Road and bridge crack repairing method

A crack repair and bridge technology, used in road repair, bridge maintenance, roads, etc., can solve problems such as road or bridge overhaul or even scrap, low degree of automation, load-bearing discount, etc., to avoid secondary cracks, improve efficiency, and connect. reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

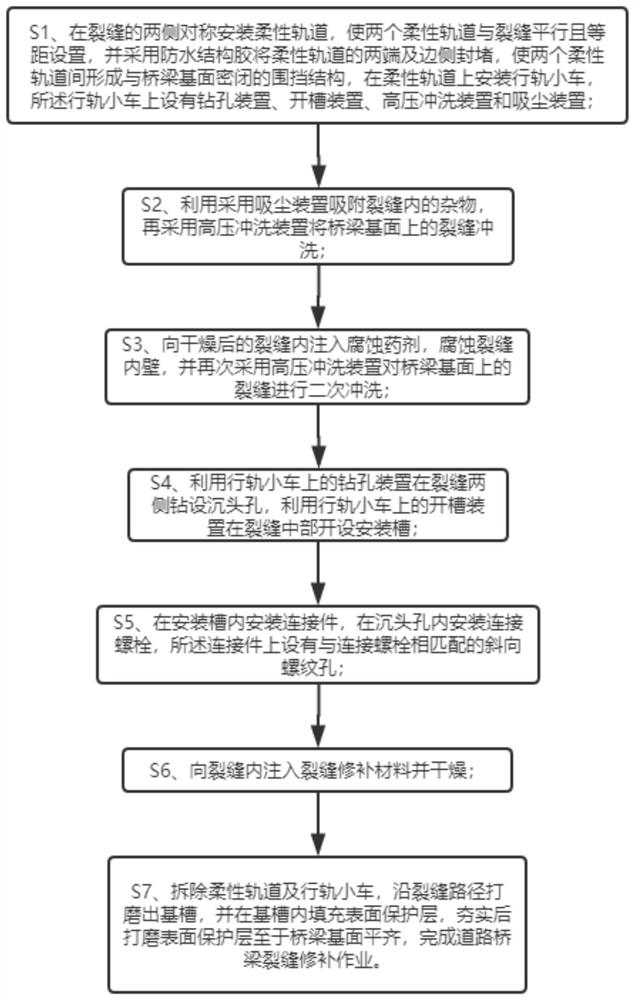

[0053] see Figure 1-7 , a road bridge crack repair method specifically comprises the following steps:

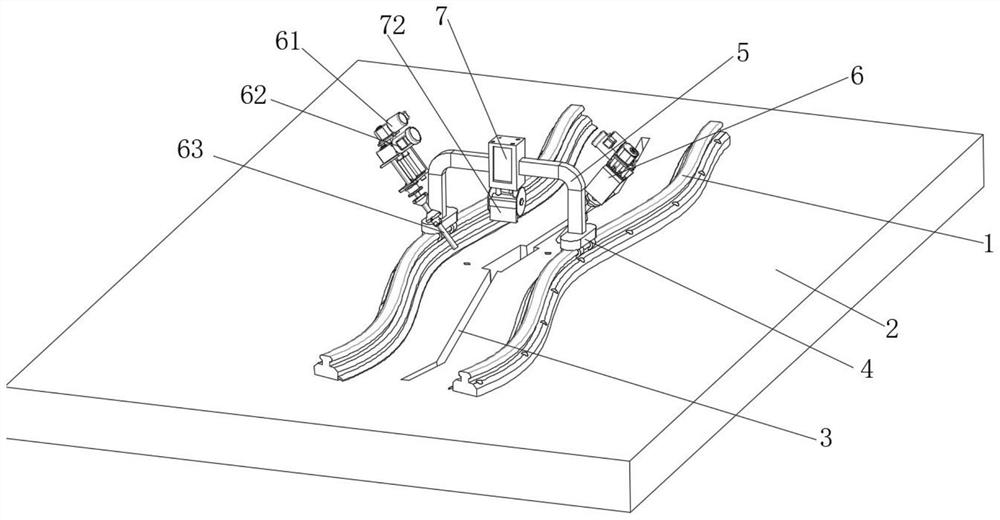

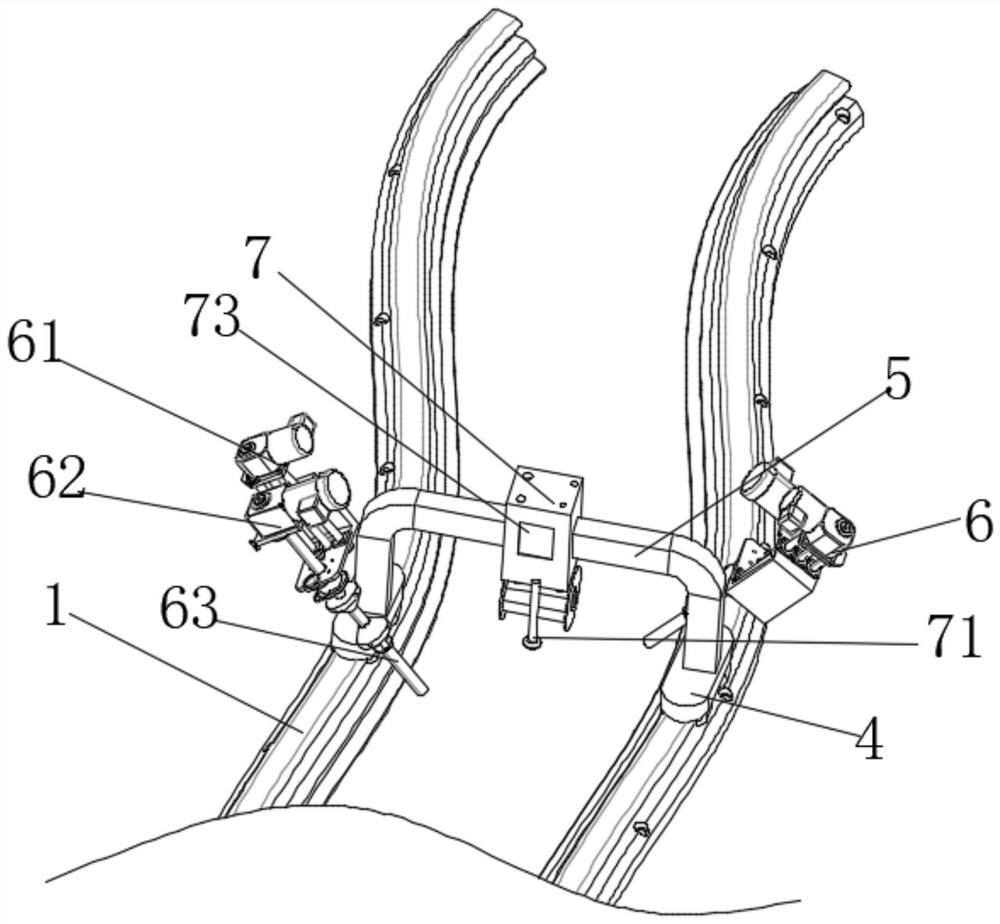

[0054] S1. Install the flexible track 1 symmetrically on both sides of the crack 3, so that the two flexible tracks 1 and the crack 3 are parallel and equidistant, and use waterproof structural glue to seal the two ends and sides of the flexible track 1, so that the two The flexible track 1 forms an airtight enclosure structure with the bridge base 2, and the track trolley 4 is installed on the flexible track 1. The track trolley 4 is equipped with a drilling device 6, a slotting device 7, a high-pressure washing device 71 and a suction Dust device 72;

[0055] S2, using the dust suction device 72 to absorb the sundries in the crack 3, and then using the high-pressure washing device 71 to wash the crack 3 on the bridge base 2;

[0056] S3. Inject corrosive agents into the dried cracks 3 to corrode the inner walls of the cracks 3, and use the high-pressure washing device 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com