Method for gas membrane-process treatment of ammonia-containing feed liquid or wastewater with renewable absorbent and by-producted strong aqua ammonia

A technology of gaseous membranes and absorbents, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high energy consumption, large sales of ammonium sulfate, and market price of ammonium sulfate Not advanced question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

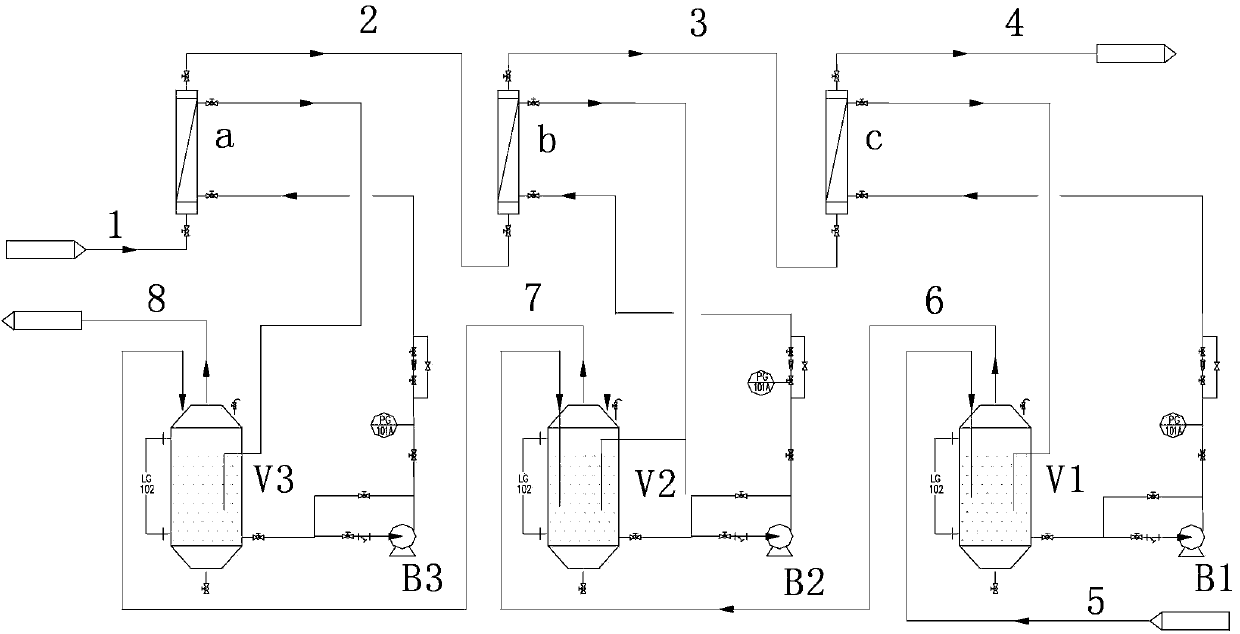

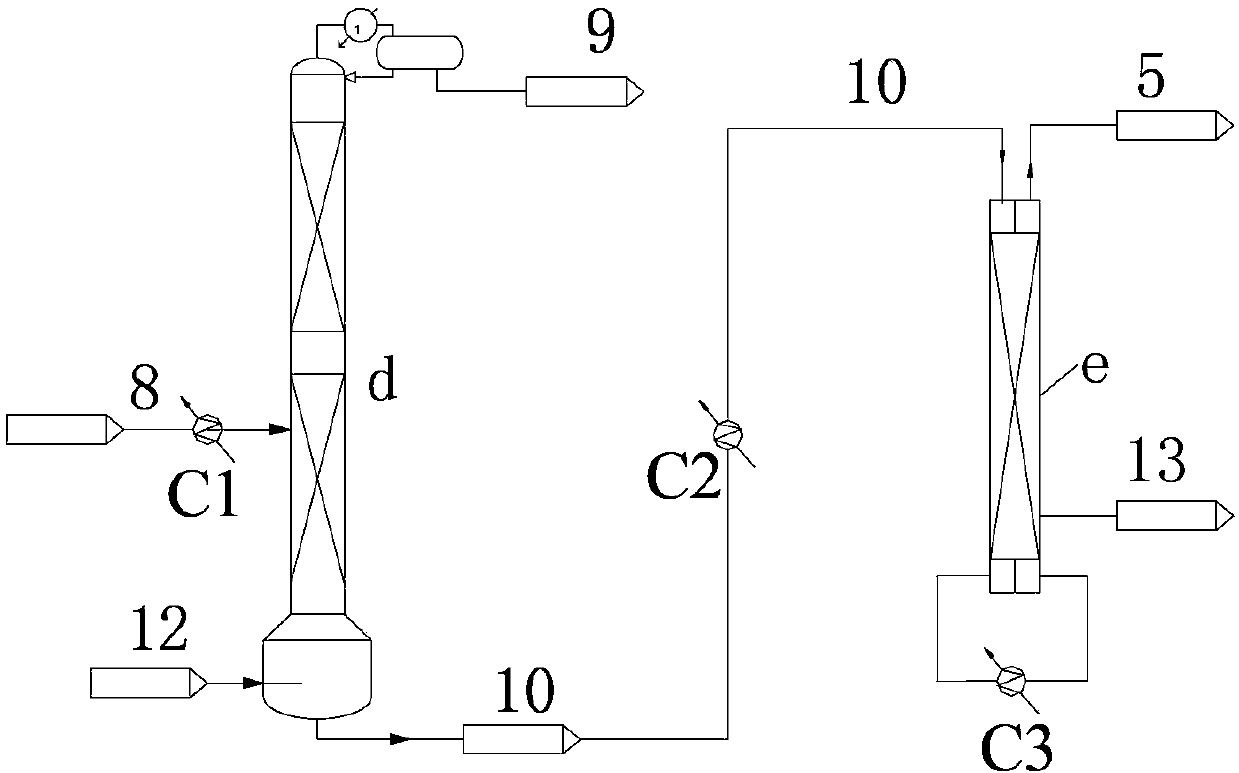

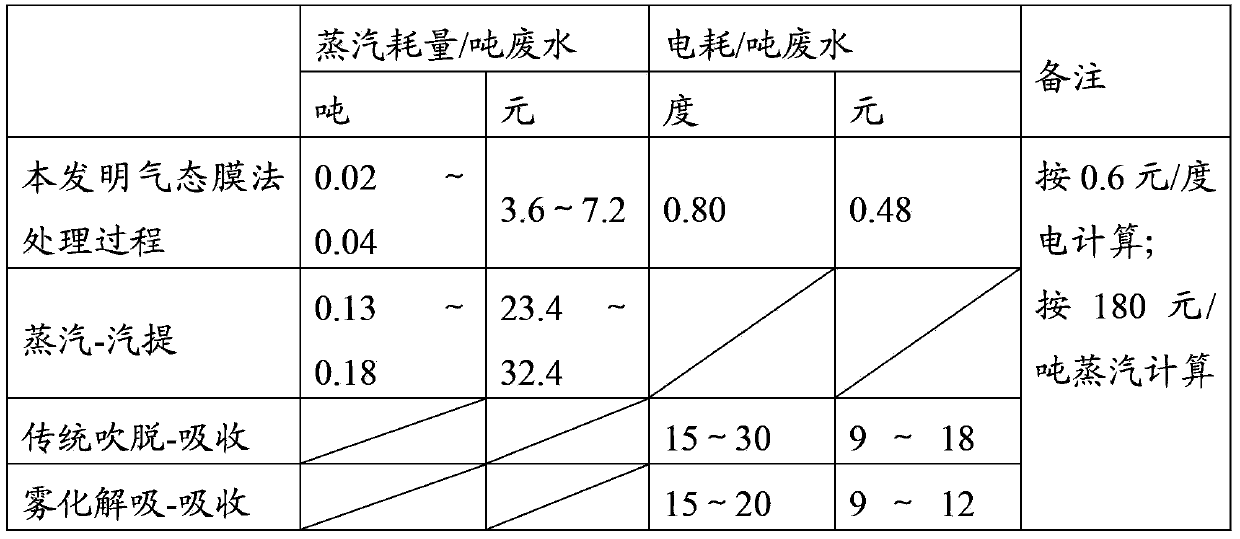

Method used

Image

Examples

Embodiment 1

[0065] Gas membrane deamination process: The polypropylene microporous hydrophobic hollow fiber gas membrane module is used to treat ammonia-containing solution. The effective membrane area is 19m 2 , The parameters of the membrane silk are: outer diameter 0.48mm, inner diameter 0.38mm, average pore diameter 0.02μm, porosity 40%. Three membrane modules are used in series.

[0066] Feed liquid: Ammonia nitrogen wastewater from a pharmaceutical factory, after pretreatment such as foam separation, ultrafiltration, and alkali addition, the surface tension is 68mN / m, pH=11.3, the concentration of ammonia nitrogen in the influent C0=1918ppm, the flow rate Q=300L / h, the temperature T=30℃;

[0067] Ammonium dihydrogen phosphate solution absorption liquid: initial pH is 4.6, initial density is 1.18kg / L, inlet flow rate is 15L / h, temperature is 30°C.

[0068] Experimental results: The concentration of ammonia nitrogen in the effluent is 45mg / L, the removal rate of ammonia nitrogen is...

Embodiment 2

[0078] Gaseous membrane deamination process: use polypropylene gaseous membrane modules to treat ammonia-containing solutions. The effective membrane area is 19m 2 , The parameters of the membrane are: outer diameter 0.48mm, inner diameter 0.38mm, average pore diameter 0.02μm, porosity 40%. Three membrane modules are used in series.

[0079] Feed liquid: ammonia nitrogen wastewater from a chemical plant, the concentration of ammonia nitrogen in the influent is C0=2480ppm, the flow rate is Q=400L / h, pH=12.0, temperature T=30℃;

[0080] Ammonium dihydrogen phosphate solution absorption liquid: initial pH is 5.8, initial density is 1.18kg / L, flow rate is 20L / h, temperature is 30°C.

[0081] Experimental results: the concentration of ammonia nitrogen in the effluent is 86mg / L, the removal rate of ammonia nitrogen is 96.5%, the pH of the outlet of the absorption liquid is 8.4, and the flow rate is 24L / h.

[0082] Regeneration process of absorption liquid by rectification method:...

Embodiment 3

[0089] Gas membrane deamination process: PTFE gaseous membrane modules are used to treat ammonia-containing solutions. The effective membrane area is 10.5m 2 , The parameters of the membrane are: outer diameter 1.2mm, inner diameter 0.60mm, average pore diameter 0.10μm, porosity 65%, three membrane modules are used in series.

[0090] Feed liquid: ammonia nitrogen wastewater from a pharmaceutical factory, the concentration of ammonia nitrogen in the influent C0=1460ppm, the flow rate Q=300L / h, pH=12.5, the temperature T=30℃, the initial surface tension is 35.0mN / m, multi-stage foam separation and super Surface tension increased to 58mN / m after filtration pretreatment;

[0091] Ammonium dihydrogen phosphate solution absorption liquid: initial pH is 5.6, initial density is 1.18kg / L, flow rate is 15L / h, temperature is 30°C.

[0092] Experimental results: The concentration of ammonia nitrogen in the effluent is 12mg / L, the removal rate of ammonia nitrogen is 99.2%, the pH value ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com