Metallographic etchant and metallographic etching method for pure titanium and beta titanium alloy

A beta titanium alloy and metallographic corrosion technology is applied in the metallographic etchant and corrosion field of pure titanium and beta titanium alloys, which can solve the problems of difficult to control corrosion time, corrosion pits, plaques, and inability to corrode tissue morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

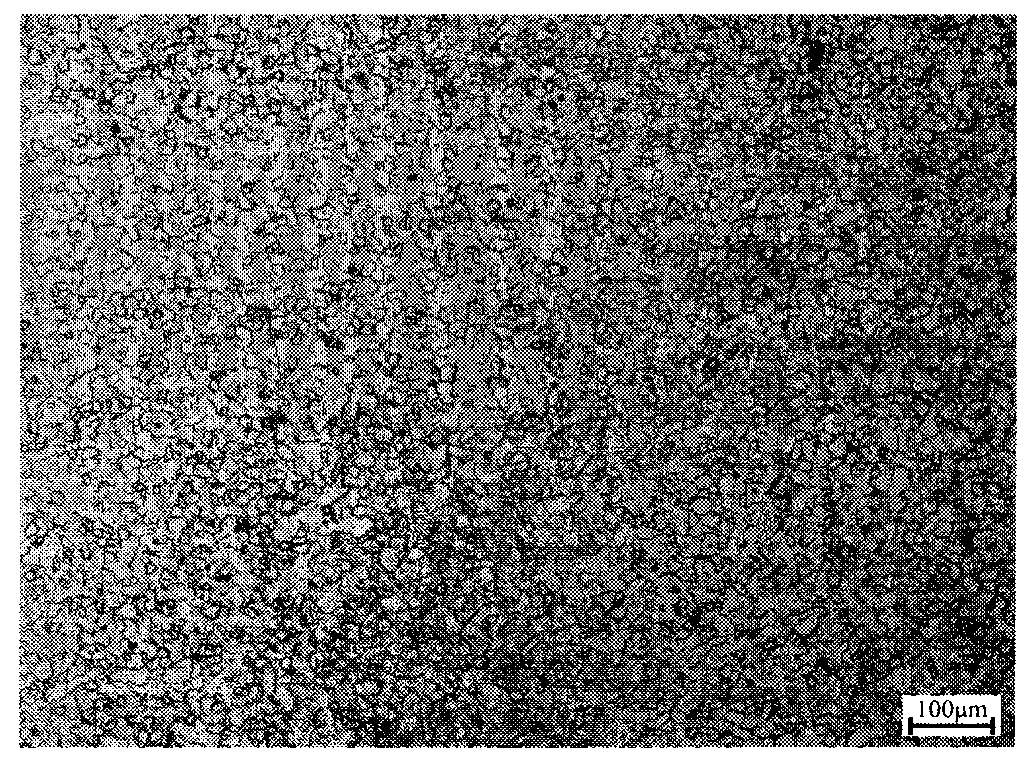

[0020] Use analytically pure nitric acid, hydrofluoric acid and water as raw materials to prepare an etching solution at a ratio of 10ml:5ml:50ml, soak the ground and polished hot-rolled pure titanium plate metallographic sample in the etching solution for 12 seconds, take out the test solution Immediately rinse the sample with tap water, and then soak it in absolute ethanol at 32°C for 14 minutes; take it out for the second polishing; use analytical pure nitric acid, hydrofluoric acid and water as raw materials to prepare a corrosion solution in a ratio of 10ml: 3ml: 60ml , Soak for 10 seconds, take out the sample and immediately rinse it with tap water, then clean it with absolute ethanol without room temperature, and finally dry it with hot air with a hair dryer. The metallographic structure of the obtained pure titanium plate is shown in Fig. 1(b). Compared with the metallographic structure corroded by the traditional method (Fig. 1(a)), the hot-rolled structure obtained by...

Embodiment 2

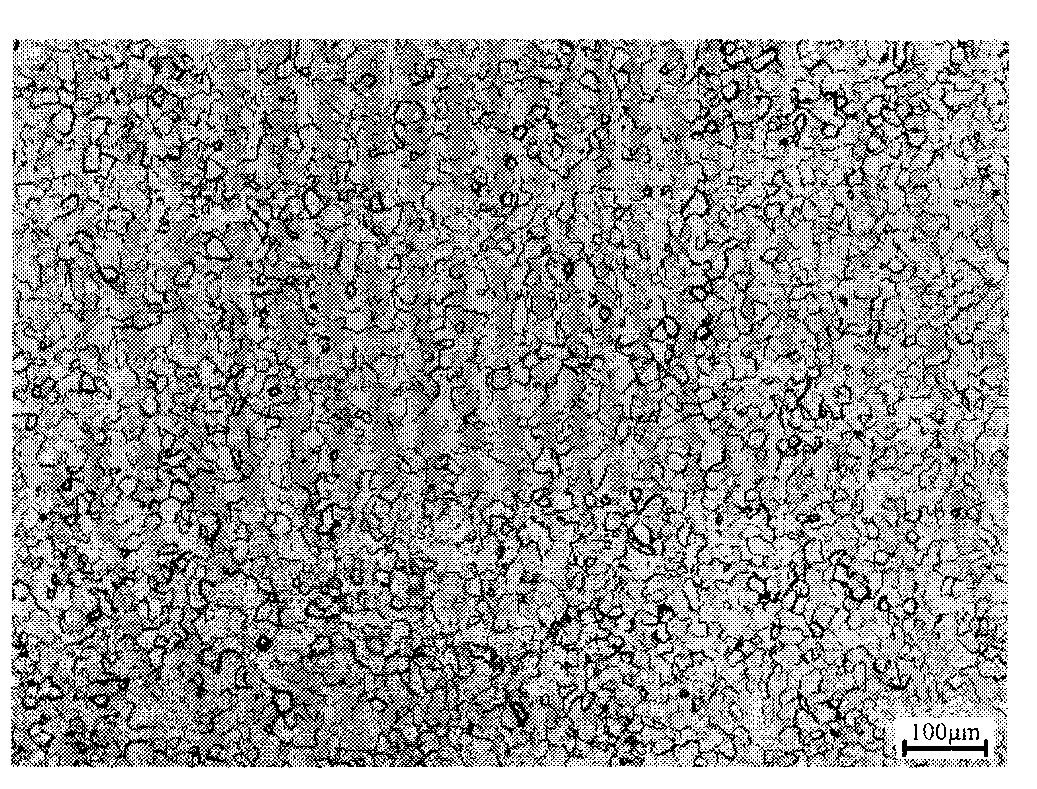

[0022] Use analytically pure nitric acid, hydrofluoric acid and water as raw materials to prepare an etching solution at a ratio of 12ml:5ml:55ml, soak the metallographic sample of the annealed pure titanium plate that has been ground and polished in the etching solution for 12 seconds, and take out the sample Immediately rinse with tap water, then soak in absolute ethanol at 38°C for 16 minutes; take it out for second polishing; use analytical pure nitric acid, hydrofluoric acid and water as raw materials to prepare a corrosion solution in a ratio of 10ml: 5ml: 62ml, Soak for 10 seconds, take out the sample and immediately rinse it with tap water, then clean it with absolute ethanol without room temperature, and finally dry it with hot air from a hair dryer. The metallographic structure of the obtained pure titanium plate is shown in Fig. 2(b). Compared with the metallographic structure corroded by the traditional method (Fig. 2(a)), the annealed structure obtained by the meth...

Embodiment 3

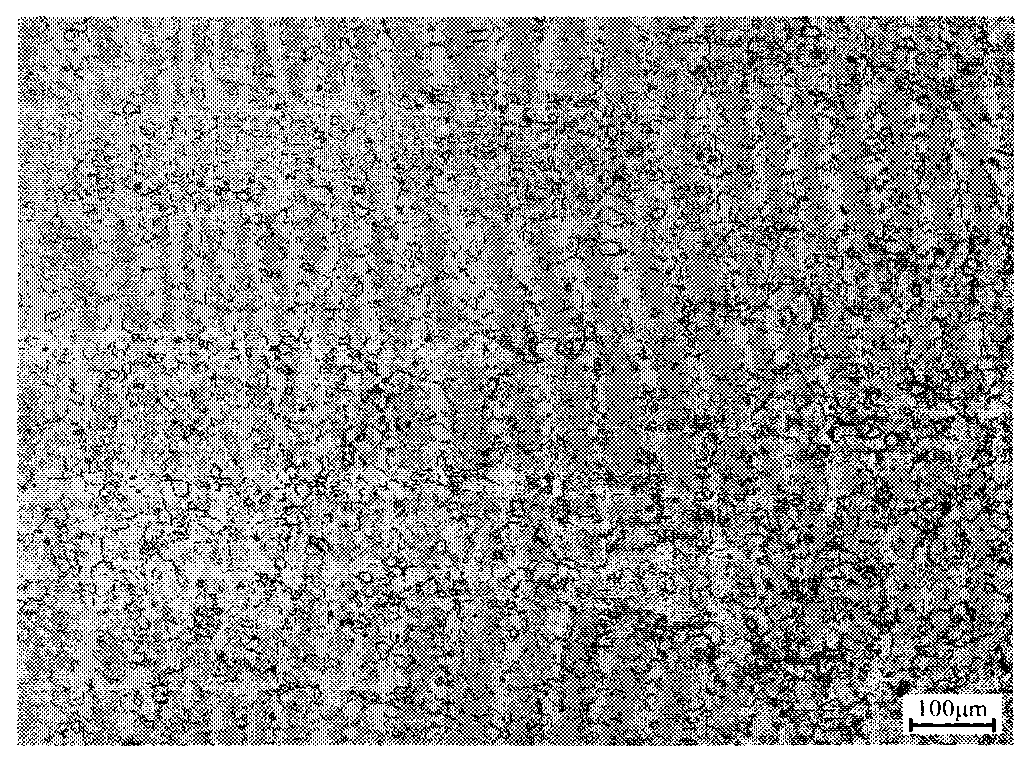

[0024] Use analytically pure nitric acid, hydrofluoric acid and water as raw materials to prepare an etching solution at a ratio of 10ml: 3ml: 45ml, soak the ground and polished hot-rolled Ti25Nb25Zr rod metallographic sample in the etching solution for 15 seconds, take out the sample Immediately rinse the sample with tap water, and then soak it in absolute ethanol at 40°C for 16 minutes; take it out for the second polishing; use analytical pure nitric acid, hydrofluoric acid and water as raw materials to prepare a corrosion solution in a ratio of 10ml: 3ml: 50ml , Soak for 12 seconds, take out the sample and immediately rinse it with tap water, then clean it with absolute ethanol without room temperature, and finally dry it with hot air with a hair dryer. The metallographic structure of the obtained hot-rolled Ti25Nb25Zr bar is shown in Figure 3(b). Compared with the metallographic structure corroded by the traditional method (Figure 3(a)), the hot-rolled structure obtained by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com