Method for improving ore grinding particle size stability rate of super-huge type mill

A stable rate and super-large technology, which is applied in special data processing applications, design optimization/simulation, grain processing, etc., can solve the problem of low stability rate of design value overflow product particle size, unreasonable particle size and composition of grinding products, Grinding cost, steel ball consumption and power consumption increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention is further described below by way of example.

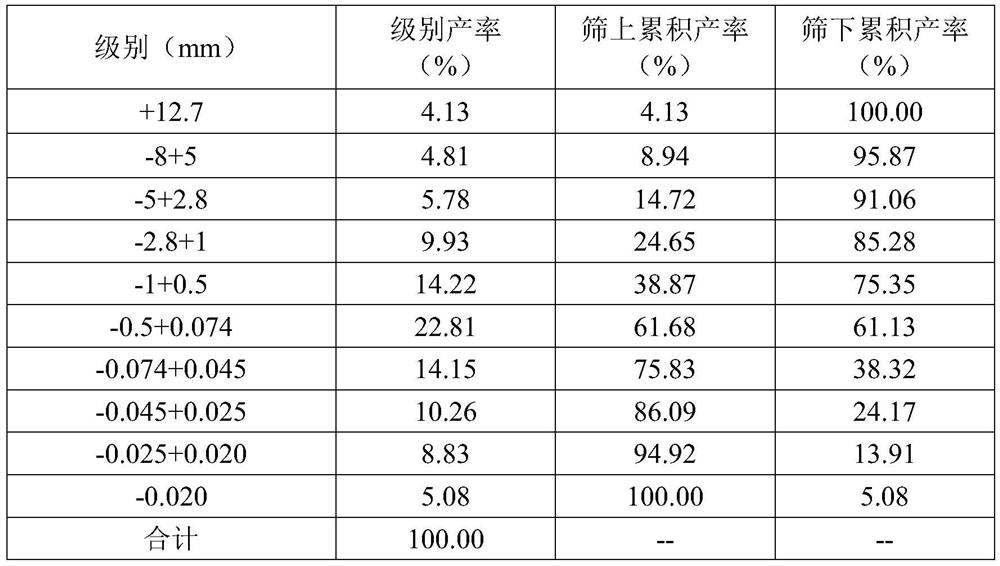

[0021] 1. Process analysis: Sampling and analyzing the process indicators of the original ball mill classification process, the analysis content includes the mechanical performance indicators of the raw ore and the particle size composition parameters of the ball mill feed.

[0022] (1), mechanical properties of ore:

[0023] The maximum density of ore is 3.60g / cm 3 , minimum density 2.90g / cm 3 , with an average density of 3.36g / cm 3 , it can be seen that the ore density in this embodiment is relatively high, and it is easy to deposit and difficult to discharge in the grinding and grading cycle, and it is easy to produce overgrinding;

[0024] The maximum Platinum hardness coefficient of the ore is 29.7, which is extremely hard, and the minimum is 5.4, which is relatively soft. It can be seen that the distribution of hardness and softness in this embodiment is uneven, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com