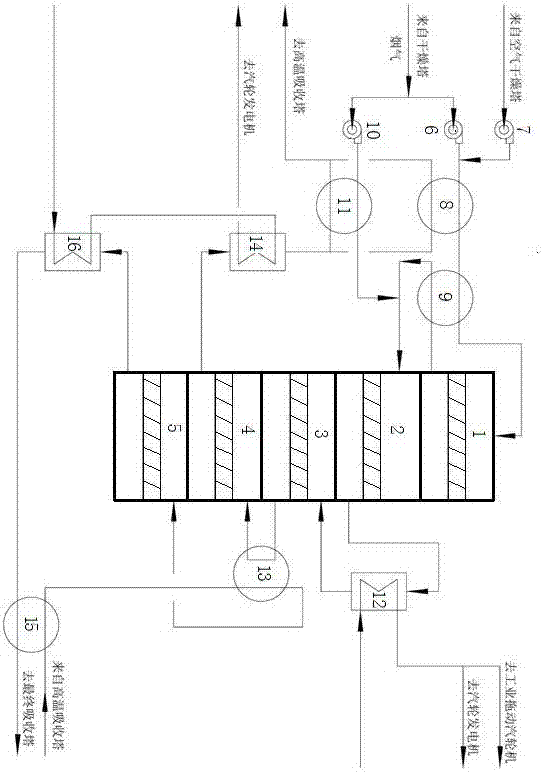

Waste heat utilization method for flue-gas acid making process

A technology for producing acid and waste heat from flue gas, which is applied in the directions of steam superheating, chemical instruments and methods, and climate sustainability. Advanced problems, to achieve the effect of efficient gas split mode, easy thermal balance of the system, and strong performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] High Concentration SO Produced by Jinfeng Continuous Copper Smelting System 2 In smelting flue gas, SO 2 Volume percentage concentration 25.5VOL%, O 2 The volume percentage concentration is 8.5VOL%. High concentration SO after purification and drying 2 The flue gas from smelting is conveyed equally by two sulfur dioxide fans arranged in parallel, and half of the flue gas is sent by the sulfur dioxide fan and mixed with the dry air sent by the air fan. Among them, the amount of air added is based on the oxygen-sulfur ratio of the total gas 0.88 and SO 2 The total amount of smoke is controlled. After the mixed gas is heated by the first heat exchanger and the pre-heat exchanger in turn, it enters the pre-bed, and the design conversion rate is 69.5%. The other half of the flue gas heated by the second heat exchanger is uniformly mixed and enters the first bed of the two-turn-two-suction process, with a design conversion rate of 75%; the first-stage outlet gas is remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com