High-speed rotation test device for ultra-hard material grinding sand wheel

A test device, high-speed rotation technology, applied in the direction of measurement device, machine/structural component test, static/dynamic balance test, etc., can solve problems such as single function, unreasonable structural design and acceleration scheme, and inability to test grinding wheel rotation. , to achieve the effect of ensuring safety, compact structure and small load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

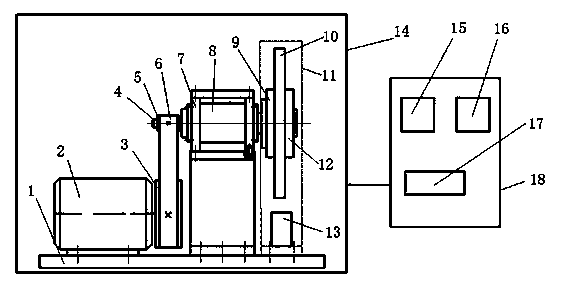

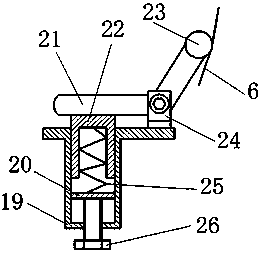

[0025] As shown in the figure: a high-speed rotation test device for superhard abrasive grinding wheels, including a base 1, a motor 2, a large pulley 3, a main shaft 4, a small pulley 5, a bearing seat 8, a flange seat 9, and a grinding wheel to be tested 10 , shell 11, flange cover 12, tester 13, machine cover 14, tachometer 15, frequency converter 16, sliding rheostat 17, control panel 18, support plate 19, spacer 20, rotating pole 21, backing plate 22 , Tensioner 23, connecting block 24, spring 25.

[0026] A motor 2 is arranged on the base 1, the motor 2 is connected to a bearing seat 8, the bearing seat 8 drives the grinding wheel 10 to be tested to rotate, and the tester 13 is arranged below the grinding wheel 10 to be tested.

[0027] The drive shaft of the motor 2 is arranged with a large pulley 3, and the main shaft 4 is arranged in the bearing seat 8, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com