Full-automatic hydraulic without excitation building block shaping machine

A block forming machine, fully automatic technology, applied in the direction of material forming presses, punching machines, presses, etc., can solve the problem of low-strength non-load-bearing blocks, equipment and mold damage failure rates, and can not be used as load-bearing blocks. and other problems, to achieve the effect of saving cement consumption, accurate appearance and size, and considerable energy saving benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

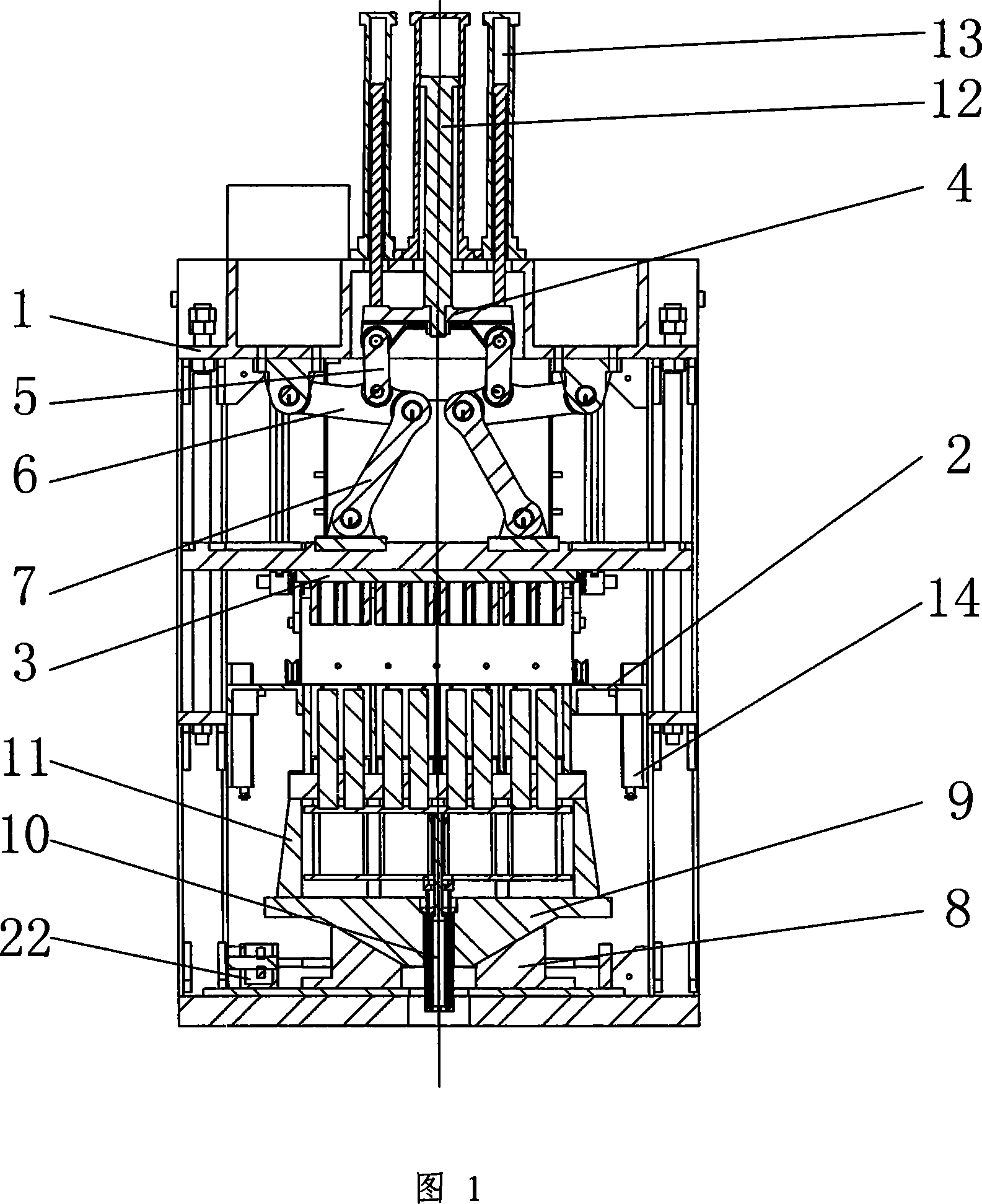

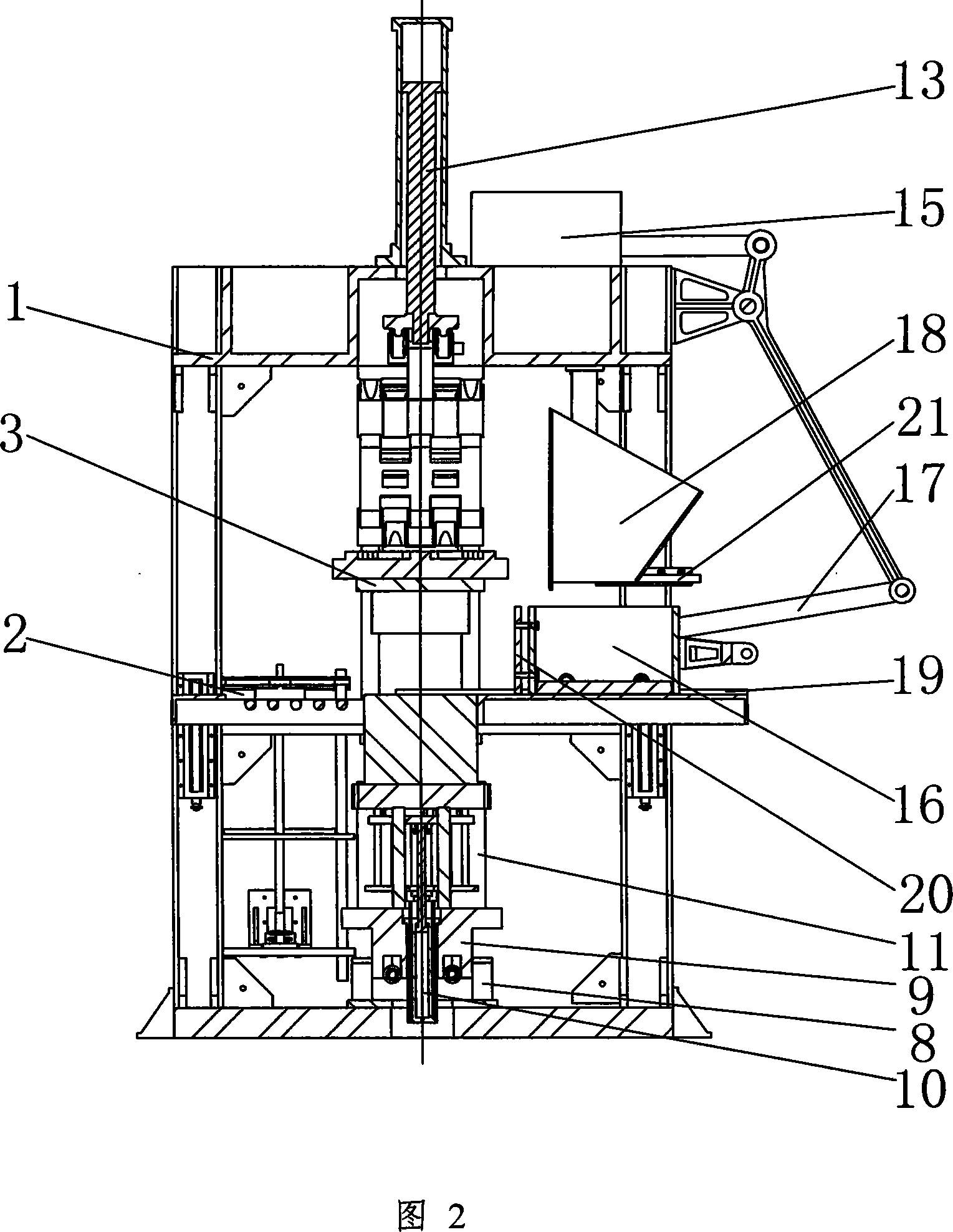

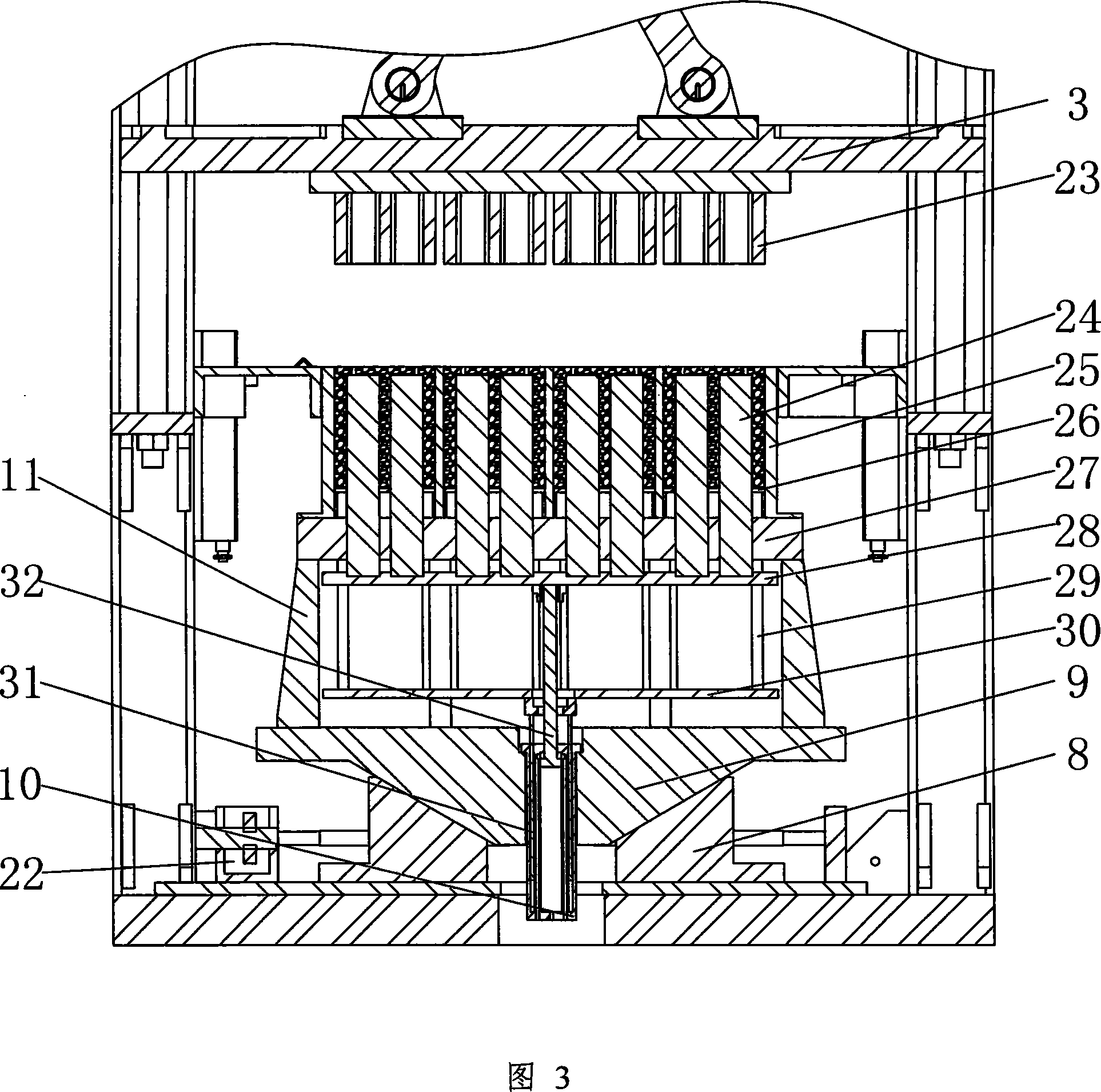

[0041] The accompanying drawings disclose a specific embodiment of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

[0042] It can be seen from Figure 1 and Figure 2 that a fully automatic hydraulic non-vibration block forming machine includes a frame 1, a workbench 2, an upper mold, a lower mold, a demoulding mechanism, a feeding mechanism, a compacting mechanism and a load height mechanism , the compacting mechanism includes a main hydraulic cylinder 12, two fast-moving hydraulic cylinders 13, a hydraulic cylinder push frame 4, and a chain rod expansion force boosting mechanism. The main hydraulic cylinder 12 is located at the center of the frame, and the two fast-moving The hydraulic cylinder 13 is located at both sides of the main hydraulic cylinder 12, the main hydraulic cylinder 12 and two fast-moving hydraulic cylinders 13 pass through the frame 1 and the lower end is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com