Steel rail milling-grinding test device

A technology of a test device and a milling device, which is applied in the field of mechanical manufacturing technology and signal detection, can solve the problems of difficult acquisition of milling-grinding cutting temperature and cutting force, and achieve the effect of simple structure, low manufacturing cost and small space limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

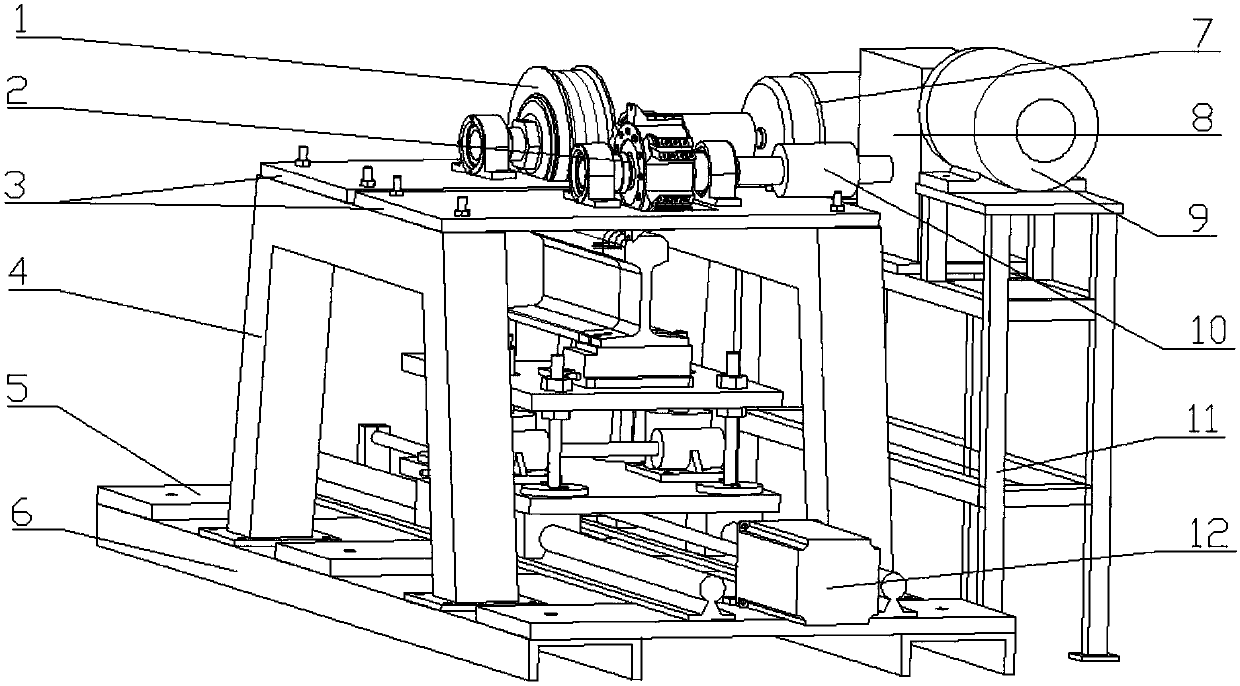

[0075] The invention discloses a rail milling-grinding test device, which comprises a support frame;

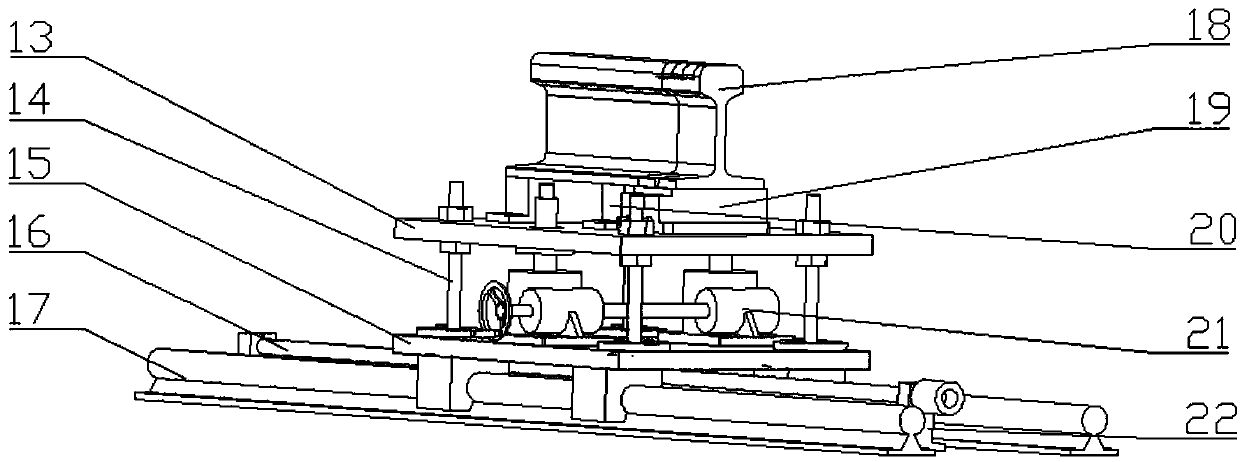

[0076] A mobile platform mechanism for carrying the rail workpiece to be tested to move in the Y-axis and Z-axis directions is arranged below the main support frame;

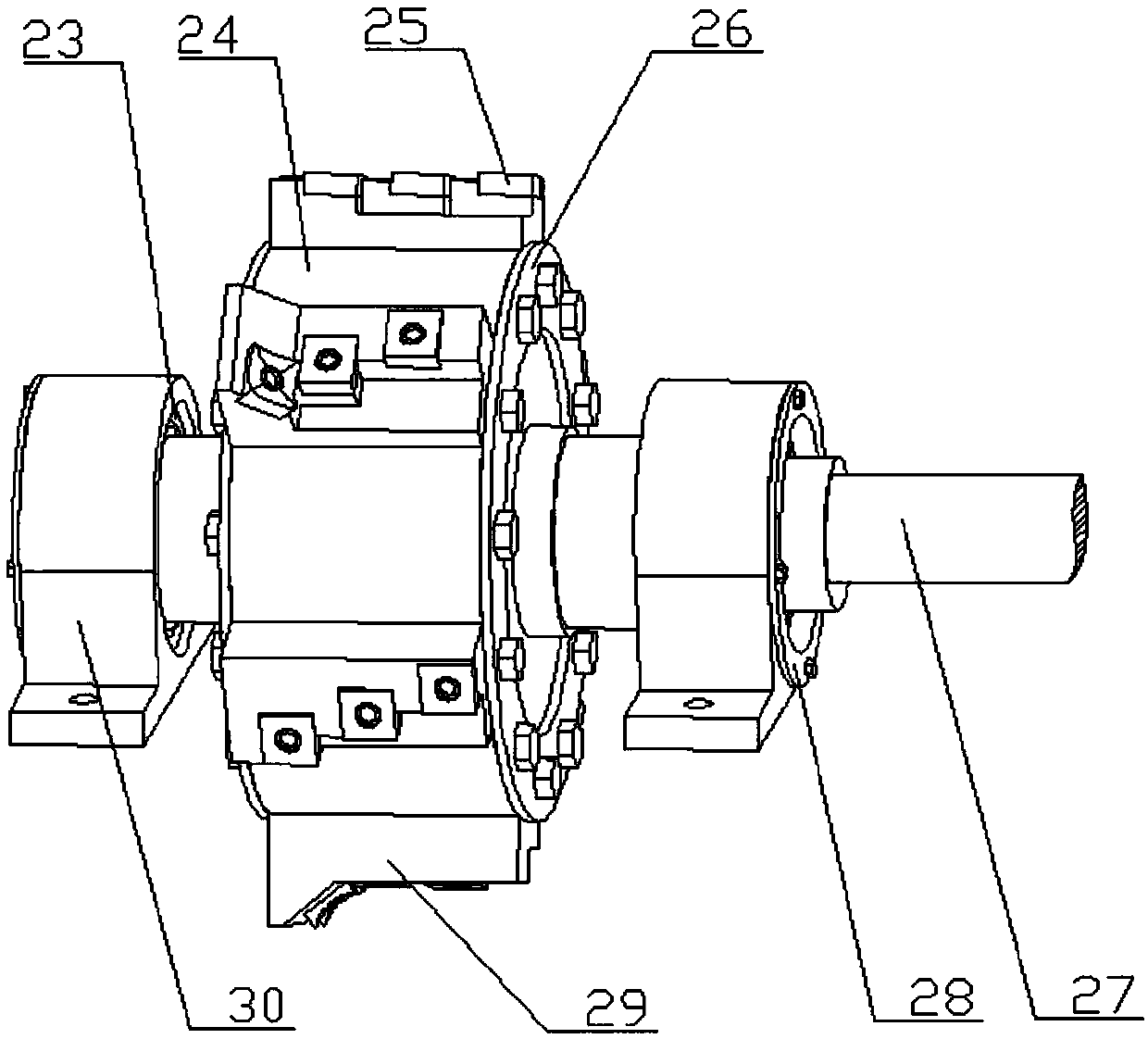

[0077] A milling device for milling and grinding the surface of the rail workpiece is arranged above the main support frame;

[0078] A secondary support frame is arranged on one side of the main support frame, and the secondary support frame is used for installing the driving mechanism of the milling device;

[0079]The rail workpiece is fixedly installed on the mobile platform mechanism through a dynamometer, which is used to collect the cutting force of the rail workpiece during the milling-grinding repair operation; a notch is opened on the side of the rail workpiece body, and a thermocouple is embedded in the notch , which is used to collect the cutting temperature of the rail workpiece during the milling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com