Gravel doped grinding system for anti-leakage wall and preparation method thereof

A technology of anti-seepage wall and gravel-mixed silo, which is applied in the preparation system and field of gravel-mixed materials for anti-seepage walls, which can solve problems such as difficult to complete the one-time processing and preparation of gravel-mixed materials, shorten the production cycle and improve production efficiency , the effect of reducing site occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

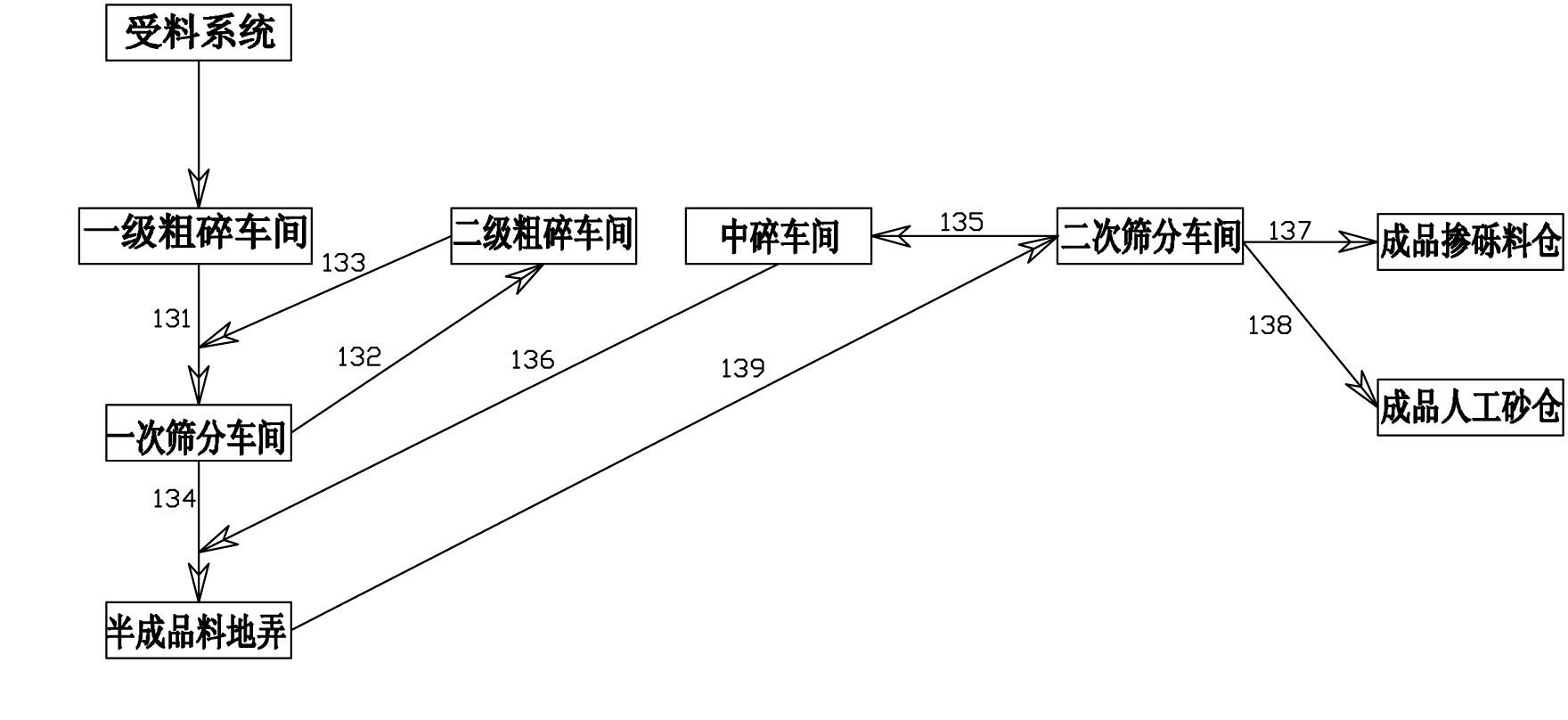

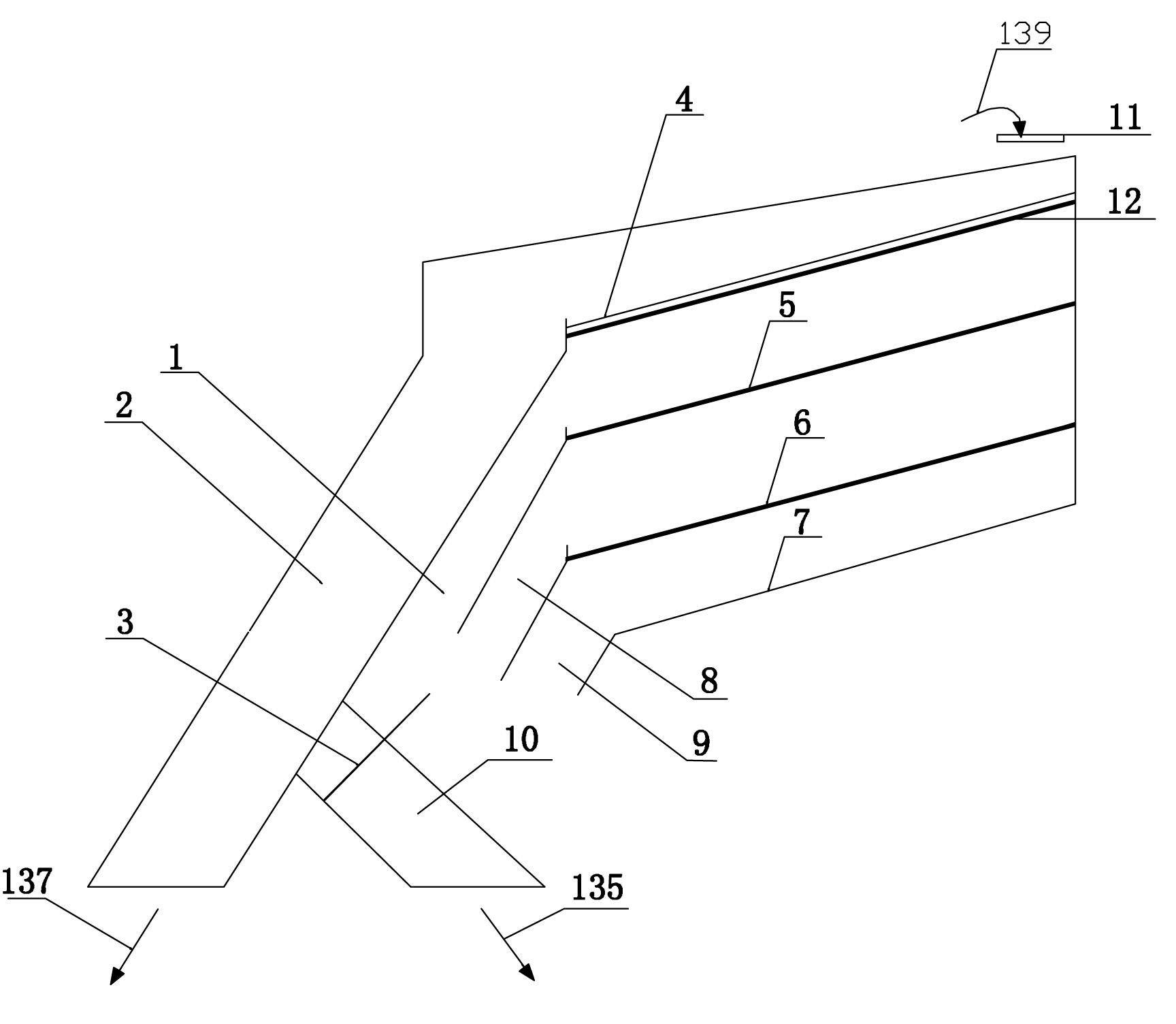

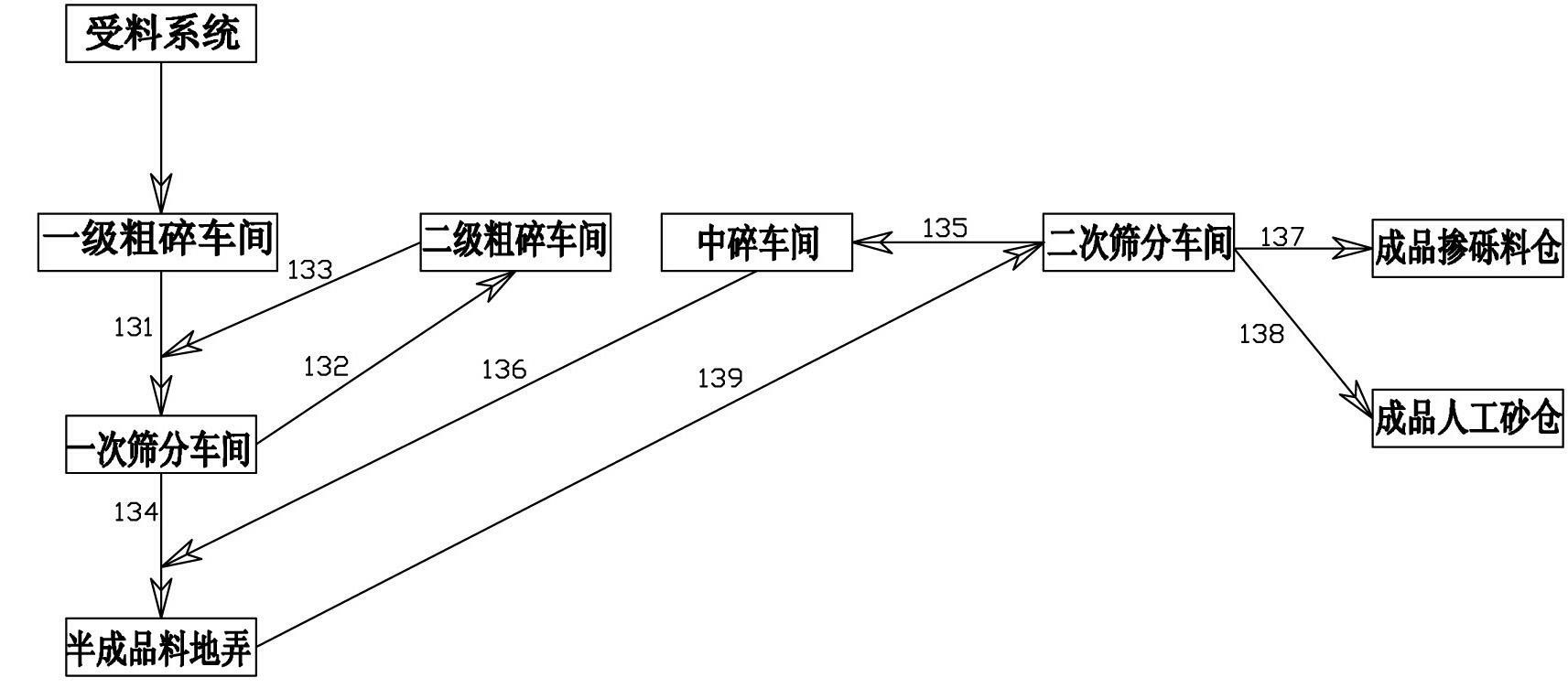

[0027] like figure 1 , figure 2 Among them, a system for preparing gravel materials for cut-off walls, the primary crushing workshop is connected with the primary screening workshop through the first belt conveyor 131, and the primary screening workshop is connected with the secondary primary crushing workshop through the second belt conveyor 132 on the sieve Connection, the secondary coarse crushing workshop is connected with the first tape machine 131;

[0028] The primary screening workshop is connected to the secondary screening workshop 11 through the fourth belt conveyor 134 and / or the ninth belt conveyor 139 under the screen, and the secondary screening workshop 11 is connected to the intermediate crushing workshop through the fifth belt conveyor 135. The intermediate crushing workshop The sixth tape machine 136 is connected with the fourth tape machine 134, the secondary screening workshop is connected with the finished gravel bin through the seventh tape machine 137...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com