Valve element synchronous grinding and deburring integrated method based on overlap value detection and system

A deburring and valve core technology, applied in machine tools suitable for grinding workpiece edges, parts of grinding machine tools, grinding/polishing equipment, etc. It can improve safety and reliability, flexible assembly and debugging, and high level of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

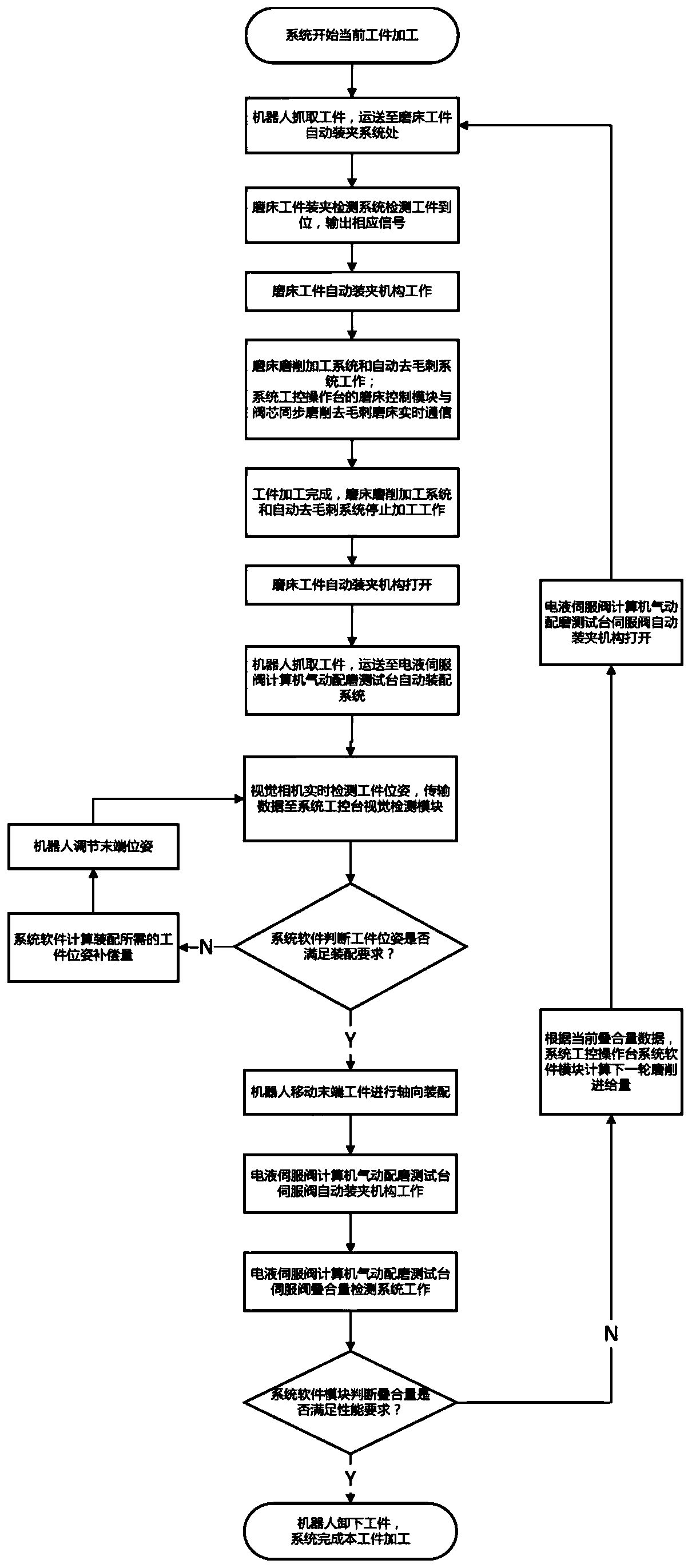

[0020] This embodiment is mainly aimed at the synchronous grinding and deburring of the servo valve core workpiece with high-precision working edge requirements, and at the same time, it needs to detect the overlapping amount, specifically for the servo valve core working edge grinding and micro burr removal and automatic detection, Integrated realization of workflows such as outputting servo valve stacking data.

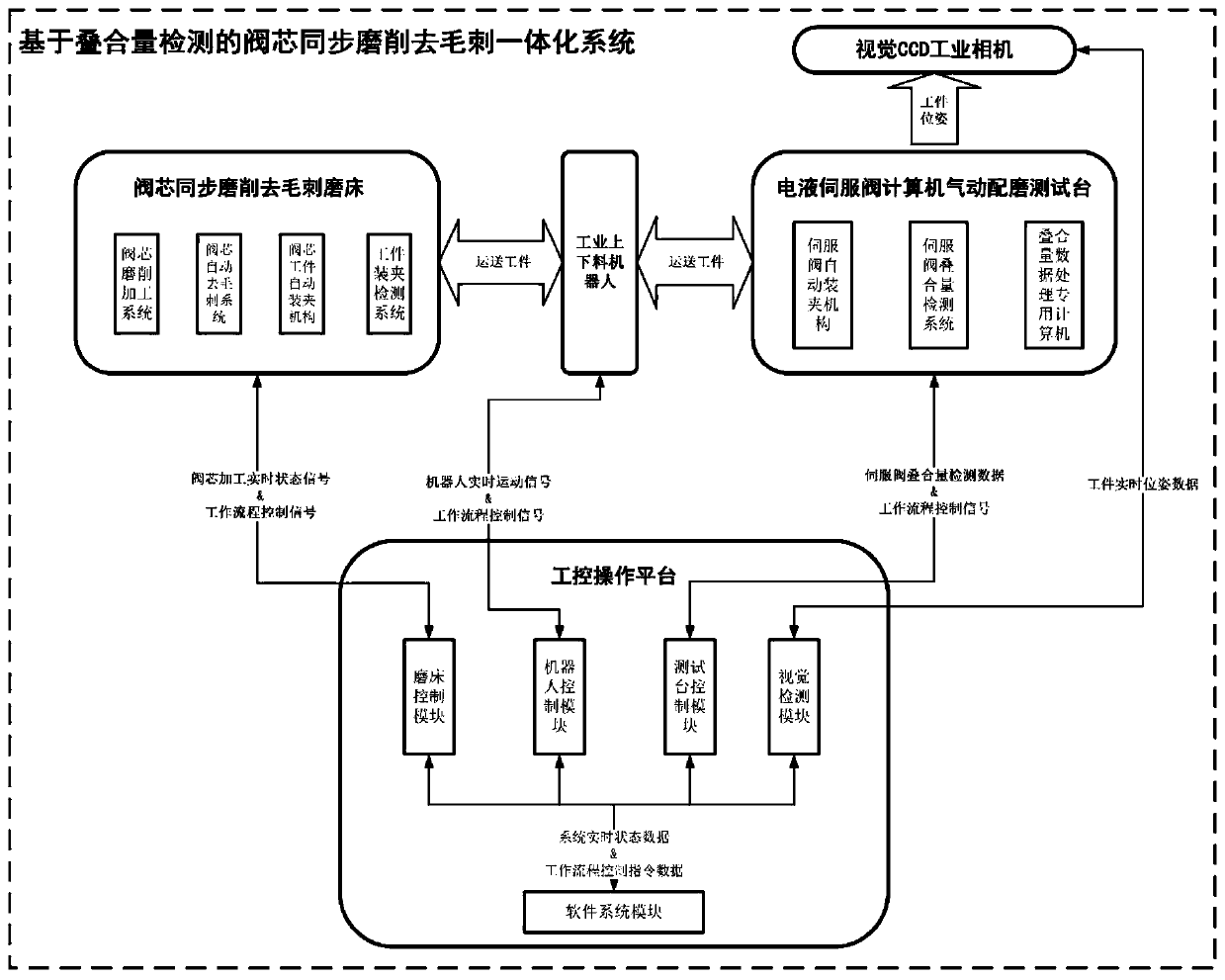

[0021] like figure 1 As shown, this embodiment relates to an integrated system for synchronous grinding and deburring of valve cores based on overlapping amount detection, including: servo valve core synchronous grinding and deburring grinder, industrial loading and unloading robot, electro-hydraulic servo valve computer pneumatic Matching grinding test bench, visual CCD industrial camera and system industrial control console, including: system industrial control console and servo valve core synchronous grinding and deburring grinder, industrial loading and unloadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com