Novel absorbent for treating ammonia-containing wastewater or feed liquid by gaseous membrane method

A technology of absorbent and gaseous membrane, applied in water/sewage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

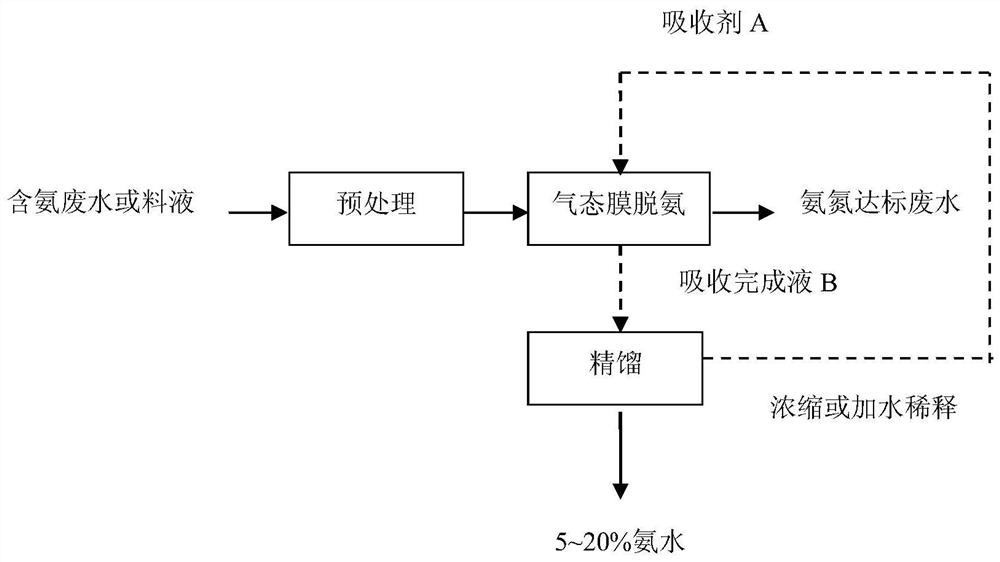

Method used

Image

Examples

Embodiment 1

[0041] Feed liquid: a factory ternary precursor mother liquor wastewater, pH = 13.5, ammonia nitrogen concentration of about 6000mg / L, sulfate ion concentration of 70g / L, surface tension of 70mN / m, slightly turbid, passed through an ultrafiltration membrane with a molecular weight cut-off of 50000 After treatment, it enters the gaseous membrane deamination device. The ultrafiltration process is well known to those skilled in the art and will not be emphasized here.

[0042] Gaseous membrane deamination process: use polypropylene gaseous membrane modules to treat ammonia-containing solutions. The effective membrane area is 65m 2 , The parameters of the membrane silk are: outer diameter 0.53mm, inner diameter 0.40mm, average pore diameter 0.02μm, porosity 50%. The three components are used in series, the water inlet flow rate is 800L / h, the inlet operating pressure is 0.042MPa, and the operating temperature is 35°C.

[0043] Absorbing solution: Potassium dihydrogen phosphate ...

Embodiment 2

[0050] Feed liquid: wastewater from a non-ferrous metal smelter, ammonia nitrogen 1500-2000mg / L, temperature 30°C, pH=12.2, surface tension 72mN / m after pretreatment such as sand filtration and ultrafiltration; devices involved in the pretreatment process and steps are well known to those skilled in the art and will not be emphasized here.

[0051] Gas membrane deamination process: use polypropylene microporous hydrophobic hollow fiber gas membrane module for treatment. The effective membrane area is 65m 2 , The parameters of the membrane silk are: outer diameter 0.53mm, inner diameter 0.40mm, average pore diameter 0.02μm, porosity 50%. Three membrane modules are used in series, the water flow rate is 700L / h, and the inlet operating pressure is 0.04MPa.

[0052] Absorbing solution: Industrial grade sodium dihydrogen phosphate is used to prepare an aqueous solution with a mass fraction of 35%. The measured initial pH is about 3.49. It circulates in the shell side of the gaseo...

Embodiment 3

[0058] Feed liquid: Ammonia nitrogen wastewater from a pharmaceutical factory, yellow and slightly turbid, the concentration of ammonia nitrogen in the influent is 1460mg / L, pH=11.8, temperature 30°C, surface tension 62mN / m; treated by polysulfone ultrafiltration membrane with a molecular weight cut-off of 50,000 Enter the gaseous membrane deamination device. The ultrafiltration process is well known to those skilled in the art and will not be emphasized here.

[0059] Gas membrane deamination process: PTFE gaseous membrane modules are used to treat ammonia-containing solutions. The effective membrane area is 10.5m 2 , The parameters of the membrane are: outer diameter 1.2mm, inner diameter 0.60mm, average pore diameter 0.10μm, porosity 65%, three membrane modules are used in series, the flow rate is 300L / h.

[0060] Absorbing solution: Add methylamine solution dropwise to 30% phosphoric acid solution to make the pH reach 4.0, used as absorbent for gaseous membrane process; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com