Method for repairing high-rise brick chimney wall surface

A repair method and chimney technology, applied in building maintenance, scaffolding accessories, towers, etc., can solve the problems of low construction efficiency and many construction safety hazards, achieve simple structure, refine repair construction technology, and improve repair construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

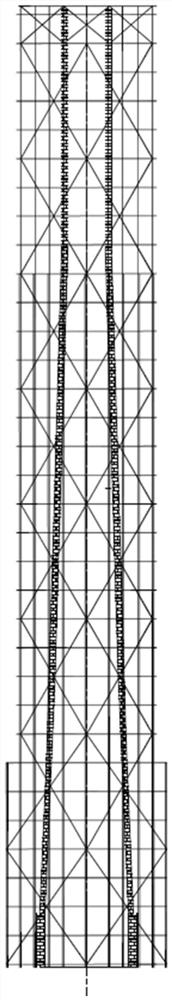

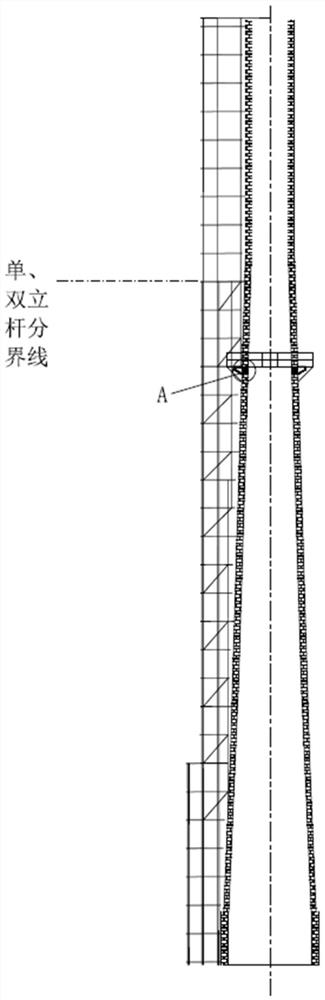

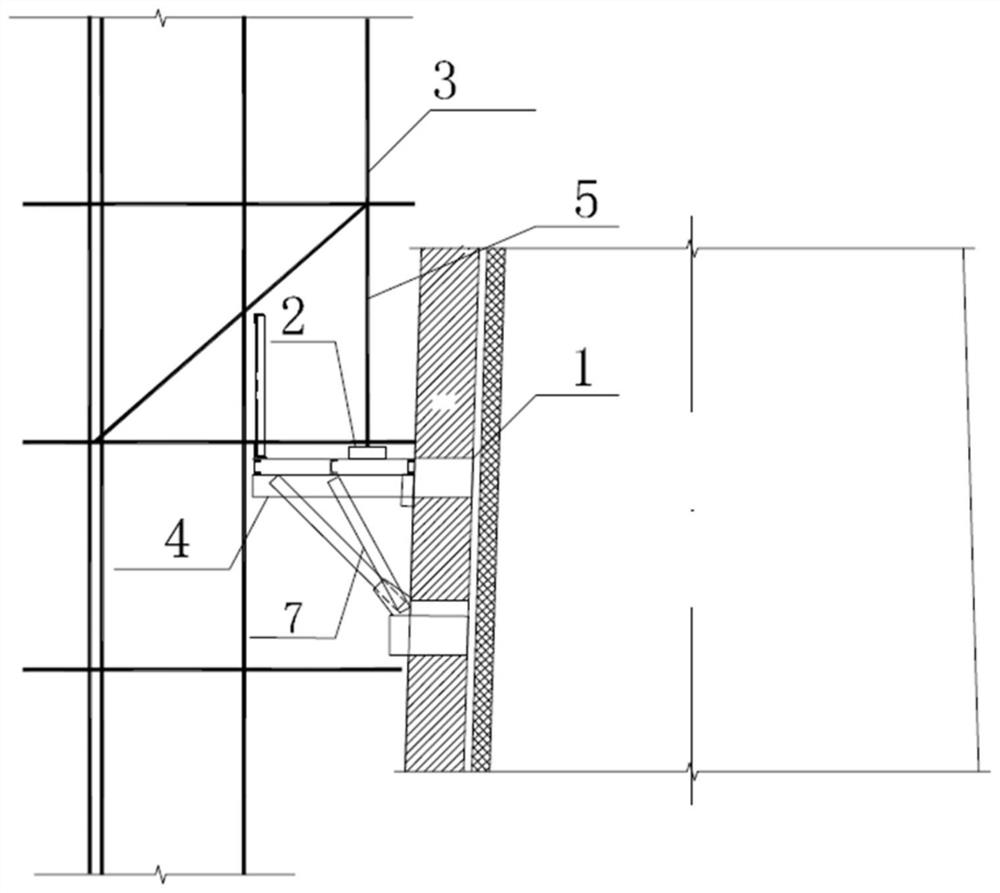

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0024] The present invention relates to a method for repairing the wall surface of a towering brick chimney, the specific examples are as follows:

[0025] Including the following steps:

[0026] Remove the flue: The flue will affect the repair of the brick wall. Remove the flue connected to the brick chimney, and seal the flue opening at the bottom with ordinary sintered bricks, and fill the top 100-120mm with grouting material. The concrete base is leveled with 15mm thick, high-strength grade I polymer mortar, and then reinforced with carbon fiber mesh cloth;

[0027] Among them, the polymer mortar is sprayed or smeared twice, the thickness of the first construction is 5mm, and the thickness of the second construction is 10mm; The lap length is 600mm.

[0028] Pouring new...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com