Abrasive particle pose controllable grinding test platform and abrasive particle pose controllable grinding test method for single abrasive particles

A single abrasive grain and grinding test technology, which is applied in the direction of testing wear resistance, etc., can solve the problems of ignoring the influence and irregularity of abrasive grains, so as to optimize the design of grinding wheel landform and grinding consumption, and control the cutting thickness of abrasive grains The effect of distribution characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

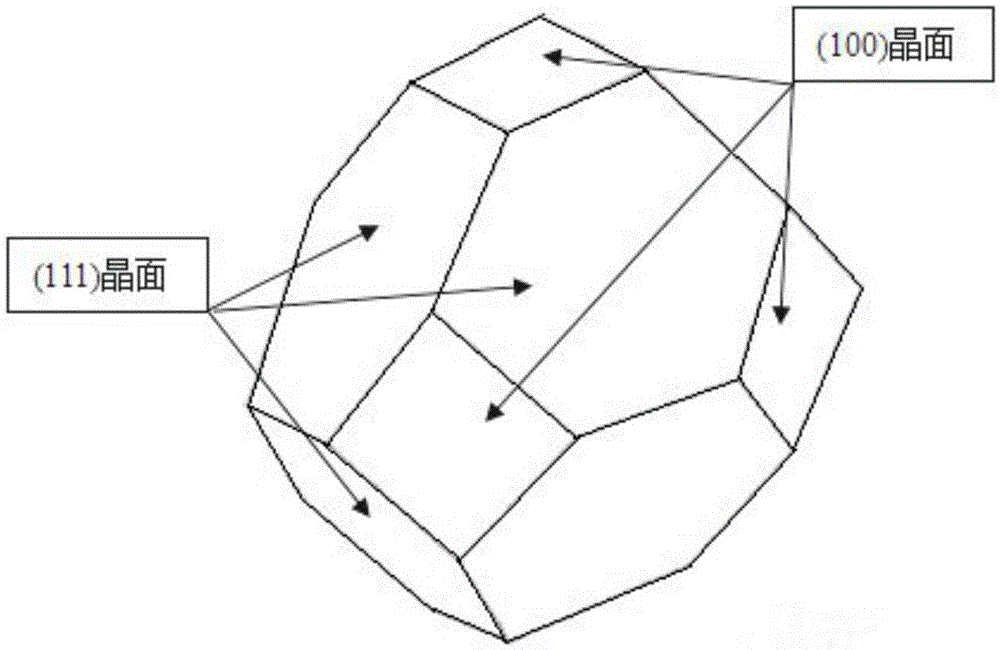

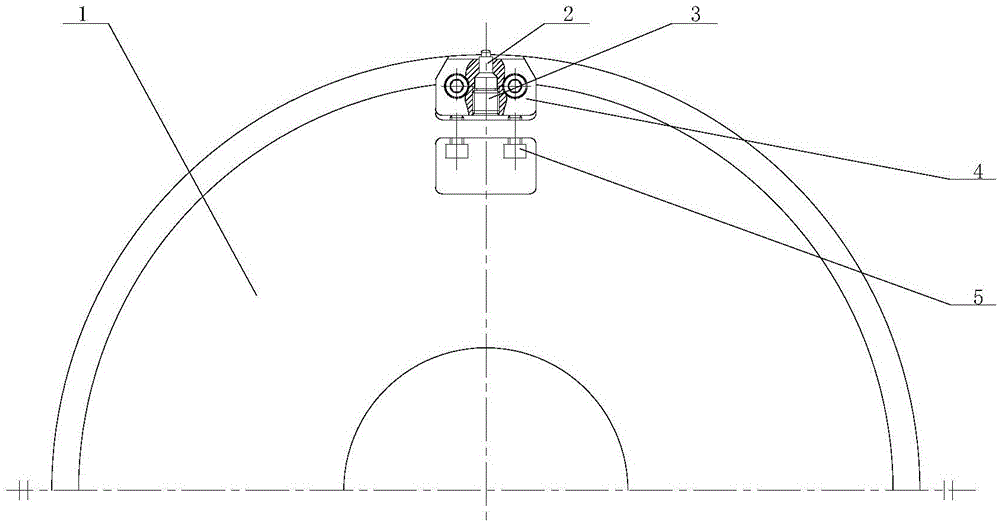

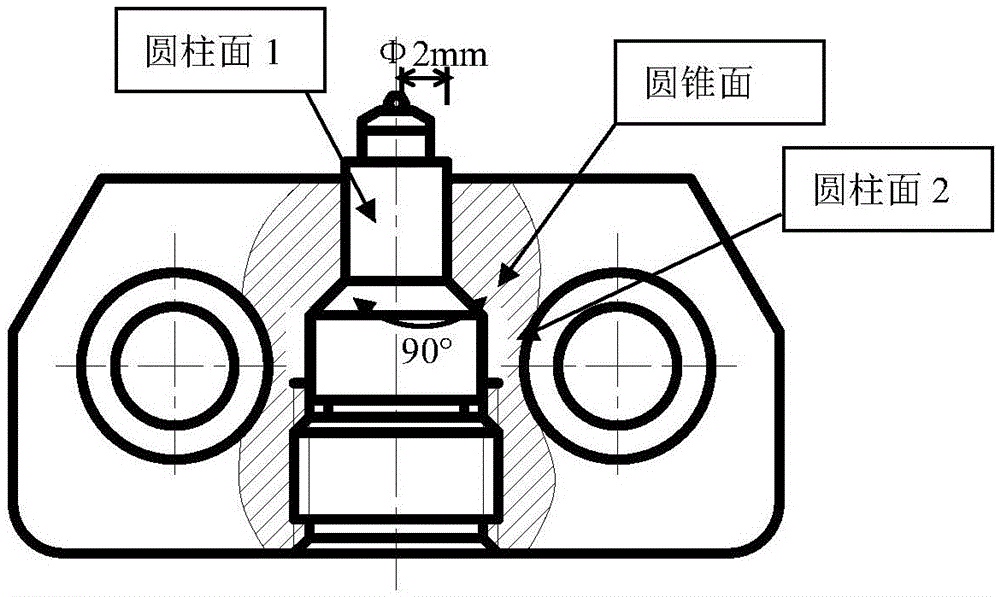

[0039] figure 1 It is a schematic diagram of a hexa-octahedron formed by a regular octahedron lacking hexagons, figure 2 is the overall schematic diagram of a single abrasive grain grinding test wheel with controllable abrasive grain position and orientation, image 3 Is the schematic diagram of the block assembly.

[0040]The single abrasive grinding wheel with controllable abrasive grain position and posture is to arrange two nodes 4 symmetrically in the center of the circle on the grinding wheel substrate 1 of the single abrasive grinding test grinding wheel, and only one of the two nodes There are abrasive grains, and another symmetrically arranged segment is used as a balance segment; an installation groove is set at the position where the segment is installed on the grinding wheel base, and the segment is placed in the installation groove, and the segment is radially tightened by means of bolts. Axial compression; the segment assembly (including the segment, jacking o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com