Underground super-long structure defect automatic repairing machine and using method thereof

A technology for structural defect and automatic repair, applied in the direction of house structure support, house structure support, building maintenance, etc., can solve the problem of low efficiency of repair of super-long structural defects, avoid high-altitude repair operations, improve construction safety, reduce The effect of staffing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

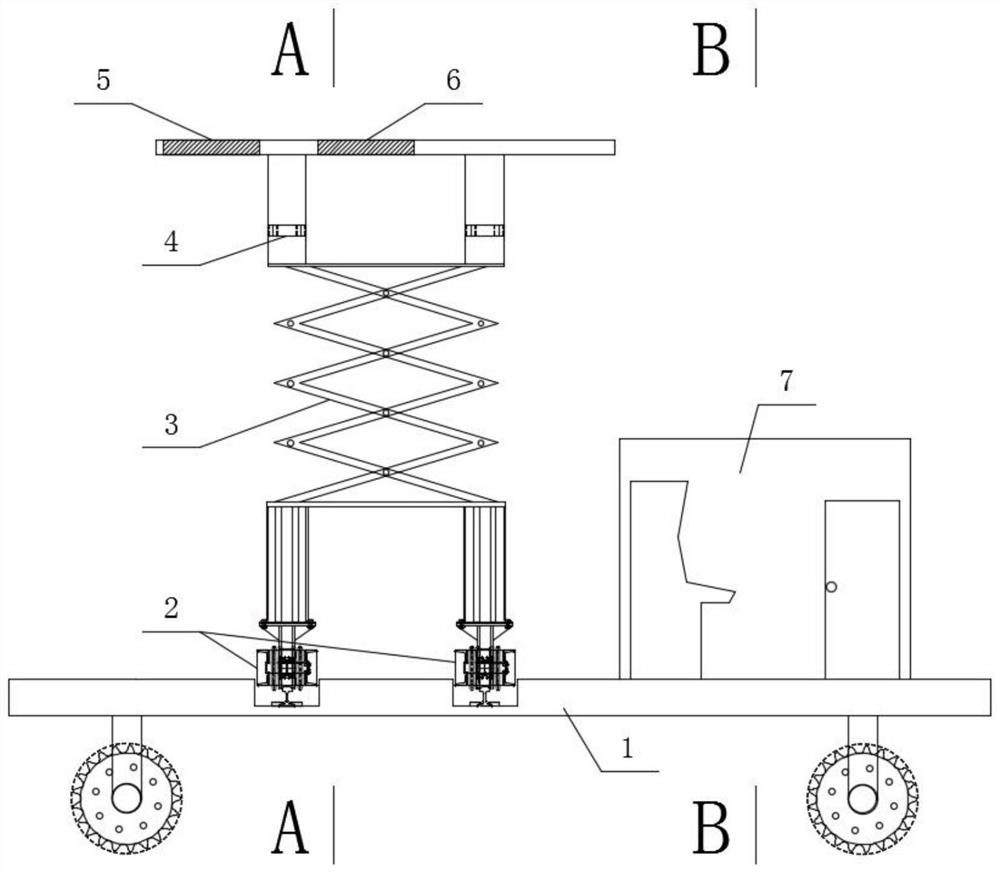

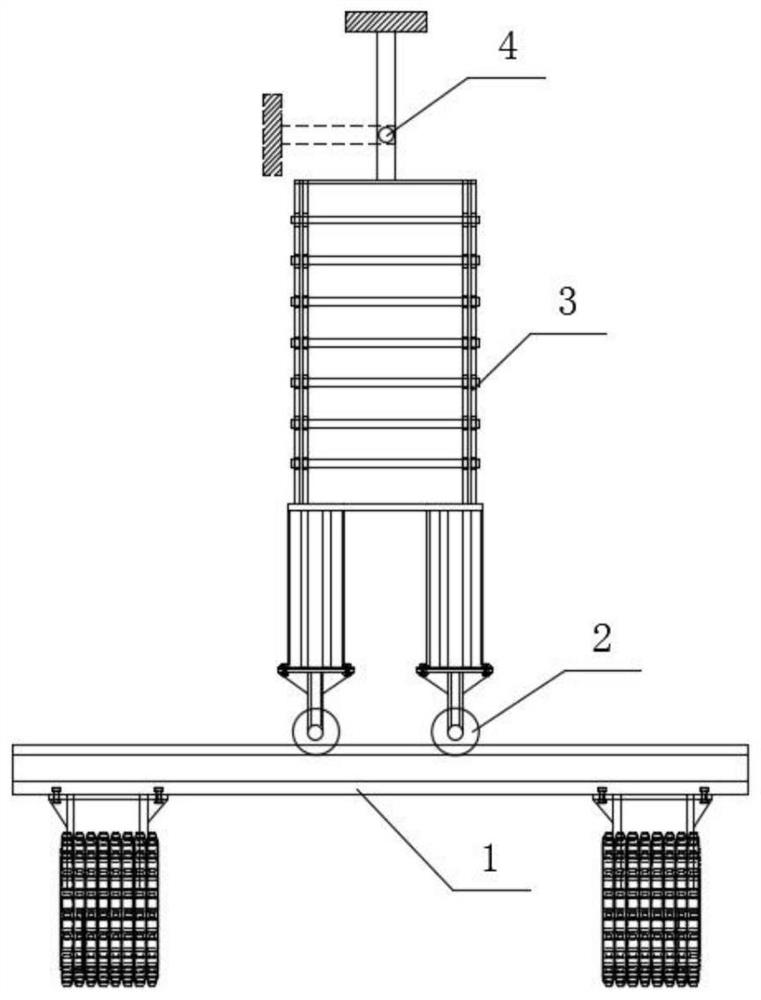

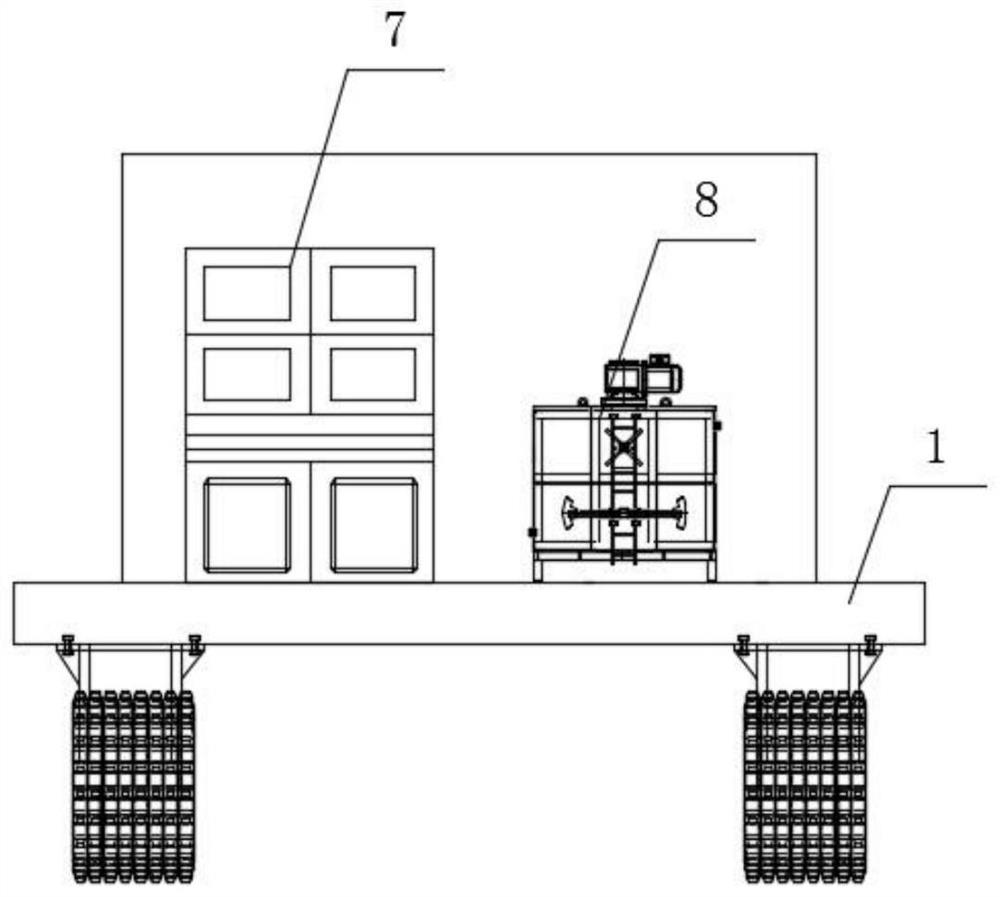

[0031] refer to Figure 1 to Figure 5 As shown, an automatic repairing machine for underground ultra-long structural defects includes a walking device 1, a sliding device 2, a lifting device 3, a rotating device 4, a scanner 5, a repairing device 6, an operating table 7 and a storage tank 8, and repairing The device 6 comprises a prosthetic body 9 , a nozzle 10 and a rolling bar 11 .

[0032] Walking device 1 comprises walking platform and walking wheel, and walking platform is used for installing and supporting other each parts, and walking wheel is located at the bottom of walking platform, is convenient to carry out flexible transition. Sliding device 2, operating platform 7 and material storage tank 8 are all installed on the walking platform.

[0033] The walking platform is provided with a sliding device 2 for horizontal and lateral movement. The sliding device 2 includes slide rails and pulleys. The slide rails are horizontally installed on the walking platform, and th...

Embodiment 2

[0041] refer to Figure 1 to Figure 5 As shown, a method of using the above-mentioned automatic repairing machine for super-long underground structures, first deploy repair materials in the storage tank 8, drive the walking device 1 to reach the bottom of the structure, and then operate the sliding device 2 and the lifting device 2 through the operating platform 7 The device 3 moves and lifts laterally. After reaching the specified height, adjust the angle of the scanner 5 and the repair device 6 to fit the structural surface through the rotating device 4, and then operate the scanner 5 to scan and photograph the structural surface through the operating platform 7. Through the image displayed on the screen of the console 7, the necessity of repair is judged and the amount of repair material is determined, and finally the repair device 6 is operated to repair the designated part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com