Through hole type alumina catalyst carrier and preparation method thereof

A catalyst carrier, alumina technology, applied in the direction of catalyst carrier, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problems of inability to obtain an array structure, prolonged electrolysis time, etc., achieve high solubility, reduce usage, and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

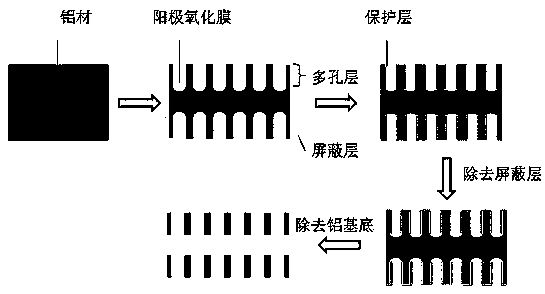

[0068] A through-hole alumina catalyst carrier, such as figure 1 As shown, the following processing steps are included:

[0069] (1) Select 5 series aluminum alloy less than 0.5cm as the base material;

[0070] (2) Pretreating the aluminum substrate, the pretreatment process is alkaline-hot water washing-alkali washing-hot water washing-cold water washing-acid washing-water washing steps.

[0071] (3) Anodize the treated aluminum substrate to form an oxide film on the surface. The solution used for anodizing is a mixture of oxalic acid, phosphoric acid and sulfosalicylic acid. The concentration of oxalic acid is 0.25M, and the concentration of phosphoric acid is is 0.2M, the concentration of sulfosalicylic acid is 0.05M, the voltage of the anodic oxidation process is 20V, and the temperature is 30 o C, current density 2A / dm 2 , time 20min.

[0072] (4) The protective film is adsorbed on the surface of the porous layer of the anodized film, and the protective film is not ad...

Embodiment 2

[0077] A through-hole type alumina catalyst carrier, comprising the following processing steps:

[0078] (1) Select 5 series aluminum alloy less than 0.5cm as the base material;

[0079] (2) Pretreating the aluminum substrate, the pretreatment process is alkaline-hot water washing-alkali washing-hot water washing-cold water washing-acid washing-water washing steps.

[0080](3) Anodize the treated aluminum substrate to form an oxide film on the surface. The solution used for anodizing is a mixture of oxalic acid, phosphoric acid and sulfosalicylic acid. The concentration of oxalic acid is 0.275M, and the concentration of phosphoric acid is is 0.3M, the concentration of sulfosalicylic acid is 0.1M, the voltage of the anodic oxidation process is 25V, and the temperature is 30 o C, current density 2.5A / dm 2 , time 25min.

[0081] (4) The protective film is adsorbed on the surface of the porous layer of the anodized film, and the protective film is not adsorbed on the shielding ...

Embodiment 3

[0086] A through-hole type alumina catalyst carrier, comprising the following processing steps:

[0087] (1) Select 5 series aluminum alloy less than 0.5cm as the base material;

[0088] (2) Pretreating the aluminum substrate, the pretreatment process is alkaline-hot water washing-alkali washing-hot water washing-cold water washing-acid washing-water washing steps.

[0089] (3) Anodize the treated aluminum substrate to form an oxide film on the surface. The solution used for anodizing is a mixture of oxalic acid, phosphoric acid and sulfosalicylic acid. The concentration of oxalic acid is 0.3M, and the concentration of phosphoric acid is is 0.4M, the concentration of sulfosalicylic acid is 0.15M, the voltage of the anodic oxidation process is 30V, and the temperature is 30 o C, current density 3A / dm 2 , time 30min.

[0090] (4) The protective film is adsorbed on the surface of the porous layer of the anodized film, and the protective film is not adsorbed on the shielding la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com