Tin-nickel solder IMC layer metallographic corrosive agent and metallographic structure display method thereof

A technology of metallographic structure display and metallographic corrosion, which is applied in the field of metallographic structure observation and test of tin-nickel solder IMC layer, can solve the problems of IMC morphology and thickness misjudgment, IMC metallographic microstructure interface blurring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

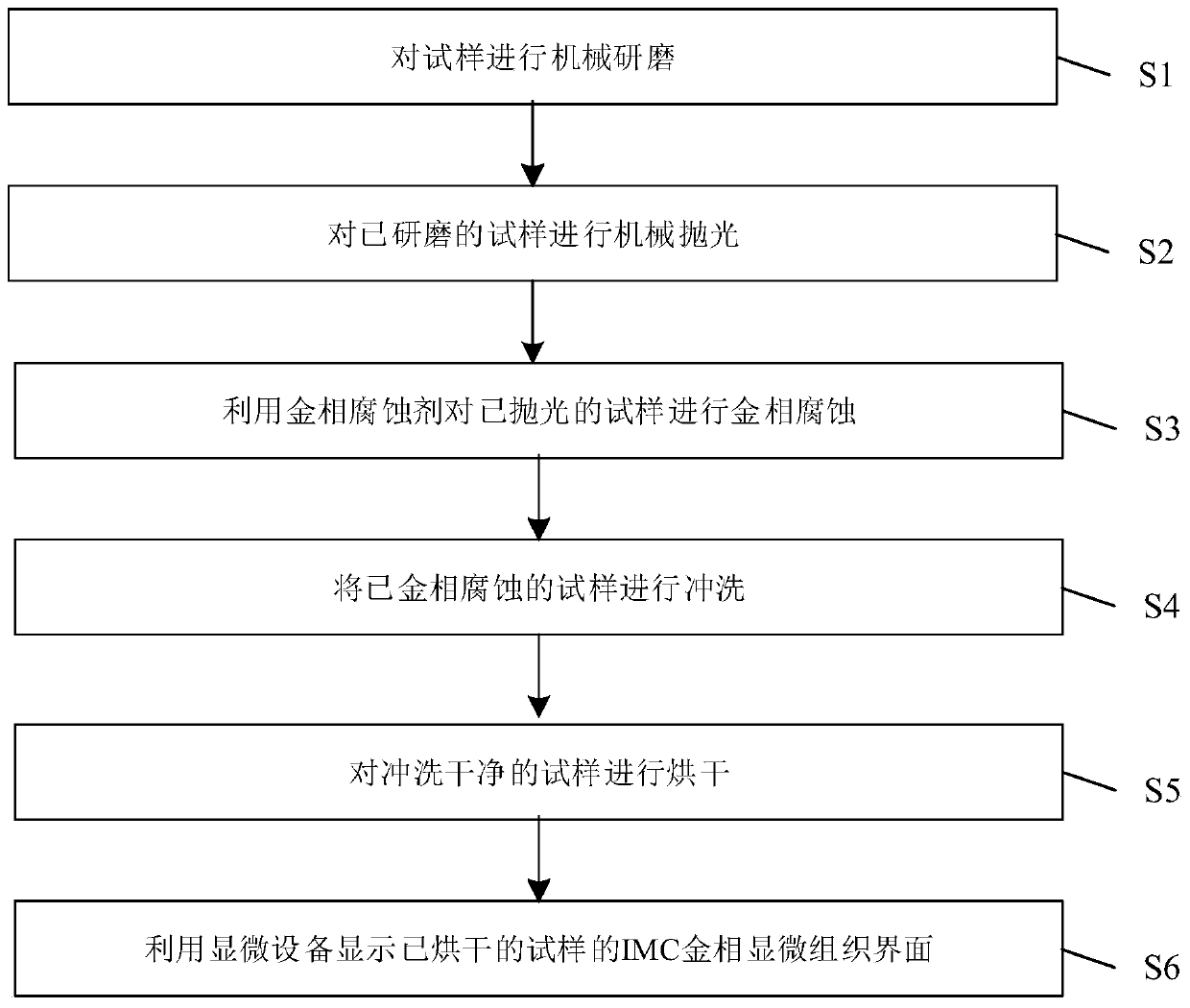

Method used

Image

Examples

Embodiment 1

[0043] The tin-nickel solder alloy metallographic etchant in this implementation case is prepared from hydrochloric acid with a mass percentage of 36% and ethanol with a mass percentage of 95.5% according to a volume ratio of 1:9.

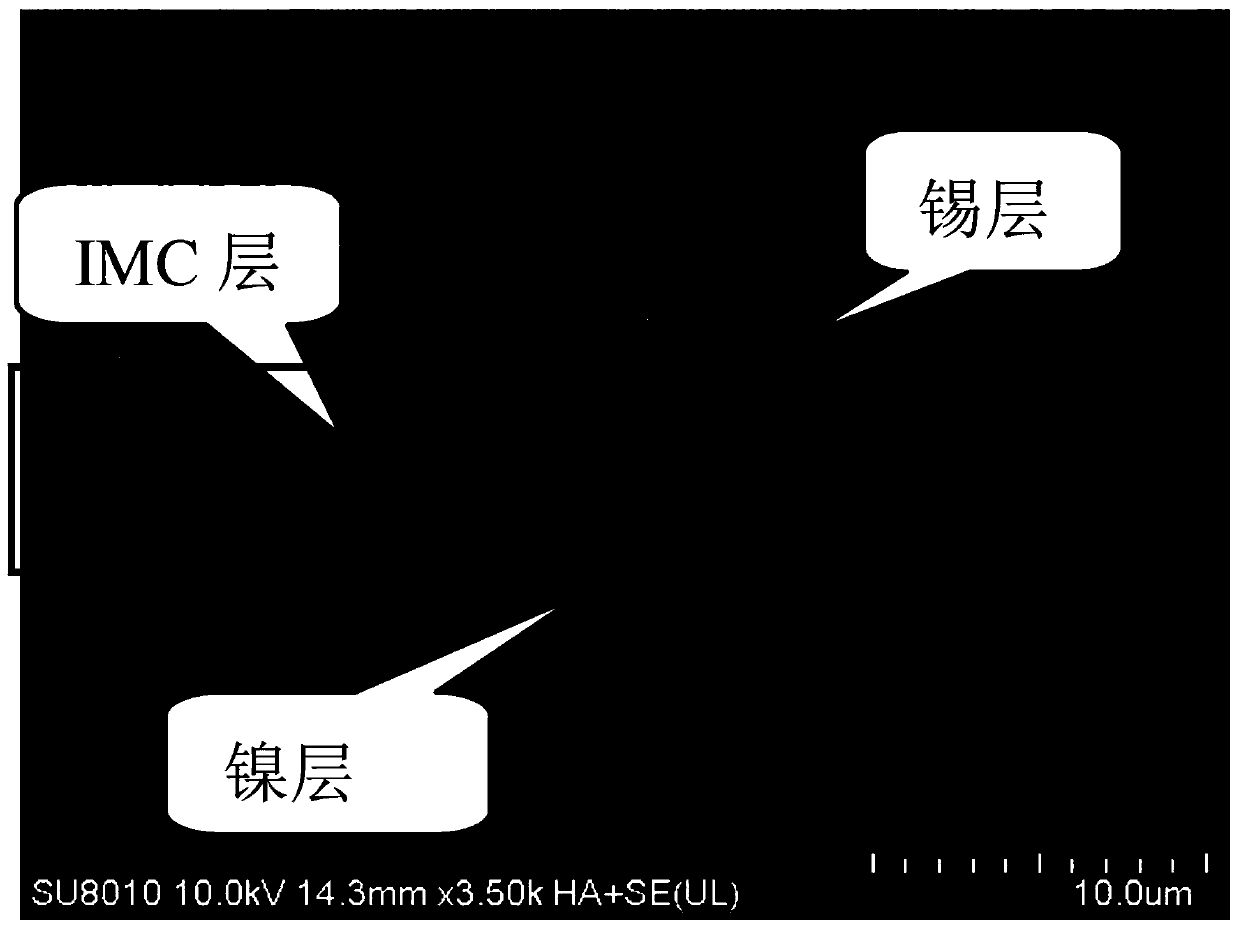

[0044] Mechanically grind and polish the solder alloy sample first, soak the mechanically polished solder alloy sample in the metallographic etchant for 50 seconds, rinse it with running water for 8 seconds, and then bake it in an oven at 50°C for 5 minutes to obtain The corroded solder alloy sample was finally observed with a high-magnification optical microscope and a scanning electron microscope. The obtained images are as follows: image 3 shown.

Embodiment 2

[0046] The tin-nickel solder alloy metallographic etchant in this implementation case is prepared from hydrochloric acid with a mass percentage of 36.7% and ethanol with a mass percentage of 96% according to a volume ratio of 1:9.

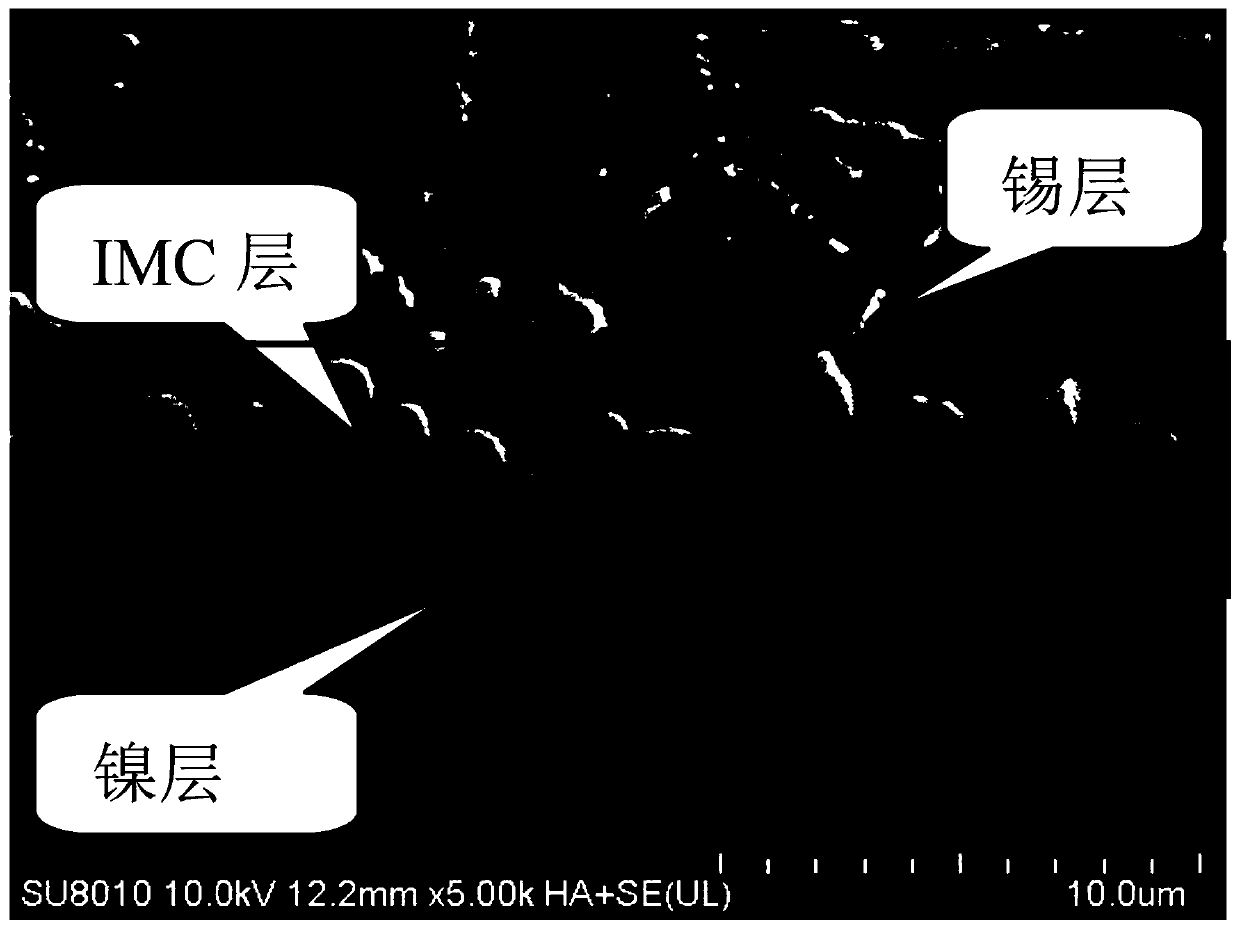

[0047] Mechanically grind and polish the solder alloy sample first, soak the mechanically polished solder alloy sample in the metallographic etchant for 45s, wash it with running water for 5s, and then bake it in an oven at 50°C for 3min to obtain The corroded solder alloy sample was finally observed with a high-magnification optical microscope and a scanning electron microscope. The obtained images are as follows: Figure 4 shown.

Embodiment 3

[0049] The tin-nickel solder alloy metallographic etchant in this implementation case is prepared from 38% by mass hydrochloric acid and 97.5% by mass ethanol according to the volume ratio of 1:9.

[0050] Mechanically grind and polish the solder alloy sample first, soak the mechanically polished solder alloy sample in the metallographic etchant for 60s, rinse with running water for 10s, and then bake in an oven at 50°C for 4min to obtain The corroded solder alloy sample was finally observed with a high-magnification optical microscope and a scanning electron microscope. The obtained images are as follows: Figure 5 shown.

[0051] Through the above examples, it is not difficult to find that because hydrochloric acid is a strong acid and ethanol has reducing properties, it can better infiltrate the surface of the sample, and the microetching effect is more ideal. Using the technical solution can greatly improve the corrosion efficiency of the IMC layer and the display effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com