Cutting line grinding test device and test method

A technology of grinding test and cutting line, which is applied in the field of grinding test, can solve the problems that the cutting performance cannot be pre-assessed, waste of resources and funds, unfavorable production process, etc., and achieve convenient and fast inspection process, cost saving and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

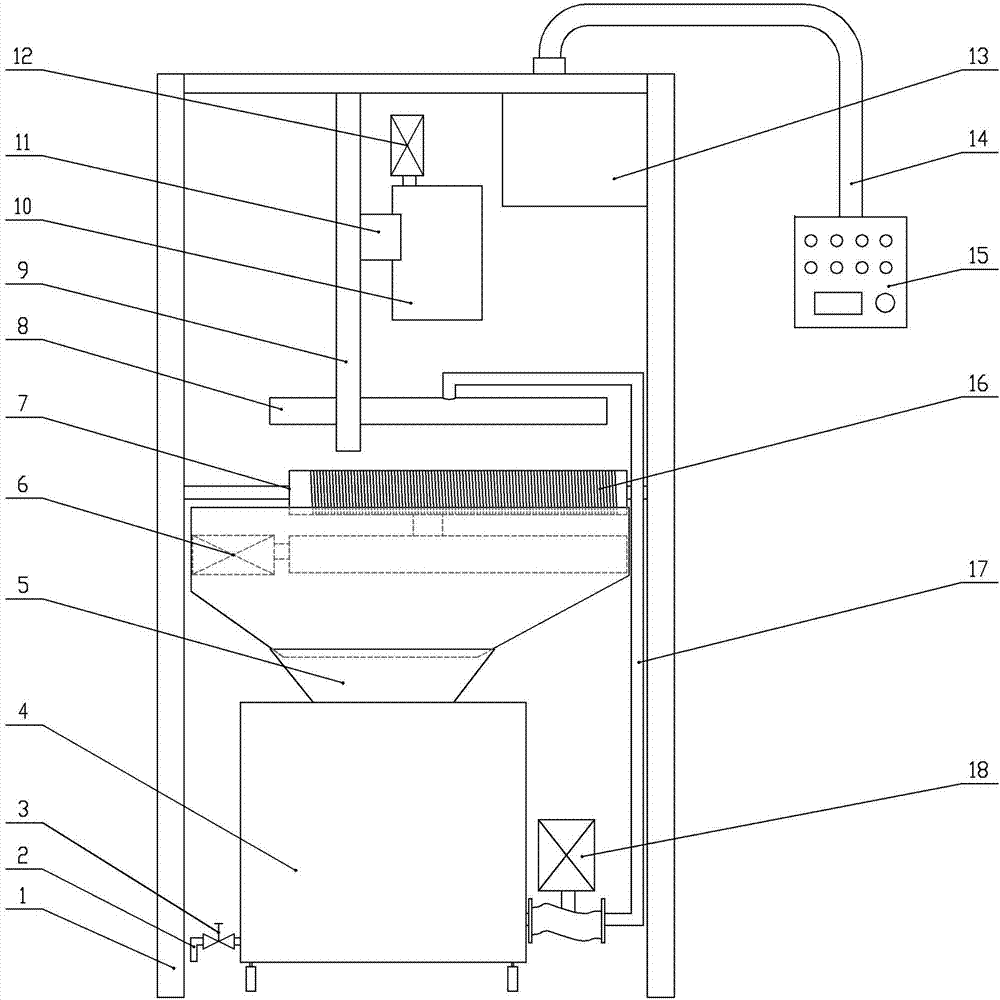

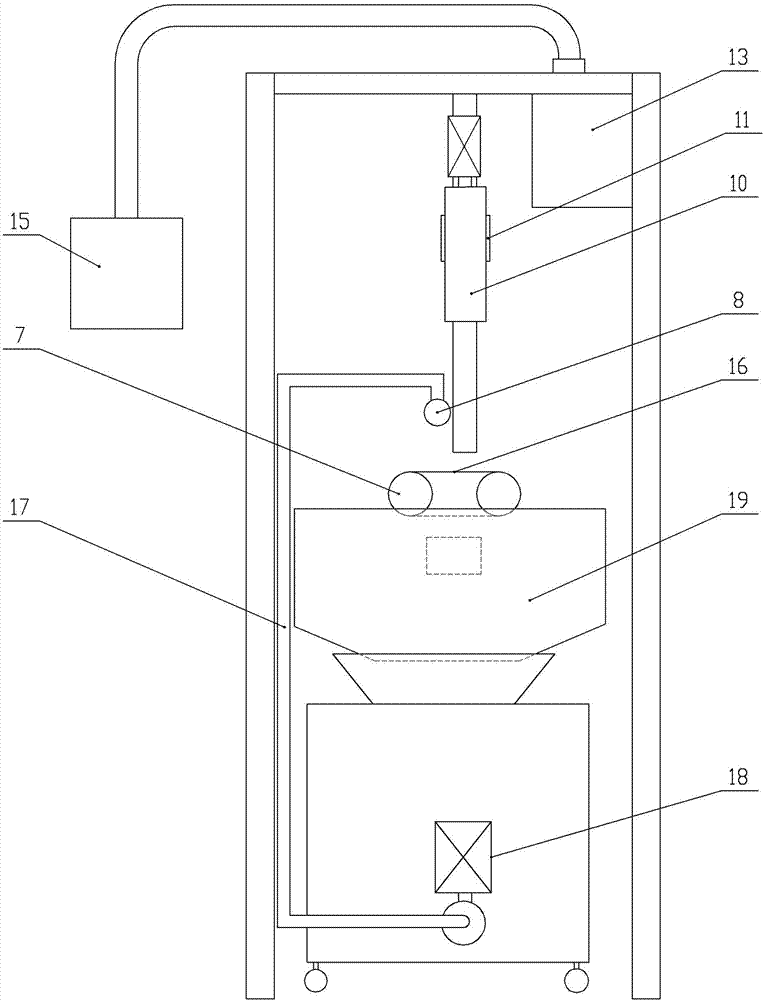

[0028] Embodiment 1: a kind of cutting wire grinding test device, see figure 1 , figure 2 , including a frame 1, a winding assembly, a spray assembly and a grinding assembly, the winding assembly is arranged in the middle of the frame 1, includes a group of horizontally arranged winding guide wheels 7 and is in phase with the winding guide wheels 7 The connected guide wheel drive motor 6 is a separate flexible connection between the guide wheel drive motor 6 and the winding guide wheel 7; The spray pipe 8 above the guide wheel 7 and the upper liquid pipe 17 communicating with the cutting fluid filter box 4 and the spray pipe 8 are installed with a quantitative pump 18 at the connection between the cutting fluid filter box 4 and the upper liquid pipe 17; The grinding assembly includes a lifting bracket 9 arranged on the top of the frame 1 and a grinding block mounting plate 11 arranged on the lifting bracket 9 , and a lifting drive motor 12 is also installed on the lifting br...

Embodiment 2

[0030] Embodiment 2: A cutting wire grinding test device. The difference from Embodiment 1 is that a funnel-shaped cutting fluid return port 5 is provided on the top of the cutting fluid filter box 4, and a cutting fluid return port 5 is provided under the winding guide wheel 7. Cutting fluid deflectors 19 are arranged around, and the lower part of the cutting fluid deflectors 19 connects with the cutting fluid return port 5 . A drain port 2 is provided at the lower part of the cutting fluid filter box 4 , and a drain valve 3 is provided at the drain port 2 . When carrying out the cutting test, the cutting fluid sprayed by the spray pipe 8 can pass through the diversion of the cutting fluid deflector 19, flow back to the cutting fluid return port 5, and then flow into the cutting fluid filter box 4 to filter the cutting fluid. The residue can be discharged through the liquid discharge port 2, and the filtered cutting fluid can be circulated for spray cooling.

Embodiment 3

[0031] Embodiment 3: use the cutting wire grinding test method of cutting wire grinding test device in embodiment 2, comprise the following steps:

[0032] (1) Place the cutting wire grinding test device on a flat ground, and then wind the cutting wire 16 to be tested equidistantly on the winding guide wheel 7 to form a cutting wire network. The cutting wire 16 to be tested is In order to cut the steel wire, the grinding block 10 used for the grinding experiment is installed on the grinding block mounting plate 11, and the cutting fluid filter box 4 is filled with cutting fluid;

[0033] (2) After the above preparatory work is completed, set the corresponding program parameters through the control panel 15, and then run the quantitative pump 18 to pump the cutting fluid in the cutting fluid filter box 4 from the upper liquid pipe 17 to the spray pipe 8, and then After spraying, flow back into the cutting fluid filter box 4 along the cutting fluid deflector 19 and the cutting f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com