Regeneration treatment method and device for black liquor of papermaking

A treatment method and papermaking black liquor technology, which is applied in the field of papermaking black liquor recycling treatment, can solve the problems of enterprise cost impact, inability to discharge directly, large investment scale, etc., to reduce enterprise energy consumption, reduce usage, and reduce enterprise emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

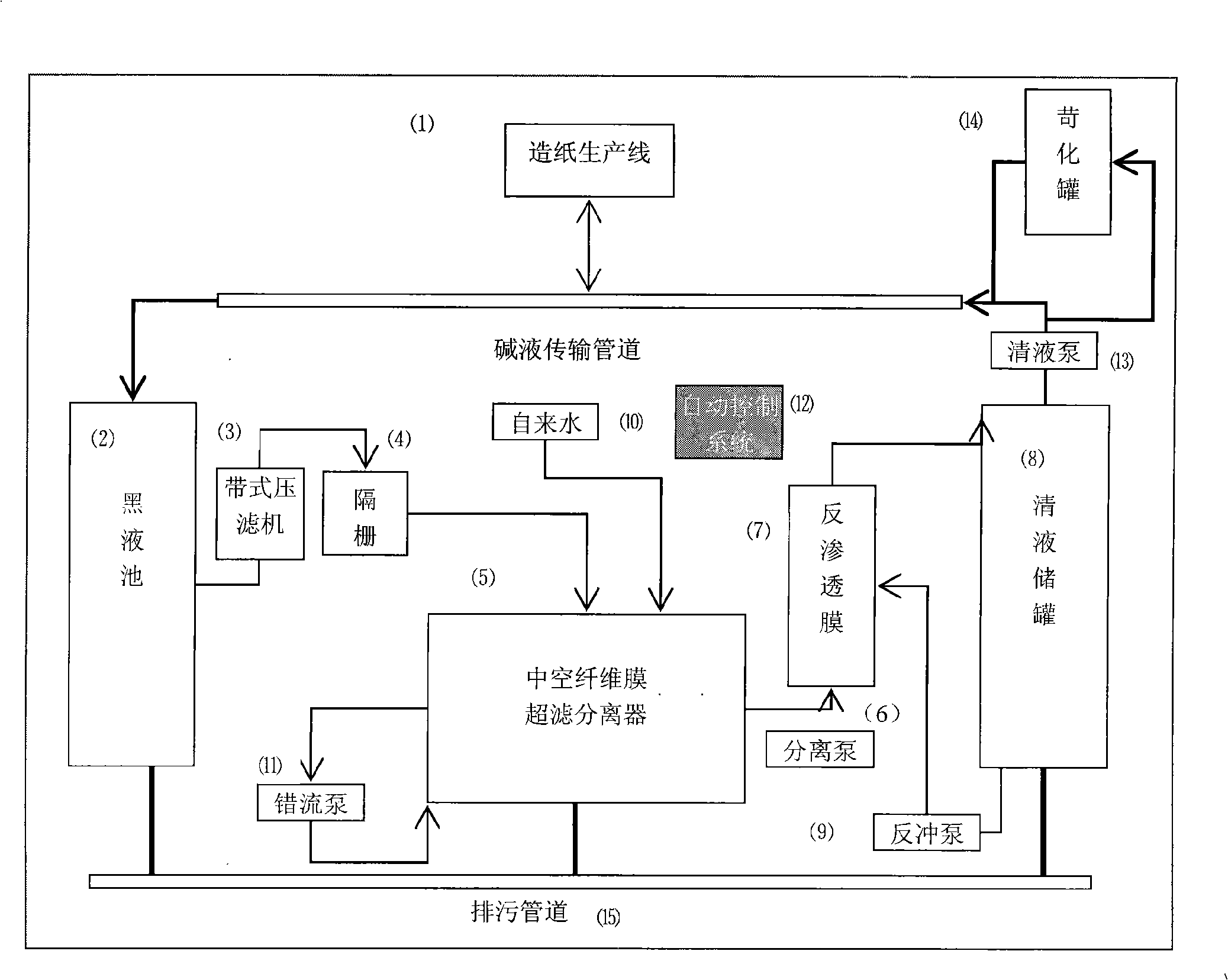

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings: the regeneration treatment method of the papermaking black liquor of the present invention, it comprises: 1 above the papermaking black liquor collection tank adopts the primary solid-liquid separation of mixed liquor by belt filter press, removes Most of the solids in the liquid, including fine fibers, can be reused for papermaking; 2. The separated liquid enters the hollow fiber membrane ultrafiltration separator through the grid, and the hollow fiber membrane is used in sheet or other packaging. The solution is extracted by negative pressure; 3 The filtrate separated by the hollow fiber ultrafiltration membrane is directly pumped into the reverse osmosis membrane system through the separation pump to realize the concentration of the caustic soda solution, and the separated water can be used in other processes without discharge; 4 The caustic soda solution concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com