Method for quickly determining optimal gradations of ceramic grinding bodies of cement ball mill

A technology of grinding body and cement ball, applied in cement production, instruments, data processing applications, etc., can solve the problems of not being able to find quickly and being wasted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

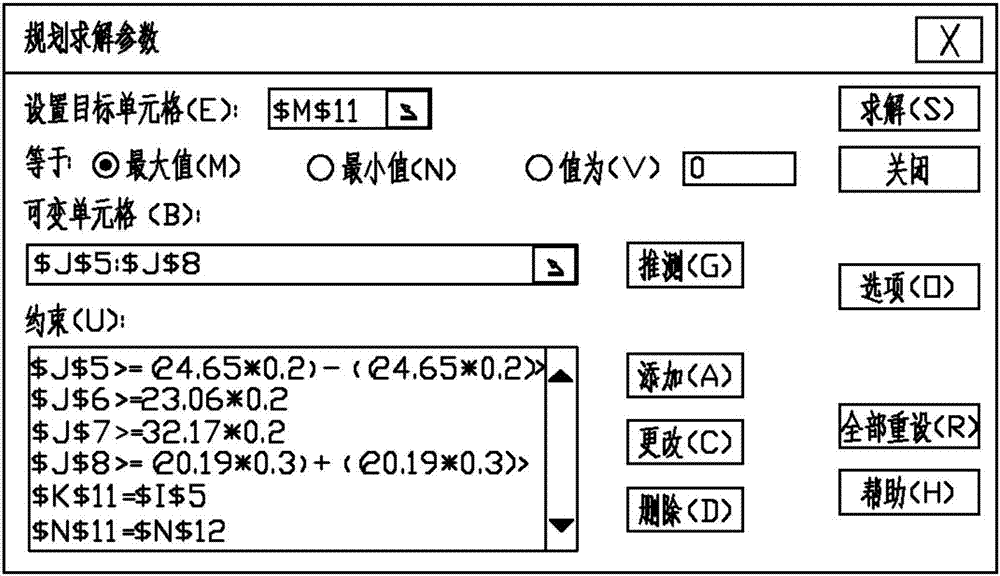

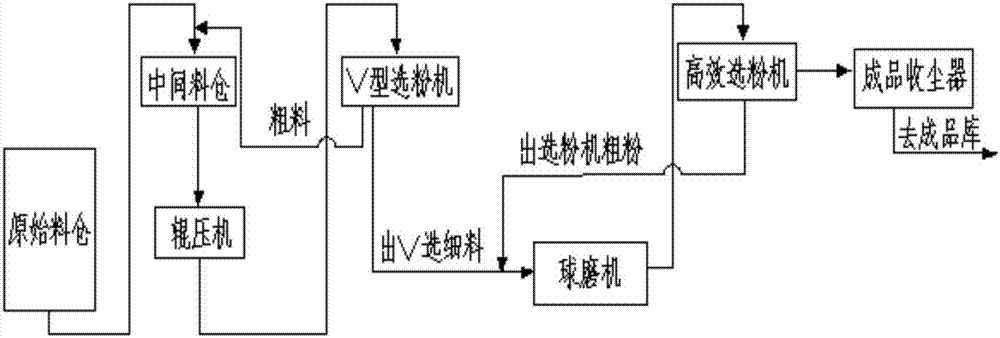

[0128] The following is a company's "roller press + V-type powder separator + ф4.2m × 13m ball mill + high-efficiency powder separator" cement grinding system (see figure 1 ) as an example to illustrate the implementation process.

[0129] 1 Calibrate the cement grinding system before using the ceramic grinding body

[0130] a) Overview of grinding system equipment

[0131] Table 1 Main Equipment Performance of Grinding System

[0132]

[0133] b) Cement type and material ratio

[0134] Table 2 Cement varieties and material ratios

[0135]

[0136] The small mill test will use a specific surface area of 330m 2 / kg to meet product quality requirements.

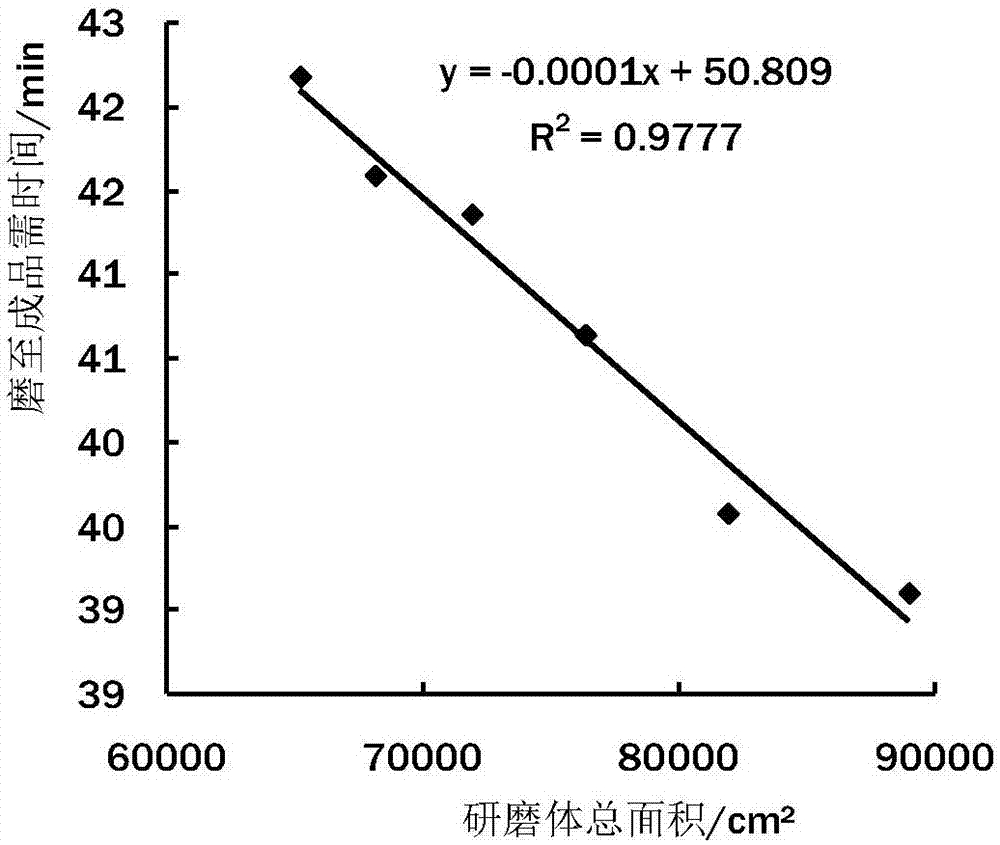

[0137] c) Changes in the fineness of materials during the grinding process

[0138] Table 3 Changes in material fineness during processing

[0139]

[0140] Note: ①D50, X 0 Respectively represent the pore size of 50% and 63.2% of the material passing through a certain sieve, which represents the overall thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com