Anti-corrosion oil pipe for oil field

A technology of oil field and oil pipe, which is applied in the field of oil field anti-corrosion oil pipe, which can solve the problems of insufficient anti-corrosion, insufficient oil pipe connection, etc., and achieve the effect of long service life, simple operation and strong pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

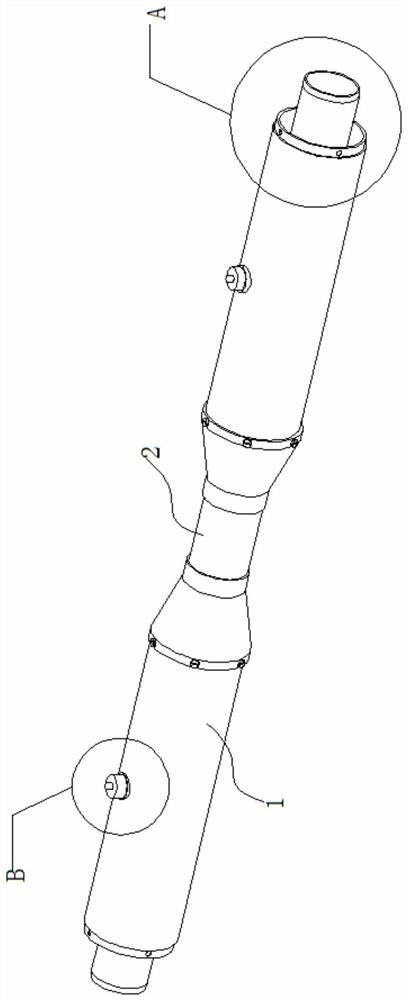

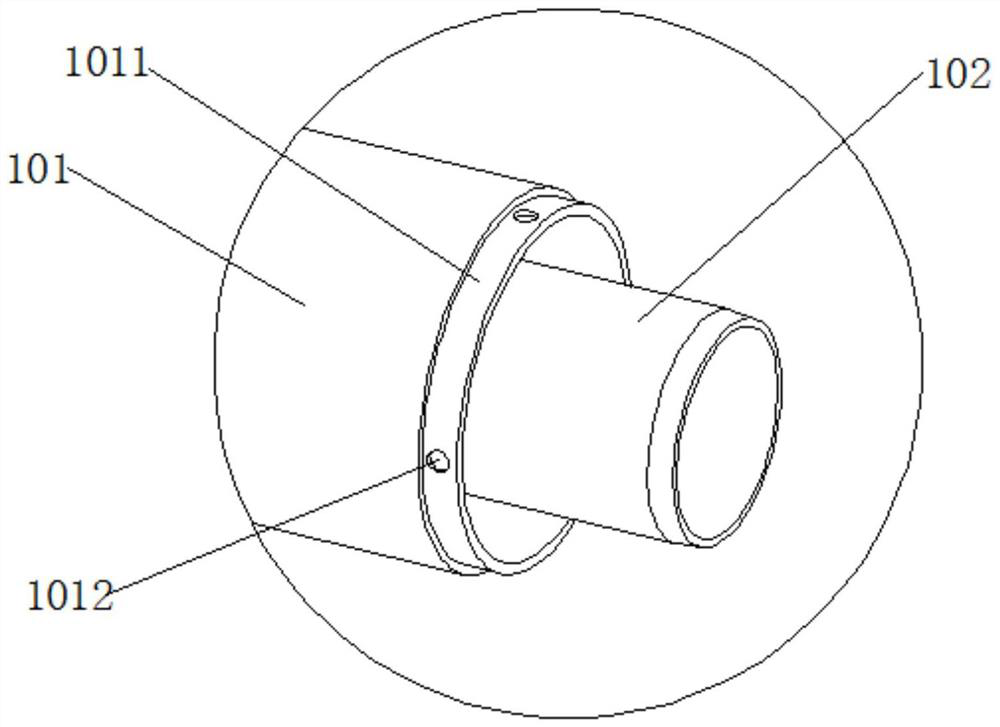

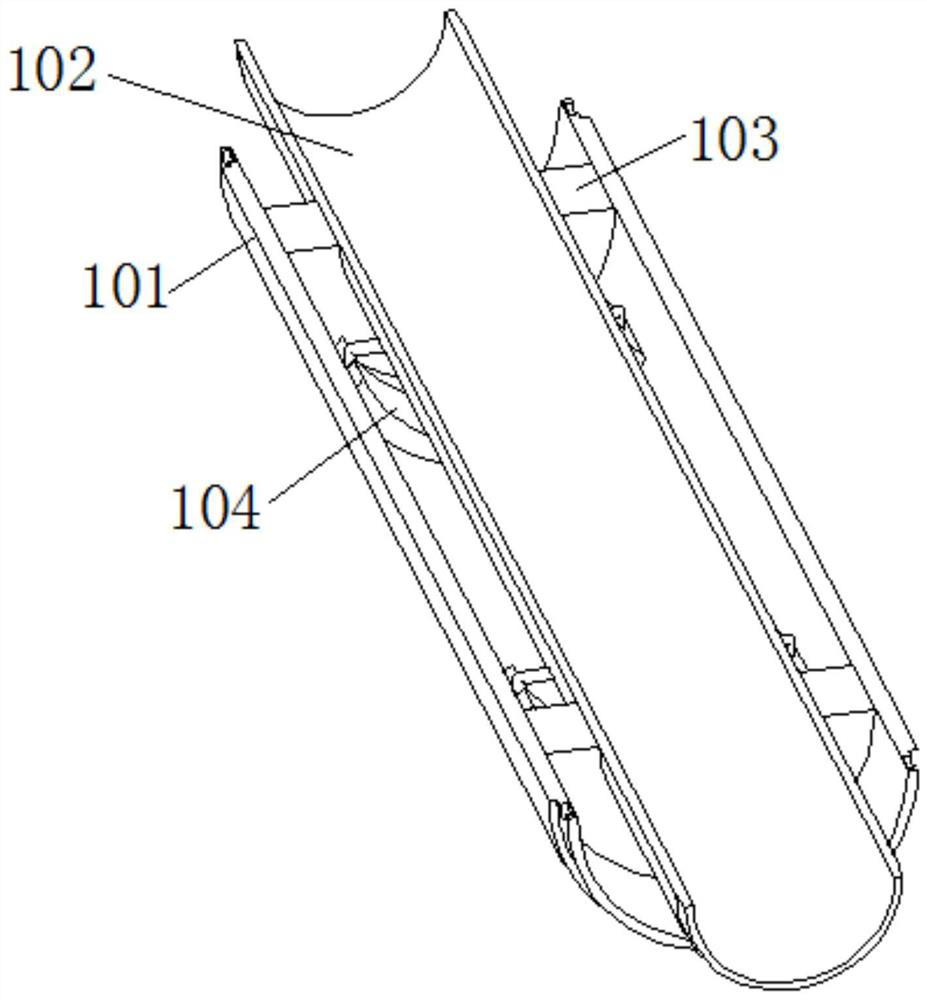

[0041] This embodiment 1 introduces an anti-corrosion oil pipe for oil field, which includes a plurality of oil field oil pipes 1 and a pipe connection device 2 for connecting two adjacent oil field oil pipes 1. The oil field oil pipe 1 includes an outer protection pipe layer 101 and an inner delivery pipe layer 102, the outer wall diameter of the inner delivery pipe layer 102 is smaller than the inner wall diameter of the outer protection pipe layer 101, and the length of the inner delivery pipe layer 102 is longer than the outer protection pipe layer 101, the inner delivery pipe layer 102 is arranged inside the outer protection pipe layer 101, and the inner The central axis of the conveying pipe layer 102 coincides with the central axis of the outer protective pipe layer 101, and both ends of the inner conveying pipe layer 102 protrude from the outer protective pipe layer 101, and both ends of the inner wall of the outer protective pipe layer 101 are provided with annular The...

Embodiment 2

[0046] This embodiment 2 introduces the improvement on the basis of embodiment 1. This embodiment 1 introduces an anti-corrosion oil pipe for oil field, including a plurality of oil field oil pipes 1 and a pipeline connection device 2 for connecting two adjacent oil field oil pipes 1 , the oilfield tubing 1 includes an outer protective pipe layer 101 and an inner conveying pipe layer 102, the outer wall diameter of the inner conveying pipe layer 102 is smaller than the inner wall diameter of the outer protective pipe layer 101, and the length of the inner conveying pipe layer 102 is longer than the outer protective pipe layer 101, The inner conveying pipe layer 102 is arranged inside the outer protective pipe layer 101, the central axis of the inner conveying pipe layer 102 coincides with the central axis of the outer protective pipe layer 101, and both ends of the inner conveying pipe layer 102 protrude from the outer protective pipe layer 101 Set, both ends of the inner wall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com