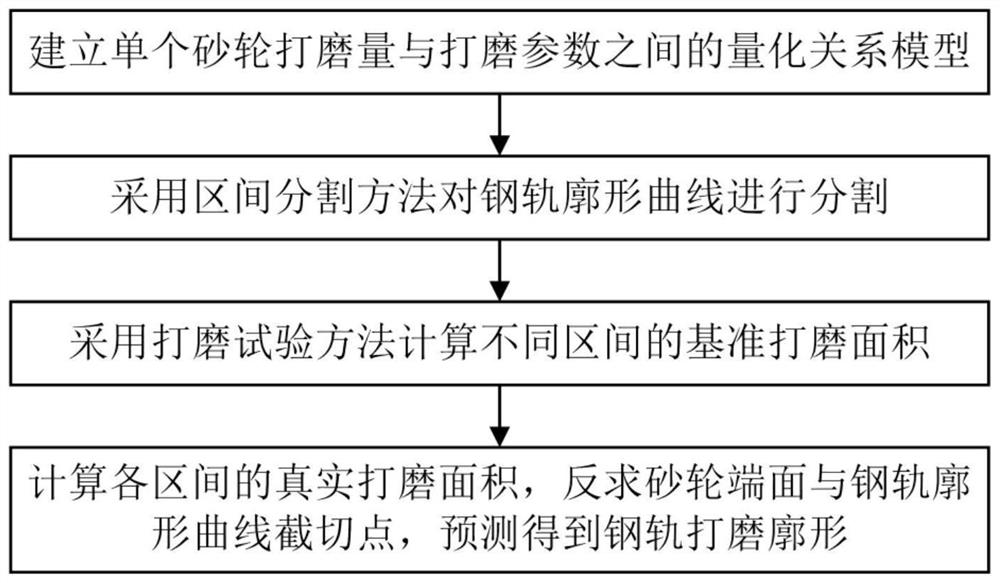

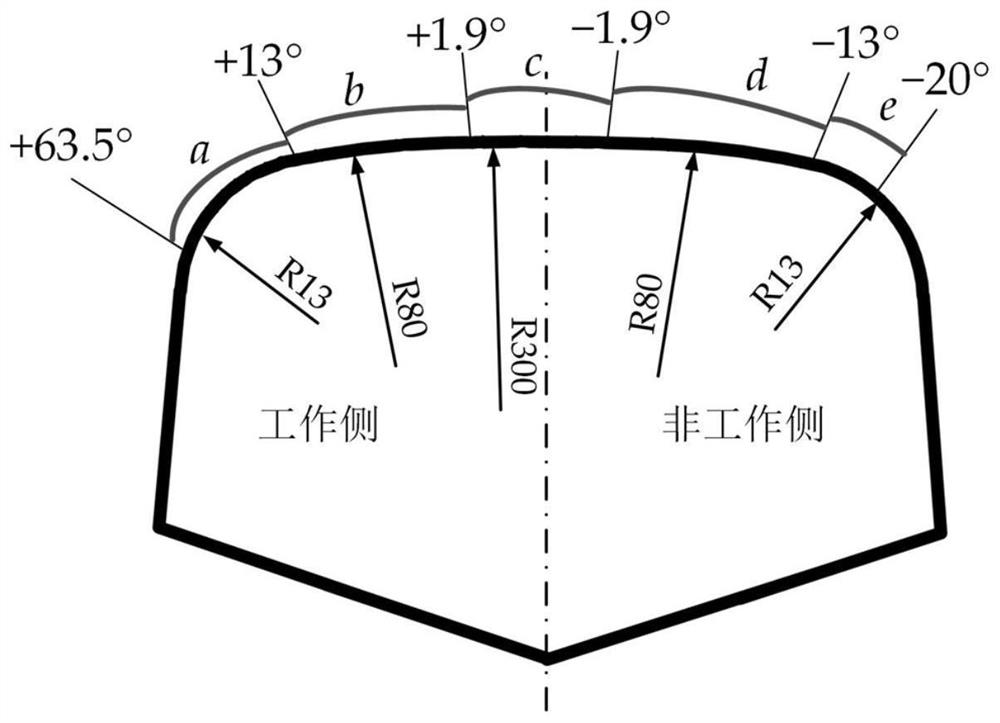

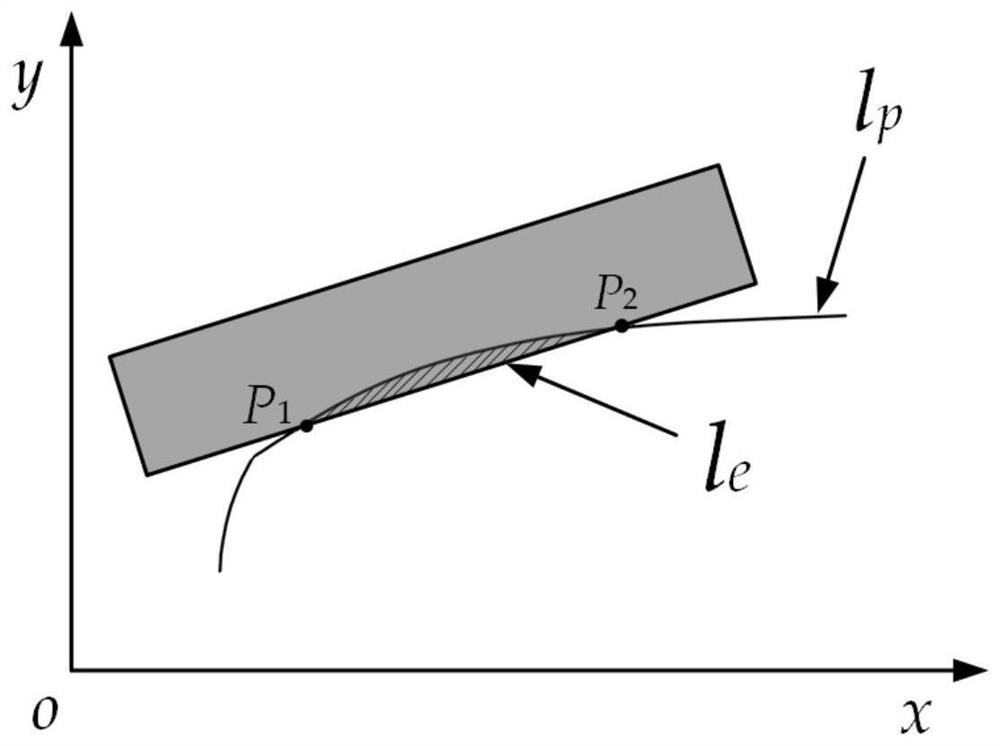

Steel rail grinding profile rapid prediction method based on interval segmentation

InactiveCN111764208AImprove sanding qualityQuick forecastRailway track constructionGrinding testRail profile

The invention discloses a steel rail grinding profile rapid prediction method based on interval segmentation. The method comprises the steps of 1, establishing a quantitative relation model between the grinding amount of a single grinding wheel and grinding parameters; 2, according to geometrical characteristics of a section profile curve of the in-service steel rail and the grinding range of a grinding train, adopting an interval segmentation method for dividing to obtain steel rail profile interval sections with different curvatures; 3, calculating reference grinding areas of different intervals by adopting a grinding test method; 4, combining the calculated reference grinding area to obtain the real grinding area of the steel rail in each segmentation interval, reversely calculating a cutting point of the end face of the grinding wheel and the profile curve of the steel rail, and finally predicting the finally obtained grinding profile of the steel rail based on the steel rail grinding sequence forming mechanism. The method has the advantages of being high in calculation efficiency and accurate in prediction result, and the problem that a traditional steel rail grinding profileprediction method cannot rapidly complete profile prediction within limited skylight time is solved.

Owner:XIJING UNIV

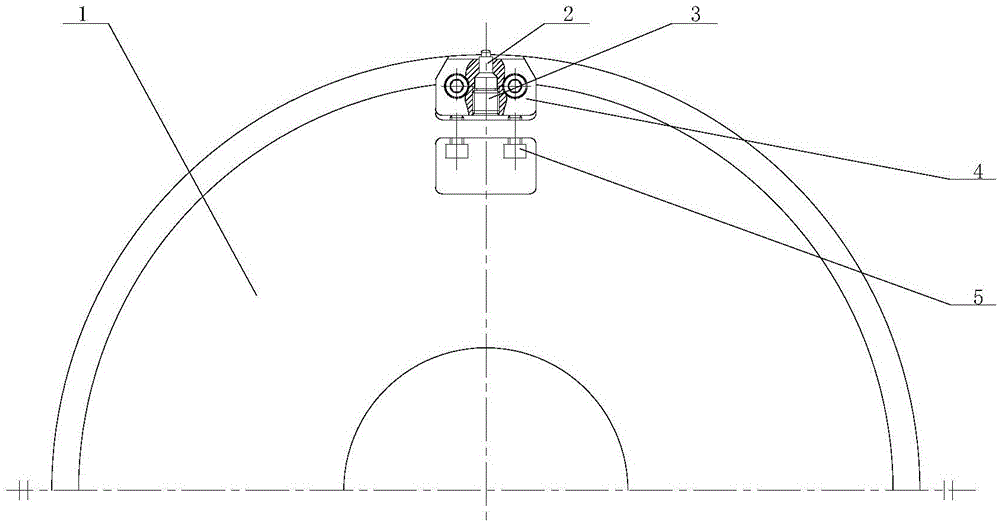

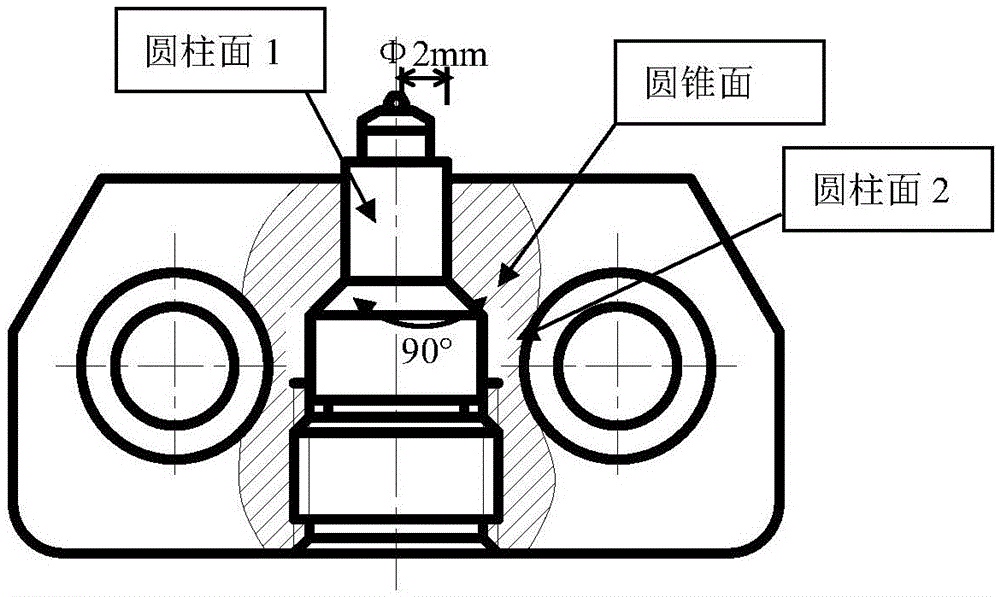

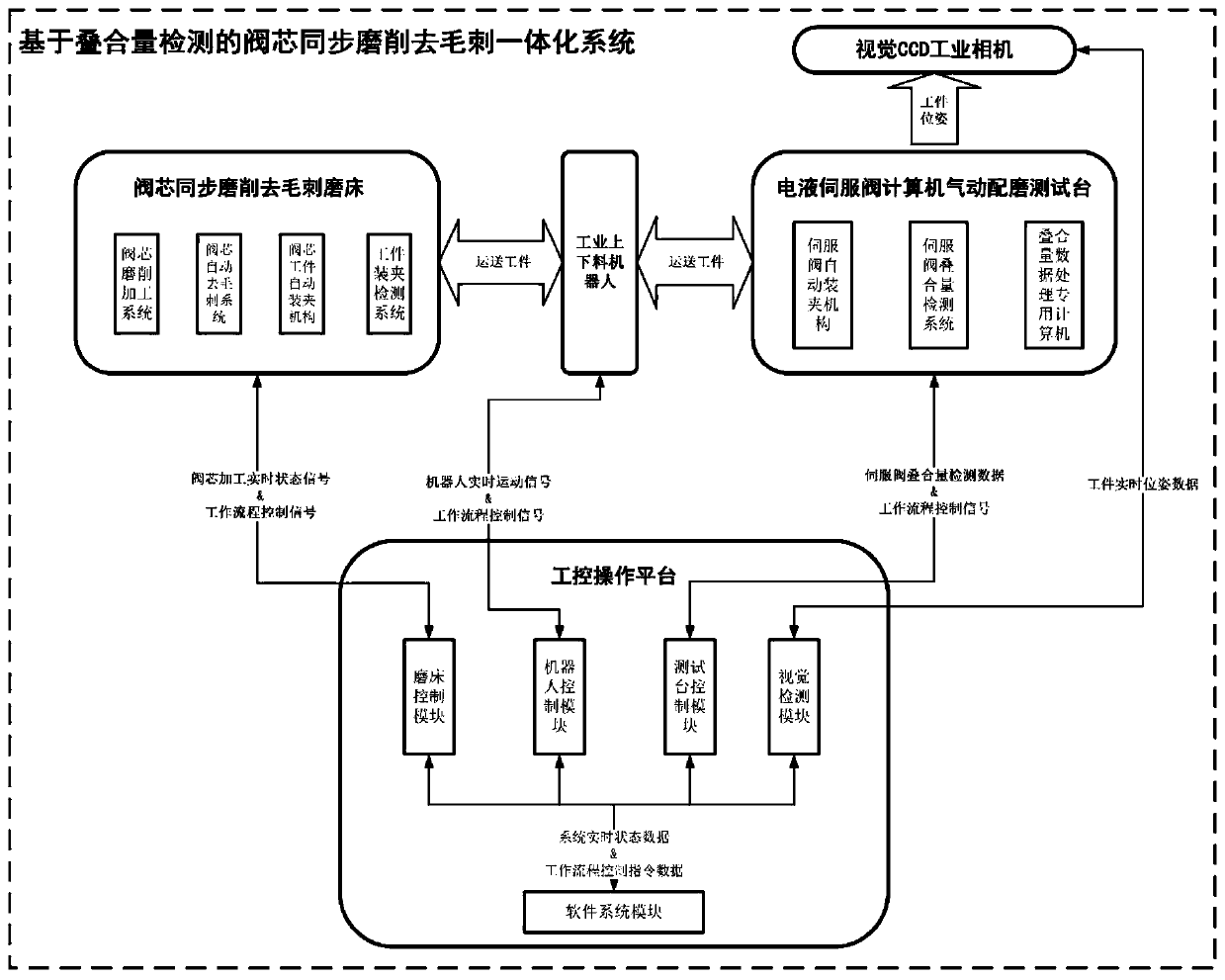

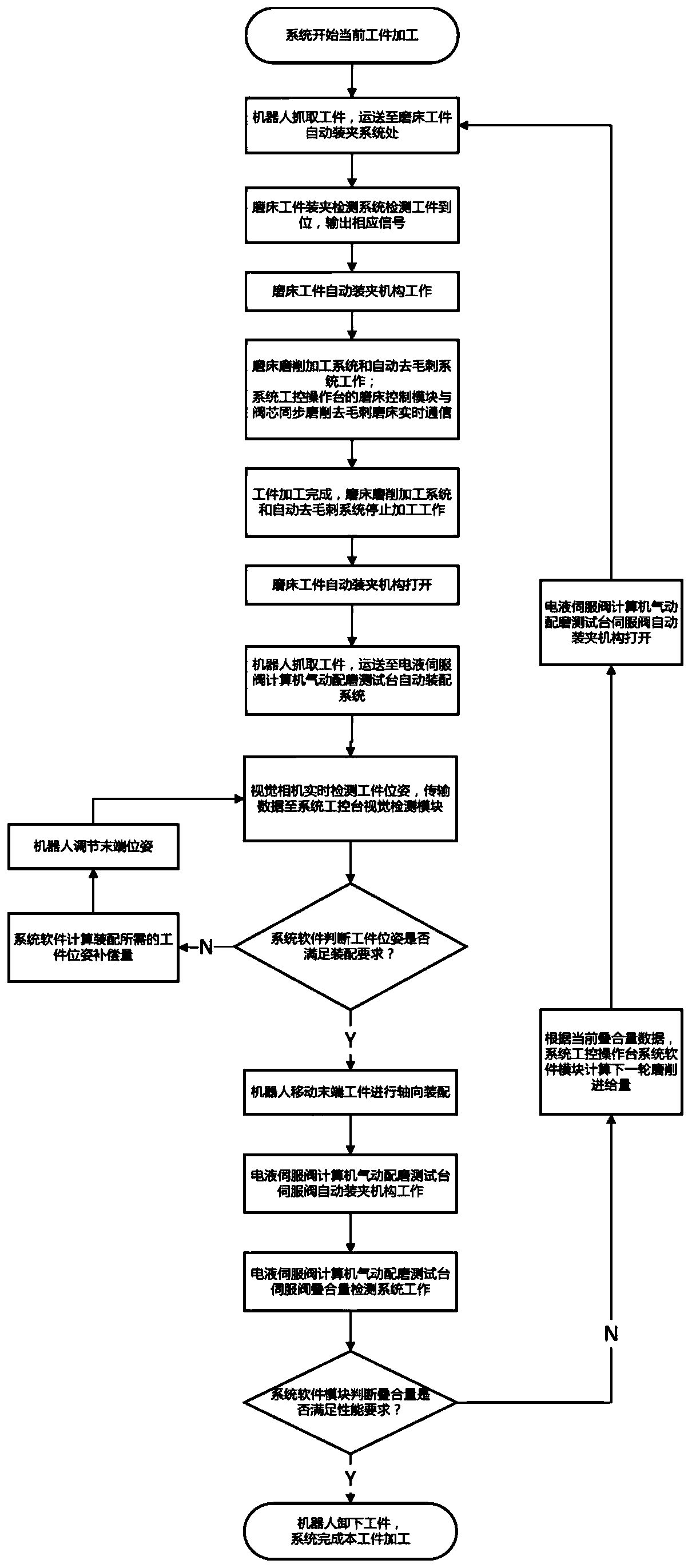

Valve element synchronous grinding and deburring integrated method based on overlap value detection and system

ActiveCN110549188AImprove processing efficiencyImprove processing yieldEdge grinding machinesGrinding feed controlGrinding testElectro hydraulic

The invention provides a valve element synchronous grinding and deburring integrated method based on overlap value detection and an automatic deburring system applying the valve element synchronous grinding and deburring integrated method. Automatic clamping of a valve element and synchronous precision grinding and deburring of a working edge can be completed by a servo valve element synchronous grinding and deburring grinding machine, a valve element workpiece is grabbed and conveyed by an industrial feeding and discharging robot, automatic assembling of a servo valve slide pair is completedunder the aided inspection of a vision CCD industrial camera, automatic clamping of the servo valve slide pair and overlay value automatic detection of a servo valve are performed by an electro-hydraulic servo valve computer pneumatic match-grinding test board, and system complete workflow real-time control and processing parameter self-adaption control are realized by a system industrial controloperating board. Automation and integration of servo valve element synchronous grinding and deburring processing and overlaying value detection are realized, the valve element synchronous grinding anddeburring integrated method and the system have the characteristics that manual aided processing is not needed, the processing efficiency is high, the manufacturing precision is high, and the rate offinished products is high; and the system is clear in division of unit functions, flexible to assemble and debug, high in degree of flexibility, and suitable for being combined with an actual servo valve industrial production line.

Owner:SHANGHAI JIAO TONG UNIV

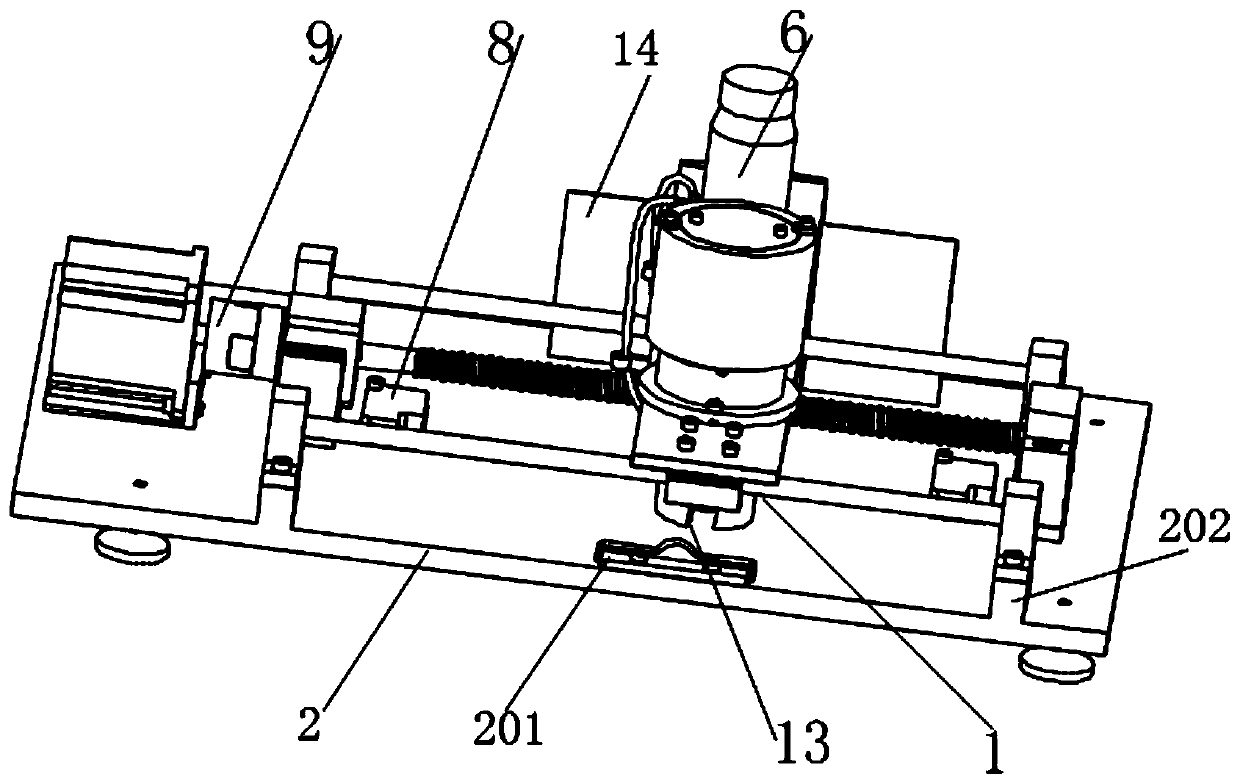

Cutting line grinding test device and test method

InactiveCN104122158AAvoid wastingConvenient inspectionInvestigating machinabilityGrinding testElectric machinery

The invention discloses a cutting line grinding test device and a test method. The objective of the invention is to solve the technical problem that cutting properties of cutting lines at present cannot be determined and measured in advance. The cutting line grinding test device comprises a rack, a winding assembly disposed in the middle part of the rack, a spraying assembly and a grinding assembly. The winding assembly comprises a group of horizontally disposed winding guide wheels, and a guide wheel driving motor connected to the winding wheels. The spraying assembly comprises a cutting fluid filter box disposed at the lower part of the rack, a spraying tube disposed above the winding wheels, and a fluid feeding pipe communicating the cutting fluid filter box and the spraying tube. An infusion pump is installed at the connecting position of the cutting fluid filter box and the fluid feeding pipe. The grinding assembly comprises a lifting support disposed at the upper part of the rack, a grinding block installing plate disposed on the lifting support, and a lifting driving motor. The cutting line grinding test device and the test method can accurately evaluate cutting properties of cutting lines, thus facilitating production quality control for a manufacturer, increasing the testing efficiency and saving the testing cost.

Owner:开封恒锐新金刚石制品有限公司

Equal-path grinding and polishing integrated device

PendingCN109834558ASimple structureImprove grinding and polishing effectGrinding carriagesPreparing sample for investigationLinear motionGrinding test

The invention discloses an equal-path grinding and polishing integrated device. The equal-path grinding and polishing integrated device comprises an abrasive paper control mechanism, a polishing clothcontrol mechanism, a test piece clamping motion mechanism and a device body, wherein the abrasive paper control mechanism is used for grinding a test piece and has the functions of automatically replacing abrasive paper and collecting waste abrasive paper; the polishing cloth control mechanism is used for polishing the test piece and has the functions of automatically replacing polishing cloth and collecting waste polishing cloth; and the test piece clamping motion mechanism has the functions of constant-pressure clamping of the test piece, test piece path motion and path planning. Two processes of grinding and polishing can be completed under one-time clamping, and thus the work efficiency is improved; and by controlling linear motion of the test piece, it is ensured that the test piecegrinding distances are equal and the paths are the same, the problem of edge subsiding of the disc rotary type grinding test piece is avoided, and the grinding quality is improved.

Owner:UNIV OF JINAN

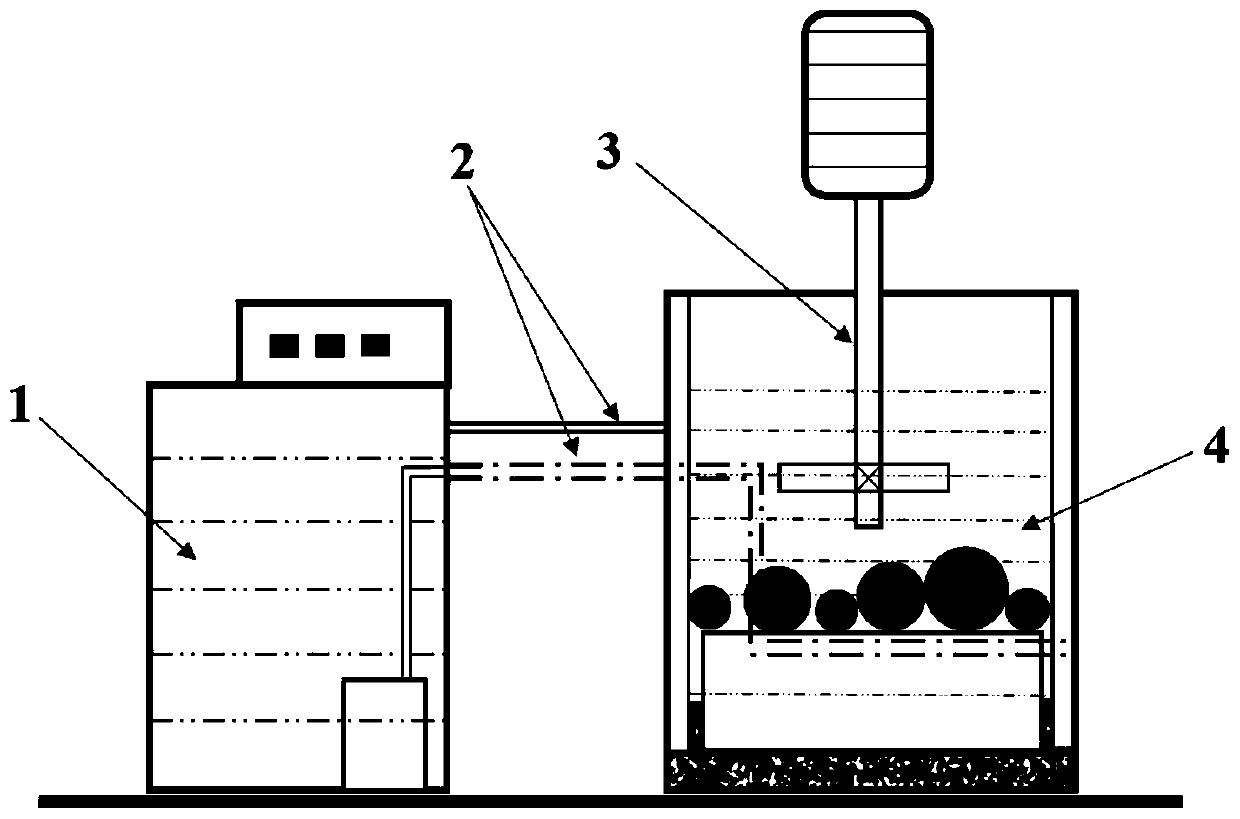

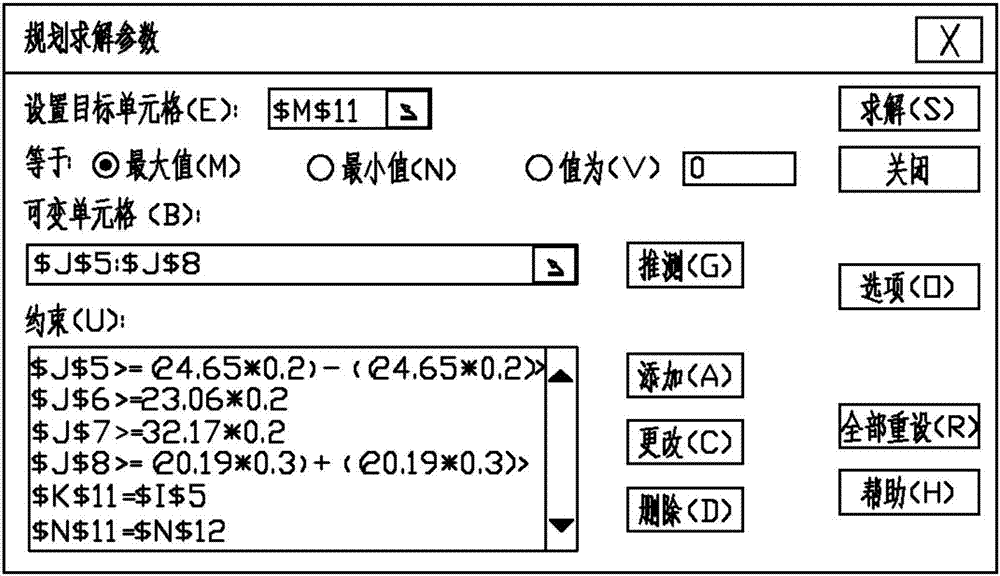

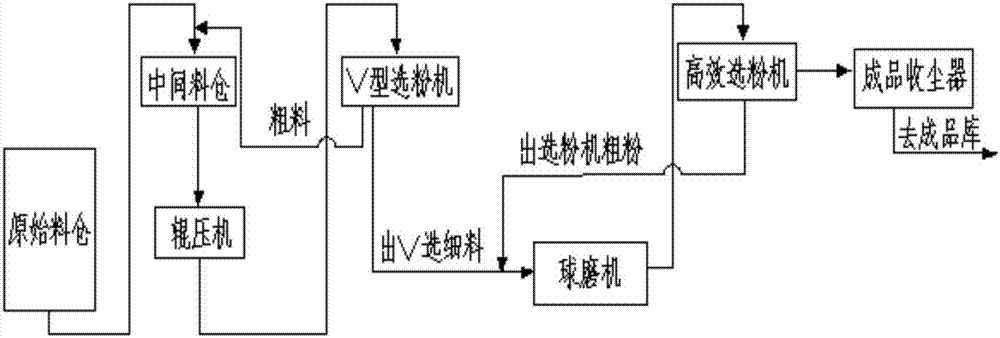

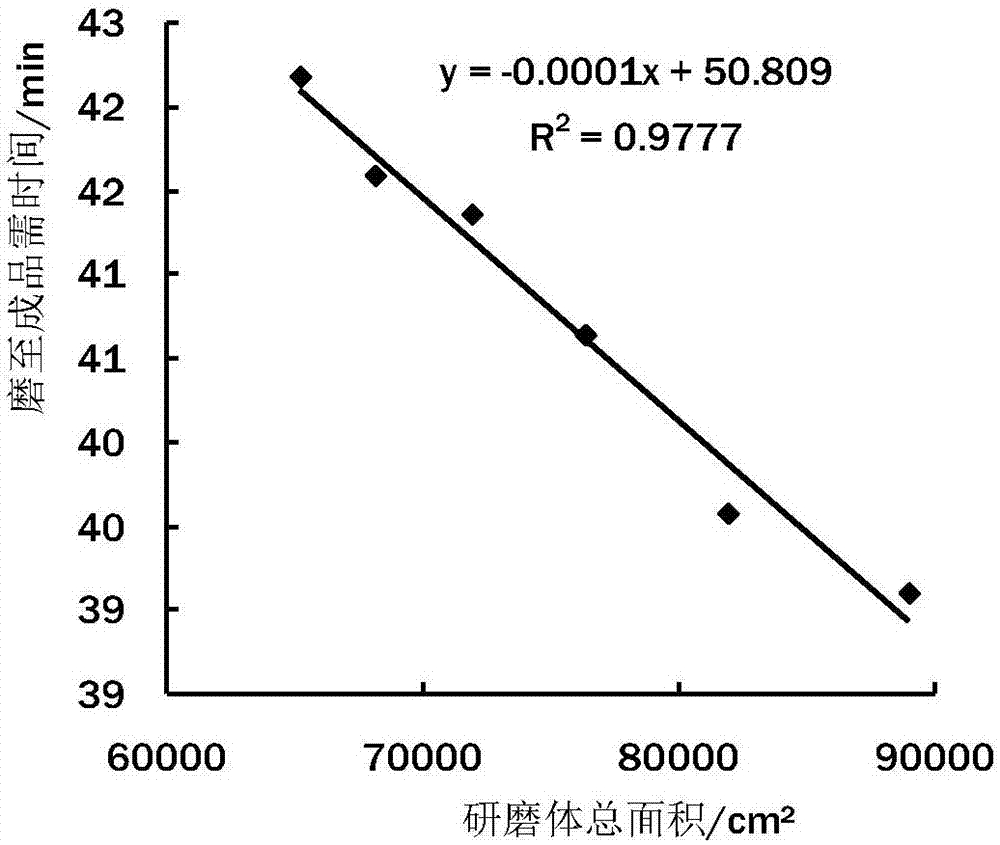

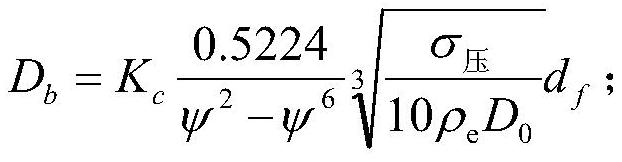

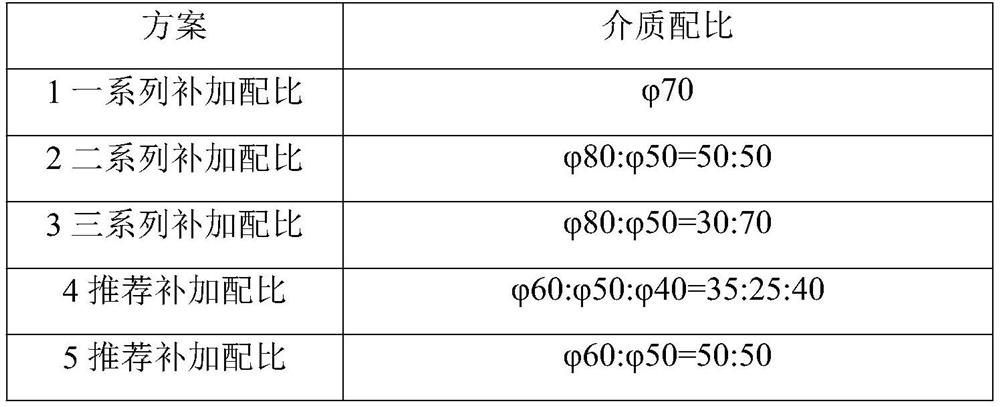

Method for quickly determining optimal gradations of ceramic grinding bodies of cement ball mill

ActiveCN107451731AAvoid risk of failureThe best grinding body grading schemeForecastingCement productionGrinding testCement grinding

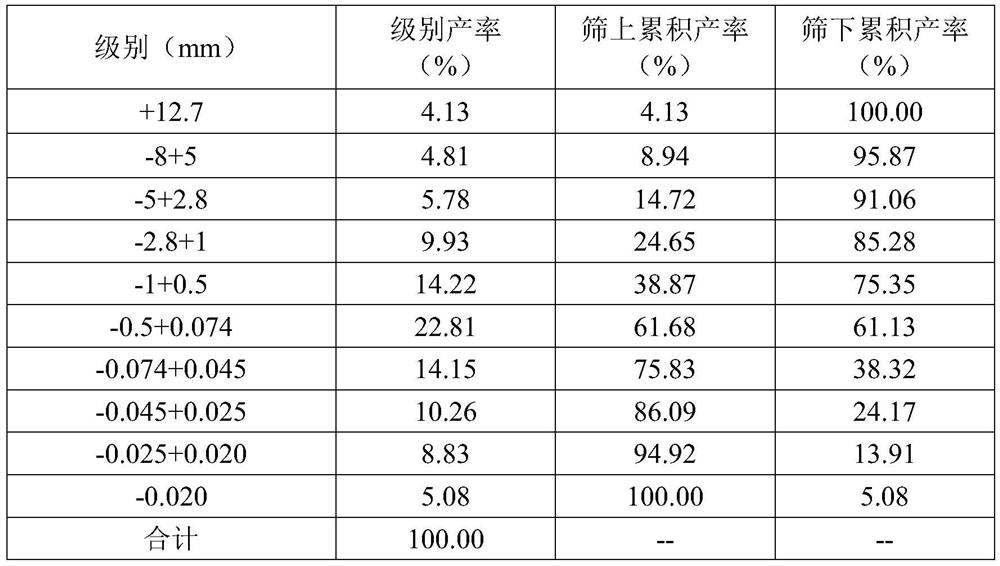

The present invention relates to a method for quickly determining the optimal gradations of the ceramic grinding bodies of a cement ball mill. The method comprises the following steps that: (1) a cement grinding system is calibrated before the ceramic grinding bodies are used; (2) the relative grindability of materials to be ground is measured; (3) materials to be ground for a libratory grinding test are selected; (4) a ceramic grinding body gradation scheme is designed; (5) the operation of the libratory grinding test is performed; (6) the yield of an industrialized grinding test is calculated according to the result of the libratory grinding test; (7) the feasibility of the gradation scheme is judged; (8) the use scheme of the ceramic grinding bodies is adjusted according to the inherent capacities of machining procedures; and (9) the gradations of grinding bodies in a second cabin in the industrialized grinding test are calculated according to the gradations of the grinding bodies in the libratory grinding test. With the method adopted, the optimal scheme for the gradation of the grinding bodies in the industrialized grinding test can be determined fast.

Owner:成安金隅太行水泥有限公司

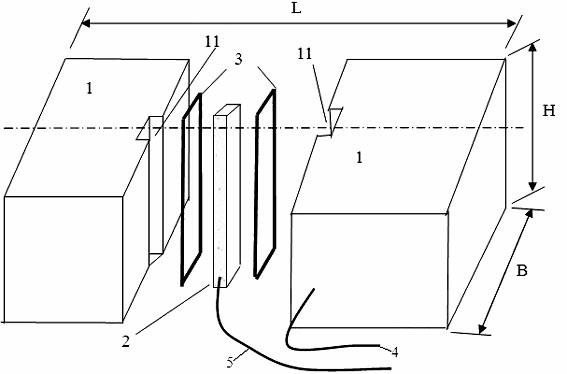

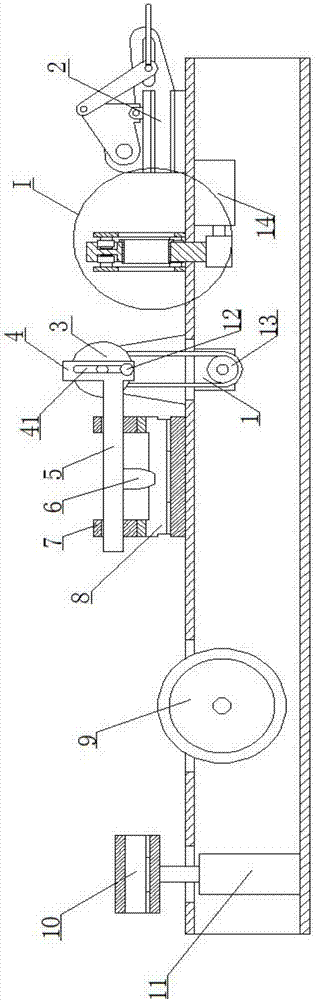

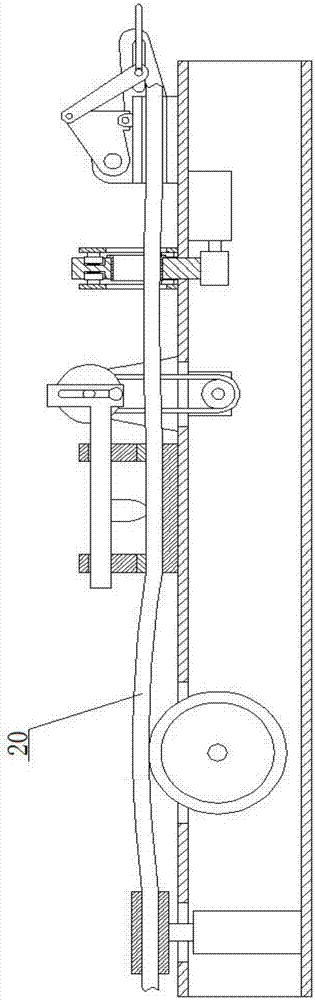

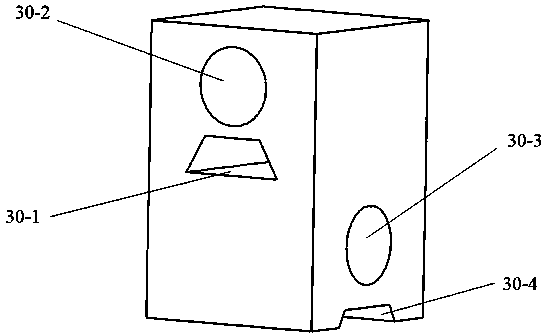

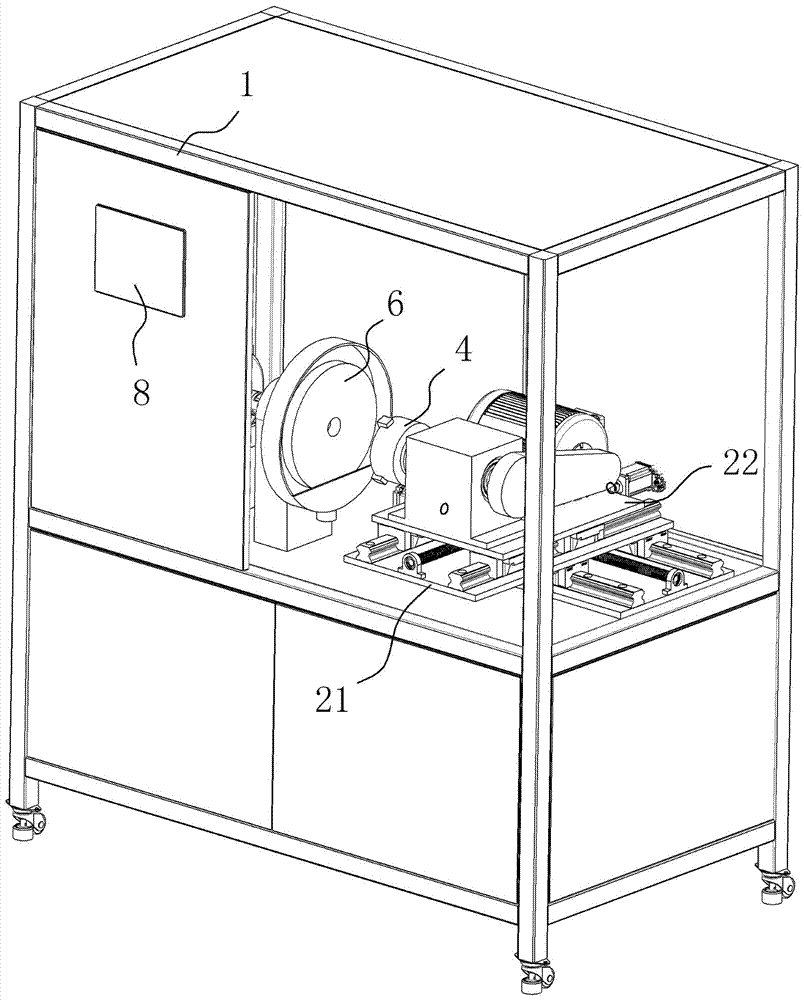

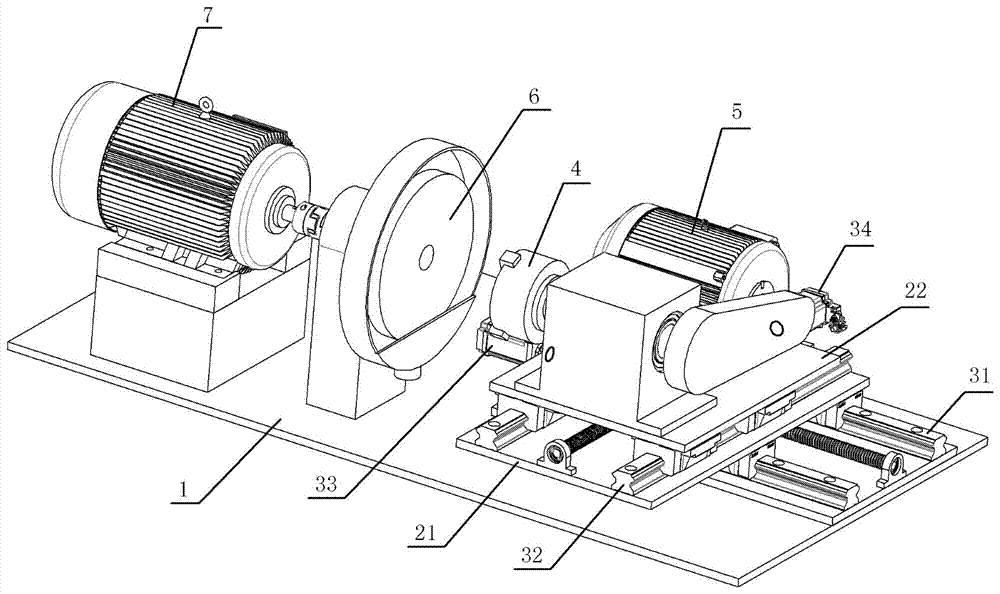

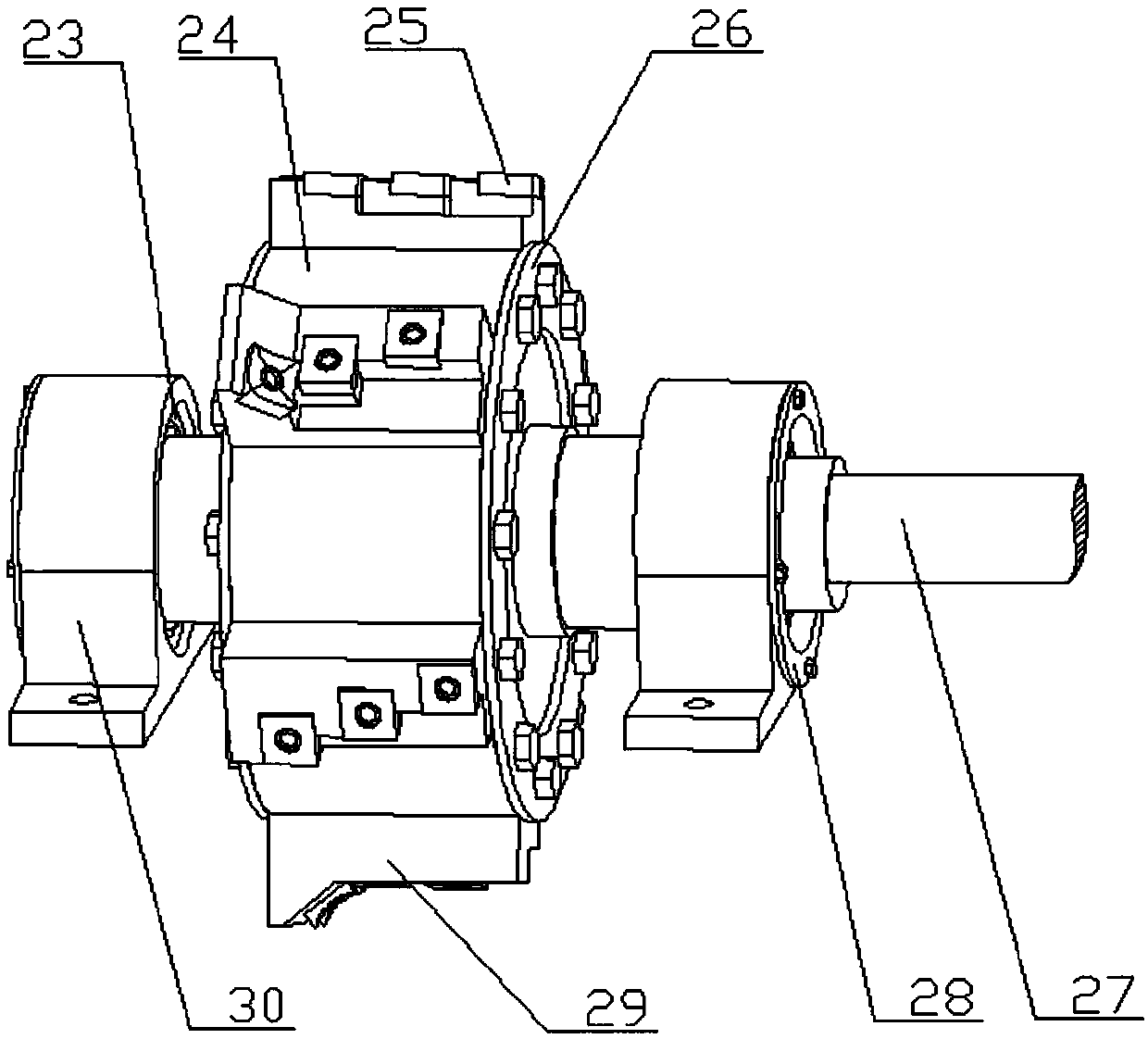

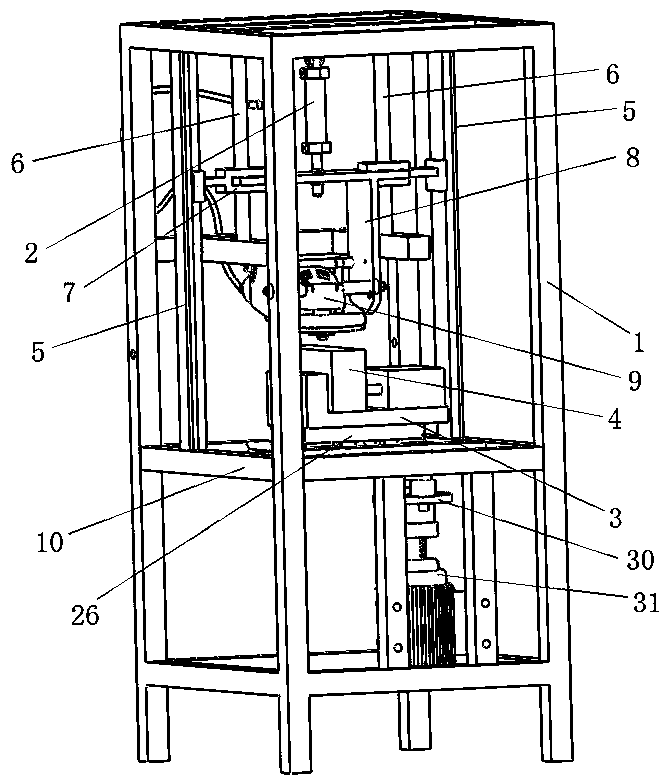

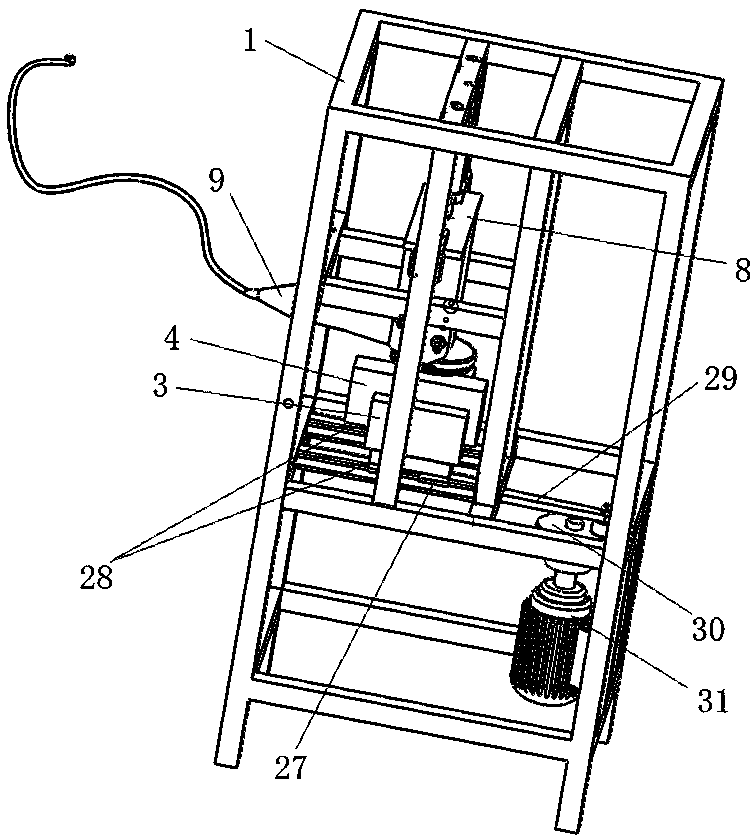

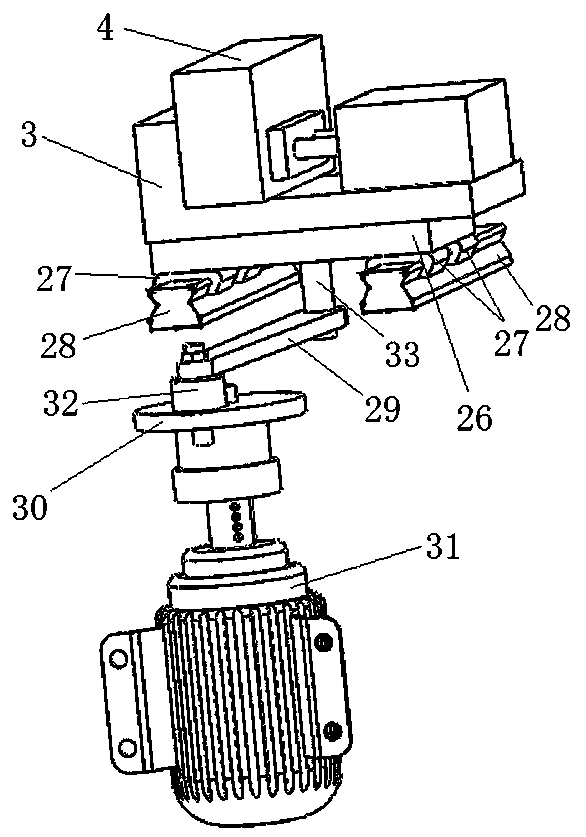

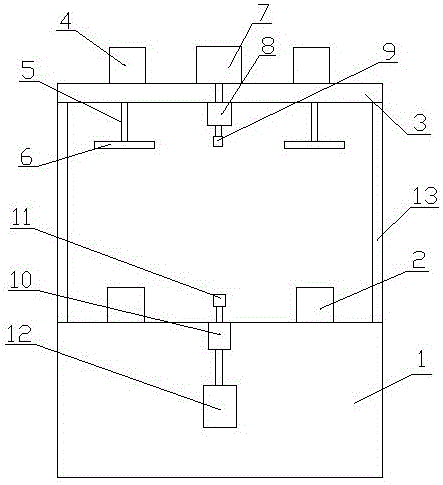

Numerical control grinding test machine

PendingCN106938442ASimulation is accurateEasy to GrindGrinding carriagesGrinding drivesNumerical controlRotational axis

The invention discloses a numerical control grinding test machine. A movable frame capable of moving transversely and longitudinally is mounted on an equipment machine frame. A rotation chuck used for clamping workpieces are mounted on the movable frame, and a rotary motor used for driving an abrasive disc to rotate is further mounted on the machine frame. The axis direction of a rotary shaft, the axis direction of the rotation chuck and the longitudinal movement direction of the movable frame are parallel to one another. A numerical control terminal is further included and connected with all the parts and controls all the parts to work. During operation, the to-be-tested workpieces are clamped and fixed through the rotation chuck, meanwhile, the rotary motor works to drive the abrasive disc to rotate, and then the movable frame moves transversely or longitudinally to conduct various grinding machining, so that actual grinding operation can be simulated more accurately, and the equipment test capacity is improved; and in addition, the test machine is provided with the numerical control terminal, the machining precision and working efficiency can be greatly improved through control of the terminal, and the grinding performance can be measured more accurately.

Owner:DYNEA GUANGDONG

Steel rail milling-grinding test device

PendingCN107677561ATo overcome the current situation that cannot meet the experimental conditions of online rail milling-grindingSimple structureInvestigating machinabilityGrinding testEngineering

The invention discloses a steel rail milling-grinding test device. A mobile platform mechanism for carrying a to-be-tested steel rail workpiece to move in Y-axis and Z-axis directions is arranged below a main supporting frame; a milling and grinding device for performing milling-grinding repair operation on the surface of the steel rail workpiece is arranged above the main supporting frame; the steel rail workpiece is fixedly arranged on the mobile platform mechanism through a dynamometer, and the dynamometer is used for acquiring the cutting force of the steel rail workpiece in the milling-grinding repair operation process; a notch is formed in one side of a steel rail workpiece body, and a thermoelectric couple is embedded into the notch and is used for acquiring the cutting temperatureof the steel rail workpiece in the milling-grinding repair operation process. The steel rail milling-grinding test device can really simulate milling-grinding operation parameters of a steel rail milling and grinding vehicle and also can monitor the force and temperature data in the milling-grinding repair process on line. The current situation that the cutting machine tool cannot meet the steel rail on-line milling-grinding test conditions is changed. Theoretical basis is provided for domestic development of milling-grinding route shaping machinery.

Owner:SOUTH CHINA UNIV OF TECH

Multifunctional automatic metallographical experimental part grinding and polishing device and environment-friendly grinding method

PendingCN110091248AGuaranteed grinding qualityImprove work efficiencyPreparing sample for investigationLapping machinesGrinding testTest sample

The invention provides a multifunctional automatic metallographical experimental part grinding and polishing device and an environment-friendly grinding method. The device partially comprises a clampA, a bottom plate, a slide bar, a lead screw, a clamp B, a mounting plate and a stepping motor. The automatic grinding device can guarantee the grinding quality of a metallographical experimental parteffectively and can grind test pieces of different thickness or grind various test pieces simultaneously, so that the work efficiency is improved, the work strength is reduced, and influence of humanfactors to the grinding quality is reduced. The device has the characteristics of being free of insertion and water spraying to the device and has the characteristic of being green and environment-friendly when grinding a test sample.

Owner:SHAANXI SCI TECH UNIV

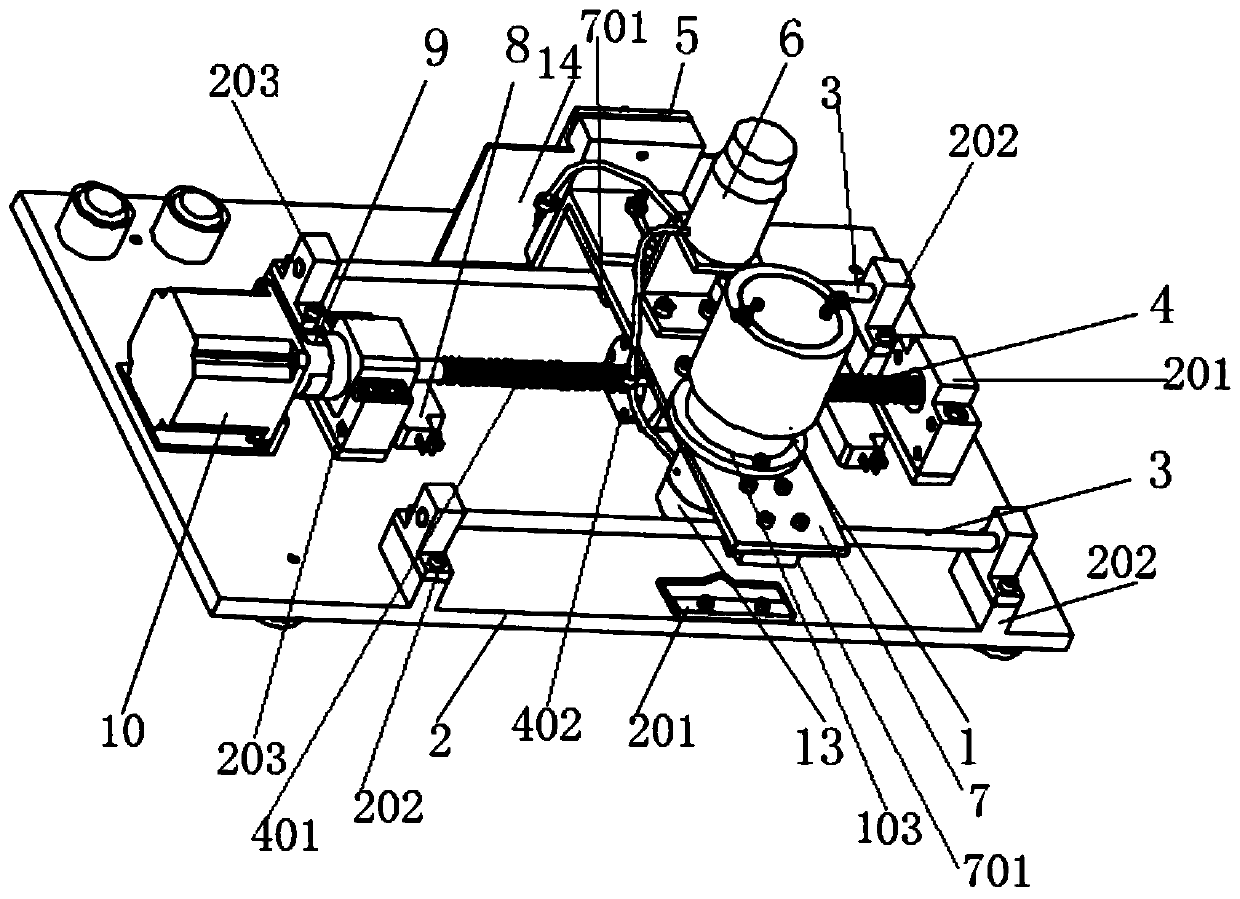

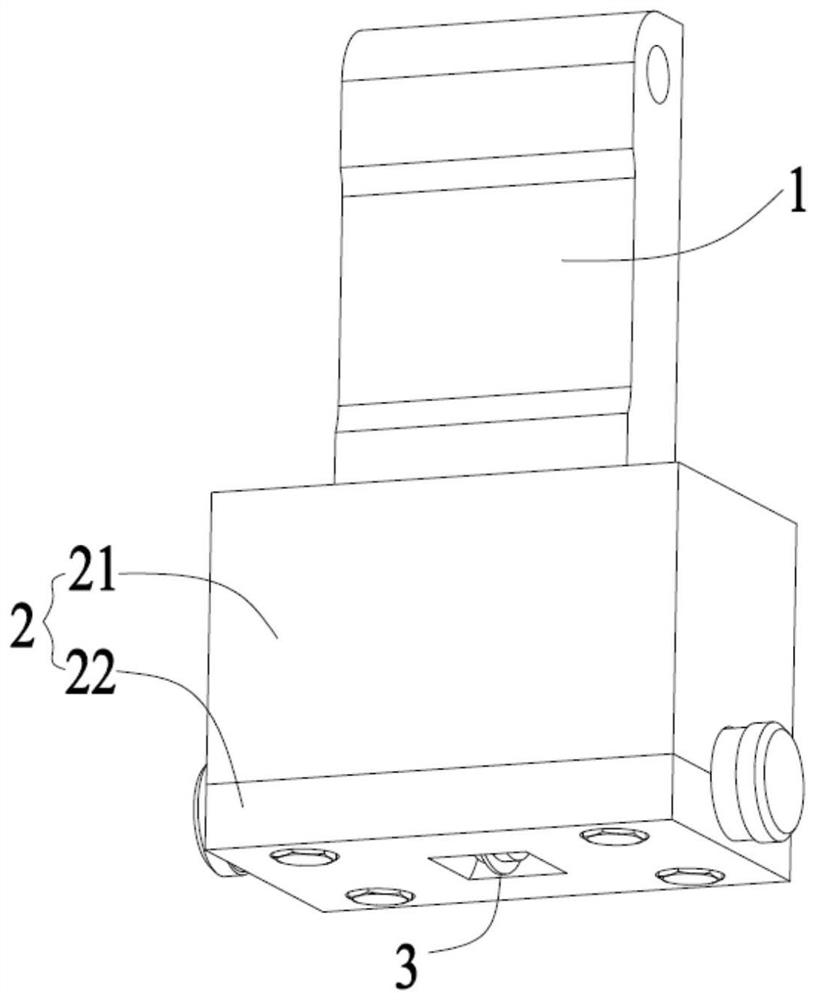

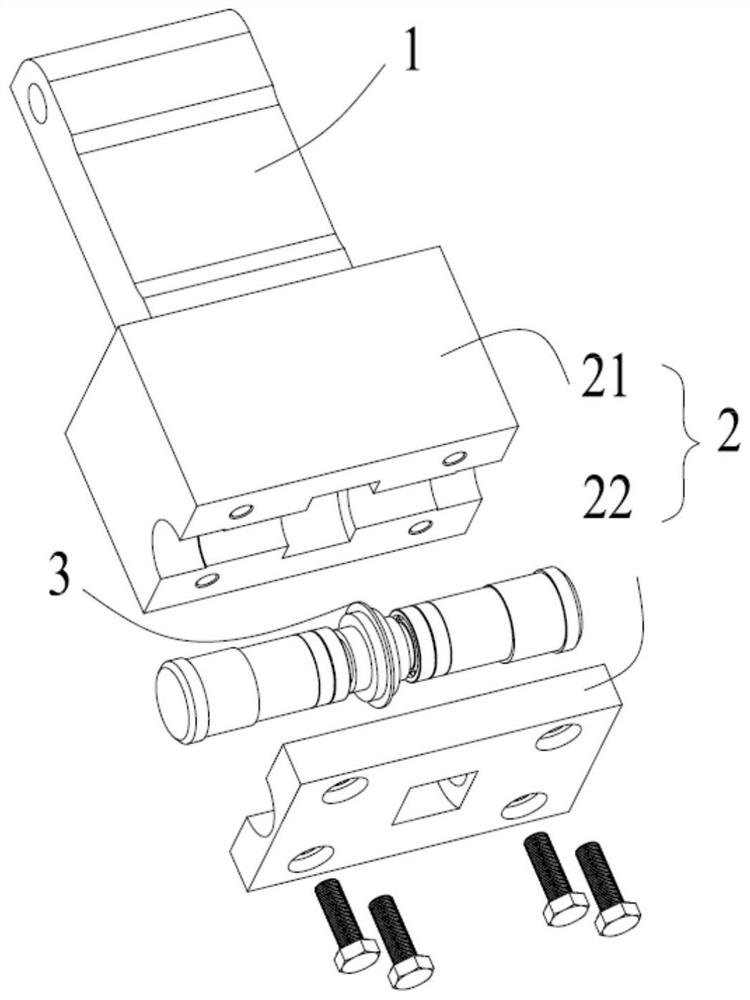

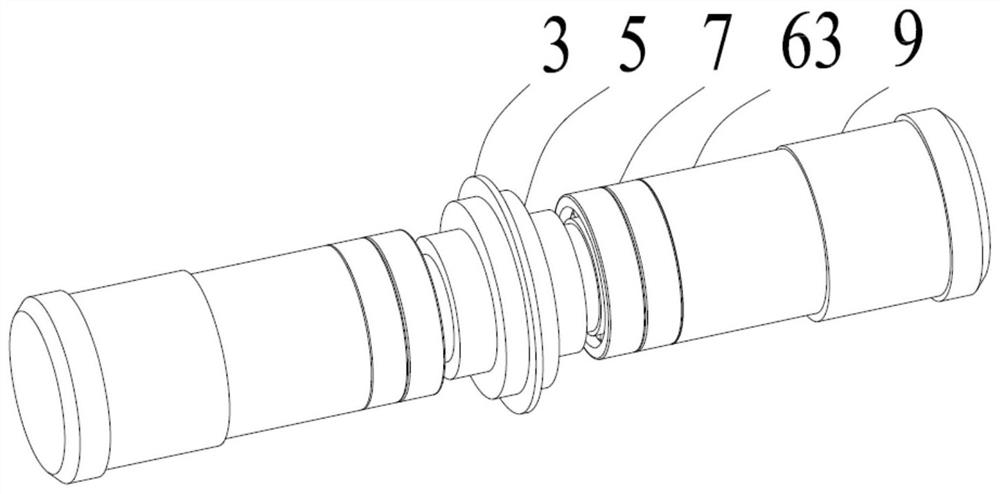

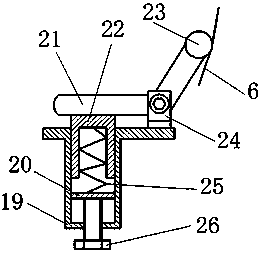

TBM hob cutter ring-rock opposite-grinding test device

ActiveCN112630017ASimple structureLow costInvestigating abrasion/wear resistanceGrinding testClassical mechanics

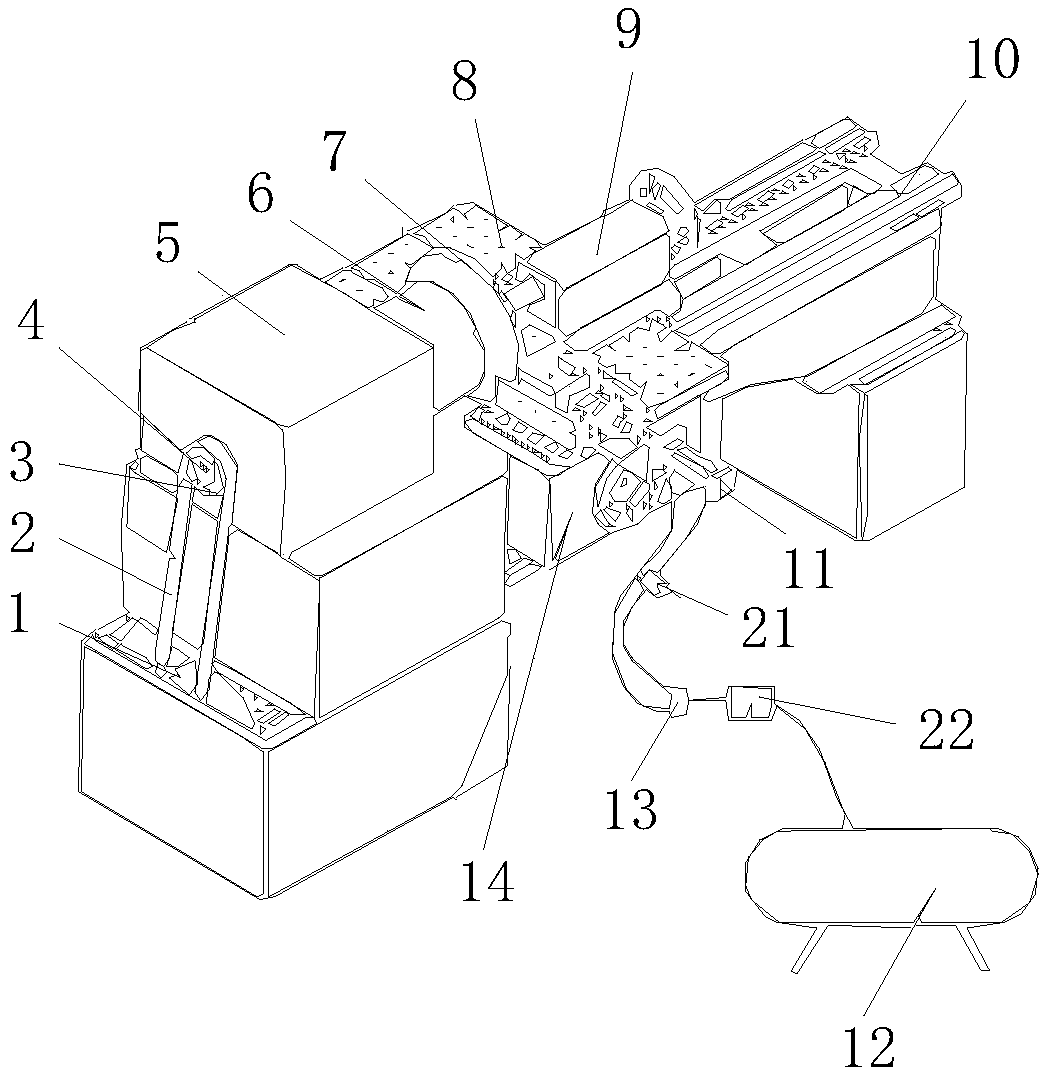

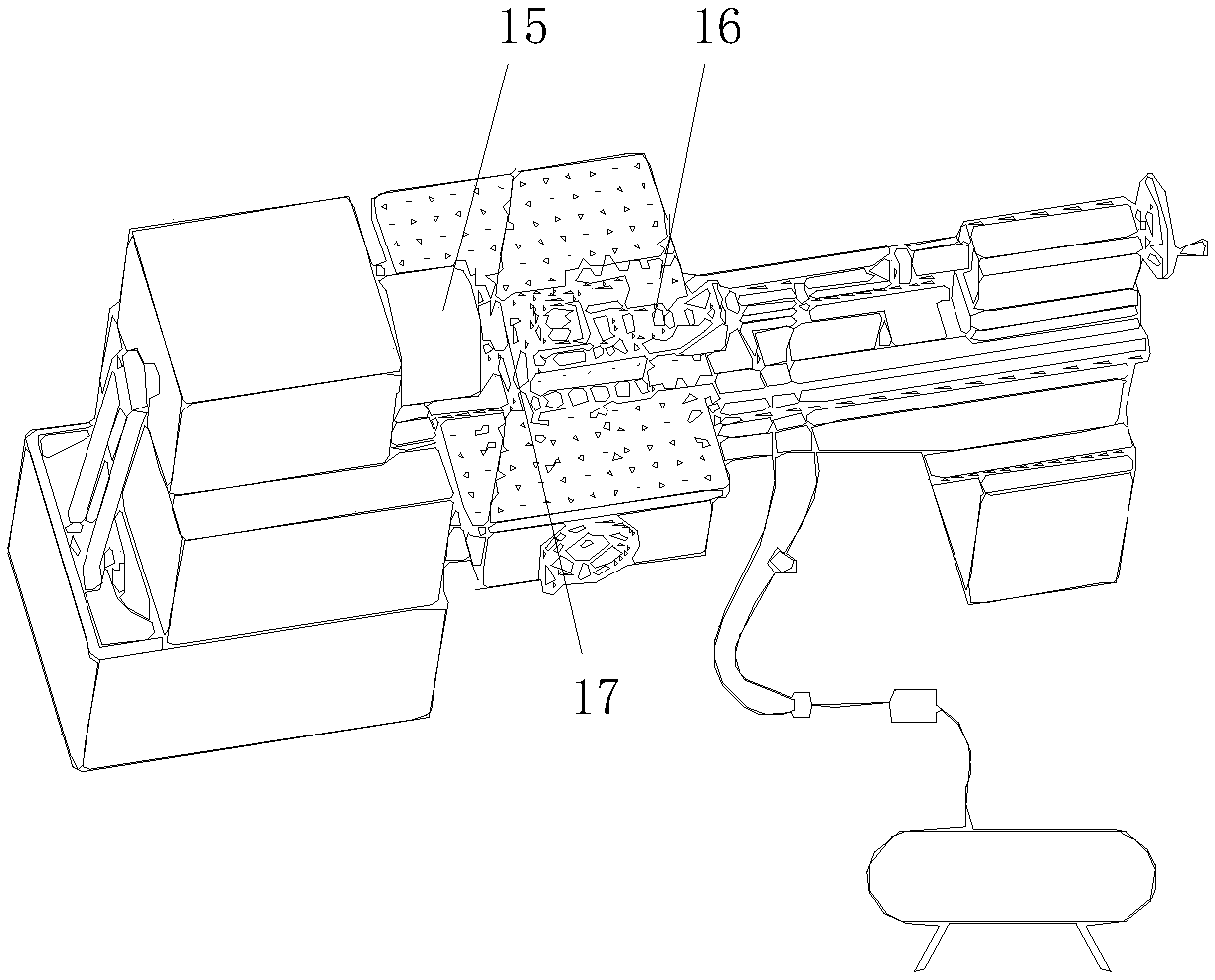

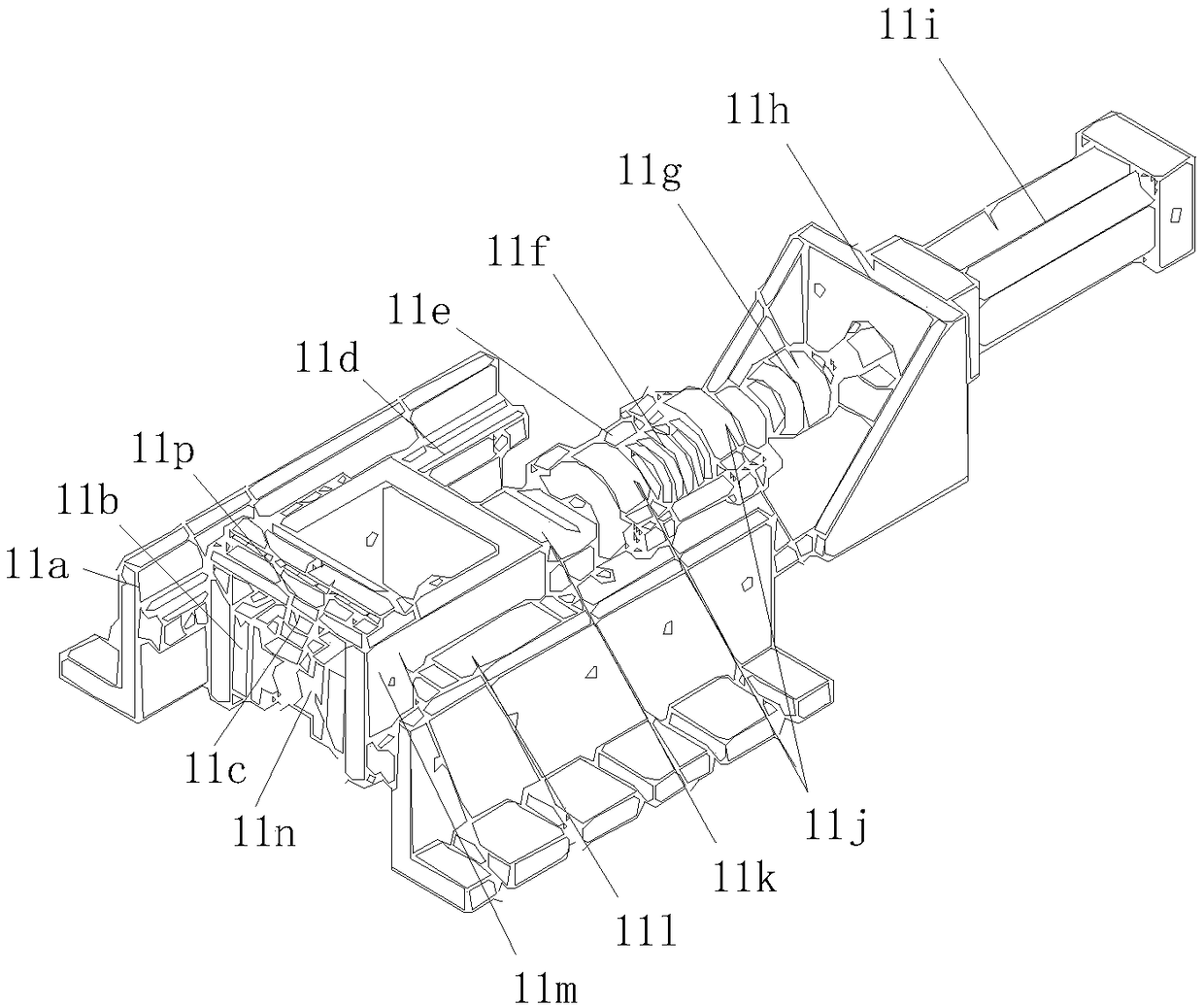

A TBM hob cutter ring-rock opposite-grinding test device comprises a rock clamping base 10, a cutter ring sample clamping head 11 and a power executing mechanism 12. The cutter ring sample clamping head 11 comprises a connecting base 1, a cutter base 2, a cutter ring sample 3, a cutter shaft 4 and a bearing 7; the cutter base 2 is fixedly connected below the connecting base 1; a groove is formed in the lower end of the cutter base 2; the cutter shaft 4 is movably mounted on the cutter base 2 in the circumferential direction through the bearing 7; the cutter ring sample 3 is coaxially mounted on the cutter shaft 4, and the outer edge of the cutter ring sample 3 is exposed out of the bottom end of the cutter base 2; the cutter ring sample 3 movably rotates along with the cutter shaft 4 relative to the circumferential direction of the cutter base 2; the rock clamping base 10 is arranged below the cutter ring sample 3; and the cutter ring sample clamping head 11 is connected with the power executing mechanism 12 through the connecting base 1. The device is high in reliability, simple in structure and manufacturing process and low in manufacturing cost; when the device is matched with a planer, the parameter control precision is high; and when the cutter spacing S of the cutter ring sample 3 is set to be zero or non-zero, three opposite-grinding test modes can be realized.

Owner:XIANGTAN UNIV

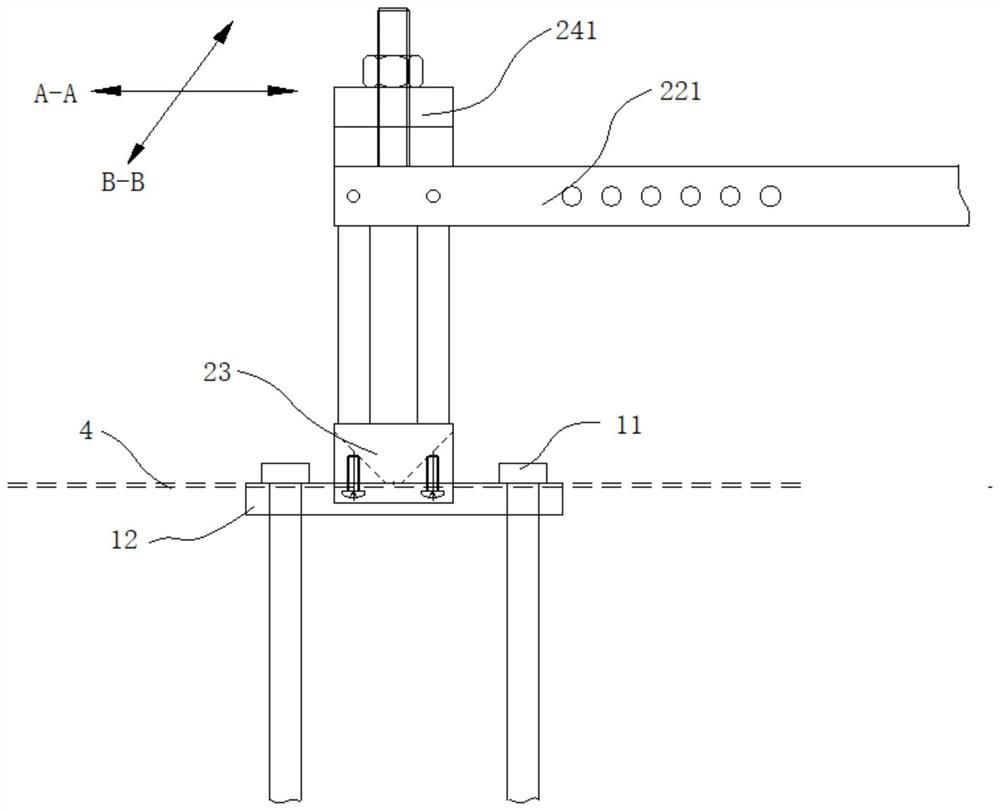

Grinding test device based on angle grinder

PendingCN110153841AStable pressureImprove effectivenessGrinding drivesStructural/machines measurementGrinding testAngle grinder

The invention relates to the technical field of grinding test, in particular to a grinding test device based on an angle grinder. The grinding test device based on the angle grinder comprises a machine frame, a grinding workbench, an angle grinder mounting frame, a driving air cylinder and a fixed clamp; the grinding workbench is arranged on the machine frame; the grinding workbench is in transmission connection with a driving device to do linear reciprocating motion relative to the machine frame; the angle grinder mounting frame is in guide cooperation with the machine frame; the driving aircylinder is connected between the machine frame and the angle grinder mounting frame and is used for driving the angle grinder mounting frame to be close to or far away from the surface of the workbench; and the fixed clamp is arranged on the angle grinder mounting frame and is used for fixing the angle grinder. The grinding test device based on the angle grinder is used for solving the problem that test data has low effectiveness when the angle grinder is held manually to test the grinding property of a sand tray.

Owner:白鸽磨料磨具有限公司

High-speed rotation test device for ultra-hard material grinding sand wheel

ActiveCN103364260ACompact structureReduce loadStatic/dynamic balance measurementStrength propertiesFrequency changerRotation test

The invention relates to a sand wheel rotation test device which is suitable for high-speed rotation test for an ultra-hard material grinding sand wheel, performs necessary rotation test on the ultra-hard material grinding sand wheel and supplies reference basis to subsequent actual processing and belongs to the field of grinding test equipment. A motor is arranged on a base and is connected with a bearing pedestal; the bearing pedestal drives the sand wheel to be tested to rotate; a tester is arranged below the sand wheel to be tested. The test device provided by the invention is compact in structure and adopts simple belt transmission; by stage-by-stage speed regulation, a frequency converter controls the motor to gradually accelerate, so that the acceleration time is long, and the load is small; by adoption of a high-speed belt and a large transmission ratio of 4.5, high-speed rotation is realized; the sand wheel rotation test device is suitable for sand wheels of phi230-phi400mm and high-speed rotation test with the extreme linear speed is up to 300m / s. In an acceleration or normal rotation process, if the sand wheel fails, a rotation system is emergently braked according to an energy consumption braking theory, so that the safety of people and the safety of devices are guaranteed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

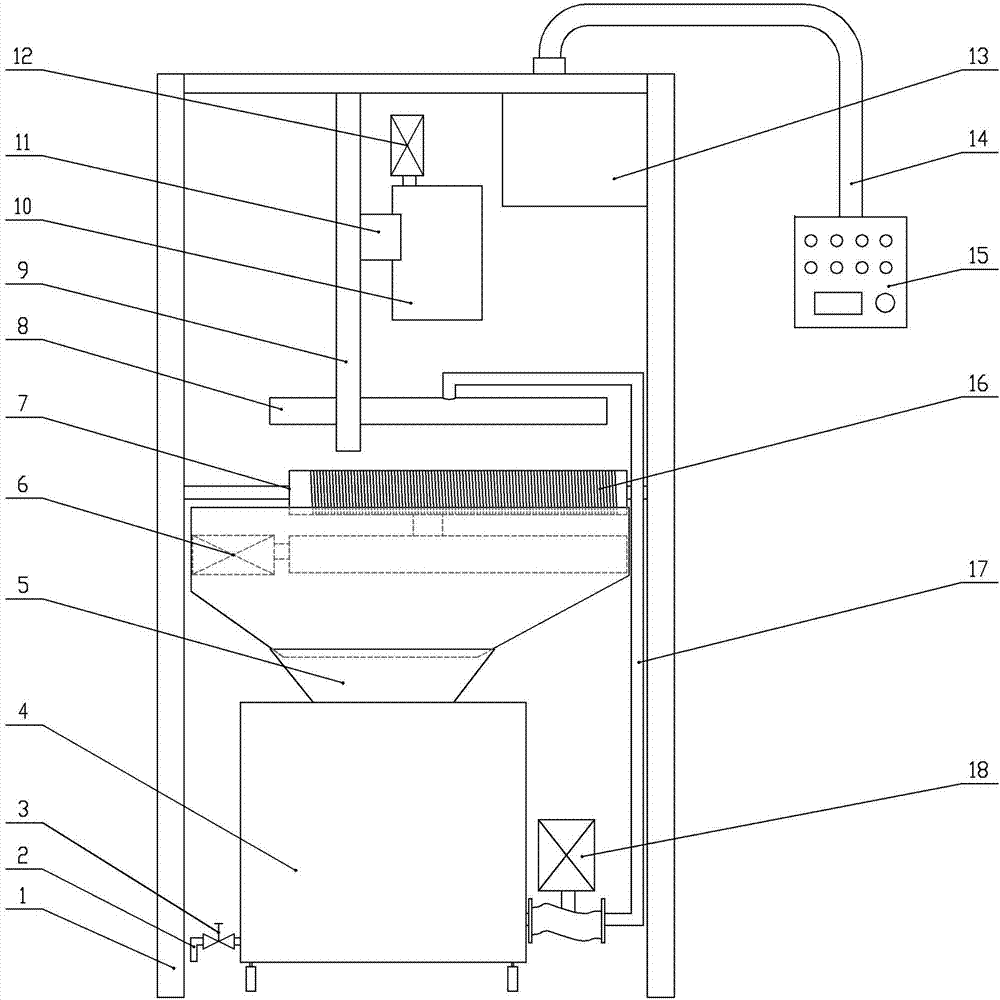

Testing device for wear resistance of anti-corrosive layer of steel plate for heat energy equipment

InactiveCN106198284AEfficient and fast sanding testInvestigating abrasion/wear resistanceGrinding testSheet steel

The invention aims at providing a testing device for the wear resistance of an anti-corrosive layer of a steel plate for heat energy equipment. The testing device is characterized in that the steel plate is flatly placed on supporting blocks at the top part of a working platform, then a clamping cylinder at the top part of a top plate is started to move a clamping plate down to press the steel plate on the supporting blocks tightly, then a push-down cylinder is started to push down an upper grinding motor and enable an upper grinding head and the upper surface of the steel plate to be in contact for grinding; a lower grinding motor is also arranged for grinding the lower surface of the steel plate. The testing device provided by the invention has the advantages that grinding test can be carried out on the anti-corrosive layer of the steel plate in a high-efficiency and fast manner, so that the testing device is applicable in production.

Owner:WUHU MINGREN THERMAL ENERGY EQUIP

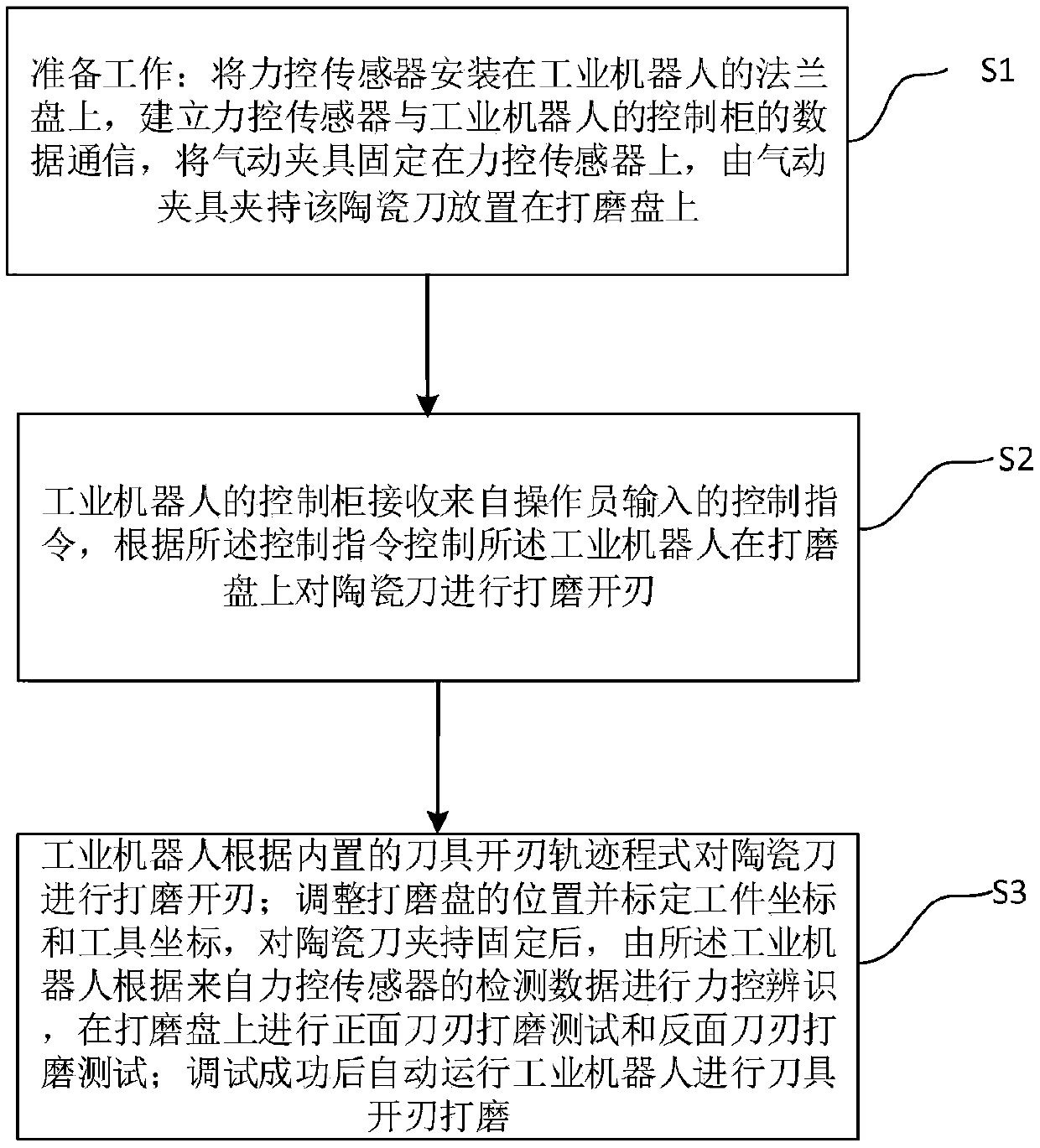

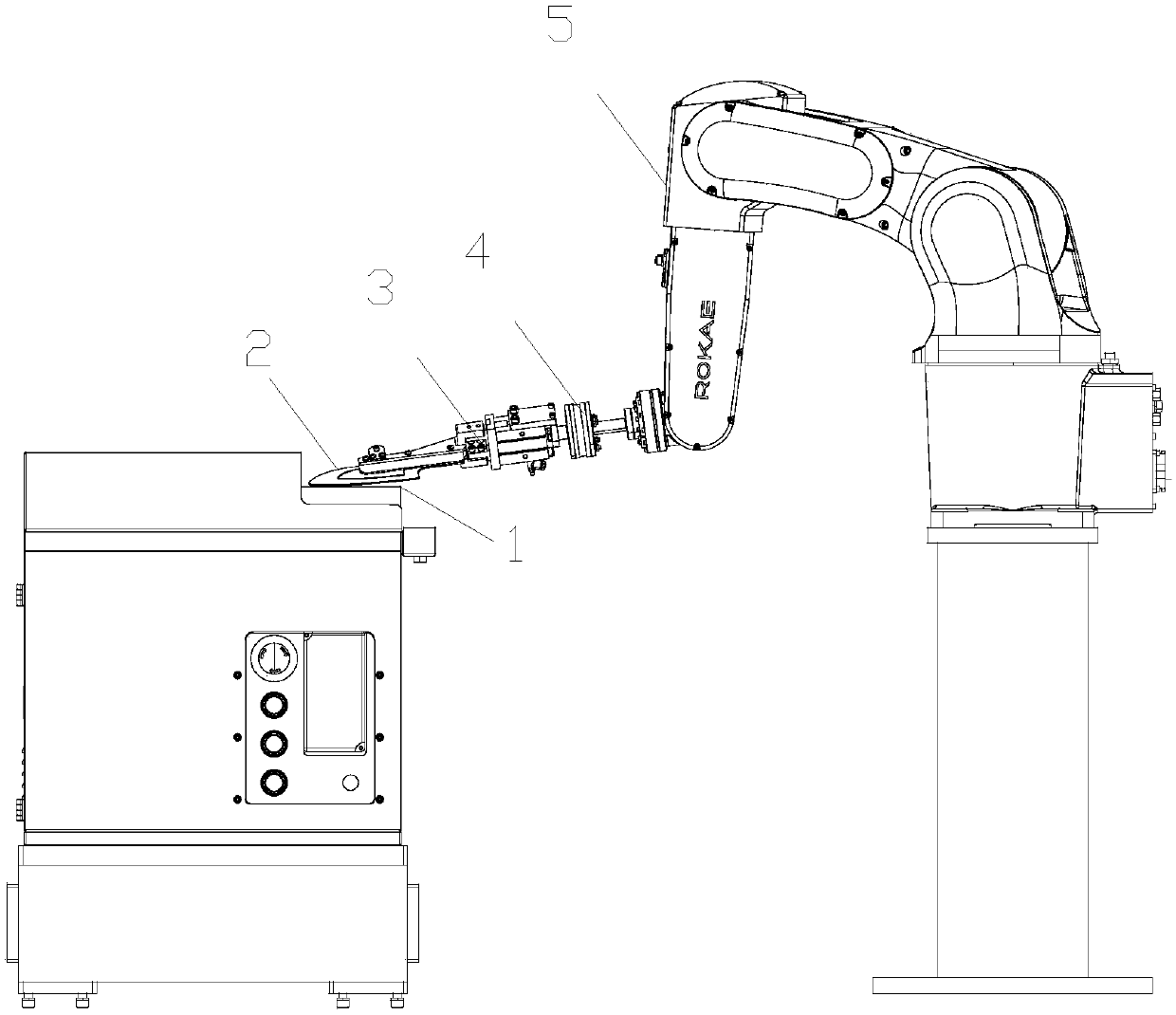

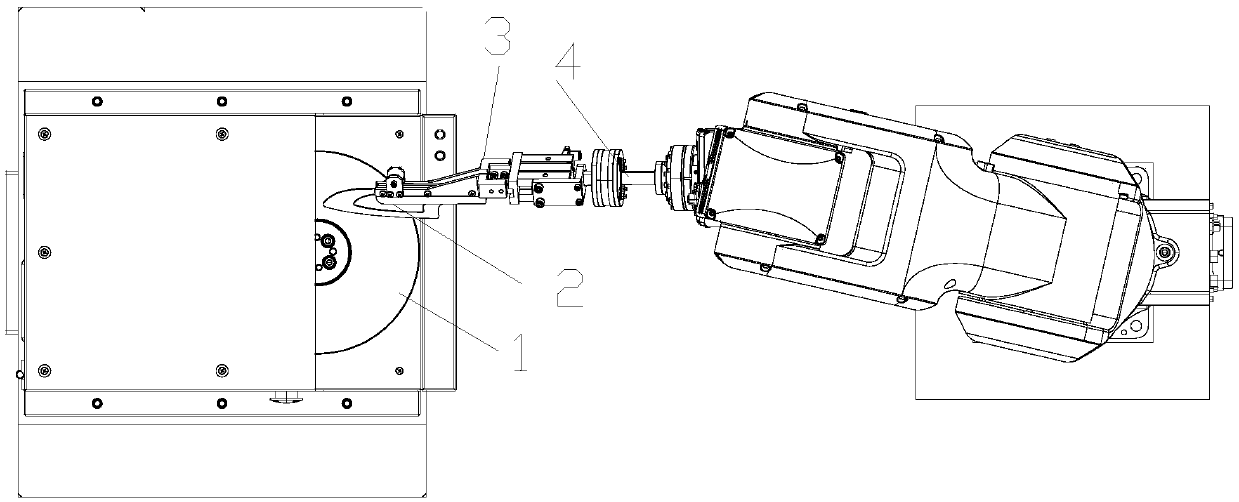

Process method and device for automatically and flexibly grinding and sharpening ceramic knife

InactiveCN109623514AGuaranteed constant grindingQuick switchOther manufacturing equipments/toolsAutomatic grinding controlGrinding testMaterials science

The invention provides a process method and device for automatically and flexibly grinding and sharpening a ceramic knife. The method comprises the following steps that a control cabinet of an industrial robot receives a control command input by an operator, and the industrial robot is controlled to carry out grinding and sharpening on the ceramic knife on a grinding disc according to the controlcommand; the industrial robot is used for grinding and sharpening the ceramic knife according to a built-in cuter sharpening track program, the position of the grinding disc is adjusted, and coordinates of a tool and coordinates of a workpiece are calibrated, after the ceramic knife is clamped and fixed, the industrial robot performs force control identification according to detection data of a force control sensor, and a front edge grinding test and a back edge grinding test are carried out on the grinding disc; and after the debugging is successful, the cutter sharpening grinding is automatically carried out. According to the method, a six-axis robot is matched with the force control sensor, so that constant force grinding in the sharpening process of the ceramic knife can be guaranteed,and a product can be rapidly switched.

Owner:珞石(北京)科技有限公司

Multifunctional rail grinding test device

PendingCN108871836AImprove stabilityGood repeatabilityStructural/machines measurementGrinding testEngineering

The invention discloses a multifunctional rail grinding test device, including a lathe spindle, a workbench, an actuator, an air compressor, a grinding wheel specimen, and a variable frequency motor arranged in a lathe motor case. An output shaft of the variable frequency motor is provided with a synchronous pulley, and the synchronous pulley is connected with a synchronous pulley of the lathe spindle through a synchronous belt. The lathe spindle is fixed via a lathe spindle box, and the other end of the lathe spindle is provided with a three-jaw chuck. The external surface of the three-jaw chuck is movably connected with a disc-shaped rail workpiece and a rail grinding wheel, the other end of a central shaft of the disc-shaped rail workpiece is movably connected with a lathe tail seat, and the bottom of the lathe tail seat is fixedly connected with a lathe body. The workbench is connected with a sliding box through bolts. The multifunctional rail grinding test device can simulate different rail grinding modes, can carry out polishing tests of different polishing pressures, rotational speeds and grinding wheel parameters, provides convenience for exploring a rail polishing mechanism, provides a certain theoretical basis for on-site rail polishing, and provides theoretical guidance for the development of grinding stones.

Owner:SOUTHWEST JIAOTONG UNIV

Method for improving ore grinding particle size stability rate of super-huge type mill

PendingCN112528466AReduce electricity consumptionDesign optimisation/simulationGrain treatmentsGrinding testProcess engineering

The invention relates to a method for improving the stability rate of the grinding granularity of a super-huge type mill, belongs to the technical field of super-huge type ball mills, and solves the technical problems of improving the grinding efficiency and reducing the energy consumption.According to the method, the actual situation of hard ore treatment of the large-diameter ball mill is combined, and the steel ball system of the ball mill is obtained through a traditional beneficiation empirical formula; A large number of ore grinding tests are conducted, the proper steel ball proportion,the medium filling rate and the steel ball adding system are determined, the ore grinding energy consumption and the ore grinding cost of the ball grinding mill are reduced, the granularity composition of ore grinding products is optimized, the granularity stability rate of the ore grinding products is effectively increased, and process products reasonable in granularity distribution are providedfor subsequent sorting operation.

Owner:太原钢铁(集团)有限公司 +1

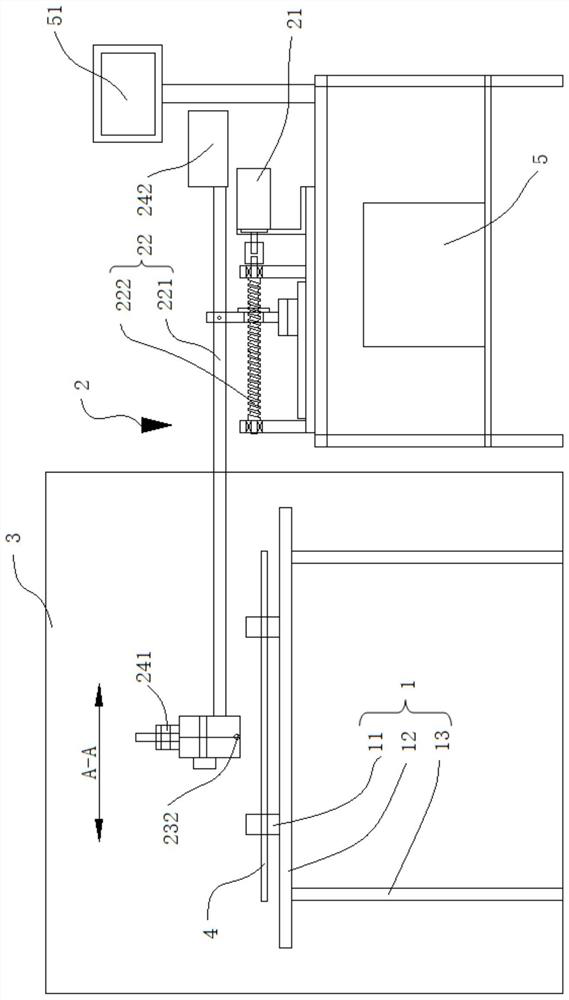

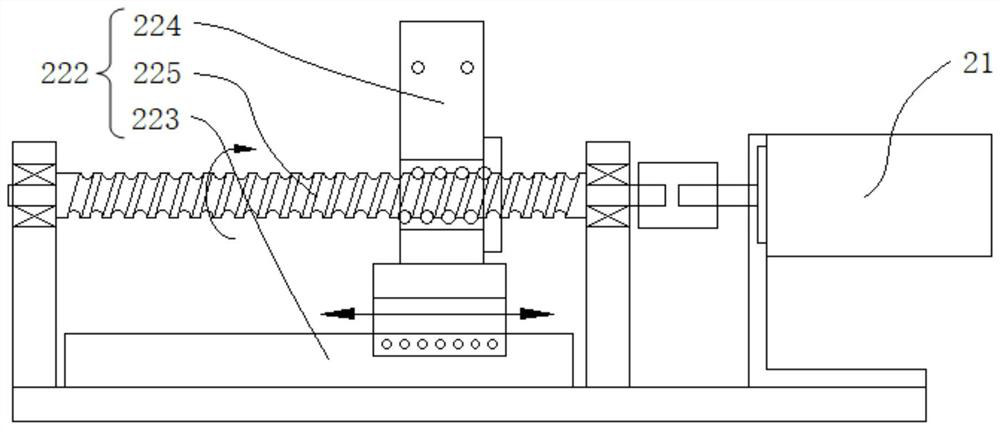

Cable scraping and grinding test platform

PendingCN113702227ASatisfy the requirements of scratch testIncrease flexibilityInvestigating abrasion/wear resistanceGrinding testElectric machinery

The invention relates to a cable scraping and grinding test platform which comprises a clamping assembly, the clamping assembly comprises a clamp and a clamping platform, the clamp is arranged on the clamping platform, the clamp clamps a cable, the axis of the cable is arranged in the first direction, and the first direction is parallel to the clamping platform; a moving assembly which comprises a driving motor, a transmission assembly and a scraping and grinding device, the transmission assembly is connected with the driving motor and the scraping and grinding device, the driving motor drives the scraping and grinding device to reciprocate in the first direction, and the scraping and grinding device moves to rub the cable; a test box, the clamping platform and the scraping and grinding device are arranged in the test box, and a temperature and humidity control module is arranged in the test box. According to the cable scraping test platform provided by the invention, the whole equipment is divided into two parts through the detachable clamping assembly and the movable assembly, the clamping assembly loaded with the to-be-detected cable can be placed in the test box, and various test environments with different temperatures and humidity are provided through the test box, and the flexibility and reconfigurability of the scraping and grinding test platform are enhanced.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

Plating solution for metallic surface wear-resistance coating

The invention relates to a metal surface wear-resistant coating electrolyte which is characterized in that the electrolyte comprises 300-100g / L of nickel sulfate, 40-65g / L of sodium tungstate, 80-100g / L of ammonium citrate, 0.5-2g / L of saccharin and 0.5-2.5g / L of 1,4-butynediol. In the invention, the wear-resistant coating is deposited on the metal surface by using electroplating technology, which does not discharge waste water and does not bring about pollution to environment. The microhardness of the coating is 1000-1250HV; the wearing resistance and the friction coefficient are higher than that of hard chromium plating. After the grinding test of a honing machine, compared with the hard chromium plating, the wear-resisting quantity rate is higher by 1.2-1.4 times.

Owner:山东圣源娜菲尔贸易有限公司

Cement automatic grinding test device

InactiveCN104568746AHigh precisionGrinding time is precisePreparing sample for investigationUsing mechanical meansMicrocomputerAutomatic control

The invention discloses a cement automatic grinding test device which includes an automatic control device, an attrition mill and a driving device, wherein the attrition mill includes a coarse grinding device and a fine grinding device; the coarse grinding device includes a grinding disc and a grindstone; the grindstone is arranged on the grinding disc; a feeding opening is formed in the middle of the grindstone; a discharge opening is formed in the grinding disc; the driving device drives the grindstone to rotate on the grinding disc; the fine grinding device includes a U-shaped trough and a grinding shaft; the grinding shaft is arranged inside the U-shaped trough; screw threads are arranged on the inner wall of the U-shaped trough and the outer wall of the grinding shaft; the driving device drives the grinding shaft to rotate inside the U-shaped trough; the discharge opening of the grinding disc is connected with the U-shaped trough; the automatic control device includes a microcomputer time switch group, a thermal relay and a contactor; the thermal relay is connected with the contactor in series; the microcomputer time switch group, the thermal relay and the contactor form a return circuit; the microcomputer time switch group can control the startup or shutdown of the contactor; a power supply is communicated with the driving device through the contactor and the thermal relay. The cement automatic grinding test device provided by the invention has the advantages of being capable of accurately controlling the grinding time and grinding fineness of the cement.

Owner:GEZHOUBA DANGYANG CEMENT

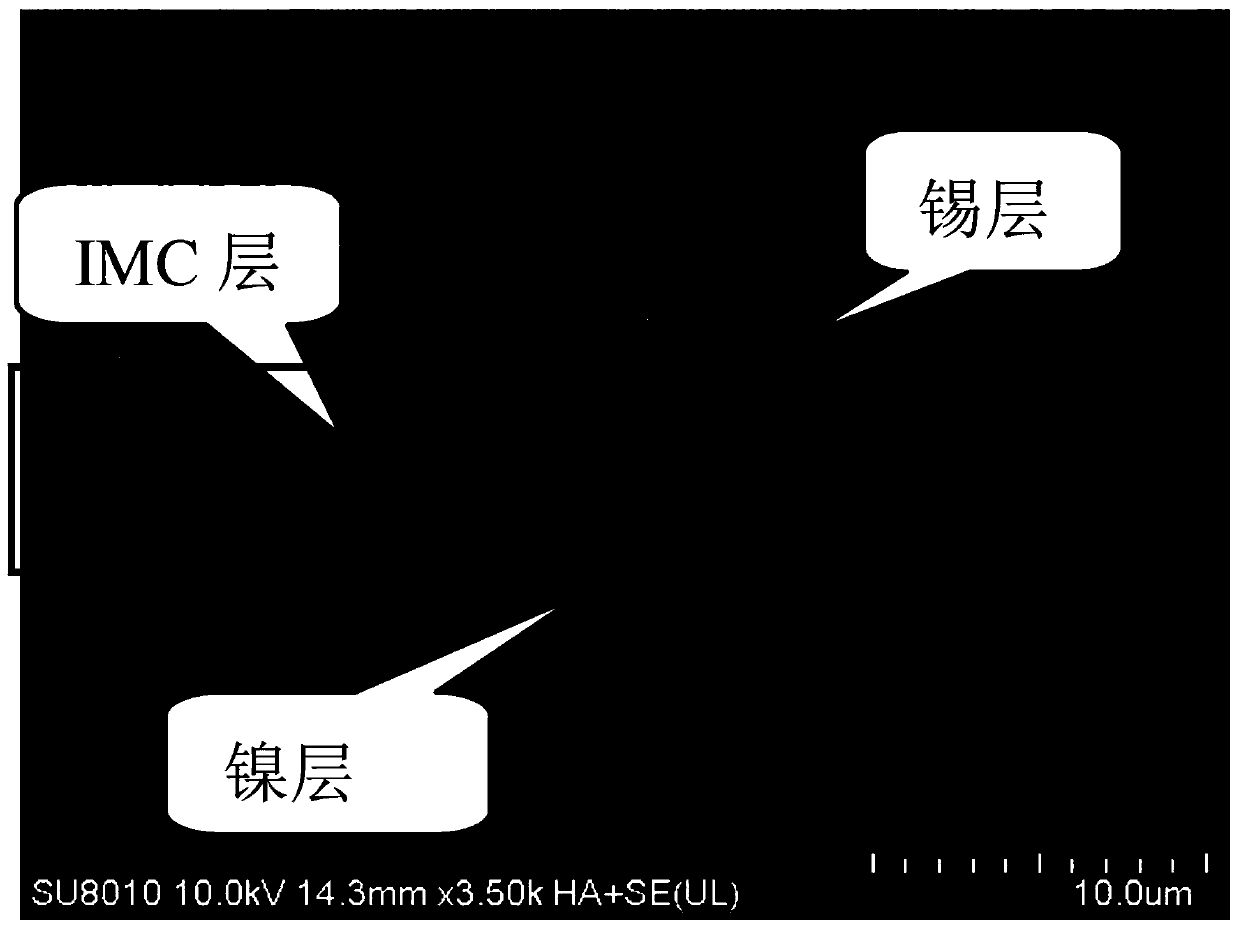

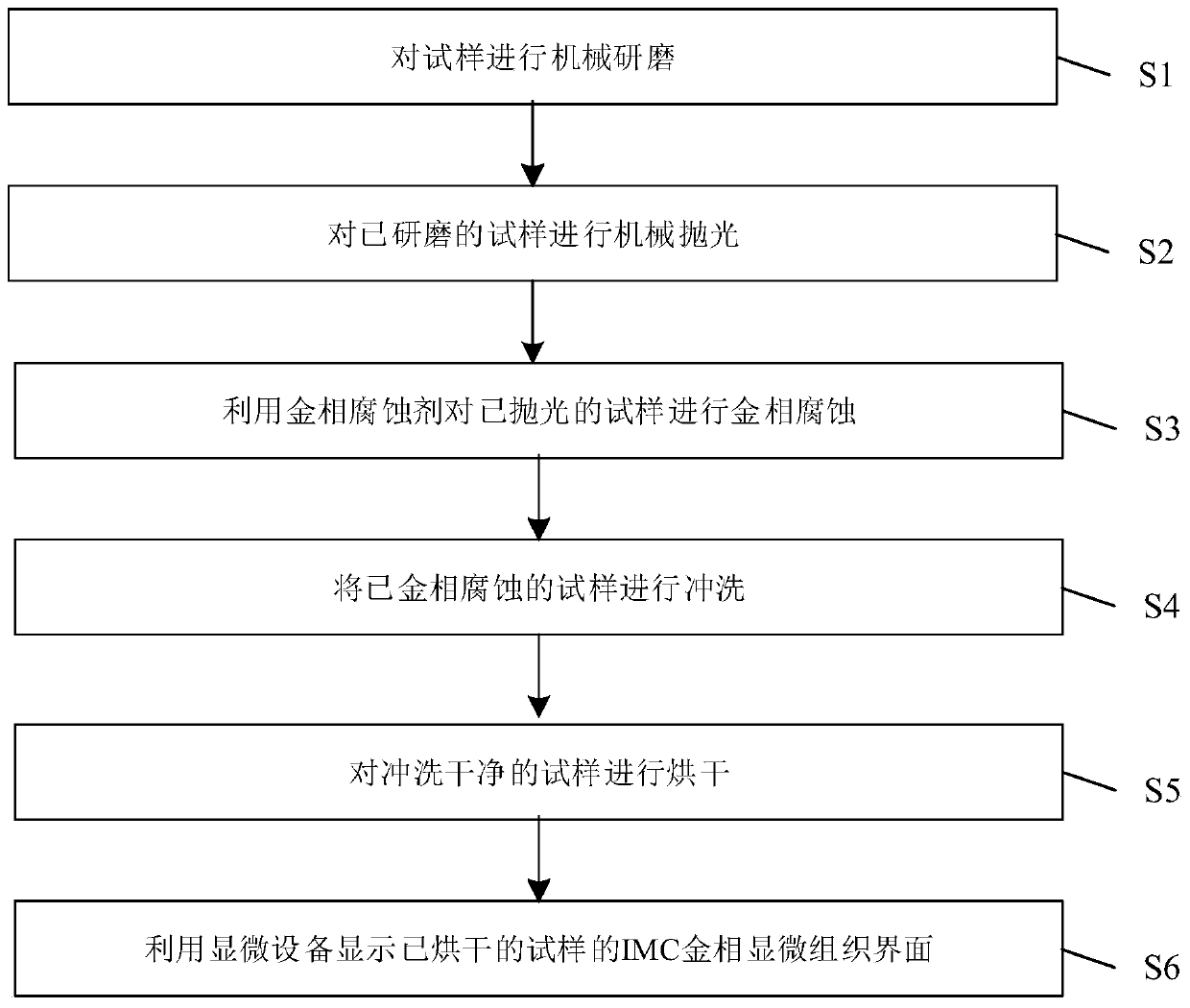

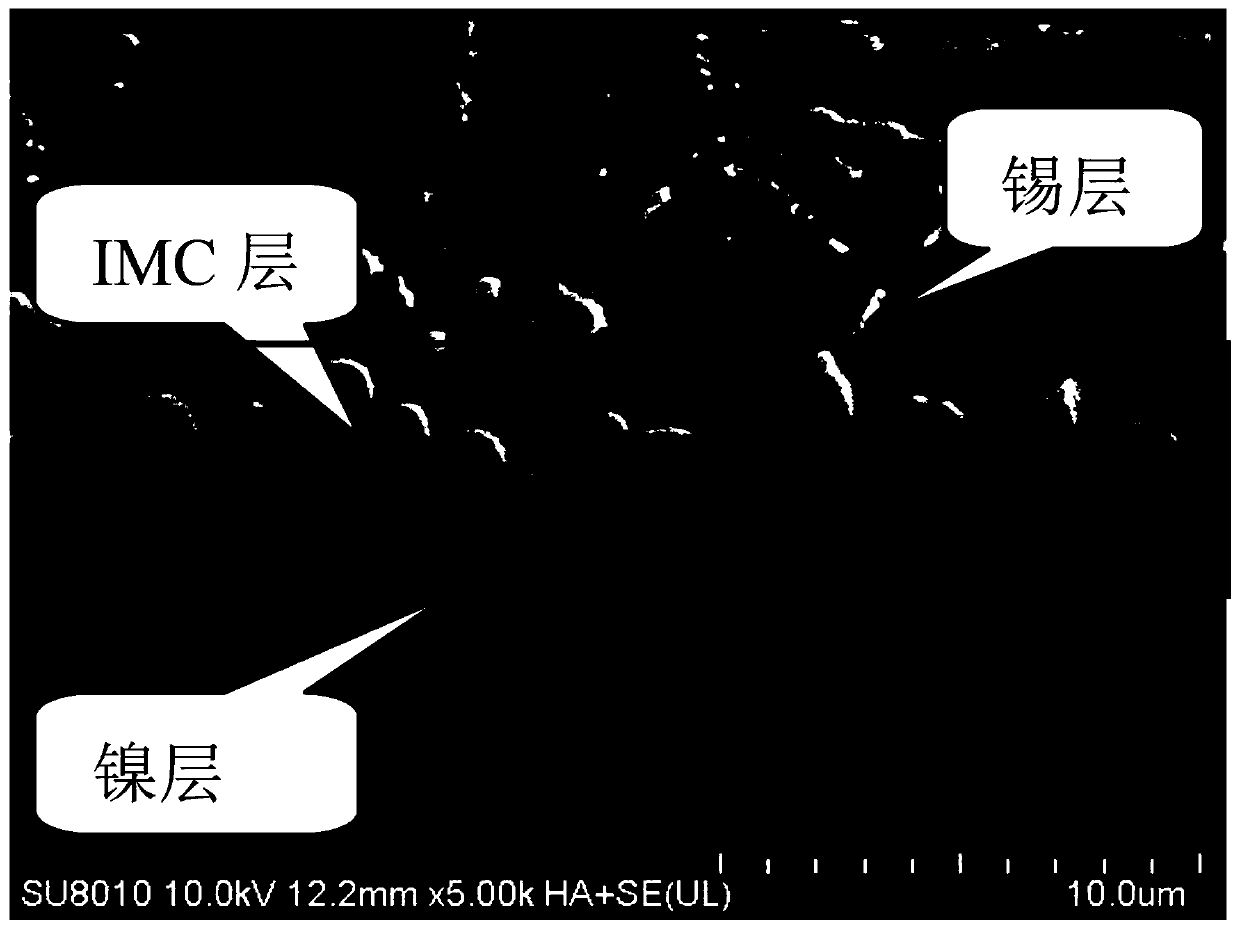

Tin-nickel solder IMC layer metallographic corrosive agent and metallographic structure display method thereof

InactiveCN109916905ACorrosion effectiveDisplay clearPreparing sample for investigationMaterial analysis by optical meansGrinding testTest sample

The embodiment of the invention discloses a tin-nickel solder IMC (Intermetallic compound) layer metallographic corrosive agent and a metallographic structure display method thereof. The metallographic corrosive agent is prepared by 36-38% of hydrochloric acid and more than 95% of ethyl alcohol in mass percent according to a volume ratio of 1:9. The metallographic structure display method comprises the following steps of: performing mechanical grinding of a test sample; performing mechanical polishing of the grinded test sample; employing the metallographic corrosive agent to perform metallographic corrosion of the polished test sample; washing the test sample after metallographic corrosion; drying the cleaned test sample; and employing a micro device to display an IMC metallographic microscopic structure interface of the dried test sample and clearly display the morphology of the tin-nickel solder IMC layer.

Owner:CHIPMOS TECHSHANGHAI

Lubricating grease for automobile switch contact and preparation method thereof

InactiveCN108774567AGood compatibilityImprove conductivityLubricant compositionGrinding testLithium hydroxide

The invention discloses a lubricating grease for an automobile switch contact and a preparation method thereof. The lubricating grease comprises, by weight, 75 to 92% of ester base oil, 1 to 14% of aliphatic diacid, 1 to 14% of 12-hydroxystearic acid, 1 to 25% of lithium hydroxide, 0.8 to 1.8% of an antiwear agent, 1 to 2.5% of an anti-oxidant and 0.5 to 2% of a conductive agent. The composite lithium-based lubricating grease prepared in the invention can still maintain a low friction coefficient after long-time grinding tests, has good wear resistance, is improved in conductivity and can avoid arc burning; and the preparation method is simple in process, low in cost and easy to promote.

Owner:深圳市合诚润滑材料有限公司

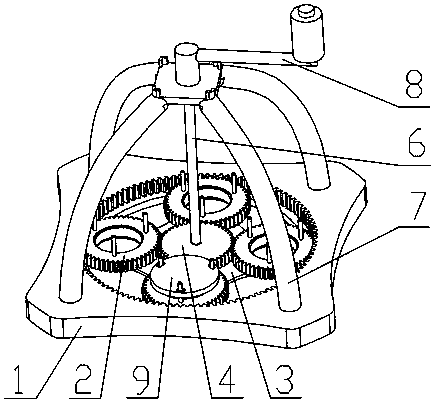

Portable metallographic sample grinding machine

PendingCN108466120AMeet the requirements of grindingImprove grinding efficiencyGrinding machine componentsPreparing sample for investigationGrinding testEngineering

A portable metallographic sample grinding machine comprises a base, a planet wheel, a planet carrier, a sun wheel, a supporting seat, a rotary shaft, a support, a crank, a weight, a servo motor and asample limiting ring. The planet carrier and the sun wheel are mounted on the supporting seat through bearings, and the planet wheel, the planet carrier and the sun wheel constitute a planet wheel transmission system together with the base. The bottom face of the supporting seat and the bottom face of the base are located on the same horizontal plane, and the support is mounted above the base. Thecrank or the servo motor is mounted above the support and connected with the sun wheel through the rotary shaft. The portable metallographic sample grinding machine is portable, easy and convenient to operate, flexible in operating and low in cost, the requirements of school teaching and researchers for metallographic grinding can be met, the problems of uneven stress, the cambered surface and alarge number of deep scratches during a metallographic manual grinding test can be effectively avoided, the labor intensity of students or the researchers or the like is reduced, and the metallographic grinding efficiency is improved.

Owner:NANCHANG UNIV

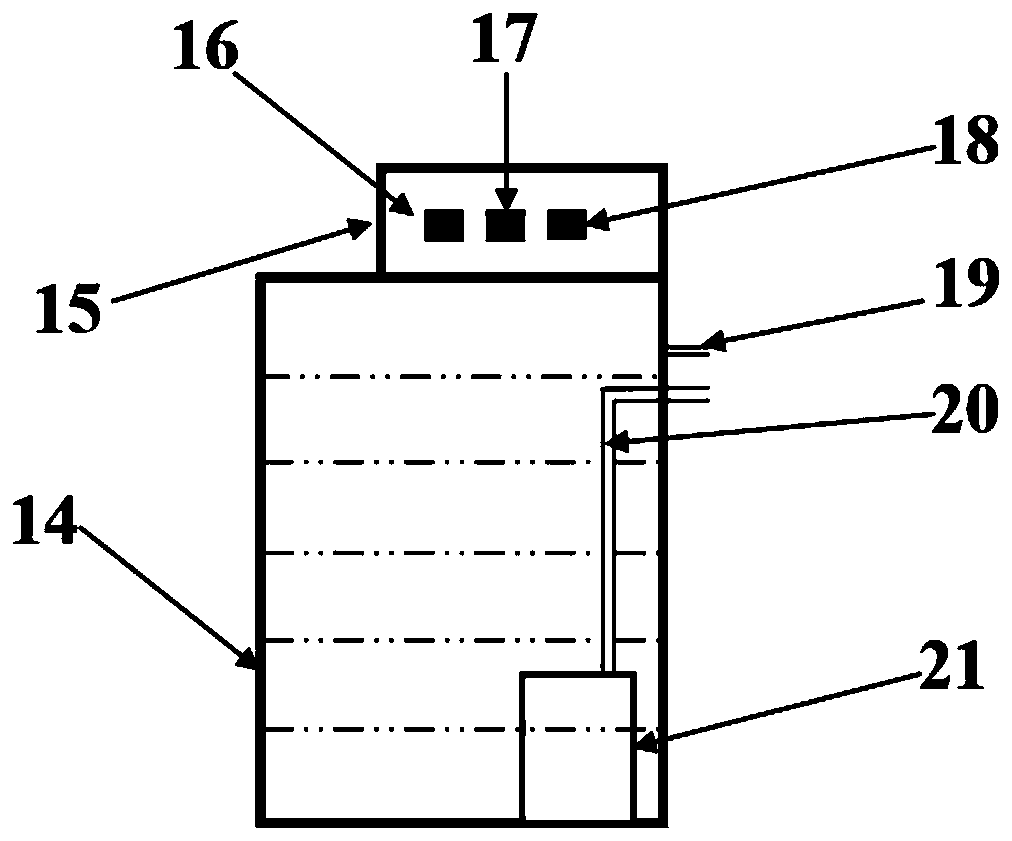

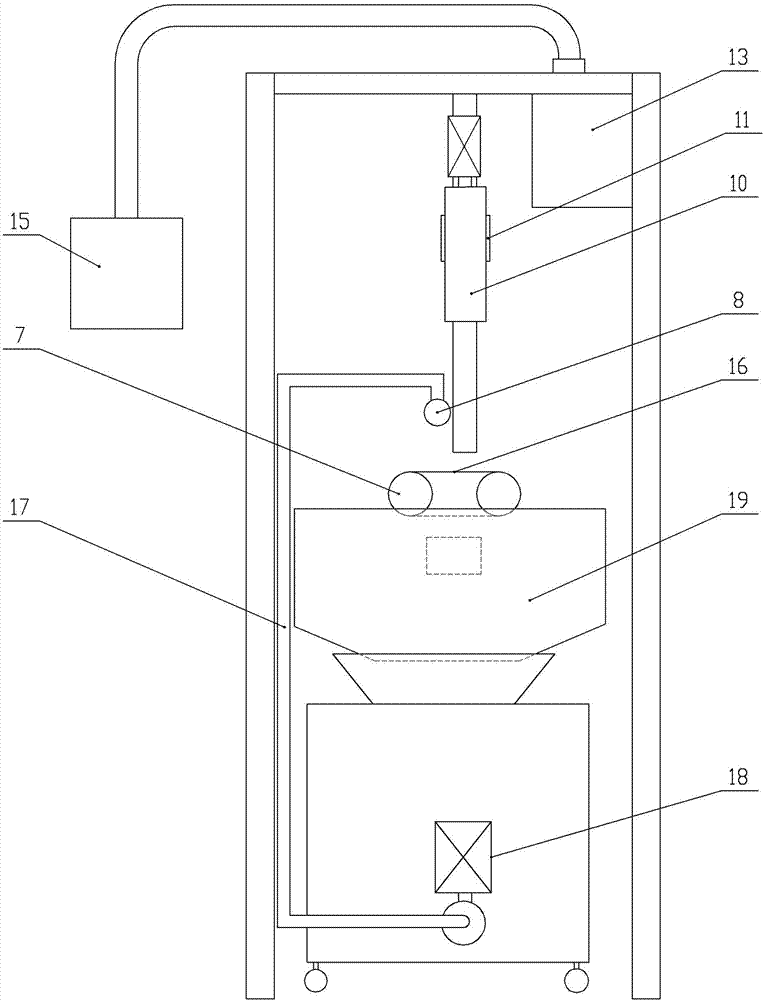

Animal tissue homogenization grinding equipment

InactiveCN110317713AReduce volatilityNo vibrationBioreactor/fermenter combinationsBiological substance pretreatmentsGrinding testEngineering

The invention discloses animal tissue homogenization grinding equipment. The equipment comprises a grinding tank, wherein the grinding tank is internally provided with a grinding cavity with an upwardopening, the grinding tank is internally provided with a low temperature cavity located in the lower side of the grinding cavity and communicated with the grinding cavity, the upper side end face ofthe grinding cavity is provided with a sealing cover, the sealing cover is internally provided with a driving cavity, the driving cavity is internally provided with a driving device used for providingpower for grinding, the grinding cavity is internally provided with a lifting device, the grinding cavity is internally provided with a grinding device located at the right side of the lifting deviceand used for grinding animal tissue, and the low temperature cavity is internally provided with a liquid nitrogen device. The animal tissue homogenization grinding equipment has the advantages that grinding is carried out through a rotary grinding mechanism, no vibration problem caused by eccentric rotating exists, so that the service life of the equipment is longer, a lifting mechanism can drivea grinding test tube to move downward, the grinding test tube enters a low temperature tank for low temperature treatment, therefore, the service life of the equipment is longer, low temperature treatment can be automatically carried out on the animal tissue, the operation is simple, and the low temperature frostbite risk is effectively reduced.

Owner:XINYANG AGRI & FORESTRY UNIV

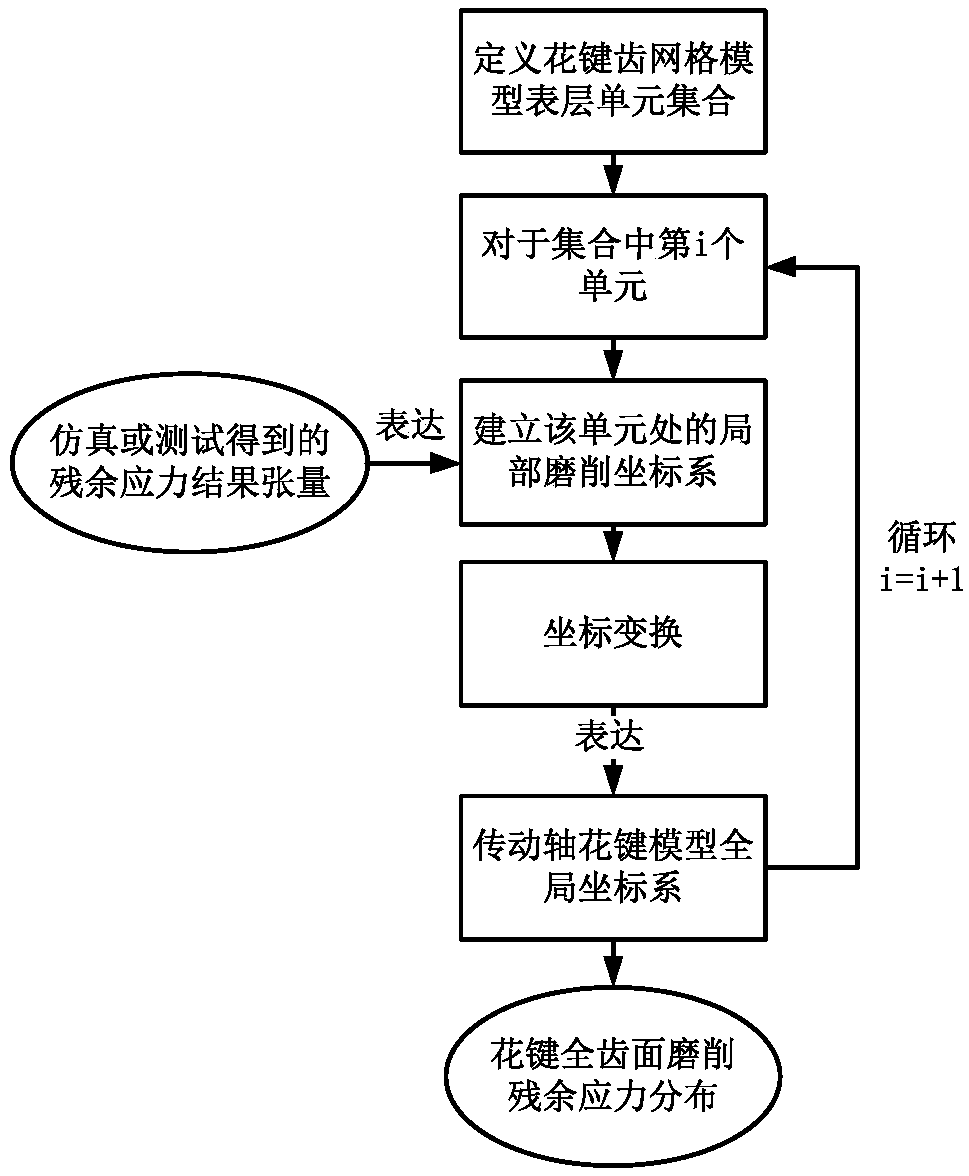

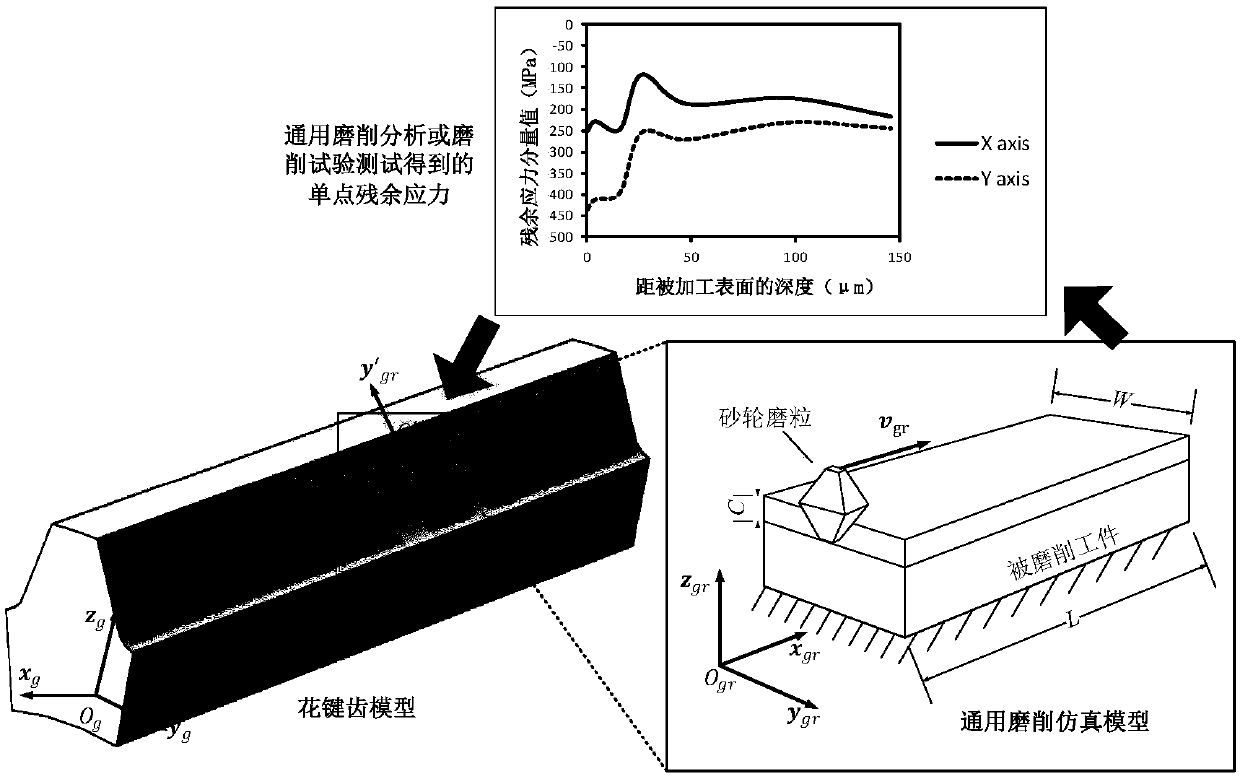

A transmission shaft spline full tooth surface grinding residual stress simulation method

InactiveCN109598084APrecise and detailed resultsAvoid time costDesign optimisation/simulationSpecial data processing applicationsEngineeringSystem transformation

The invention relates to a transmission shaft spline full tooth surface grinding residual stress simulation method. The method comprises the following steps: 1, preparing a residual stress analysis ortest result of universal grinding; 2, establishing a local grinding coordinate system for each finite element grid unit on the surface layer of the spline tooth; 3, according to the coordinate transformation relation between the local grinding coordinate system on the spline tooth and the spline global coordinate system, converting the single-point universal grinding residual stress obtained through analysis or testing to the spline global coordinate system for expression; And 4, traversing all tooth surface grid units, and carrying out the coordinate system transformation operation to finally obtain the residual stress distribution of the full tooth surface. A spline part grinding test and a test process can be replaced by a simple and universal grinding test and finite element simulation combined way, a tooth surface residual stress distribution result which is finer and clearer than that of a complete part test is obtained, meanwhile, the number of samples is greatly reduced, the test period is shortened, and the economic cost and the time cost are reduced.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com