U-shaped fixed carriage type mine car

A car box and U-shaped technology, which is applied in the field of U-shaped fixed car box type mine cars, can solve the problems of accelerated oxidation and corrosion of cast iron mine cars, easy damage to the box body of the mine car, affecting the normal use of the mine car, etc. Long life, high smoothness, and less residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

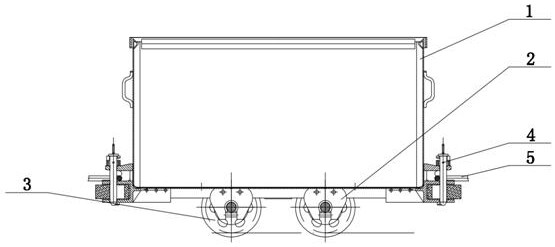

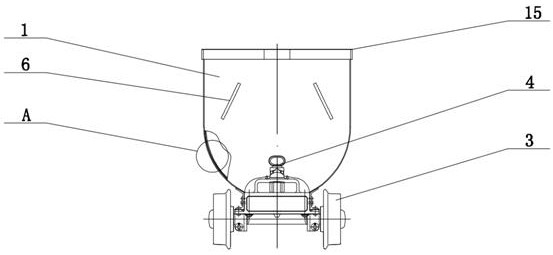

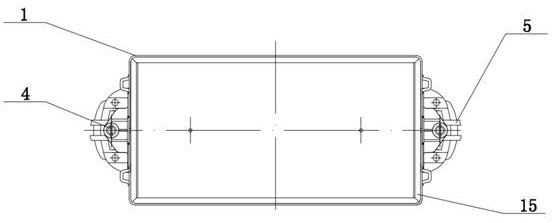

[0020] see Figure 1-Figure 4 As shown, the technical scheme adopted in this specific embodiment is: it is made up of carriage 1, vehicle frame 2, open wheel pair 3, anti-off bolt 4, three-ring chain 5, handle 6, and carriage 1 box body is made of anti-collision layer 11. The buffer layer 12, the adhesion layer 13, and the anti-corrosion layer 14 are composed. The anti-collision layer 11 is the outermost layer of the carriage 1. The buffer layer 12 is glued and pasted on the inner wall of the anti-collision layer 11. The adhesion layer 13 adheres to the buffer layer 12 and the anti-corrosion layer. Corrosion layer 14, the frame 2 is fixed to the bottom of the carriage 1 by multiple bolts, two sets of frame 2 are provided, the open wheel set 3 is fixed on both sides of the frame 2 by bolts, and four open wheel sets 3 are set in total , the anti-off bolt 4 is installed on the connecting seat connected to the carriage 1, the three-ring chain 5 is placed on the connecting seat and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com