Patents

Literature

48results about How to "Corrosion effective" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

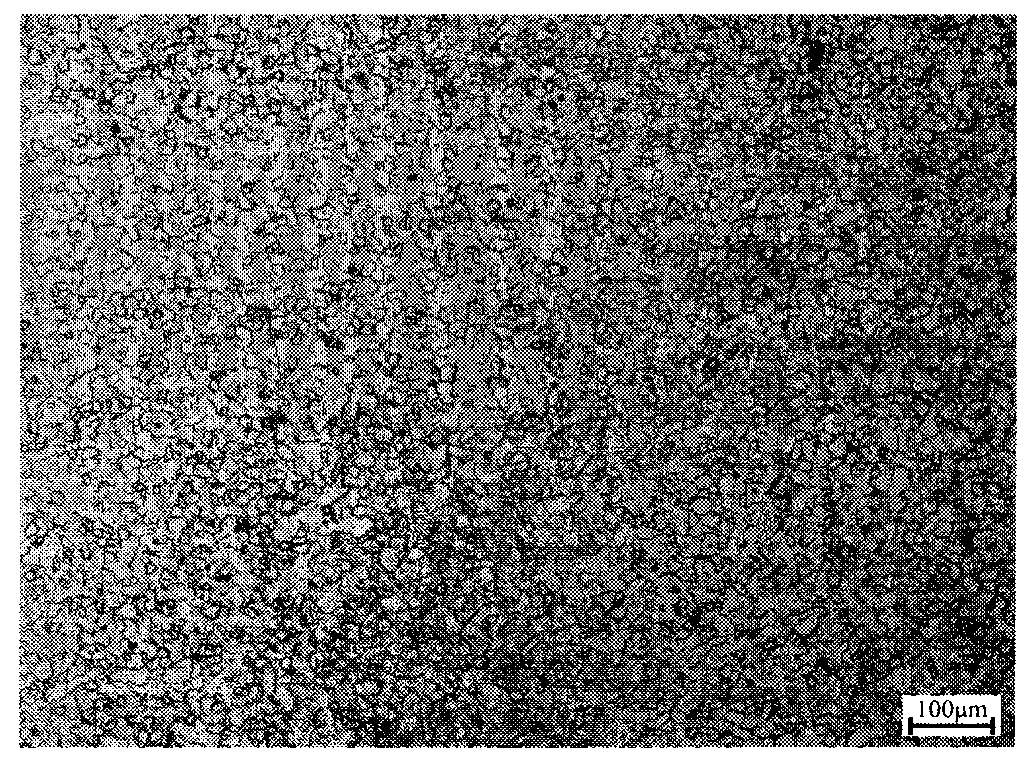

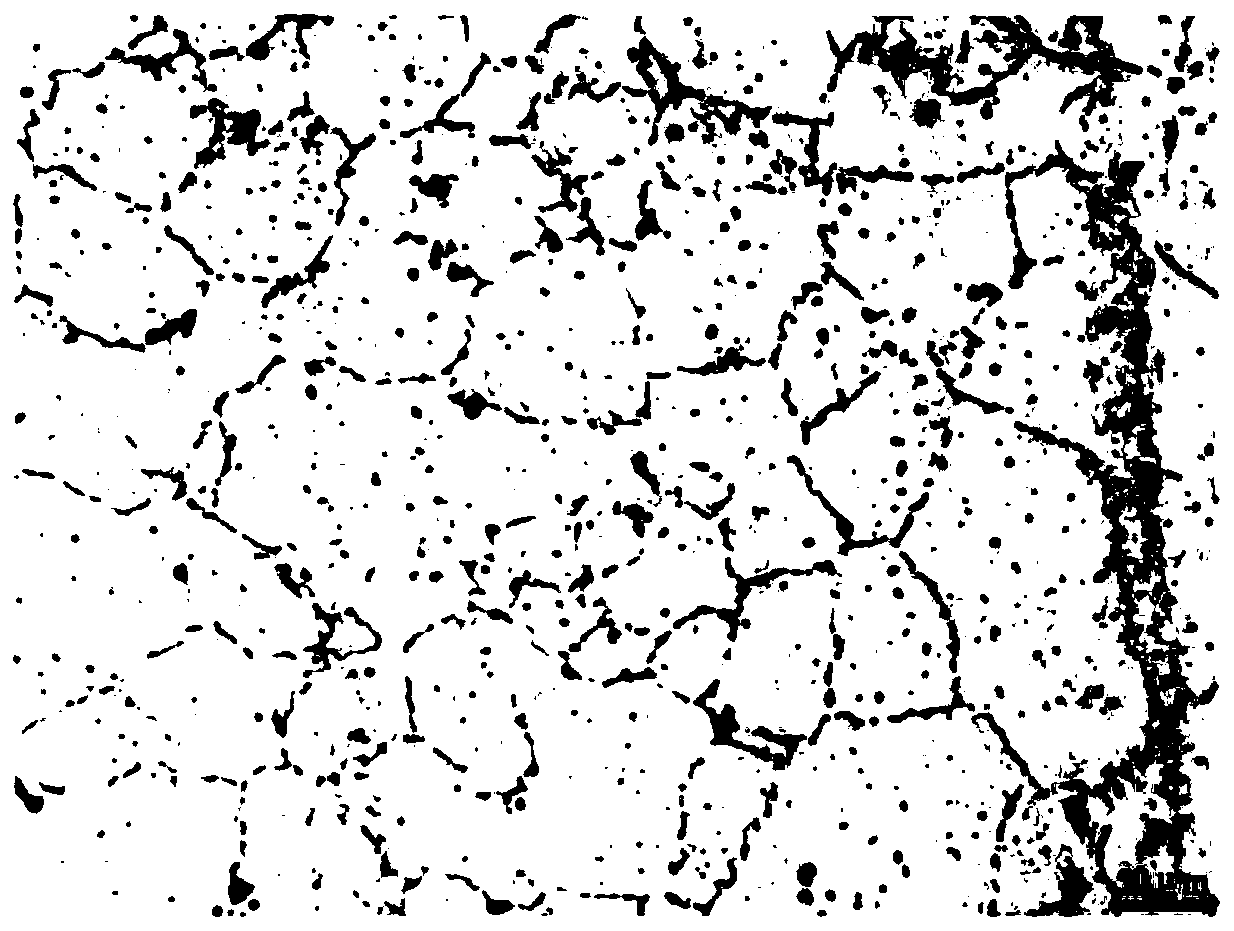

Metallographic etchant and metallographic etching method for pure titanium and beta titanium alloy

InactiveCN102808179AAccelerated corrosionFast corrosionPreparing sample for investigationHydrofluoric acidEtching

The invention relates to the field of metallographic etching of titanium and titanium alloy and discloses metallographic etchant and a metallographic etching method for pure titanium and beta titanium alloy. The metallographic etchant and the metallographic etching method are mainly used for metallographic etching of the pure titanium and the beta titanium alloy. The etchant consists of 10 to 40 volume parts of nitric acid, 5 to 10 volume parts of hydrofluoric acid, and 30 to 100 volume parts of water. The method comprises the following steps of: soaking a ground and polished metallographic specimen in the etchant for a certain period of time, then placing the metallographic specimen in warm absolute ethanol at the temperature of between 30 and 50 DEG C for a moment, polishing again to ensure that the etching layer is polished completely, and etching the metallographic specimen for the second time by using etchant which is similar to the etchant used in the first-time etching to obtain a single-phase metallographic structure. By the method, processing-state and annealing-state pure titanium and beta titanium alloy bars, wires and plates are subjected to metallographic etching, and the obtained single-phase metallographic structure is clear and complete in crystal boundary, and abnormal etching pits or plaques in a single crystal grain can be avoided.

Owner:西安赛特新材料科技股份有限公司

Environment-friendly stainless steel substrate plating stripping agent

The invention discloses an environment-friendly stainless steel substrate plating stripping agent. Nitrate is optimally selected as an oxidizing agent for stripping nickel, chromium, copper, tin, and other plating on a stainless steel substrate, and as generally, nitrate is relatively stable in property and relatively low in toxicity, so that when the stripping agent provided by the invention is used, exhaust gases and waste water are not generated, and the stripping agent is non-corrosive to a device and highly friendly to the environment; at the same time nitrate is matched with citrate, potassium sodium tartrate and a proper amount of polyhydroxyl aldehyde, so that the speed for stripping the nickel plating on the stainless steel substrate is effectively increased, the plating stripping is achieved in a short time, and the production cycle is shortened while the substrate is not damaged; and the stripping rate of the nickel plating on the stainless steel substrate can be effectively increased through the combination of mannitol and sodium diacetate. Relative to the prior art, the stripping agent has the advantages of being free of corrosion, poisonous gases and pollution, high in efficiency, environment-friendly in use, easy and convenient to maintain, and the like.

Owner:HUIZHOU CITY HIROMI CHEM CO LTD

Composite material with high bonding force

ActiveCN111286770ANo damageFacilitate corrosion reactionSurface reaction electrolytic coatingAluminum metalElectroplating

The invention provides a composite material with high bonding force. A shielding layer at the bottom of an anodized film, an aluminum metal substrate is exposed, and then single-metal electroplating treatment is carried out, so that bonding of an anodized substrate and a coating is effectively improved.

Owner:瑞安市奥丰实业有限公司

Iron substrate plating neutral stripping agent

The invention discloses an iron substrate plating neutral stripping agent. Nitrate is optimally selected as an oxidizing agent for stripping nickel, chromium, copper, tin and other plating on an iron substrate, and as generally, nitrate is relatively stable in property and relatively low in toxicity, so that when the stripping agent provided by the invention is used, exhaust gases and waste water are not generated, and the stripping agent is non-corrosive to a device and highly friendly to the environment; at the same time nitrate is matched with citrate, potassium sodium tartrate and a proper amount of polyhydroxyl aldehyde, so that the speed for stripping the nickel plating on the iron substrate is effectively increased, the plating stripping is achieved in a short time, and the production cycle is shortened while the substrate is not damaged; and particularly, calcium nitrate is optimally as the oxidizing agent, and ammonium ferric citrate is adopted as a first complexing agent, and calcium nitrate and ammonium ferric citrate are combined with mannitol and sodium diacetate, so that the stripping rate of the nickel plating on the iron substrate can be effectively increased. Relative to the prior art, the stripping agent has the advantages of being free of corrosion, poisonous gases and pollution, high in efficiency, environment-friendly in use, easy and convenient to maintain, and the like.

Owner:惠州市博美新材料科技有限公司

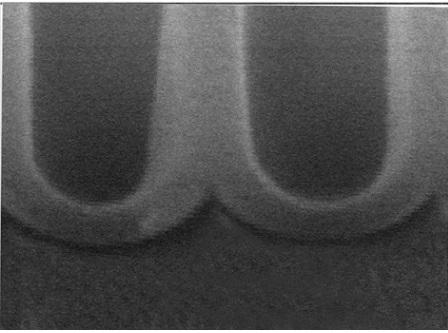

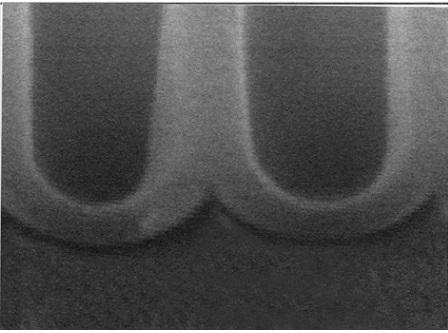

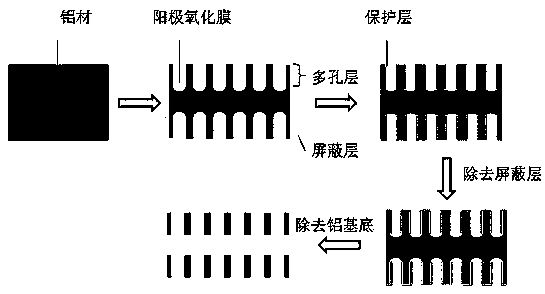

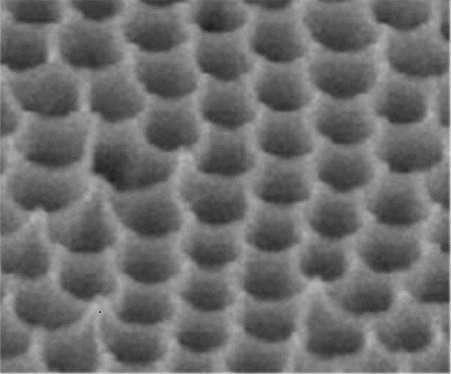

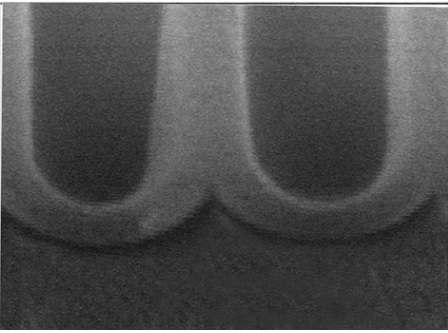

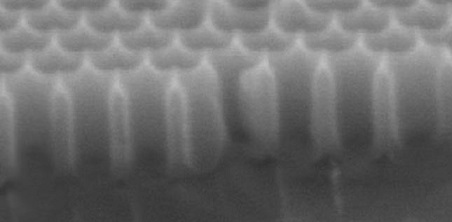

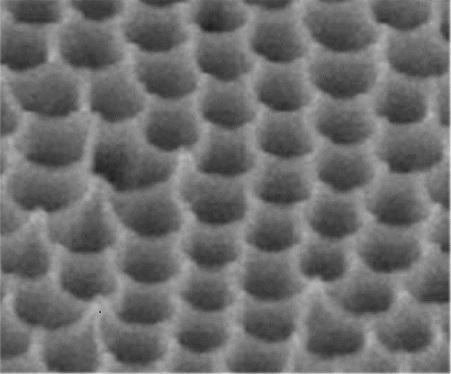

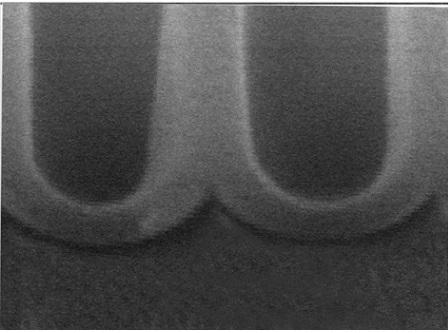

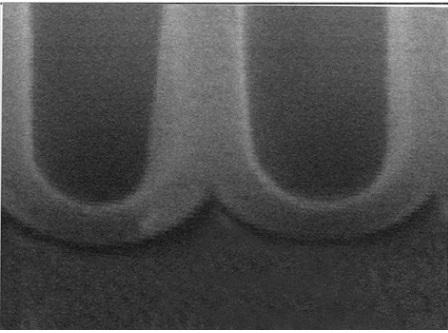

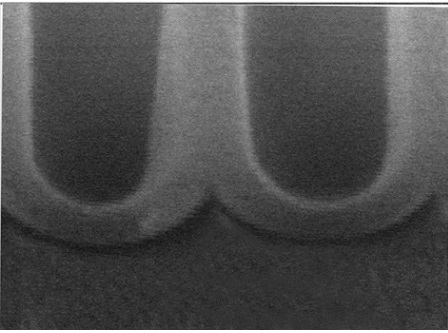

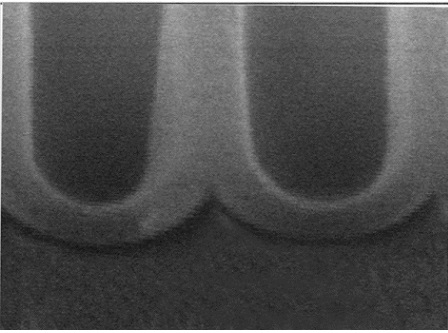

Preparation method of high bonding force coating taking anodic alumina as base material

ActiveCN111101164ANo damageFacilitate corrosion reactionSurface reaction electrolytic coatingAluminum metalAluminium oxides

The invention provides a preparation method of a high bonding force coating taking anodic alumina as the base material. A shielding layer at the bottom of an anode oxide film is removed to expose thealuminum metal base material, and then, electroplating monometallic treatment is carried out, and finally, combination of the anodic oxidation base material and the coating is effectively improved.

Owner:李玉龙

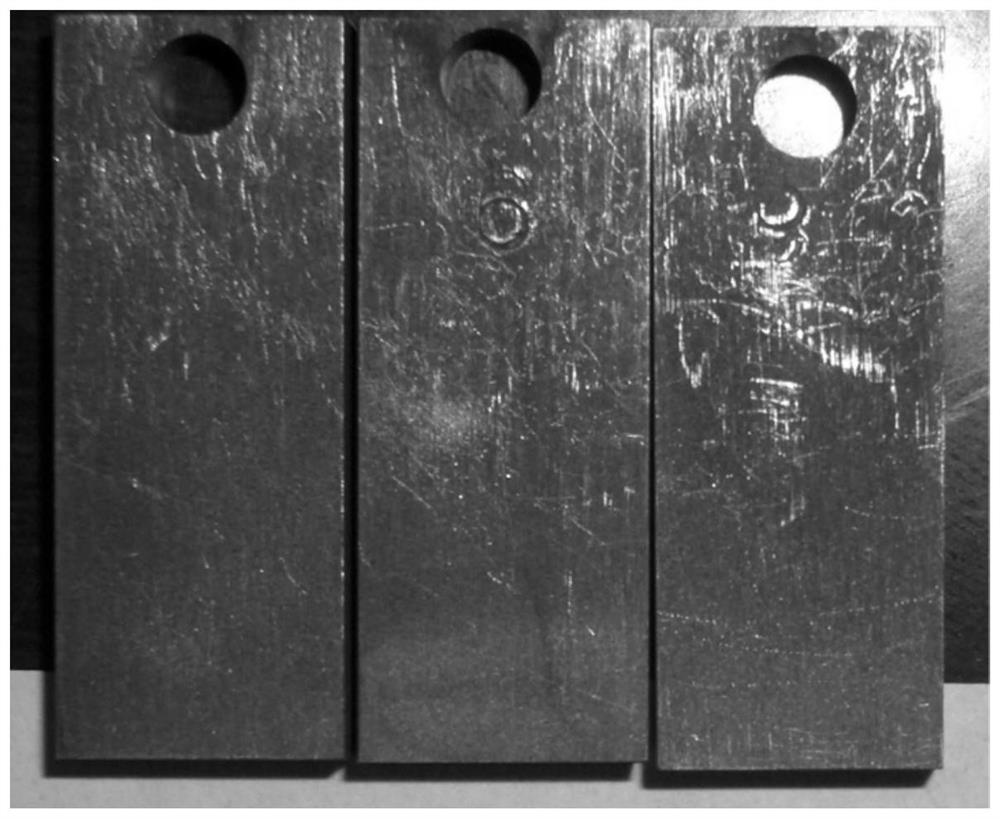

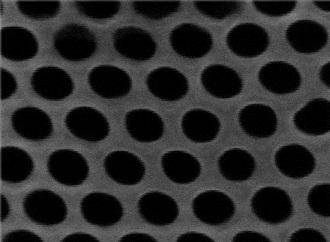

Nickel-based powder high-temperature alloy corrosion solution and corrosion method

PendingCN112048720ACorrosion effectiveEasy to observePreparing sample for investigationThermal waterCopper sulfate

The invention provides a nickel-based powder high-temperature alloy corrosion solution and a corrosion method. The corrosion solution takes hydrochloric acid as a solvent, and solute components and concentrations are as follows: 60-80g / L sulfuric acid, 150-180 g / L of copper sulfate, and 80-100 ml / L of absolute ethyl alcohol, wherein the mass fraction of the adopted hydrochloric acid is 36%-38%, and the mass fraction of the sulfuric acid is 95%-98%. The corrosion method comprises the processes of incoming part inspection, oil removal, hot water cleaning, cold water washing, corrosion, flowing cold water washing, light transmission, flowing cold water washing, hot water washing, blow-drying, inspection and hydrogen removal. According to the corrosion solution and the corrosion method, the alloy surface appearance can be clearly displayed, various defects of the alloy surface can be analyzed and judged more conveniently, and meanwhile the problems that a corrosion layer is too deep and acorrosion product is difficult to remove are effectively solved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

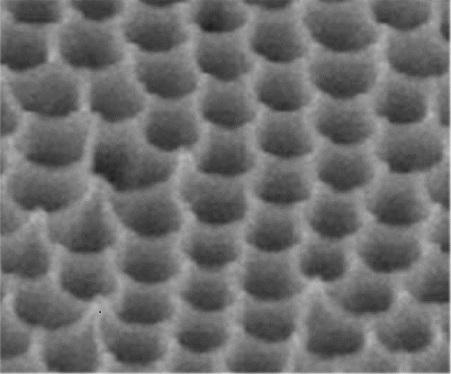

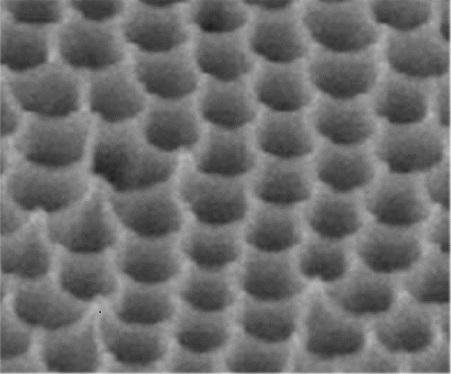

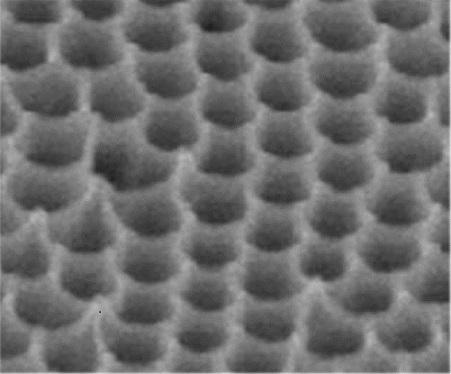

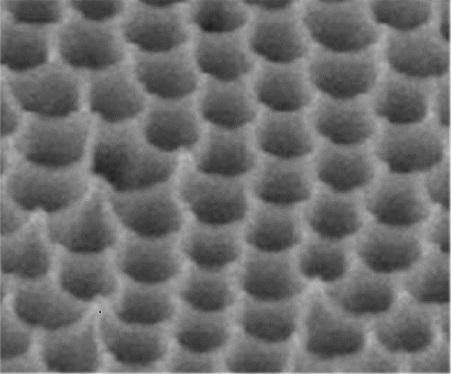

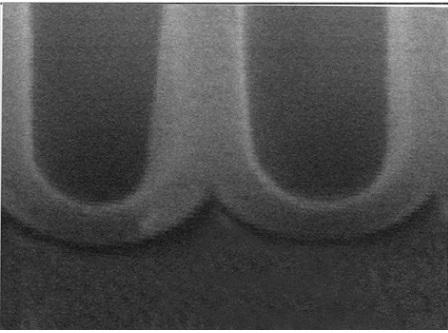

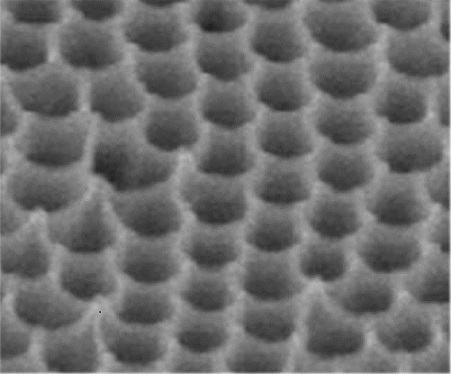

Anodized aluminum material

ActiveCN111172575ANo damageFacilitate corrosion reactionAnodisationCorrosion reactionTrimethylsilane

The invention provides an anodized aluminum material. A porous layer and a shielding layer are subjected to a selective adsorption reaction through gamma-chloropropyl trimethylsilane, and a subsequentalkaline corrosion reaction can effectively etch the shielding layer at the bottom of an anodized film porous channel, so that the conductivity of the anodized aluminum material is effectively improved.

Owner:创隆实业(深圳)有限公司

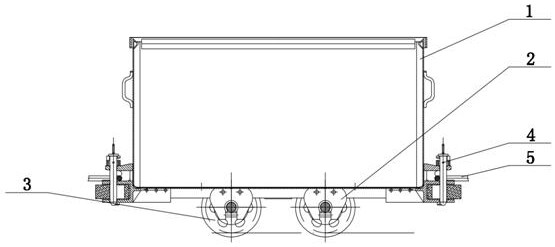

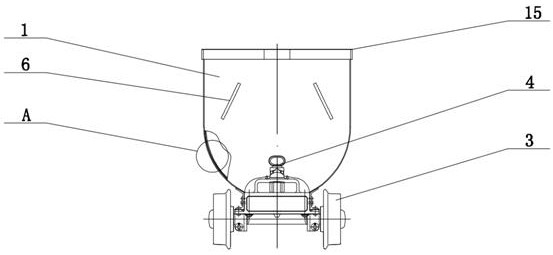

U-shaped fixed carriage type mine car

PendingCN111717227AEffective protectionImprove corrosion resistanceMine carsVehicle frameEngineering

The invention discloses a U-shaped fixed carriage type mine car and relates to the field of mine car equipment. The mine car comprises a carriage, car frames, open type wheel sets, an anti-falling plug pin, a three-ring chain and handles. The carriage body is composed of an anti-collision layer, a buffer layer, an adhesion layer and an anti-corrosion layer. The anti-collision layer is the outermost layer of the carriage; the buffer layer is glued and adhered to the inner wall of the anti-collision layer; the adhesion layer adheres to the buffer layer and the anti-corrosion layer; the car frames are fixed at the bottom of the carriage through a plurality of bolts; and the number of the car frames is two, the open wheel sets are fixed to the two sides of the car frames through bolts, the number of the open wheel sets is four, the anti-falling plug pin is installed on a connecting base connected with the carriage, the three-ring chain is placed on the connecting base and connected to theanti-falling plug pin in a sleeving mode, and the four handles are fixed to a front side and a rear side of the carriage through screws. By adopting a multi-layer carriage wall structure, a stainlesssteel inner wall can effectively prevent a carriage inner wall from being corroded and is convenient to clean, the adhesion layer and the buffer layer can reduce impact on the stainless steel inner wall and prolong a service life of the stainless steel inner wall, and a cast iron protective layer can protect the inner wall from being impacted by an external force and improve durability of the minecar.

Owner:张泽霖

Environment-friendly multi-effect type cooling liquid for testing engine

InactiveCN108949119AImprove rust resistanceExcellent vapor phase rust resistanceHeat-exchange elementsWater jacketStain

The invention discloses environment-friendly multi-effect type cooling liquid for testing an engine. The environment-friendly multi-effect type cooling liquid comprises the following components in percentage by mass: 8-10% of a ferrous metal antirusting agent, 2-3% of a non-ferrous metal antirusting agent, 15-20% of organic amine, 3-5% of a vapor-phased corrosion inhibitor, 5-8% of all-purpose cellosolve, 0.1-0.2% of a defoaming agent and the balance of deionized water, wherein the total percentage is 100%. The environment-friendly multi-effect type cooling liquid disclosed by the invention has the beneficial effects that the anti-rusting property and the vapor-phased anti-rusting property are excellent, no corrosion to metals under high temperature is achieved, the anti-rusting property is stable, the cleaning property is excellent, oil-stain impurities in a water jacket of the engine can be effectively cleaned, condensation of steam is prevented from rusting an inner cavity, the engine can be protected from being corroded, the anti-rusting period is long (up to more than 90 days), residual liquid and other engine antifreezing liquids have excellent compatibility, and after addition of a proper amount of the antifreezing agent, the cooling liquid can be used as the engine antifreezing liquid and is safe and environment-friendly.

Owner:HUBEI CHENGXIANG TECH

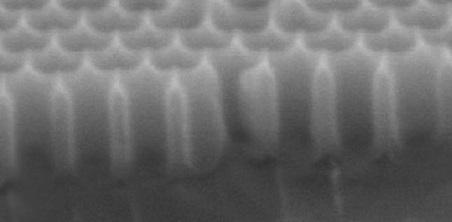

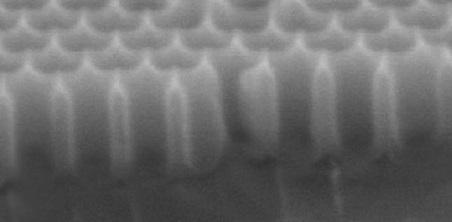

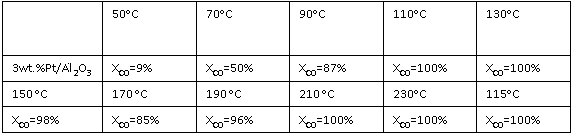

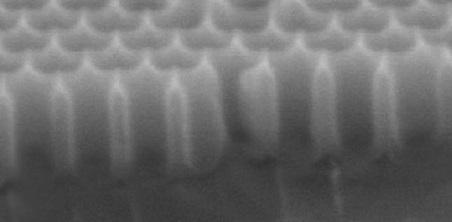

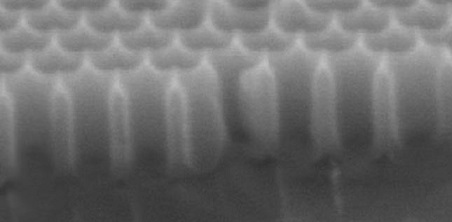

High-efficiency CO oxidation catalyst and preparation method thereof

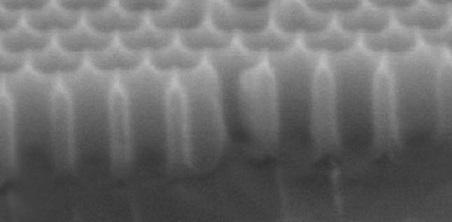

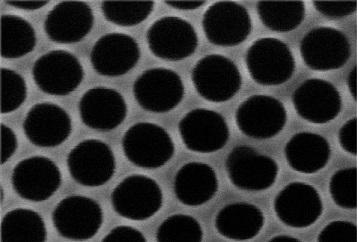

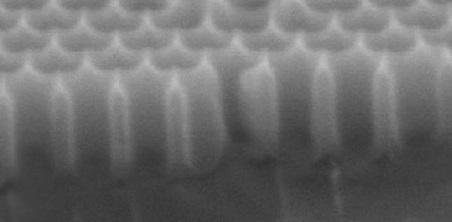

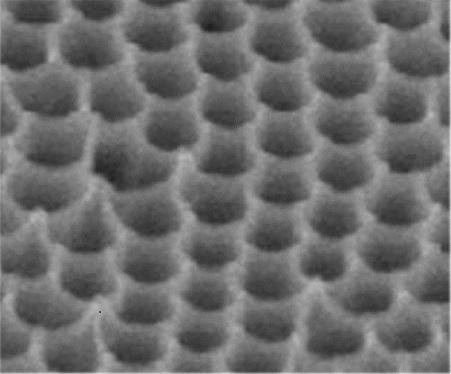

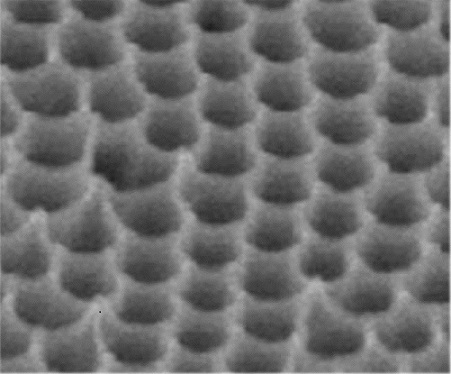

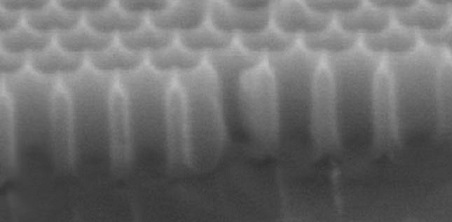

ActiveCN111203200ALess corrosiveLess irritatingCatalyst carriersHydrocarbon from carbon oxidesPtru catalystAluminium oxides

The invention provides a CO oxidation catalyst and a preparation method thereof. The catalyst carrier is a through-hole type aluminum oxide pore channel array obtained by calibrating a corrosion anodeoxide film and a replacement reaction, no shielding layer exists in the aluminum oxide pore channel array, the pore channel structure of the array is complete and uniform, and a Pt active component is impregnated on the surface of the aluminum oxide pore channel array to obtain the Pt / Al2O3 catalyst.

Owner:SHENZHEN ZHENGTIANWEI TECH

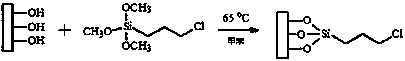

Through hole type alumina catalyst carrier and preparation method thereof

ActiveCN111185147ALess corrosiveLess irritatingCatalyst carriersCatalyst activation/preparationCorrosion reactionPtru catalyst

The invention provides a preparation method of a through hole type alumina catalyst carrier. The preparation method comprises the following steps: performing a selective adsorption reaction on a porous layer and a shielding layer by gamma-chloropropyltrimethylsilane, performing subsequent an alkaline corrosion reaction, effectively removing the shielding layer at the bottom of a pore channel, andperforming a chemical replacement reaction to remove an aluminum base material, thereby obtaining the through-hole type aluminum oxide catalyst carrier.

Owner:山东嘉虹化工有限公司

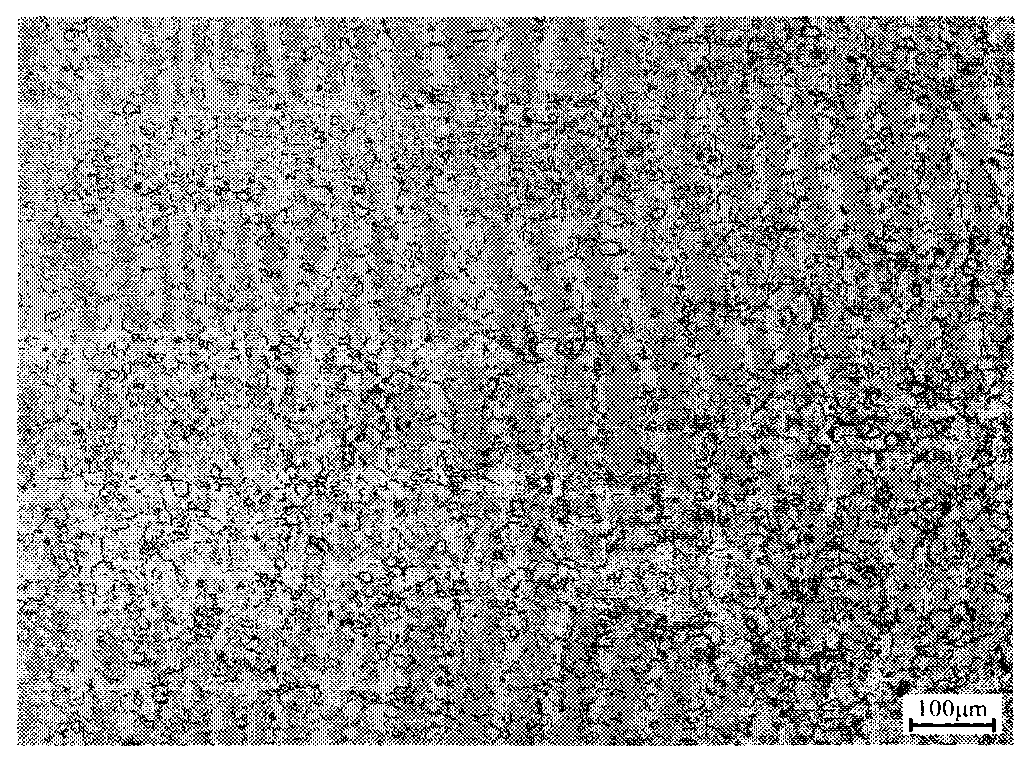

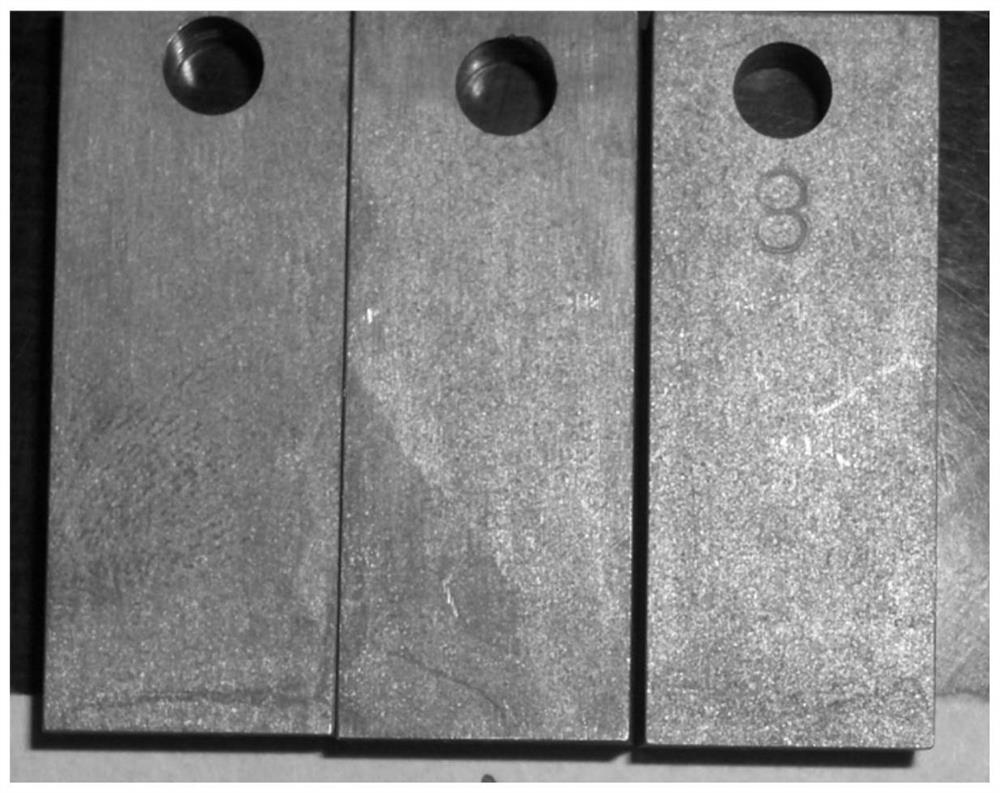

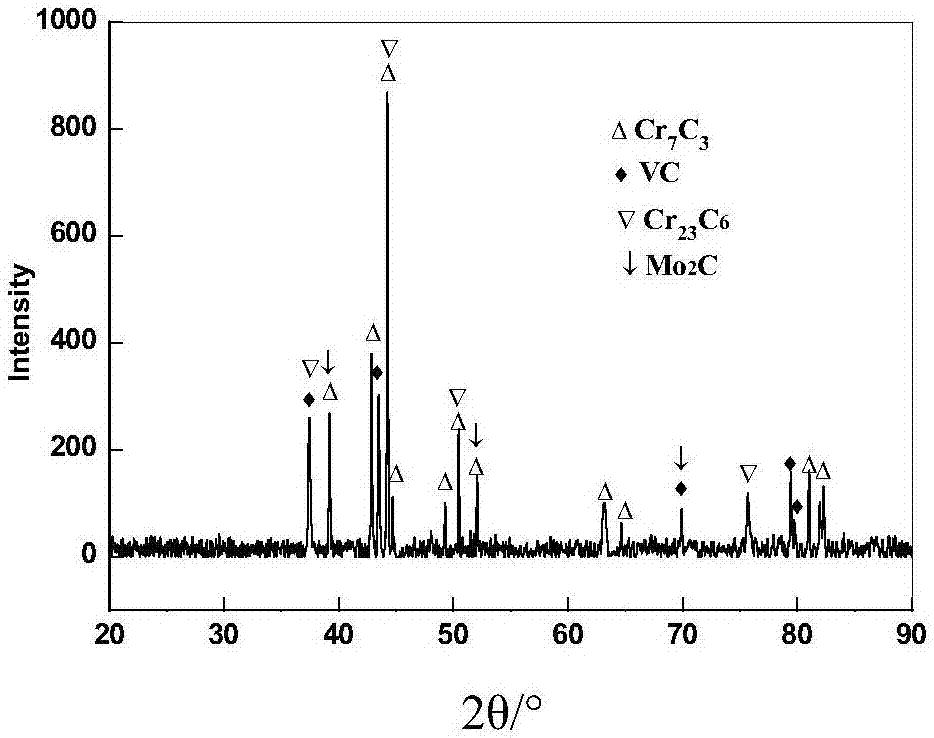

Corrosive agent used for preparing carbide in alloy steel, preparation method of corrosive agent and preparation method of carbide

ActiveCN107541728ACorrosion effectiveReduce corrosionPreparing sample for investigationGluconic acidSurface-active agents

The invention relates to a corrosive agent used for preparing a carbide in alloy steel, a preparation method of the corrosive agent and a preparation method of the carbide, and belongs to the technical field of preparation of the carbide in steel. The corrosive agent used for preparing the carbide in the alloy steel is prepared from a surface active agent and the following raw materials of, by volume parts, 6-12 parts of hydrochloric acid, 1-5 parts of nitric acid and 1-3 parts of gluconic acid, wherein the mass ratio of the surface active agent to the hydrochloric acid is 0.5-2: 6.9-13.8. Thecorrosive agent used for preparing the carbide in the alloy steel is simple in composition, relatively stable and good in reproducibility, not only can effectively corrode steel substrates, but alsocan relieve corrosion of the carbide in the steel, and can achieve rapid preparation of the carbide in the alloy steel.

Owner:HENAN UNIV OF SCI & TECH

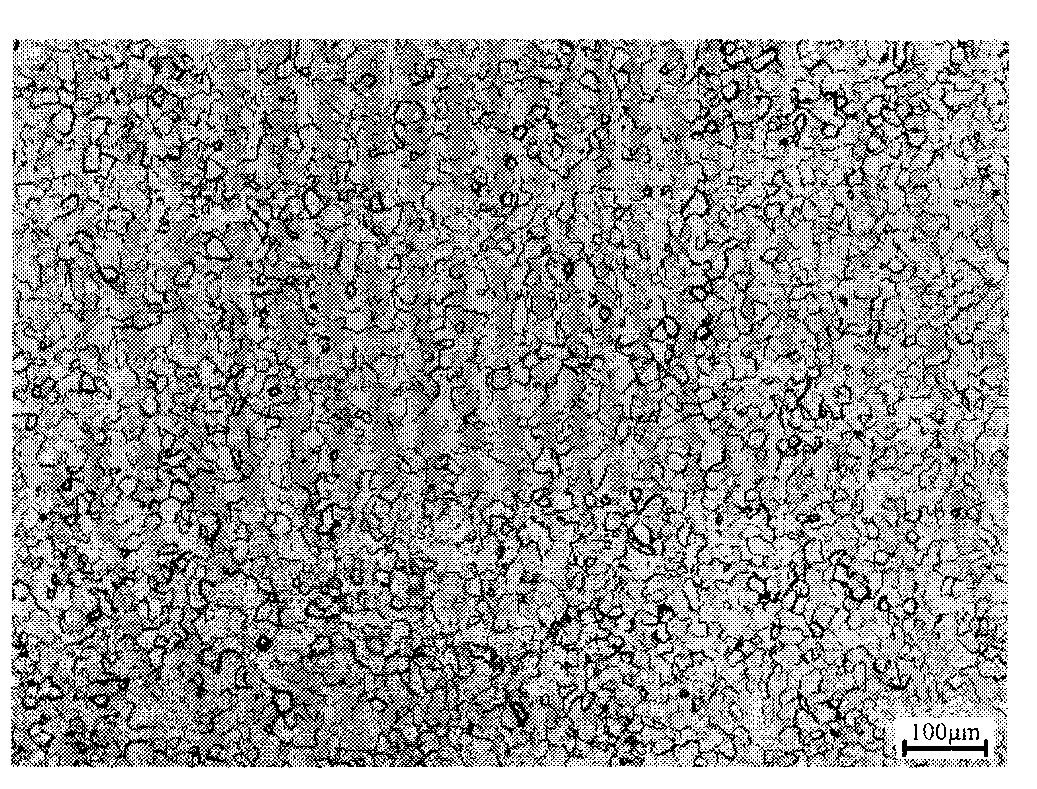

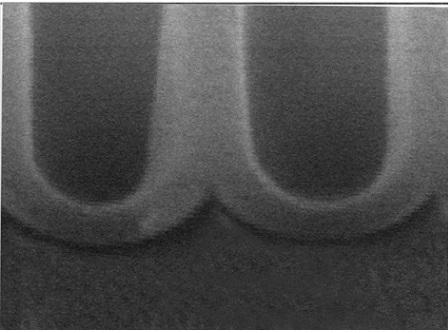

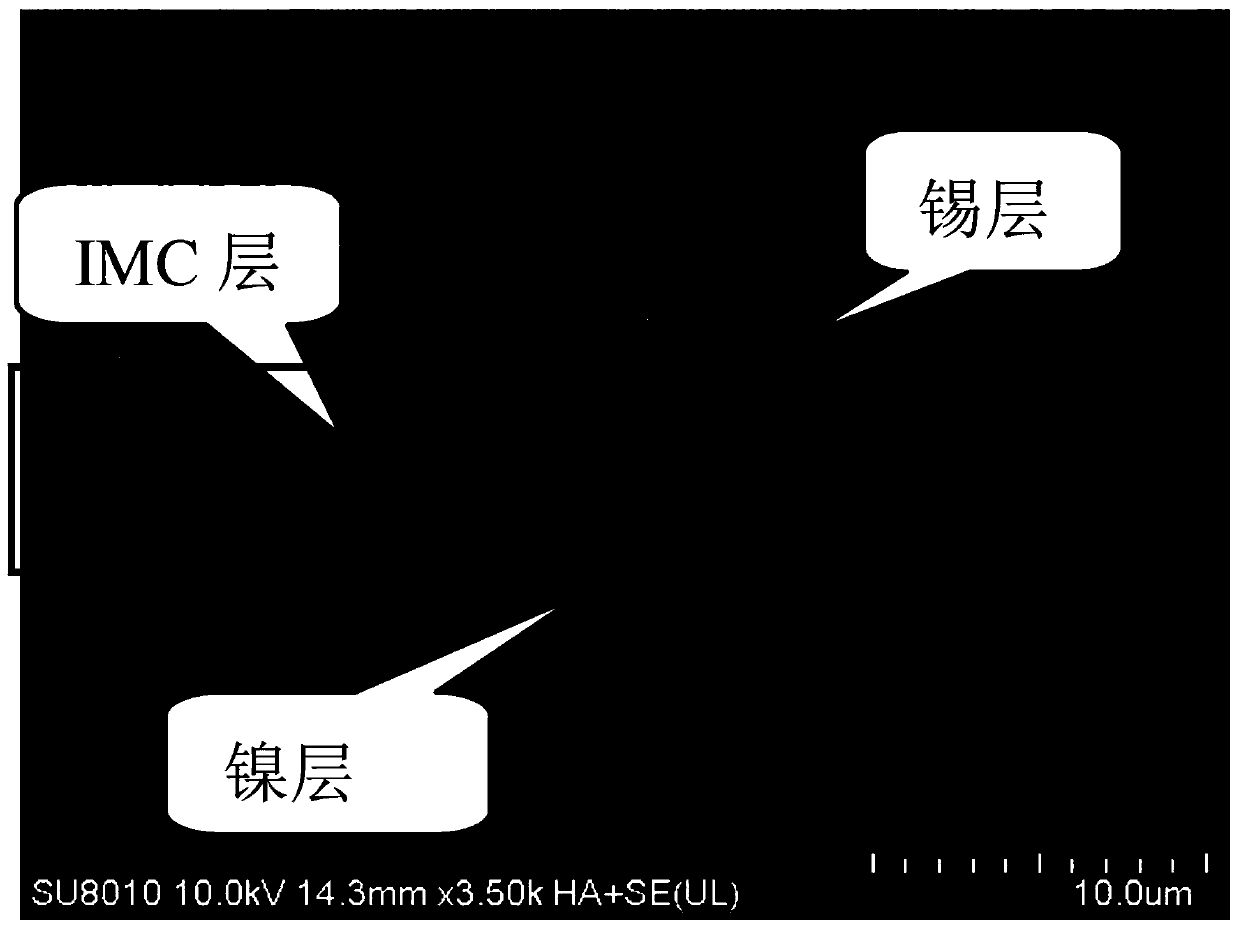

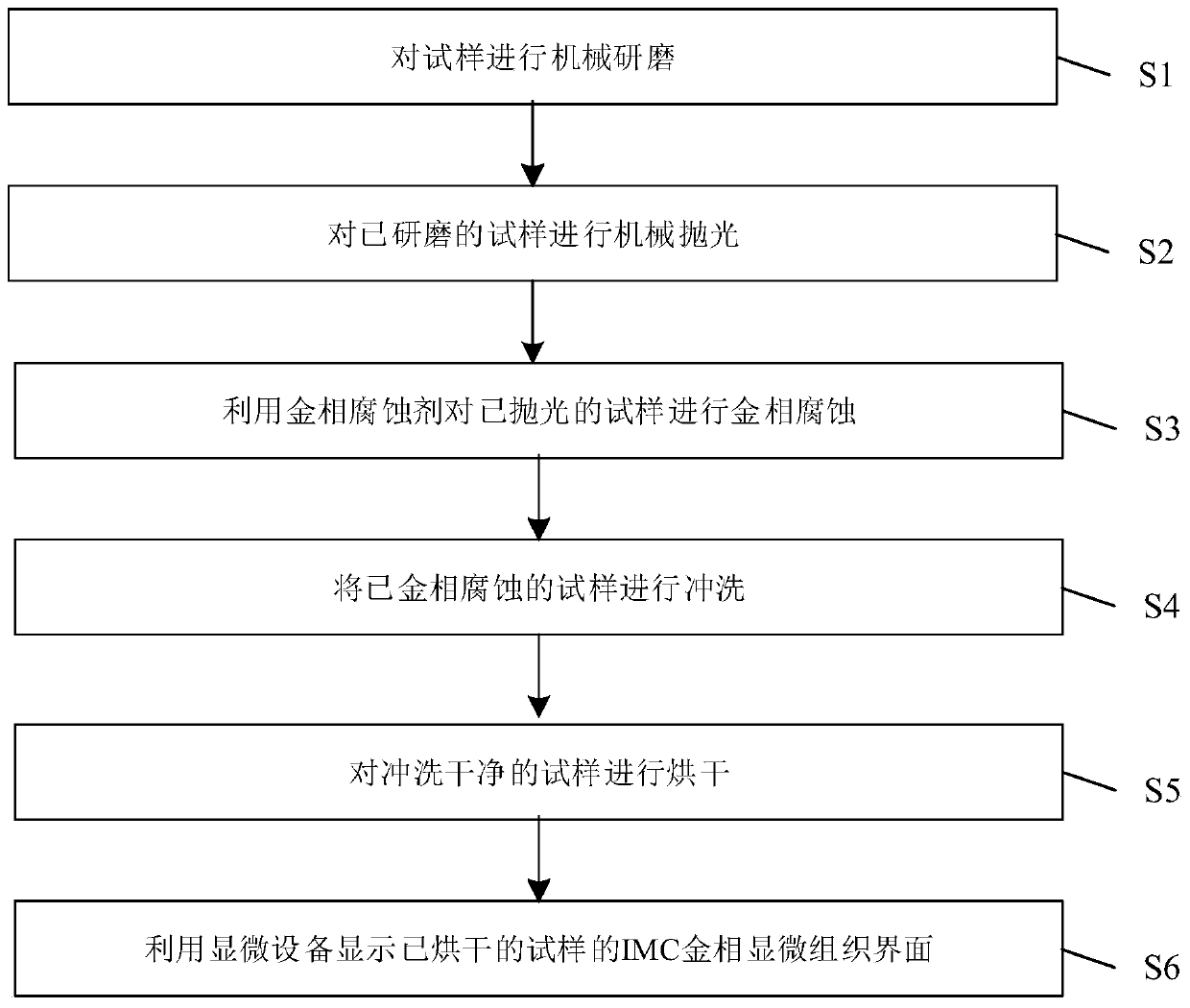

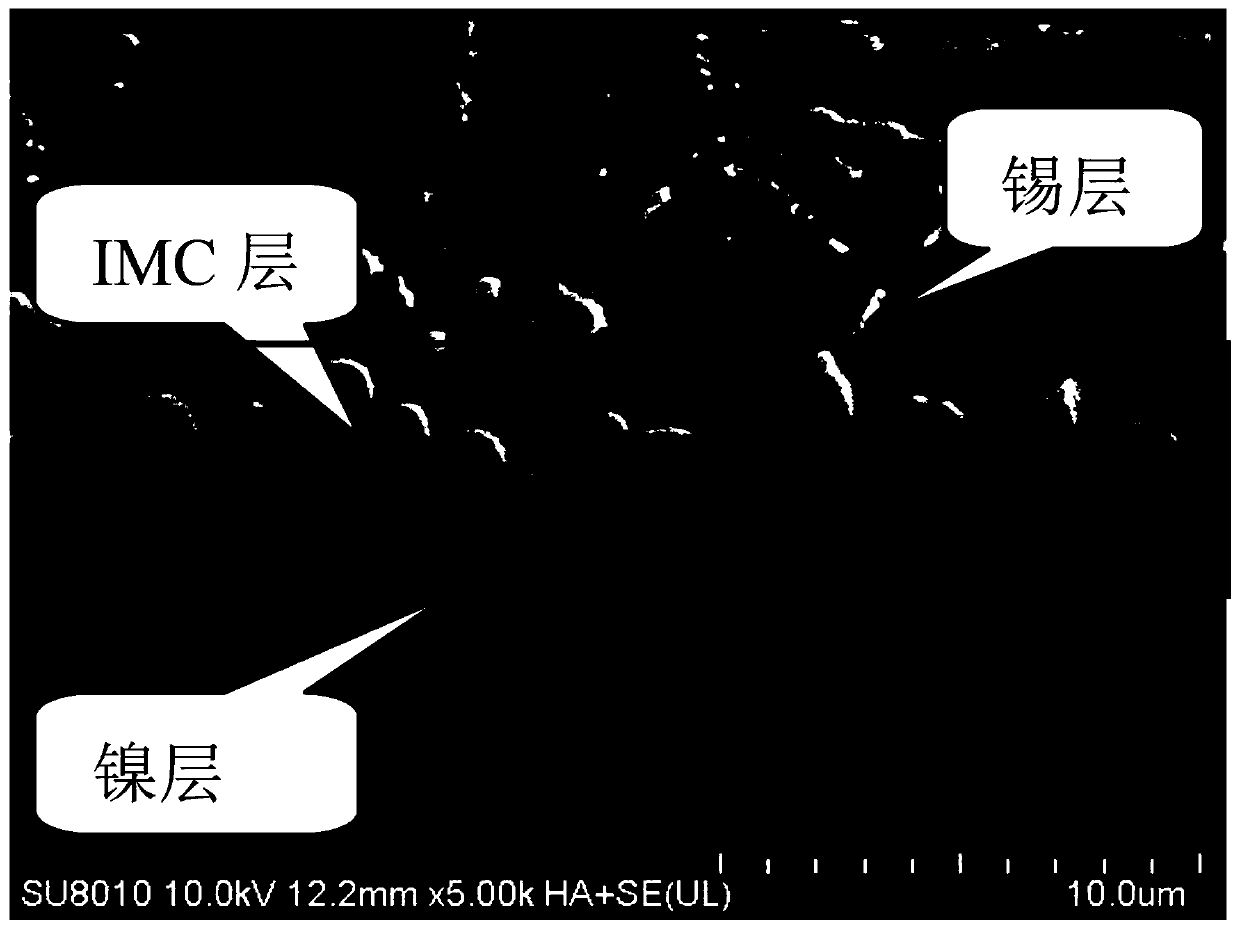

Tin-nickel solder IMC layer metallographic corrosive agent and metallographic structure display method thereof

InactiveCN109916905ACorrosion effectiveDisplay clearPreparing sample for investigationMaterial analysis by optical meansGrinding testTest sample

The embodiment of the invention discloses a tin-nickel solder IMC (Intermetallic compound) layer metallographic corrosive agent and a metallographic structure display method thereof. The metallographic corrosive agent is prepared by 36-38% of hydrochloric acid and more than 95% of ethyl alcohol in mass percent according to a volume ratio of 1:9. The metallographic structure display method comprises the following steps of: performing mechanical grinding of a test sample; performing mechanical polishing of the grinded test sample; employing the metallographic corrosive agent to perform metallographic corrosion of the polished test sample; washing the test sample after metallographic corrosion; drying the cleaned test sample; and employing a micro device to display an IMC metallographic microscopic structure interface of the dried test sample and clearly display the morphology of the tin-nickel solder IMC layer.

Owner:CHIPMOS TECHSHANGHAI

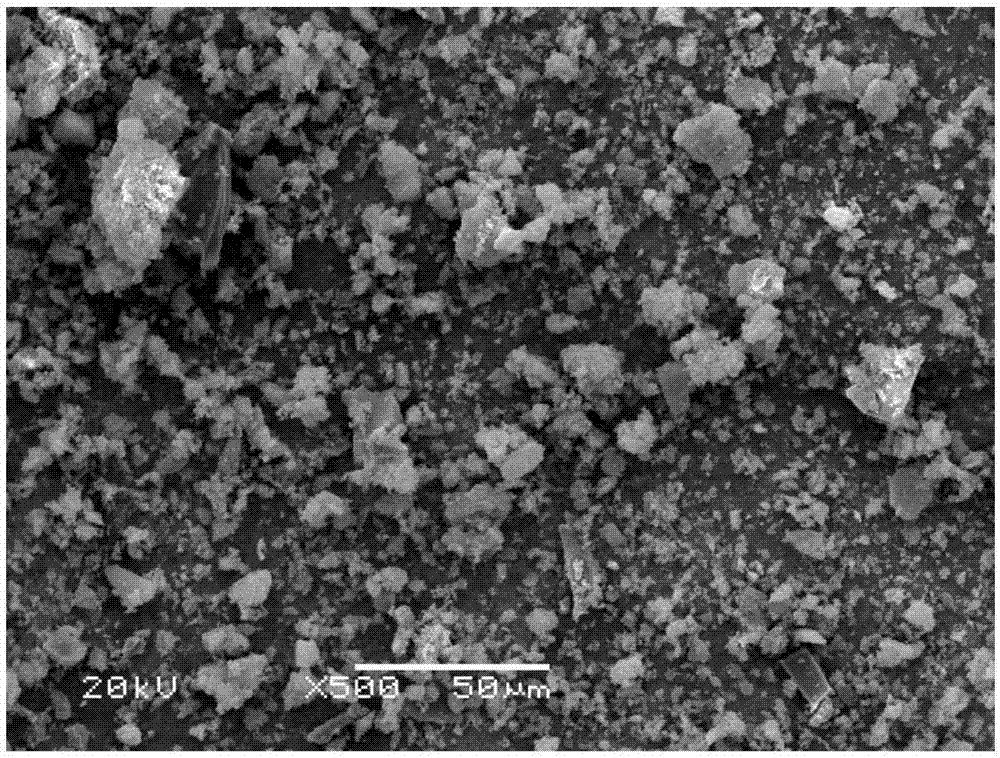

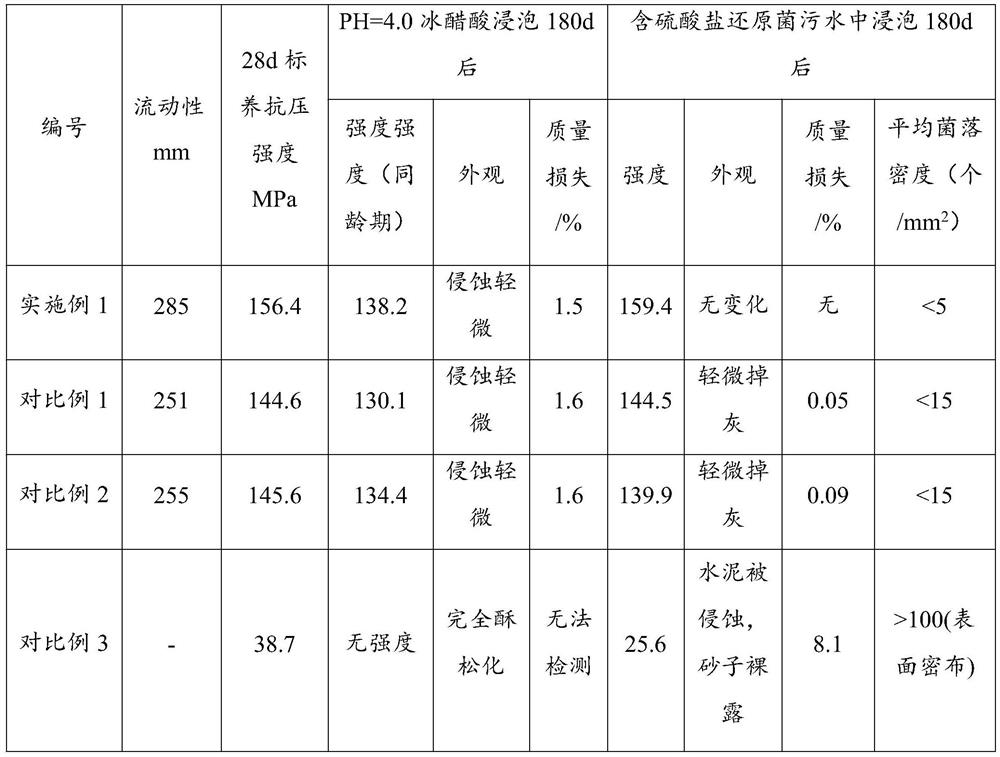

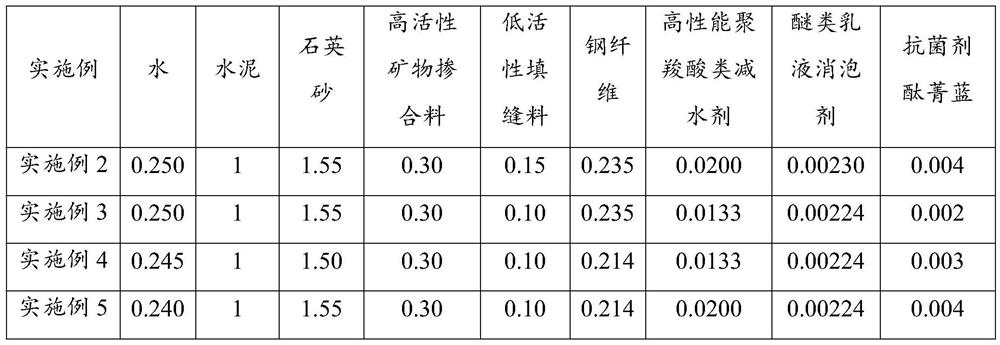

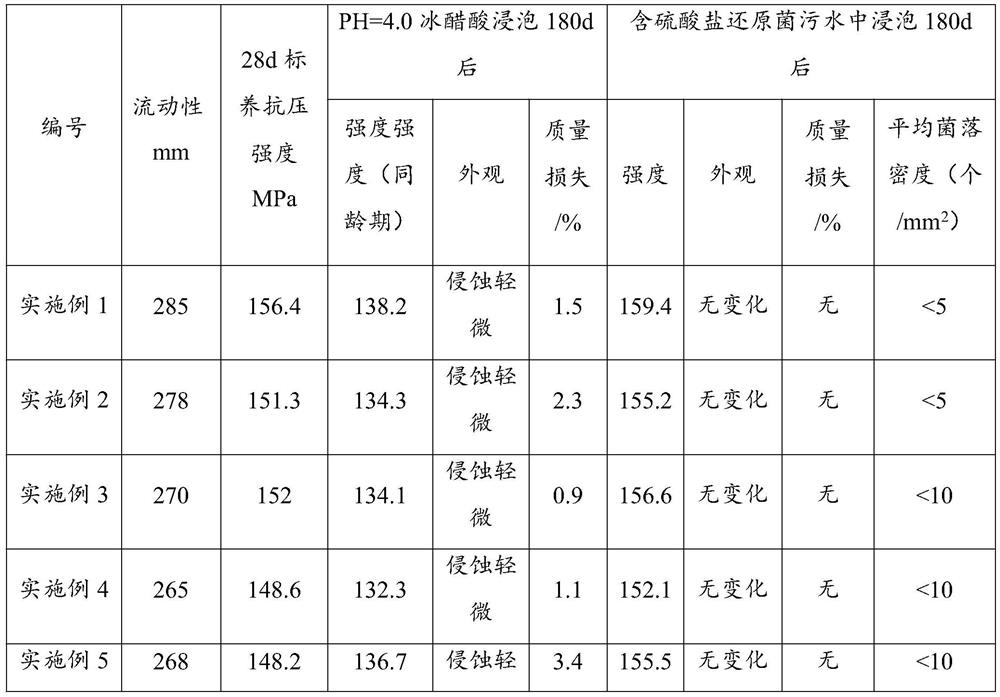

UHPC suitable for long-term sewage environment and preparation process thereof

PendingCN113896488AGood biocorrosionImproves strength and mobilityEnvironmental chemistrySilicate Cement

The invention provides UHPC suitable for a long-term sewage environment and a preparation process thereof. The UHPC comprises the following components: water, cement, fine aggregate, a mineral admixture, metal fibers, an additive and an antibacterial agent, wherein the antibacterial agent is beta-type phthalocyanine blue with a particle size of 0.005-0.015 [mu]m, and the cement is a mixture of ordinary Portland cement and calcium aluminate cement. According to the invention, the antibacterial agent phthalocyanine blue matched with UHPC is creatively introduced, and the high performance of the UHPC is combined, so that the material has good biological corrosion resistance, and the flowability and the strength of the material are improved; part of calcium aluminate cement is used for replacing ordinary Portland cement, so that the UHPC has a relatively low biological erosion rate, and the erosion-resistant period of the UHPC is further prolonged; and the UHPC is more suitable for serving under the working condition of sewage and waste treatment, the corrosion resistance of components can be greatly improved, the service life of the structure is prolonged, the later maintenance cost is reduced, and the UHPC has wide market prospects.

Owner:CHINA CONSTR THIRD BUREAU GREEN IND INVESTMENT CO LTD

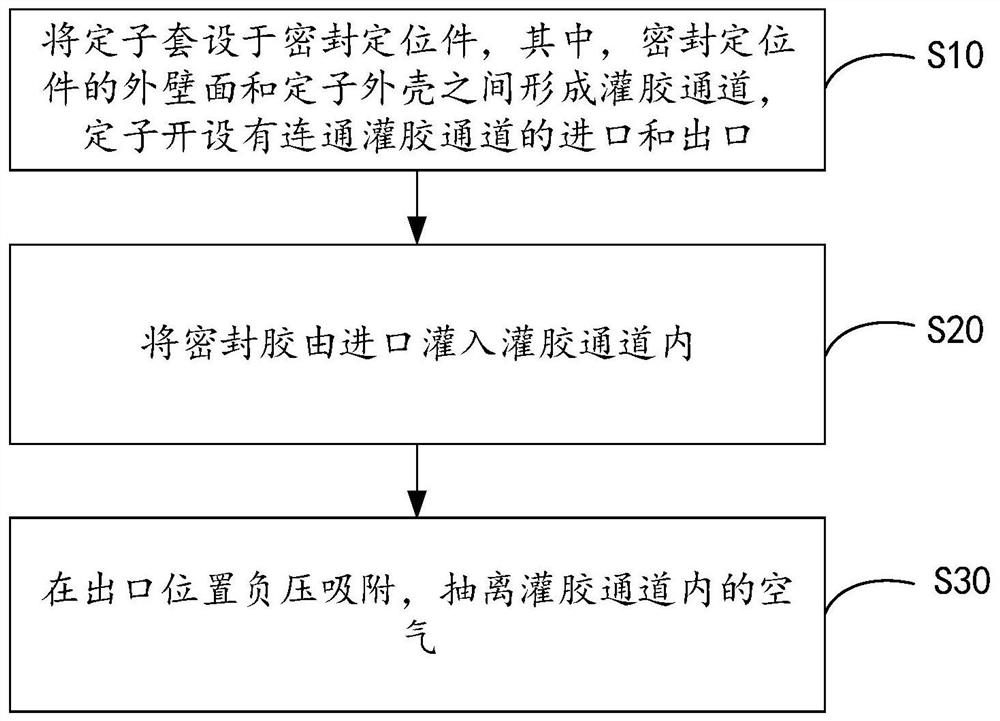

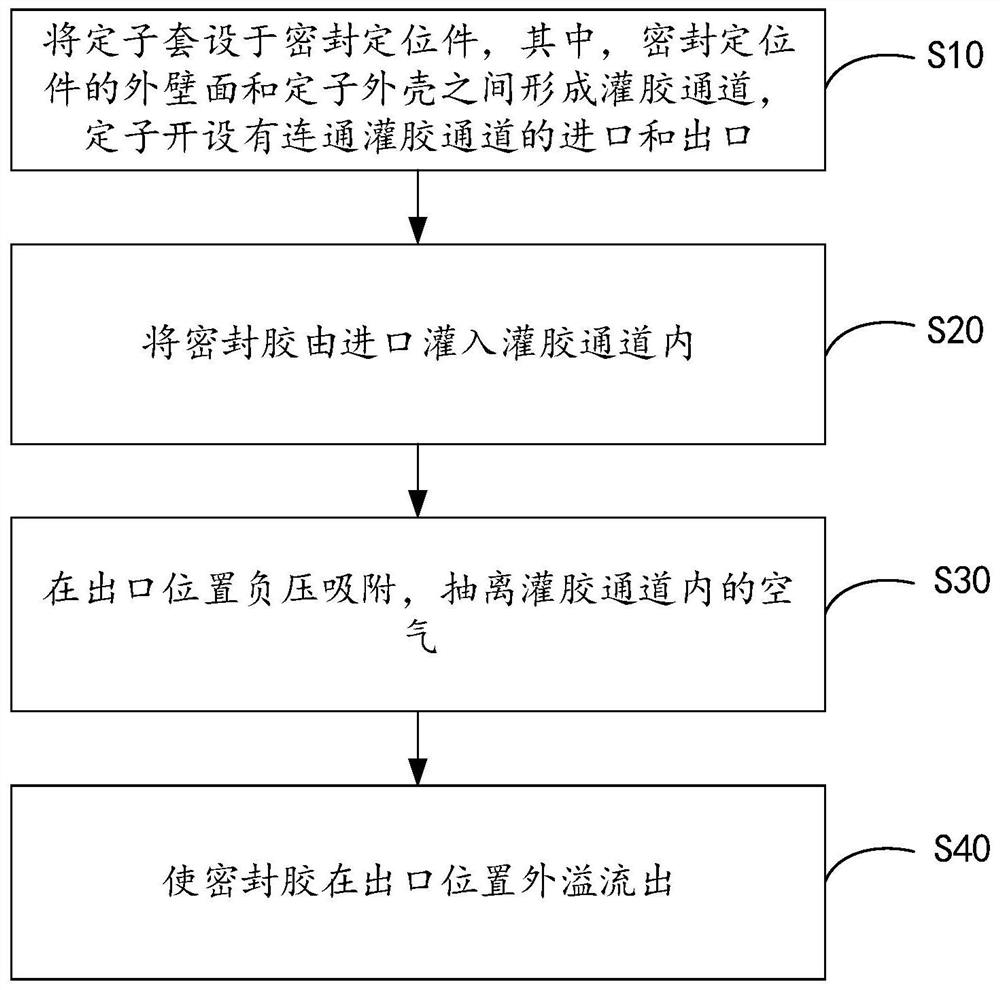

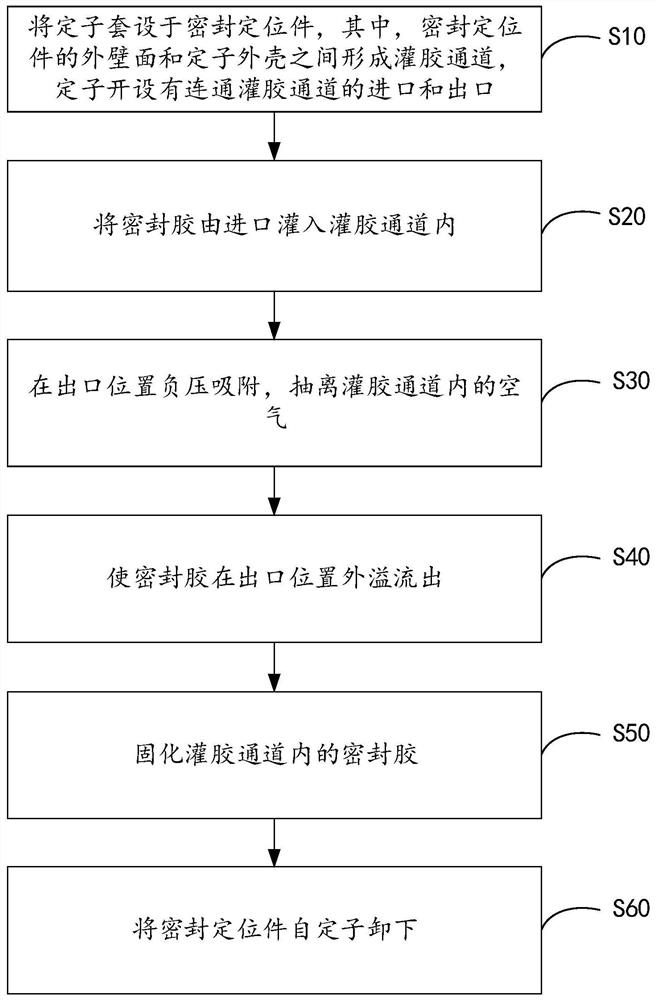

Glue pouring method and glue pouring assembly of propeller

InactiveCN112893003AReduce corrosionCorrosion isolationLiquid surface applicatorsCoatingsStructural engineeringMechanical engineering

The invention discloses a glue pouring method and glue pouring assembly of a propeller. The propeller comprises a stator and a stator shell arranged on the outer side of the circumference of the stator. The glue pouring method further comprises the steps that the stator is arranged on a sealing positioning piece in a sleeving mode, wherein a glue pouring channel is formed between the outer wall face of the sealing positioning piece and the stator shell; the stator shell is provided with an inlet and an outlet which communicate with the glue pouring channel; seal glue is poured into the glue pouring channel from the inlet; and air in the glue pouring channel is extracted through negative pressure adsorption at the position of the outlet. By means of the technical scheme, corrosion of external water vapor and air to the stator of the propeller can be effectively reduced, and the service life of the stator of the propeller is prolonged.

Owner:SHENZHEN WEIDU INTELLIGENT TECH CO LTD

Interface processing agent and preparation method thereof

ActiveCN105330192AIncrease the effective surface areaCorrosion effectiveCorrosionHexadecylpyridinium bromide

The invention provides an interface processing agent and a preparation method thereof. Cation exchange resin and a fluoric acid compound are taken as a corrosive agent, and hydrofluoric acid is generated in an aqueous solution, elements in a material is effectively corroded, the smoothness of the material interface is destroyed, the interface effective surface area is enlarged, and the adhesive force of the material surface is increased. Also, when the corrosion type interface processing agent is used, a phosphate compound, a hydrochloride compound and a nitrate compound form a mixed acid, and thus corrosion of the single acid hydrofluoric acid is avoided and corrosion acceleration effect is reached. The invention also provides a corrosion inhibition type interface processing agent and a preparation method thereof. Cation exchange resin and a fluoric acid compound are taken as a corrosive agent, the interface effective surface area is enlarged and the interface adhesive force is increased. A surfactant 1227, hexadecyl trimethyl ammonium bromide and hexadecylpyridinium bromide effectively prevent hydrofluoric acid from generating erosion and hydrogen osmosis effects on the material surface, reduce corrosion efficiency and reach corrosion inhibition effect.

Owner:莱恩斯新材料科技开发(北京)有限公司

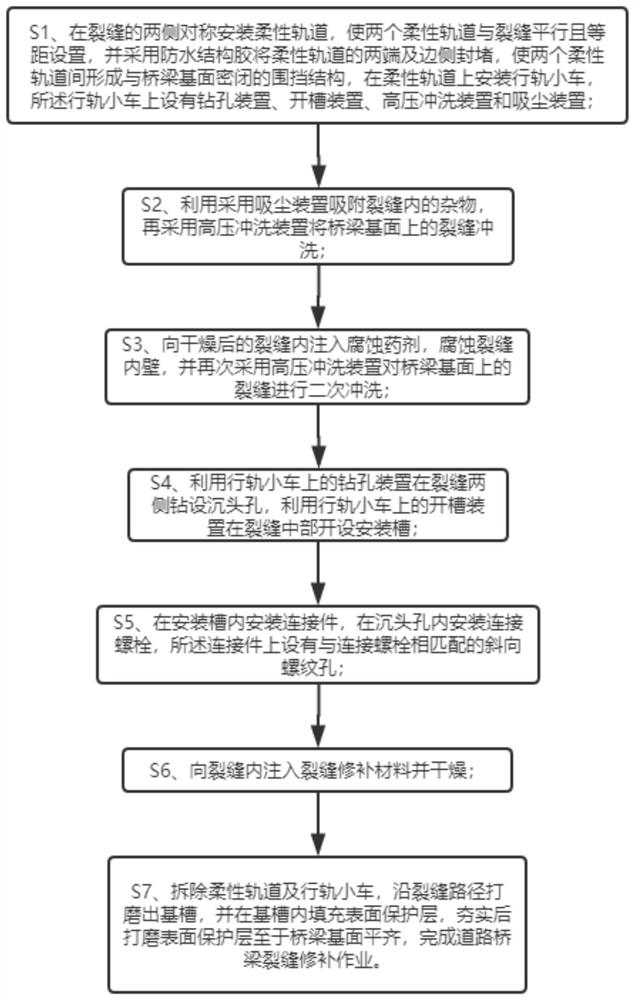

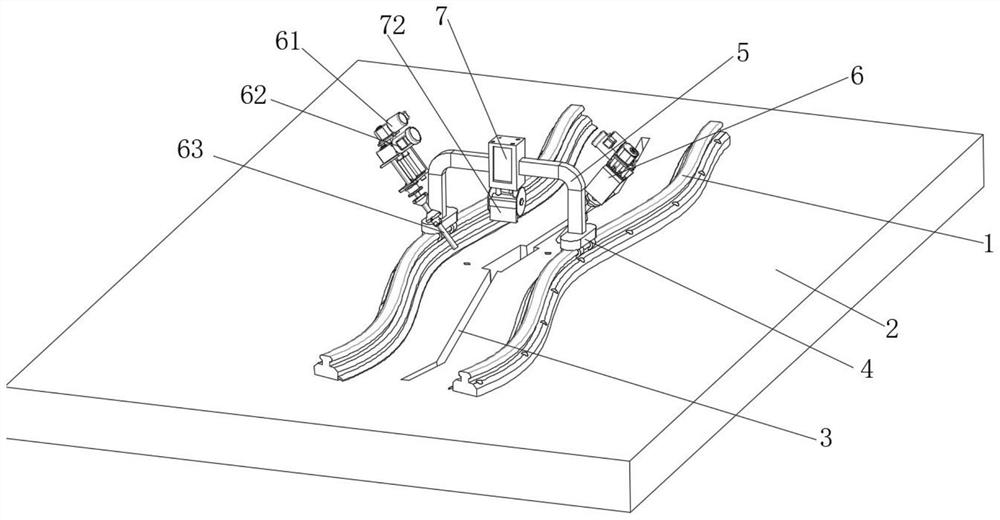

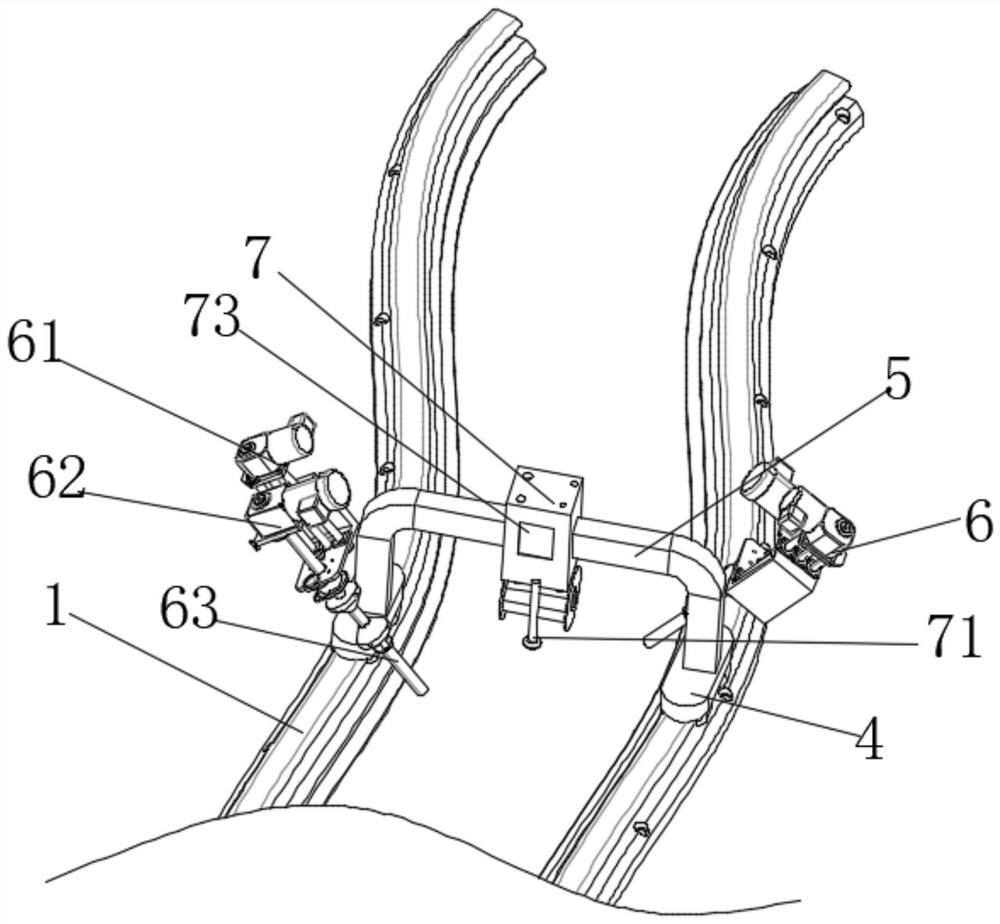

Road and bridge crack repairing method

InactiveCN113430955AImprove the efficiency of repair constructionQuick fixPaving detailsBridge erection/assemblyArchitectural engineeringCounterbore

The invention discloses a road and bridge crack repairing method, and belongs to the field of road bridges, the road bridge crack repairing method specifically comprises the following steps: S1, flexible rails are symmetrically installed on two sides of a crack; s2, a dust suction device is used for adsorbing sundries in the crack, and then a high-pressure flushing device is used for flushing the crack on the base plane of the bridge; s3, a corrosion agent is injected into the dried crack, and secondary flushing is carried out; s4, a counterbore is drilled, and a mounting groove is formed; s5, connecting pieces are mounted in the mounting groove, and connecting bolts are mounted in the counterbore; s6, a crack repairing material is injected into the crack and dried; and S7, the flexible rails are dismantled, the foundation trench is ground out, a surface protection layer is filled, and after tamping, the surface protection layer is ground to be flush with the bridge base plane. The method is easy to operate, rapid in crack repairing and firm in connection, effectively avoids the possibility of secondary cracking of the crack, has market prospects and is suitable for popularization.

Owner:刘琦

an anodized aluminum

ActiveCN111172575BCorrosion effectiveComplete pore structureAnodisationCorrosion reactionPorous layer

The invention provides an anodized aluminum material, which can effectively corrode the anodized film through the selective adsorption reaction of gamma-chloropropyltrimethylsilane on the porous layer and the shielded layer, and the subsequent alkaline corrosion reaction The shielding layer at the bottom of the channel can effectively improve the conductivity of the anodized aluminum material.

Owner:创隆实业(深圳)有限公司

Method for removing shielding layer in anodized aluminum pore channel

ActiveCN111172576ANo damageFacilitate corrosion reactionAnodisationCorrosion reactionTrimethylsilane

The invention provides a method for removing a shielding layer in an anodized aluminum pore channel. Through selective adsorption reaction of gamma-chloropropyl trimethylsilane with a porous layer andthe shielding layer and subsequent alkaline corrosion reaction which can effectively corrode the shielding layer located at the bottom of the anodized film pore channel, the electrical conductivity of an anodized substrate is effectively improved.

Owner:佛山市南海一铭金属塑料标牌有限公司

Novel multilayer composite anti-corrosion material for bolt

InactiveCN109467968AInhibitionReduce tensionAnti-corrosive paintsTectorial membrane(Hydroxyethyl)methacrylate

The invention discloses a novel multilayer composite anti-corrosion material for a bolt, and relates to the technical field of bolt corrosion resistance. The material is multilayer composite anti-corrosion coating liquid for the bolt, and a formula of the material is prepared from the following components in parts by mass: 100 to 150 parts of silicone resin, 1 to 2 parts of an anti-settling agent,12 to 30 parts of zinc phosphate, 50 to 100 parts of ethylene propylene emulsion, 16 to 23 parts of mica iron oxide, 3 to 5 parts of an adhesion promoter and 5 to 6 parts of an anti-skinning agent. According to the novel multilayer composite anti-corrosion material for the bolt, by cooperative use of the silicone resin, the zinc phosphate, the ethylene propylene emulsion, the mica iron oxide, dimethylaminoethyl methacrylate, hydroxyethyl methacrylate, butyl acrylate, phenolic resin and the ethylene propylene emulsion, the whole prepared anti-corrosion coating forms a layer of protective filmwhich effectively protects spirals and avoids severe economical loss of an enterprise due to halt of working equipment caused by corrosion of the bolt.

Owner:张雅慧

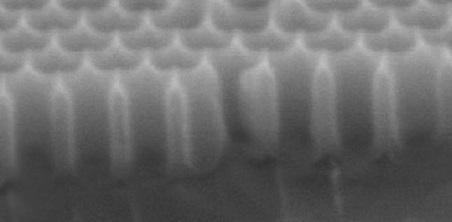

Preparation method of alloy electroplating material with high bonding force

ActiveCN111118557ACorrosion effectiveComplete pore structureSurface reaction electrolytic coatingElectrogalvanizationAlloy

The invention provides a preparation method of an alloy electroplating material with the high bonding force. According to the preparation method, a shielding layer at the bottom of an anodic oxidationfilm is removed, an aluminum metal base material is exposed, then a zinc transition layer and a zinc-nickel electroplating layer are sequentially electroplated, and the bonding force of the base material and the plating layer is finally effectively improved.

Owner:东莞市原琦五金有限公司

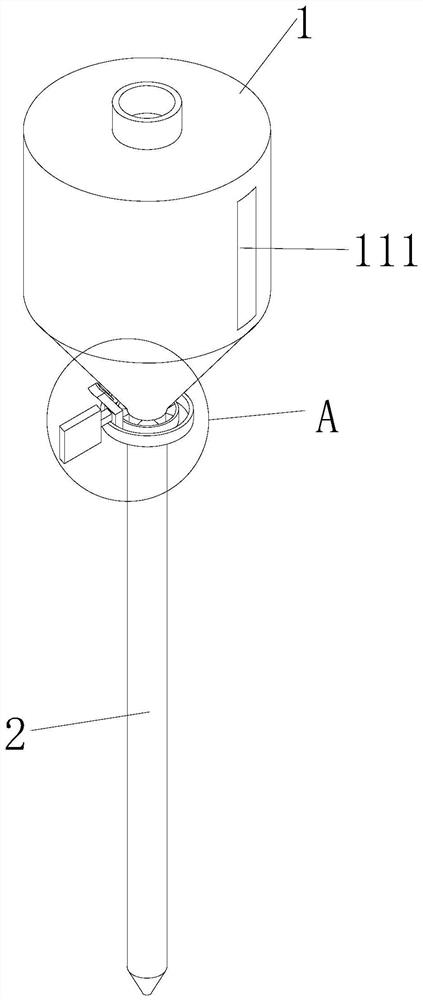

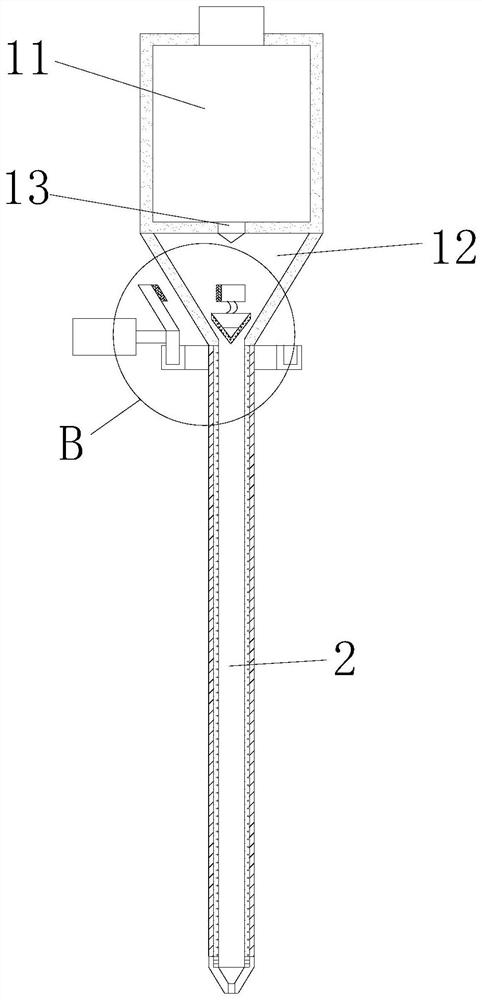

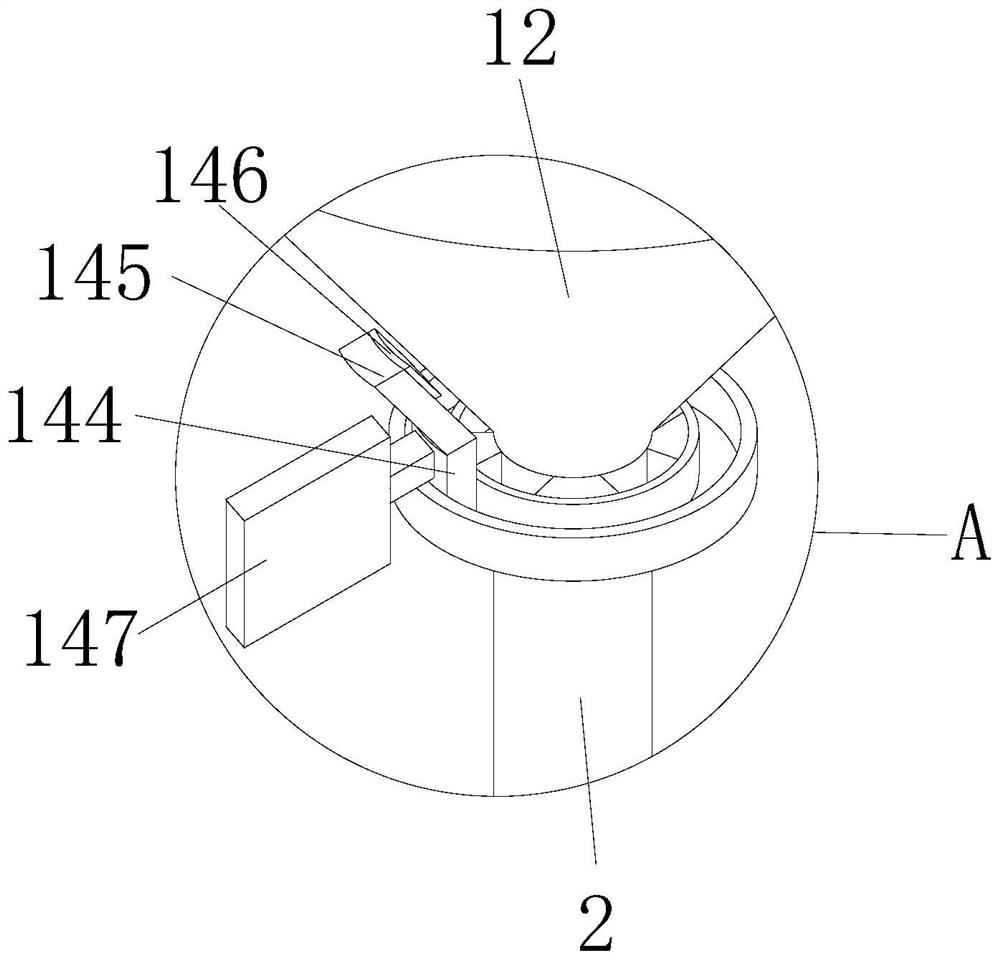

Irrigation device for agricultural planting

PendingCN113207656ASave waterPrevent the sun from evaporating water and fertilizerRoot feedersRotary stirring mixersFertilizerAgriculture

The invention provides an irrigation device for agricultural planting. The device comprises a water storage barrel, the water storage barrel comprises a water storage cavity and a drip irrigation cavity, the water storage cavity is formed in the water storage barrel, a water outlet hole is formed in the inner wall of the bottom face of the water storage cavity, the drip irrigation cavity is formed under the water outlet hole, a stirring assembly is arranged in the drip irrigation cavity, and the stirring assembly comprises an annular sliding groove and a stirring floating block. The stirring floating block is arranged in the drip irrigation cavity, the bottom surface of the stirring floating block is movably connected with a floating piston, the outer surface of the drip irrigation cavity is sleeved with an annular sliding groove, a sliding block is slidably connected into the annular sliding groove, a connecting rod is arranged on the upper surface of the sliding block, a magnetic strip is arranged on the side, opposite to the stirring floating block, of the connecting rod, and fan blades are arranged on the side, away from the outer wall of the drip irrigation cavity, of the sliding block. A dropper is arranged in the center of the bottom surface of the water storage cavity and connected with the drip irrigation cavity. According to the device, water resources are saved in a drip irrigation mode, water and fertilizer in the drip irrigation cavity can be stirred during drip irrigation and water storage, the phenomena of accumulation and precipitation of the fertilizer are prevented, and the irrigation effect is improved.

Owner:宁远盛景农业发展有限公司

Alloy electroplating material with high bonding force

ActiveCN111118556ANo damageFacilitate corrosion reactionSurface reaction electrolytic coatingElectrogalvanizationAlloy

The invention provides a preparation method of an alloy electroplating material with high bonding force. A shielding layer at the bottom of an anodic oxide film is removed, an aluminum metal base material is exposed, then a zinc transition layer and a zinc-nickel electroplating layer are sequentially electroplated, and finally the bonding force of the base material and the plating layers is effectively improved.

Owner:深圳市桑达兴业机械实业有限公司

Corrosive agent for displaying metallographic structure of cobalt chromium molybdenum alloy and corrosion method

InactiveCN111424279AShort corrosion timeImprove corrosion effectPreparing sample for investigationCobalt-Chromium-Molybdenum AlloyOxidizing agent

The invention discloses a corrosive agent for displaying a metallographic structure of a cobalt chromium molybdenum alloy and a corrosion method. The corrosive agent for displaying the metallographicstructure of the cobalt chromium molybdenum alloy contains strong alkali, oxidant and water. According to the corrosive agent, the corrosion time can be effectively reduced, and the corrosion effect is improved, so that the gold phase crystal boundary is clearly displayed.

Owner:GOERTEK OPTICAL TECH CO LTD

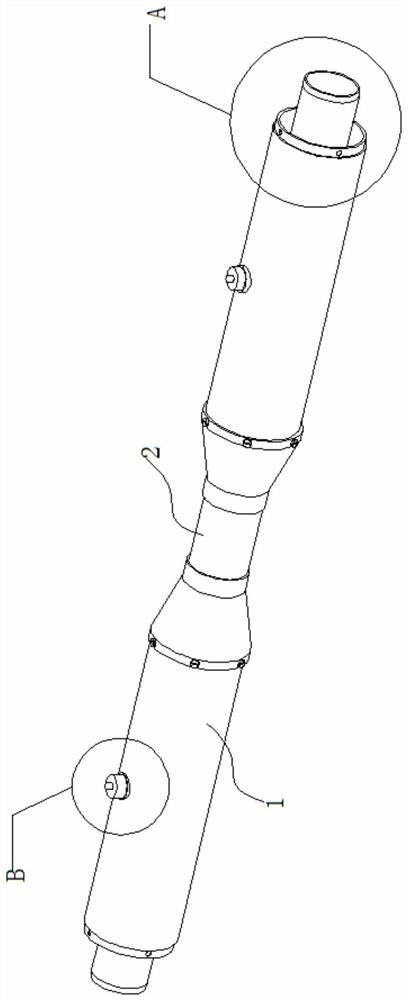

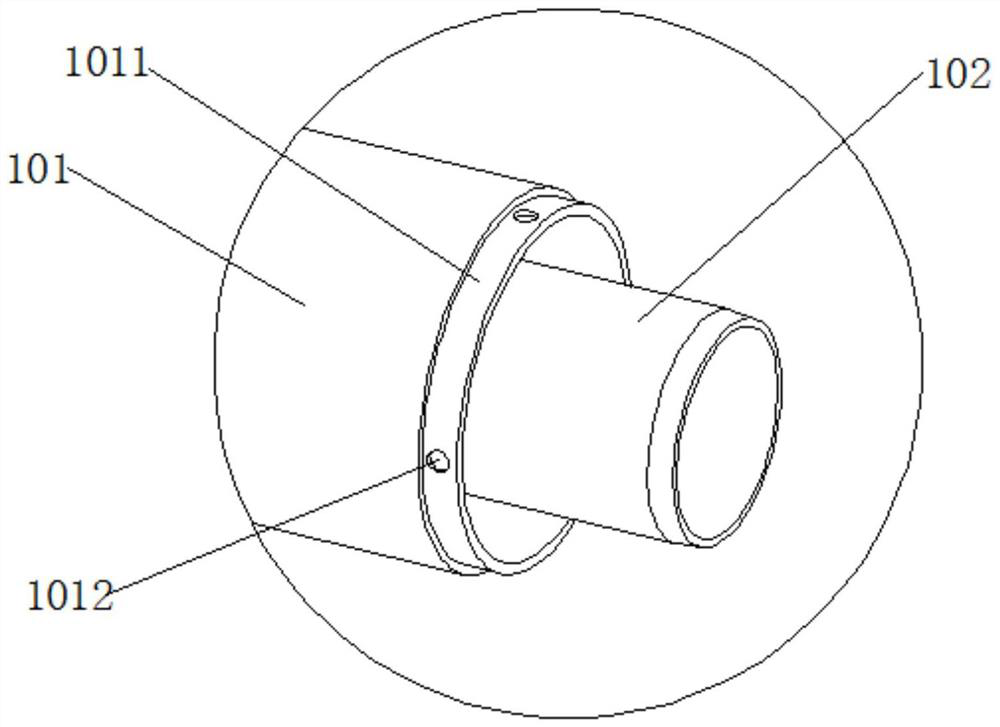

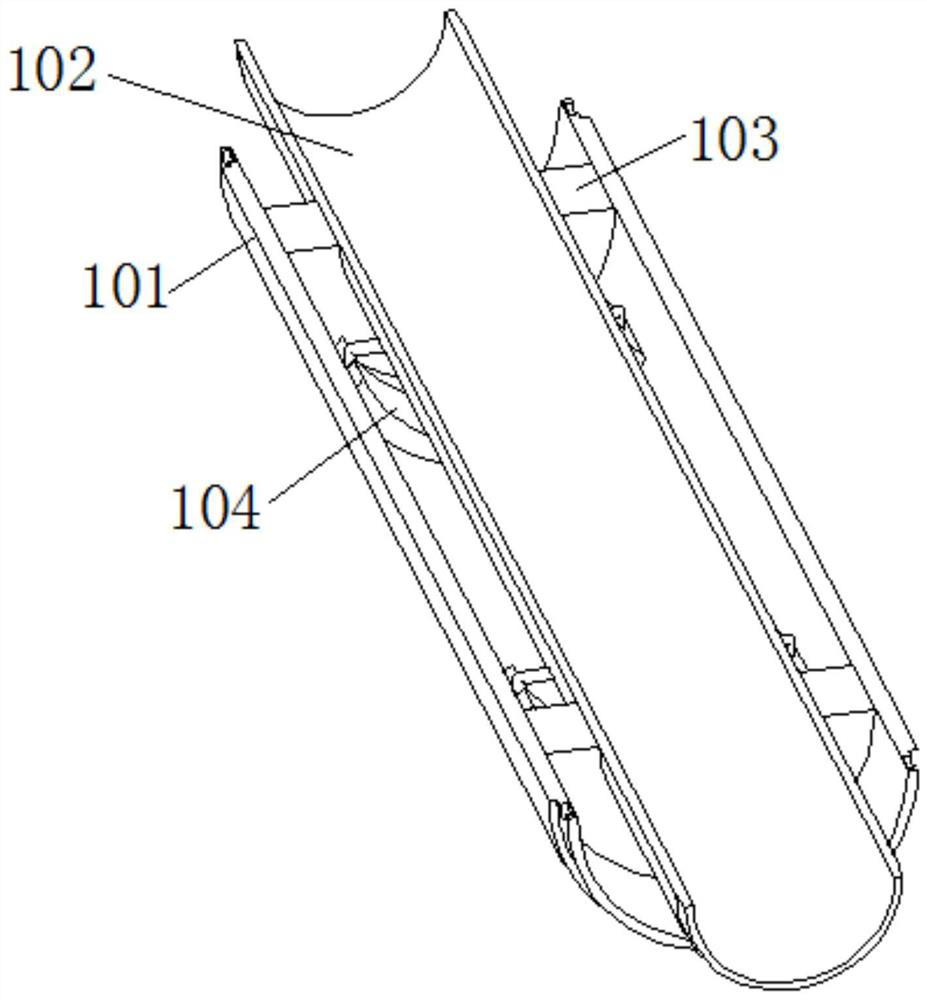

Anti-corrosion oil pipe for oil field

ActiveCN112032427ACorrosion effectiveSolving Corrosion ProblemsSleeve/socket jointsPipe elementsThermodynamicsOil field

The invention relates to the technical field of oil field oil well drilling, in particular to an anti-corrosion oil pipe for an oil field. The oil pipe comprises a plurality of oil field oil pipe bodies and pipeline connecting devices used for connecting every two adjacent oil field oil pipe bodies, wherein the oil field oil pipe bodies comprise outer protection pipe layers and inner conveying pipe layers, a plurality of anode zinc blocks are fixed to the inner walls of the parts, located between two annular fixing blocks, of the outer protection pipe layers, wires are connected to the anode zinc blocks, the other ends of the wires are connected to the inner conveying pipe layers, threaded sleeves penetrating the outer protection pipe layers are welded to the inner walls of the parts, located between the two annular fixing blocks, of the outer protection pipe layers and cylinders are arranged in inner threaded holes of the threaded sleeves. Through a cathode protection method of sacrificial anodes, the corrosion effect of electrochemistry of an oil material on an inner conveying pipe layer can be greatly reduced in a transportation process of the oil material, the problem that theinner layer and the outer layer of an existing oil field oil pipe are corroded at the same time is effectively solved, and the service life of the oil pipe is longer.

Owner:东营市东达机械制造有限责任公司

A method for removing the inner shielding layer of anodized aluminum channel

ActiveCN111172576BCorrosion effectiveComplete pore structureAnodisationCorrosion reactionTrimethylsilane

The invention provides a method for removing a shielding layer in an anodized aluminum pore channel. Through selective adsorption reaction of gamma-chloropropyl trimethylsilane with a porous layer andthe shielding layer and subsequent alkaline corrosion reaction which can effectively corrode the shielding layer located at the bottom of the anodized film pore channel, the electrical conductivity of an anodized substrate is effectively improved.

Owner:佛山市南海一铭金属塑料标牌有限公司

A high-binding composite material

ActiveCN111286770BCorrosion effectiveComplete pore structureSurface reaction electrolytic coatingAluminum metalElectroplating

The invention provides a composite material with high bonding force. A shielding layer at the bottom of an anodized film, an aluminum metal substrate is exposed, and then single-metal electroplating treatment is carried out, so that bonding of an anodized substrate and a coating is effectively improved.

Owner:瑞安市奥丰实业有限公司

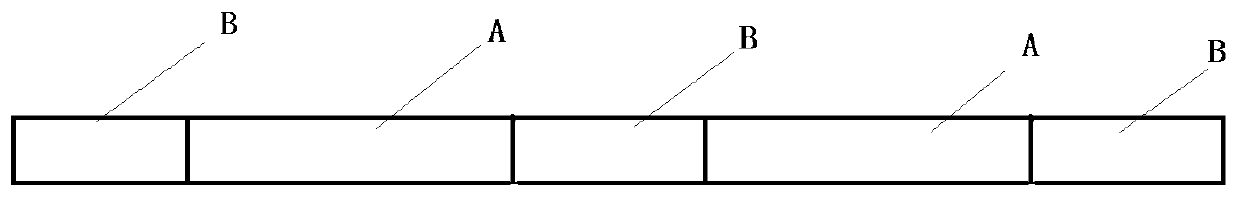

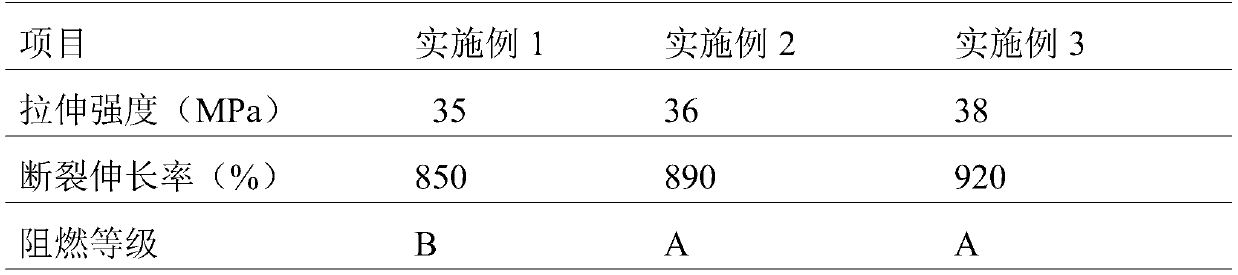

Traceless splicing cable protective sheath and preparation method thereof

ActiveCN107501796BImprove flame retardant performanceImprove toughnessPlastic/resin/waxes insulatorsFlexible cablesAlkali saltEngineering

The invention relates to a traceless spliced cable protective jacket and a preparation method thereof, which belong to the technical field of electric power facilities, and solves the problem of providing a cable protective jacket which is high in strength, good in toughness, good in flame retardance, corrosion resistance and long in service life and a preparation method of the cable protective jacket. The protective jacket consists of sections A and sections B which are alternately arranged, the length ratio of the section A to section B is (2 to 4): 1, the section A and the section B which are adjacent to each other are connected in a fusion manner, and the outer surfaces of the section A and the section B are coated with protective paint C. The protective jacket is good in flame retardance, good in toughness, high in strength, resistant to sunlight, excellent in anticorrosion performance, and capable of effectively preventing the corrosion of acid and alkali salts; moreover, the protective jacket has good high temperature resistance, can effectively protect the cable for a long time and can prevent the safety potential danger; by virtue of the detection in test, the tensile strength of the protective jacket is greater than 35MPa, the elongation at break is 850 percent or above, the flame-retardant grade can reach grade A, and after being stored at the high temperature or soaked for a long time in acid and alkali salts, the surface of the protective jacket has no change.

Owner:STATE GRID CORP OF CHINA +1

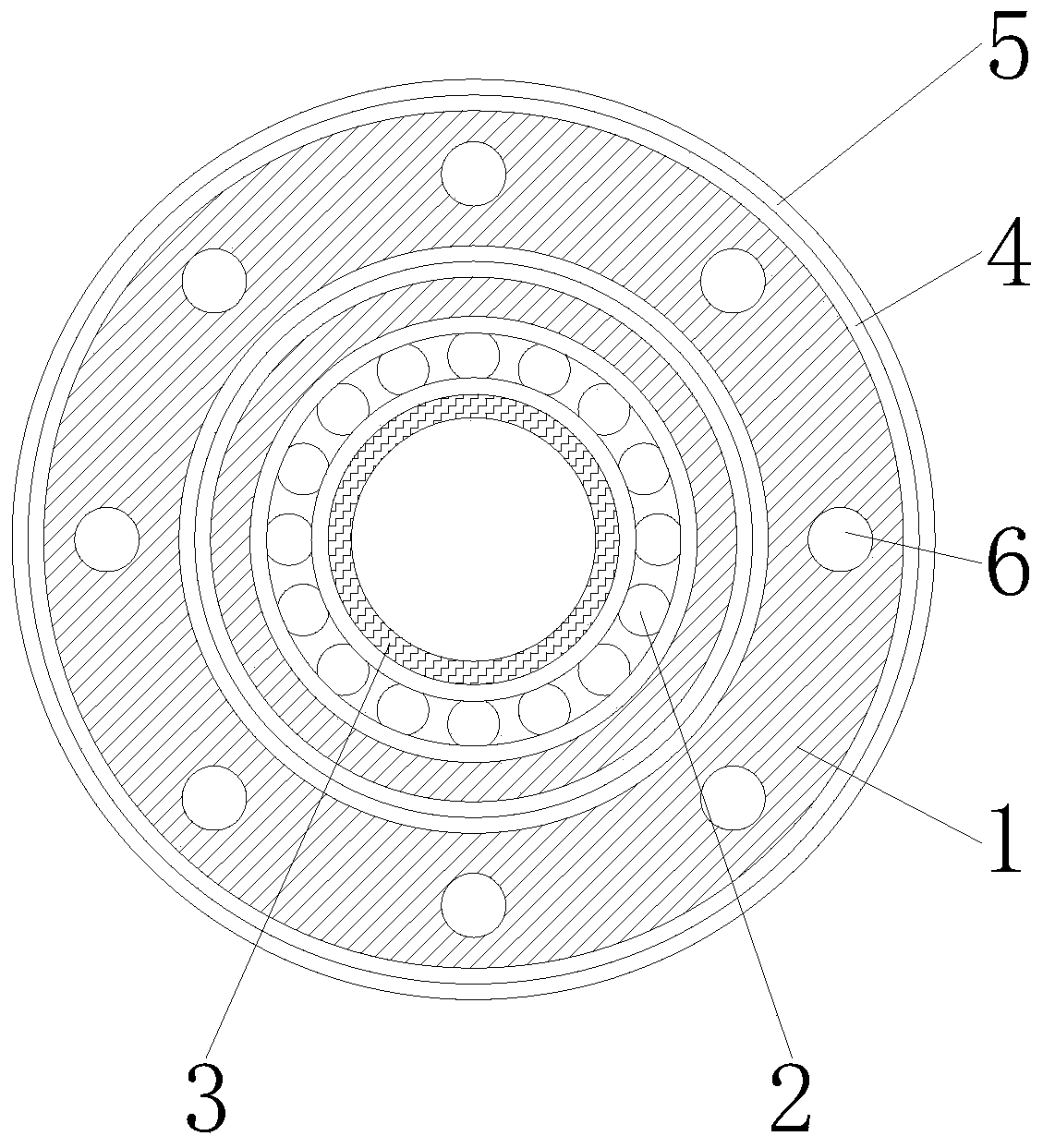

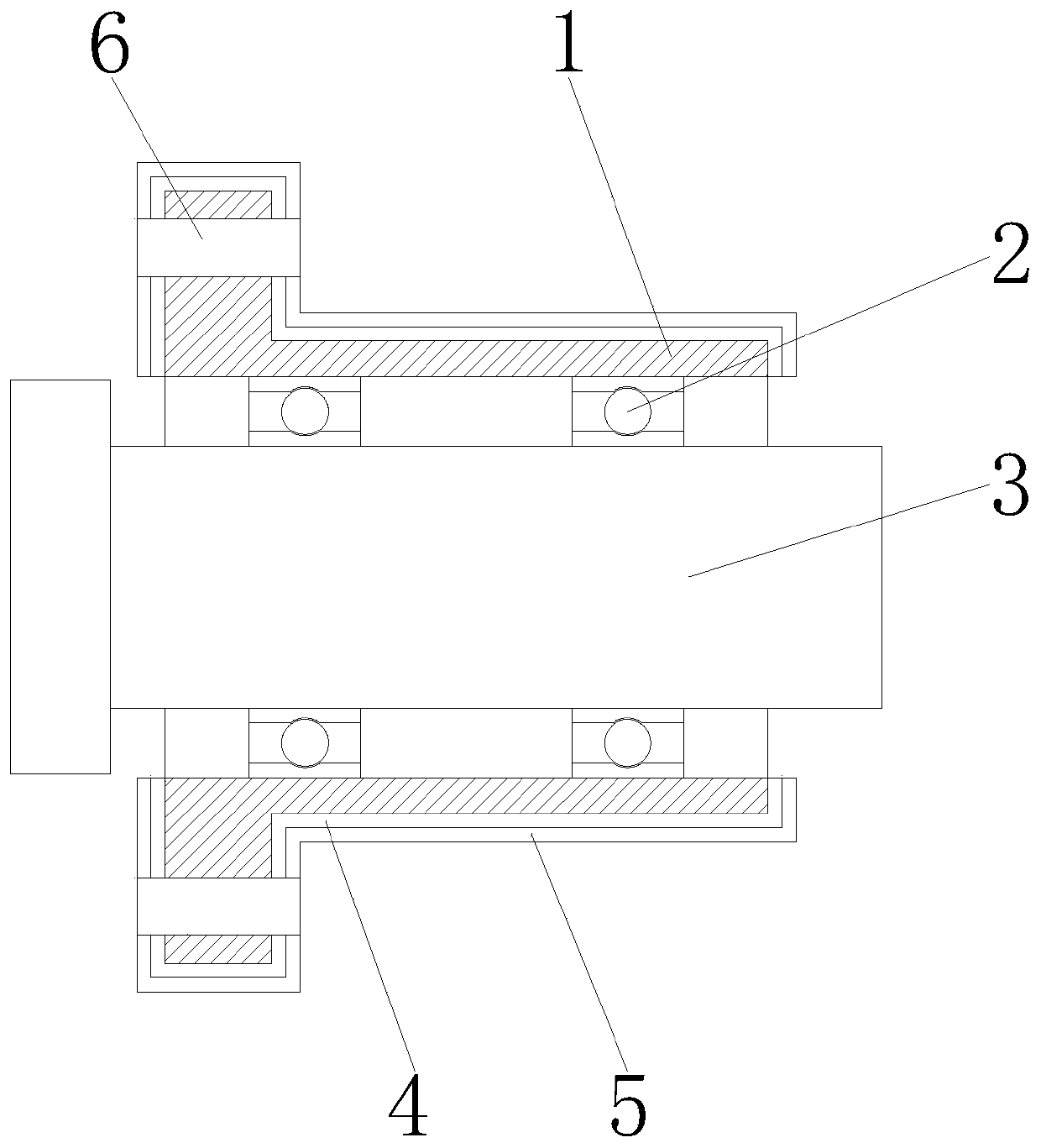

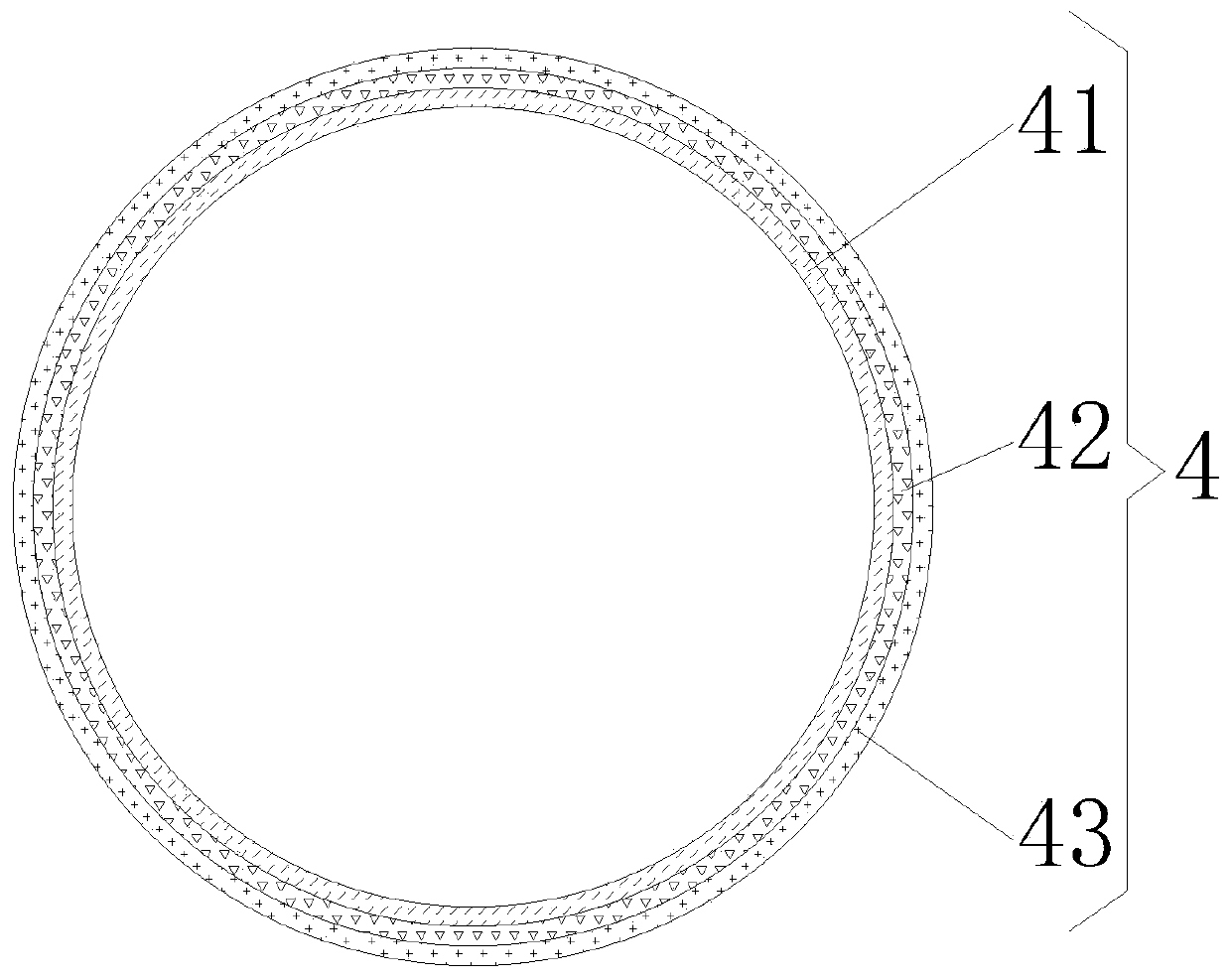

Optical fiber slip ring for optical communication equipment

InactiveCN111045159AEffective insulationCorrosion effectiveCoupling light guidesEpoxyColloidal silica

The invention discloses an optical fiber slip ring for optical communication equipment, which comprises a slip ring stator, wherein bearings are fixedly connected to the front end and the rear end ofthe inner wall of the slip ring stator, the inner walls of the bearings are fixedly connected with a slip ring rotor, the surface of the slip ring stator is provided with an insulating layer, and a corrosion-resistant layer is arranged on the side, which is away from the slip ring stator, of the insulating layer. According to the invention, the advantages of insulation and corrosion resistance ofthe optical fiber slip ring are achieved through mutual cooperation of the bearings, the insulating layer, an insulating plastic layer, an insulating rubber layer, an insulating silica gel layer, thecorrosion-resistant layer, a phenolic resin paint layer, an epoxy resin coating layer and an inorganic zinc-rich paint layer; when the optical fiber slip ring is in contact with a power supply, the optical fiber slip ring can be effectively insulated, the problem that the optical fiber is short-circuited and even damaged due to the fact that electricity is conducted into the optical fiber is prevented, the service life of the optical fiber is prolonged, the corrosion resistance of the optical fiber slip ring is improved, the optical fiber slip ring is prevented from being corroded and damaged,and the service life of the optical fiber slip ring is prolonged.

Owner:深圳市国扬通讯有限公司 +1

Interface treatment agent and preparation method thereof

The invention provides a corrosion-increasing interface treatment agent and a preparation method thereof. Cationic exchange resins and fluoride compounds are used as corrosive agents to generate hydrofluoric acid in an aqueous solution to effectively corrode elements in materials and destroy The smoothness of the material interface can expand the effective surface area of the interface and increase the adhesion of the material surface. Secondly, when the corrosion-increasing interface treatment agent is used, phosphate compounds, hydrochloride compounds, and nitrate compounds can form mixed acids, thereby avoiding the corrosion of a single acid of hydrofluoric acid and achieving a corrosion-increasing effect. The present invention also provides a corrosion-inhibiting interface treatment agent and a preparation method thereof, using cation exchange resin and fluoride compounds as corrosive agents to expand the effective surface area of the interface and increase the interface adhesion; surfactant 1227, hexadecyl Trimethylammonium bromide and cetylpyridinium bromide can effectively block the corrosion and hydrogen penetration of hydrofluoric acid on the material surface, reduce the corrosion efficiency, and achieve the corrosion inhibition effect.

Owner:莱恩斯新材料科技开发(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com