Multifunctional rail grinding test device

A test device and multi-functional technology, applied in the field of multi-functional rail grinding test device, can solve problems such as short service life, unfavorable analysis of workpieces, backward technology, etc., and achieve improved stability and repeatability, thick and stable lathe structure, The effect of saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

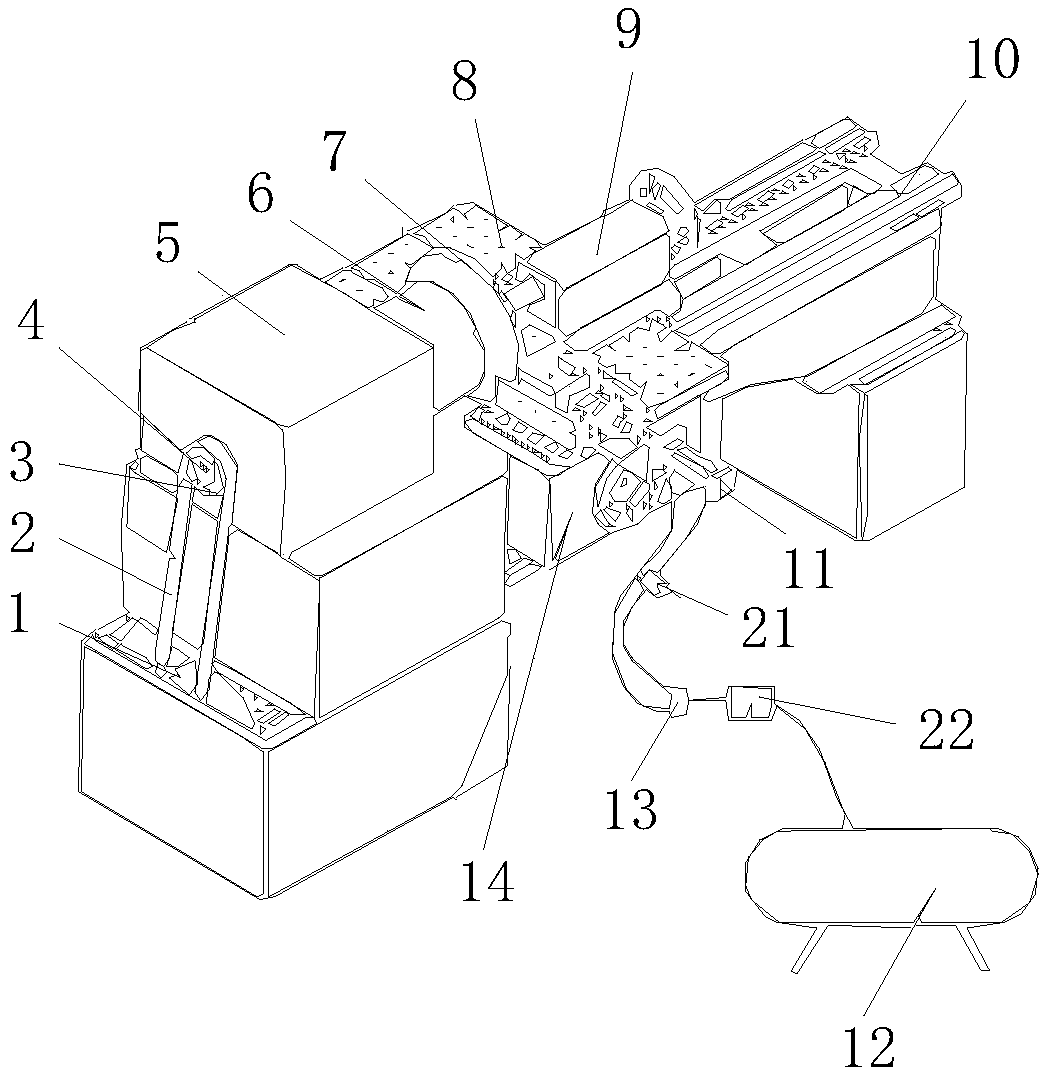

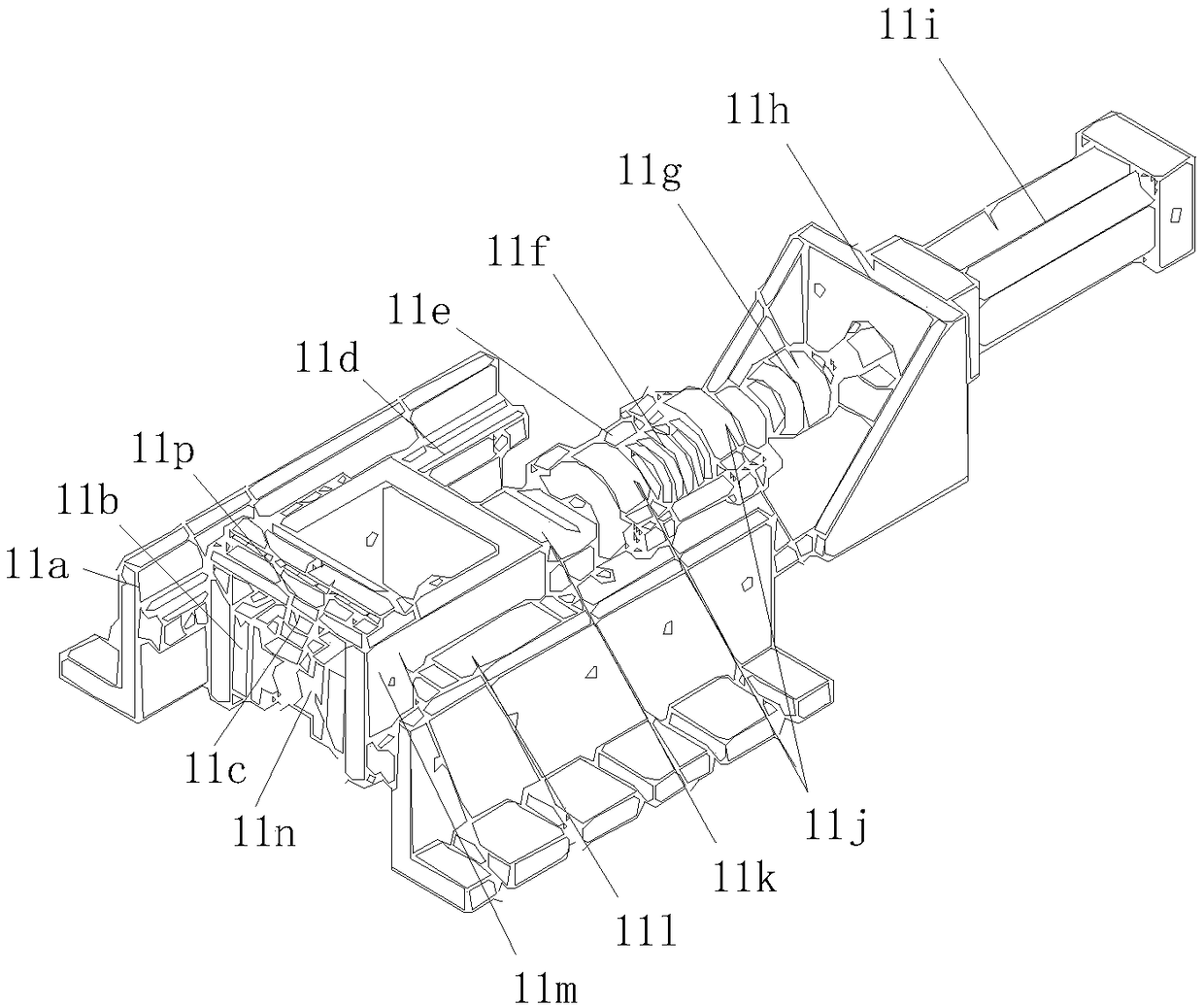

[0023] see figure 1 , image 3 and Figure 5, a multifunctional rail grinding test device, comprising a lathe main shaft 4, a workbench 8, an actuating device 11, an air compressor 12, a grinding wheel sample 19 and a frequency conversion motor 1 installed in a lathe motor box, the frequency conversion motor 1 The output shaft of the output shaft is equipped with a synchronous pulley 3, and is connected with the synchronous pulley 3 of the lathe spindle 4 through the synchronous belt 2, the lathe spindle 4 is fixed by the lathe spindle box 5 and the other end is equipped with a three-jaw chuck 6, and a three-jaw chuck 6 The outer surface of the disc is movably connected with a disc-shaped rail workpiece 7 and a rail grinding wheel 15. The disc-shaped rail workpiece 7 is to intercept a whole piece of material from a billet. After processing, the same measures as the rail heat treatment process are carried out. The workpiece 7 has the same mechanical properties and microstruct...

Embodiment 2

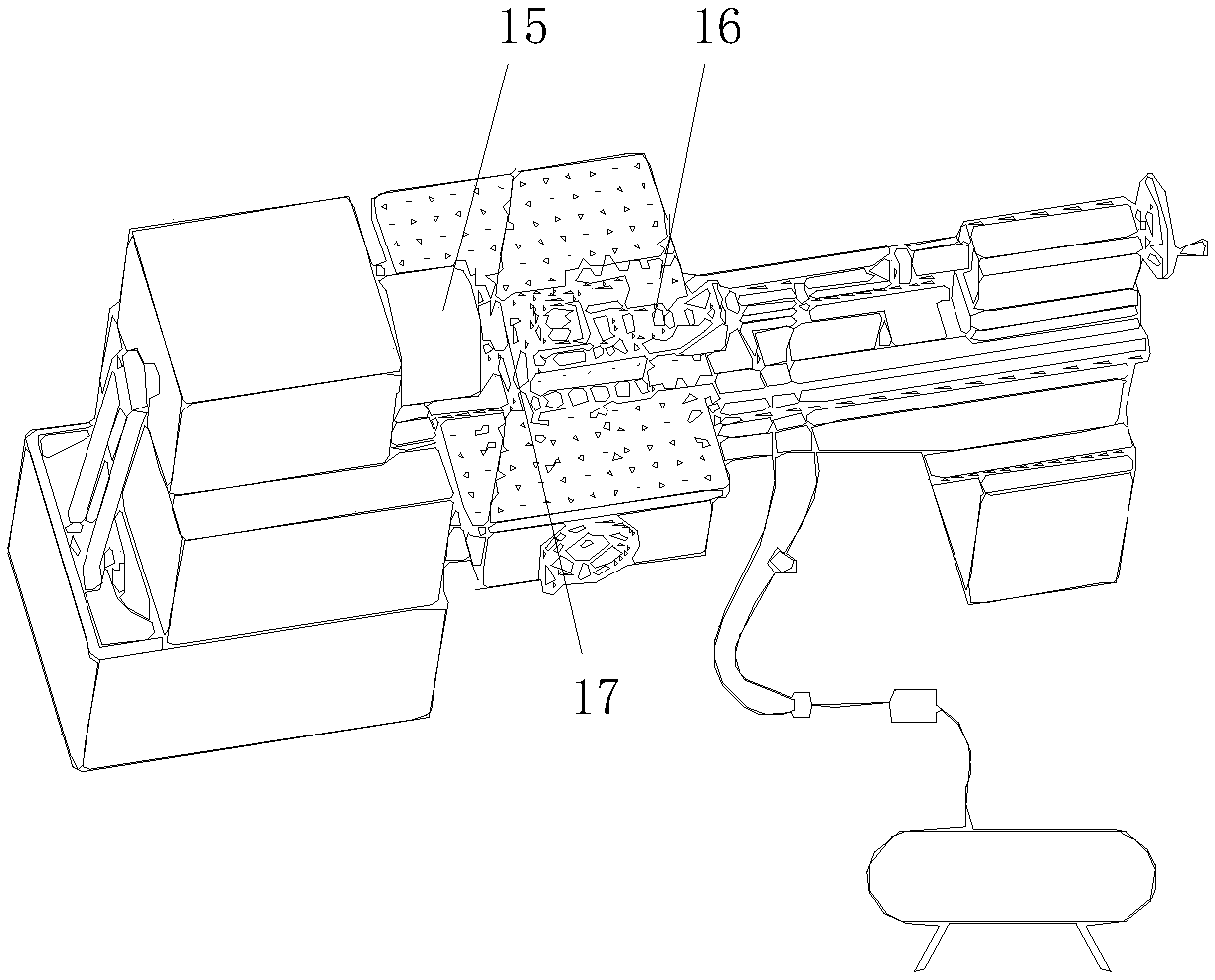

[0025] see figure 2 , image 3 and Figure 4 , a multifunctional rail grinding test device, comprising a lathe main shaft 4, a workbench 8, an actuating device 11, an air compressor 12, a grinding wheel sample 19 and a frequency conversion motor 1 installed in a lathe motor box, the frequency conversion motor 1 The output shaft of the output shaft is equipped with a synchronous pulley 3, and is connected with the synchronous pulley 3 of the lathe spindle 4 through the synchronous belt 2, the lathe spindle 4 is fixed by the lathe spindle box 5 and the other end is equipped with a three-jaw chuck 6, and a three-jaw chuck 6 The outer surface of the disc is movably connected with a disc-shaped rail workpiece 7 and a rail grinding wheel 15. The disc-shaped rail workpiece 7 is to intercept a whole piece of material from a billet. After processing, the same measures as the rail heat treatment process are carried out. The workpiece 7 has the same mechanical properties and microstru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com