Nickel-based powder high-temperature alloy corrosion solution and corrosion method

A technology for corrosion solution and superalloy, applied in the field of nickel-based powder superalloy corrosion solution and corrosion, can solve the problems of invisible corrosion surface, operator damage, interference analysis and judgment, etc. easy-to-see effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of corrosion solution and corrosion method for FGH97 powder superalloy sheet test piece used for aero-engine, comprising the following steps:

[0027] (1) Degreasing: Use Viennese lime to degrease the surface of the alloy sheet, and then perform hot water cleaning, cold water cleaning, and water film continuity inspection;

[0028] (2) Preparation of low-magnification corrosion solution: taking mass fraction as 36% concentrated hydrochloric acid as solvent, each solute component and concentration are, copper sulfate: 160g / L; sulfuric acid (mass fraction is 98%): 80g / L; Water ethanol: 100ml / L, mix well;

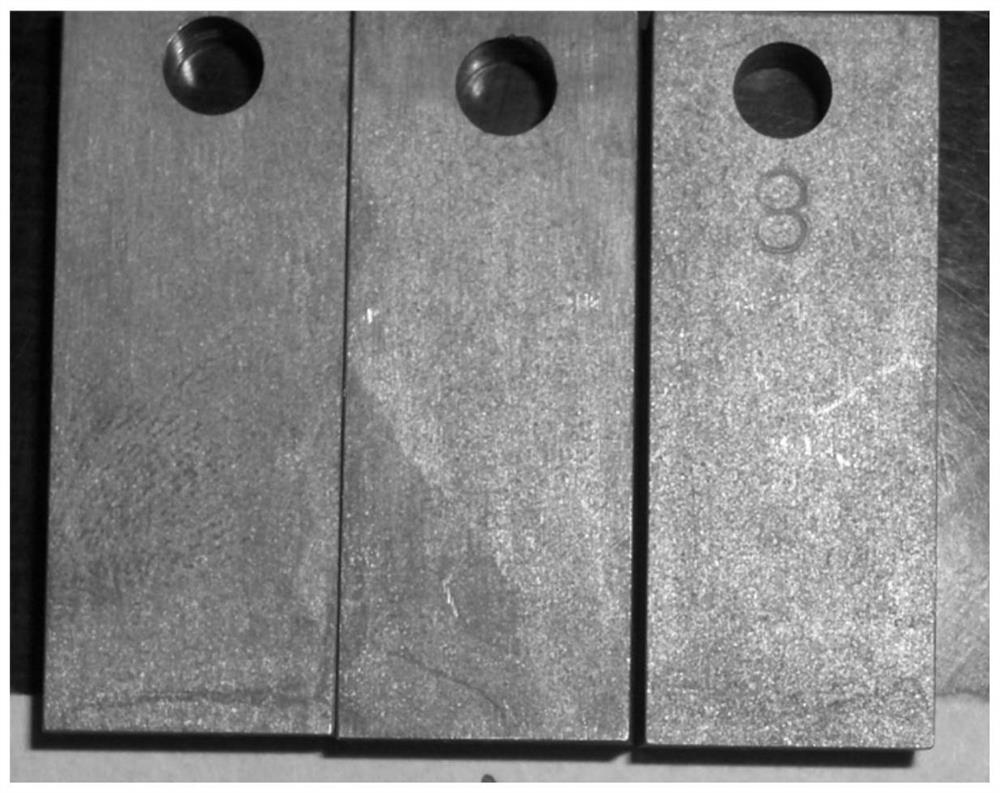

[0029] (3) Corrosion process: the temperature of the solution to be corroded is naturally cooled to 25°C, and the powder alloy specimen is put into the corrosion solution. Check the piece, take out the test piece after soaking and corroding for 10 minutes, the surface of the test piece shows crystal grains, take out the test piece and rinse it with flowing cold ...

Embodiment 2

[0038] A kind of corrosion solution and corrosion method for FGH97 nickel-based powder superalloy disk used for aeroengine, comprising the following steps:

[0039] (1) Degreasing: Use Viennese lime to degrease the surface of the alloy, then perform hot water cleaning, cold water cleaning, and water film continuity inspection;

[0040] (2) Preparation of low-magnification corrosion solution: taking mass fraction as 36% concentrated hydrochloric acid as solvent, each solute component and concentration are, copper sulfate: 180g / L; sulfuric acid (mass fraction is 98%): 70g / L; Water ethanol: 90ml / L;

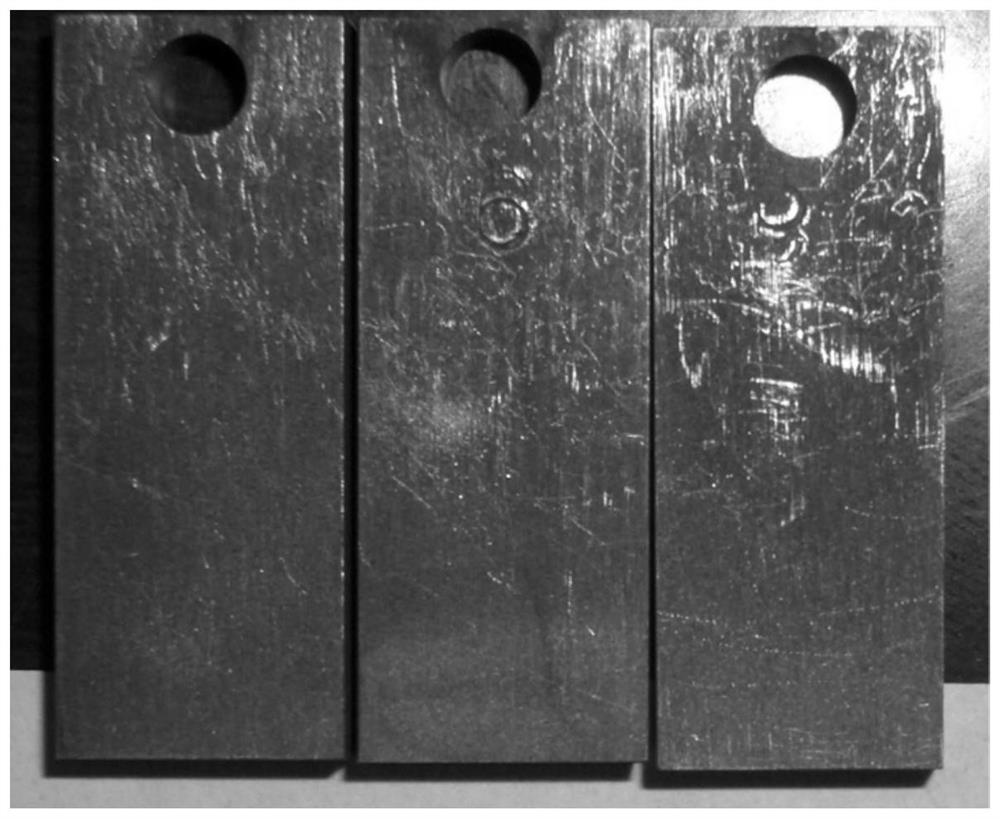

[0041] (3) Corrosion process: the temperature of the solution to be corroded is naturally cooled to 20°C, the powder alloy disk specimen is hung on the fixture, and put into the corrosion solution. Take out the test piece every two minutes to check, soak and corrode for 10 minutes, the surface of the test piece shows grains, take out the test piece and rinse it with flowing cold wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com