Traceless splicing cable protective sheath and preparation method thereof

A technology for cable protection and protective coating, applied in cable/conductor manufacturing, insulated cables, bendable cables, etc., can solve problems such as unsatisfactory, and achieve the effects of corrosion prevention, stable structure and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the above-mentioned non-marking splicing cable protective cover, the steps are as follows:

[0042] Step 1. Weigh each material according to the components and parts by weight of section A, and fully mix them uniformly in a stirring mixer to obtain the mixture of section A;

[0043] Step 2. Weigh each material according to the components and parts by weight of section B, and fully mix them uniformly in a stirring mixer to obtain the mixture of section B;

[0044] Step 3, put epoxy resin and polytetrafluoroethylene powder into a stirring container, add 40% of the total amount of organic solvent, keep stirring at a speed of 1000r / min, stir for 0.5-1h to make it fully mixed, and then mix the obtained Put the liquid material into the dispersion container, add anti-UV additives, vermiculite, glass powder, paraffin, nano-silver and hollow microspheres with a particle size of 1000-1250 mesh, add the remaining organic solvent, keep the speed at 2500r / m...

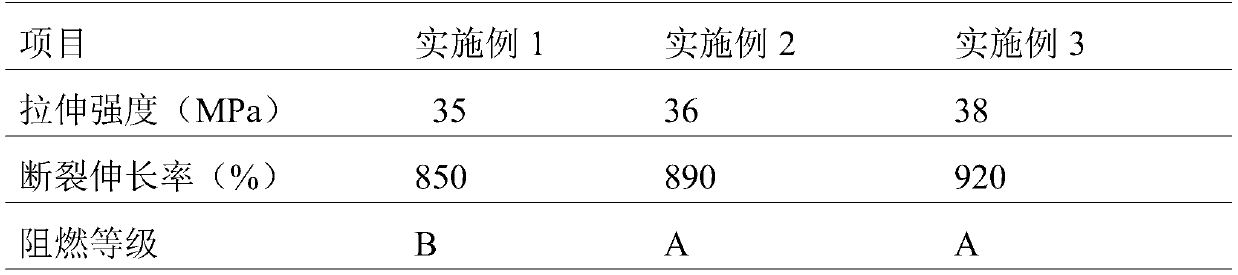

Embodiment 1

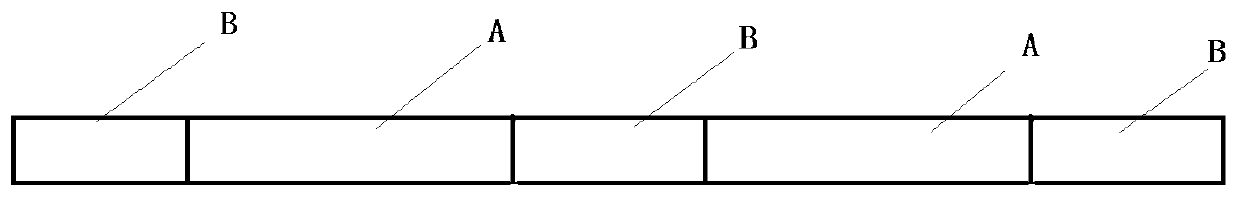

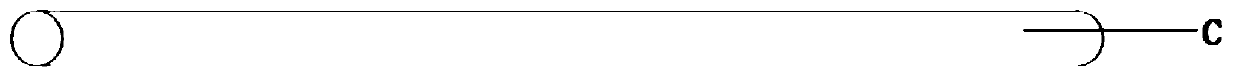

[0050] The non-marking splicing cable protective sleeve is composed of alternately arranged sections A and B. The length ratio of sections A and B is 2:1. Adjacent sections A and B are fused and connected. Outside sections A and B The surface is coated with a protective coating C with a thickness of 100 microns;

[0051] Among them, the components and parts by weight of section A are: 100 parts of polyvinyl chloride, 10 parts of borosilicate rubber, 10 parts of ABS, 2 parts of borax, 1 part of nano silica gel, 5 parts of barium stearate, 3 parts of paraffin, 0.5 parts of gum 1 part, 1 part of white carbon black, 1 part of antimony trioxide and 1 part of kaolin;

[0052] The components and parts by weight of section B are: 100 parts of polyvinyl chloride, 10 parts of borosilicate rubber, 8 parts of zinc stearate and 10 parts of compound flame retardant, and the mass ratio of compound flame retardant is 1:0.5 : 0.5 mixture of red phosphorus, graphite powder, antimony trioxide; ...

Embodiment 2

[0061] The non-marking splicing cable protective sleeve is composed of alternately arranged sections A and B, the length ratio of sections A and B is 3:1, and the fusion connection between adjacent sections A and B, the outer section of A and B The surface is coated with a protective coating C with a thickness of 100 microns;

[0062] Among them, the components and parts by weight of section A are: 100 parts of polyvinyl chloride, 12 parts of borosilicate rubber, 13 parts of ABS, 2.5 parts of borax, 2 parts of nano silica gel, 6 parts of barium stearate, 4 parts of paraffin, 0.8 parts of gum 1.5 parts of white carbon black, 3 parts of antimony trioxide and 1.5 parts of kaolin;

[0063] The components and parts by weight of section B are: 100 parts of polyvinyl chloride, 12 parts of borosilicate rubber, 13 parts of zinc stearate and 12 parts of compound flame retardant, and the mass ratio of compound flame retardant is 1:0.5 : 1 mixture of red phosphorus, graphite powder, anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com